Patents

Literature

36results about How to "Heat shrinkable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Processing method for improving easy-care performance of moist crosslinking finishing yarn-dyed fabric

ActiveCN108457082AAdequate responseGood flatness effectHeating/cooling textile fabricsWrinkle resistant fibresYarnProduct inspection

The invention belongs to the technical field of textile dyeing and finishing, and particularly relates to a processing method for improving easy-care performance of a moist crosslinking finishing yarn-dyed fabric. The processing method comprises the steps of singeing, desizing, mercerizing, liquid ammonia, pre-softening, moist crosslinking rolling, moist crosslinking, baking, primary washing, secondary washing, tentering and finished product inspection and packaging. Baking is carried out with a baker at a baking temperature of 120 to 140 DEG C for 3 to 5 minutes. According to the invention, two crosslinking is creatively adopted, the water shrinkage and heat shrinkage of a fabric are more stable, a pre-shrinking process is omitted, and thus the production cost of the fabric is reduced; the baking process is introduced into the moist crosslinking finishing process, and the time of moist crosslinking finishing piling is shortened by 6 to 12 hours, and the usage amount of resin and a catalyst is reduced by 20% to 50% compared with a traditional moist crosslinking process; the easy-care performance of the moist crosslinking finishing yarn-dyed fabric is enhanced by 0.2 to 0.5 grade, the fabric can be washed for 50 times, the easy-care degree is 4.0 or above.

Owner:LUTAI TEXTILE

Thermal shrinkage-reversible polyarylamide with dibenzo 8-membered ring (DBCOD) structure containing main chain and preparation method thereof

ActiveCN107163246APrecise structureHeat shrinkableOrganic compound preparationHydrocarbonsPolymer sciencePhosphorylation

