Ultraviolet curable adhesive sheet

A technology of adhesive sheets and ultraviolet rays, which is applied in the direction of adhesive types, ester copolymer adhesives, film/sheet adhesives, etc., can solve the problems of wafer surface contamination and adhesion, and prevent adhesive residue , cost reduction, excellent light peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0096] Preparation of Adhesive Base Polymer Solution

[0097] 100 parts by weight of 2-ethylhexyl acrylate, 25.5 parts by weight of acryloylmorpholine, 18.5 parts by weight of 2-hydroxyethyl acrylate, 0.2 parts by weight of a polymerization initiator (benzoyl peroxide (BPO)), and The solvent (toluene) was mixed, thereby preparing a monomer composition. Put this monomer composition into a 1L round-bottom detachable flask equipped with a detachable lid, a separatory funnel, a thermometer, a nitrogen introduction tube, a Liebig condenser, a vacuum seal, a stirring rod, and a stirring blade for polymerization. In the experimental apparatus, nitrogen substitution was performed at room temperature for 6 hours while stirring. Thereafter, while blowing nitrogen gas, the mixture was kept at 60° C. for 8 hours while stirring to perform polymerization to obtain a resin solution.

[0098] After cooling the obtained resin solution to room temperature, 2-isocyanatoethyl methacrylate (man...

manufacture example 2

[0099] Preparation of intermediate layer base polymer

[0100] 50 parts by weight of butyl acrylate, 50 parts by weight of ethyl acrylate, 5 parts by weight of acrylic acid, and 0.1 part by weight of azobisisobutyronitrile were polymerized in toluene under a nitrogen atmosphere at 60°C for 6 hours to obtain a weight average molecular weight of 65 million acrylic resins.

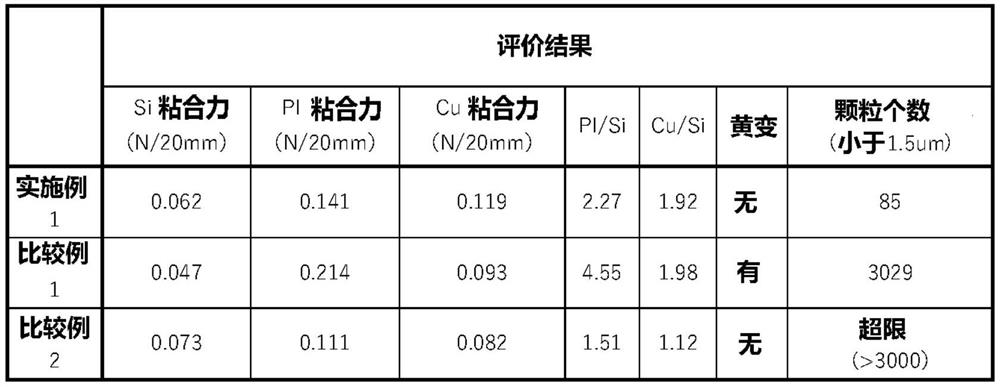

Embodiment 1

[0102] (Preparation of Adhesive Layer Forming Composition)

[0103] In 100 parts by weight of the polymer solution obtained in Production Example 1, 2 parts by weight of a crosslinking agent (manufactured by Tosoh Corporation, trade name: Coronate L) and 1 part by weight of a photopolymerization initiator (manufactured by IGM Resins, trade name: Omnirad 127, 2-hydroxyl-1-{4-[4-(2-hydroxyl-2-methyl-propionyl)-benzyl]-phenyl}-2-methyl-propane-1-one) 3 parts by weight and carry out Stirring was carried out to obtain an ultraviolet curable adhesive composition.

[0104] (Preparation of Intermediate Layer Forming Composition)

[0105] To 100 parts by weight of the acrylic resin obtained in Production Example 2, 1 part by weight of a crosslinking agent (manufactured by Tosoh Corporation, trade name: Coronate L), 1 part by weight of a photopolymerization initiator (manufactured by IGM Resins, trade name: Omnirad 127 , 2-hydroxyl-1-{4-[4-(2-hydroxyl-2-methyl-propionyl)-benzyl]-pheny...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com