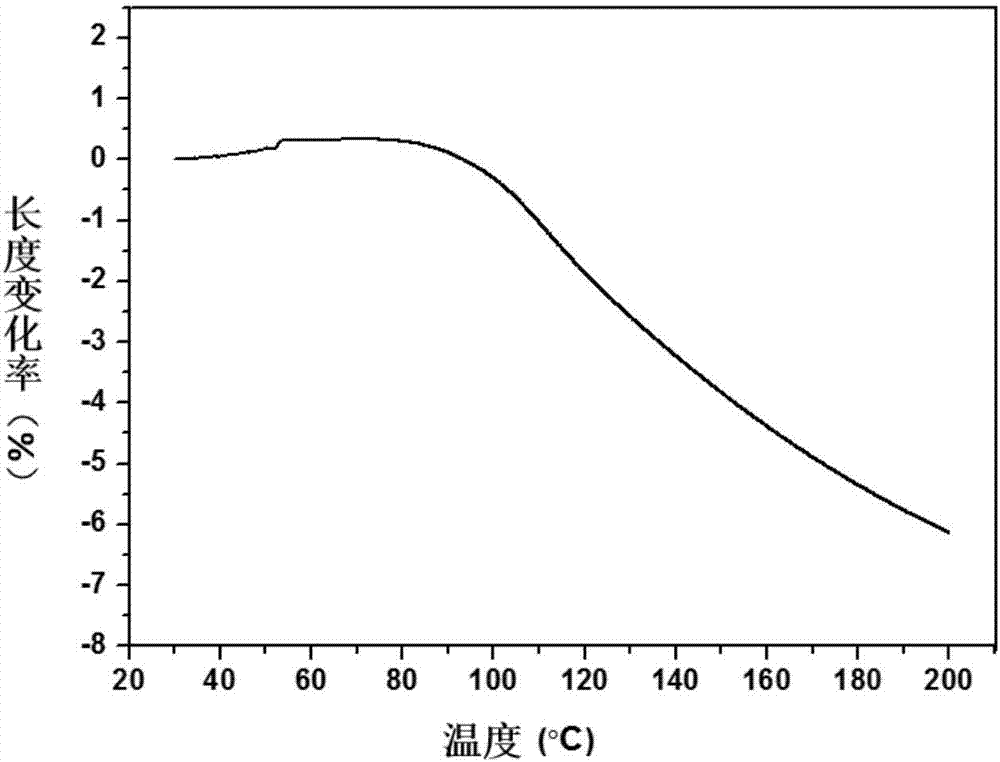

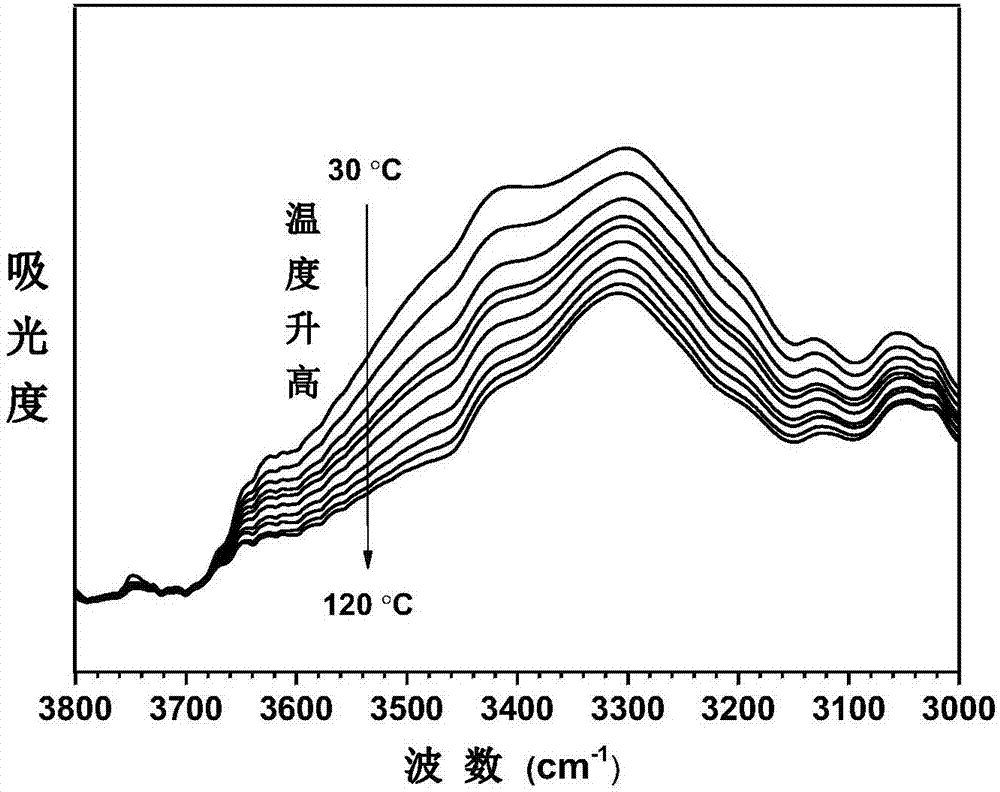

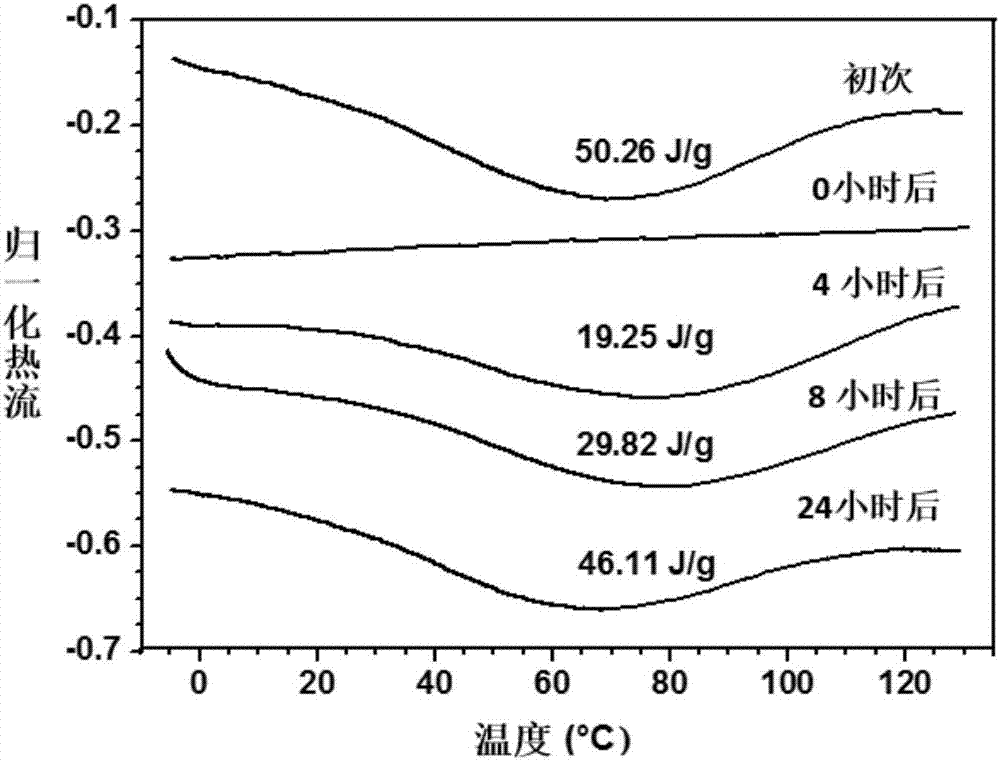

The invention belongs to the technical field of polymer materials and particularly relates to polyarylamide with a dibenzo 8-membered ring (DBCOD) structure containing main chain and a preparation method thereof. The invention also relates to DBCOD-containing diacids: 5, 6, 11, 12-tetrahydro dibenzo [a, e] [8] annulene-2, 8-dicarboxylic acid and 5, 6, 11, 12-tetrahydro dibenzo [a, e] [8] annulene-2, 9-dicarboxylic acid and a preparation method thereof. According to the preparation method of the polyacrylamide, a Yamazaki-Higashi phosphorylation condensation polymerization is adopted and the thermal shrinkage coefficient of the polyarylamide is adjusted through changing the feeding proportion of diacid monomers in the preparation process. The polyacrylamide provided by the invention has excellent solution film forming property and thermal stability and especially unique reversible thermal shrinkage and cold expansion characteristics, which are related to the conformation change of 8-membered rings; and the polyarylamide can serve as a thermal shrinkage material.

Owner:FUDAN UNIV

Block copolymer mixture and heat shrinkable film using it

ActiveUS20070196604A1Improve fracture resistanceImprove rigidityWrappers shrinkageShrinkage connectionsPolymer scienceAromatic hydrocarbon

A block copolymer mixture comprising block copolymers (A), (B) and (C) each block comprising vinyl aromatic hydrocarbon and conjugated diene monomer units: wherein block (A) comprises from 75 to 95 mass % of a vinyl aromatic hydrocarbon and from 5 to 25 mass % of a conjugated diene, and which has a block portion composed mainly of a vinyl aromatic hydrocarbon having a number average molecular weight of from 30,000 to less than 150,000: block (B) comprises from 50 to 80 mass % of a vinyl aromatic hydrocarbon and from 20 to 50 mass % of a conjugated diene, and which has a block portion composed mainly of a vinyl aromatic hydrocarbon having a number average molecular weight of from 20,000 to less than 120,000, and block (C) comprises from 60 to 95 mass % of a vinyl aromatic hydrocarbon and from 5 to 40 mass % of a conjugated diene, which has at least one random copolymer block portion comprising, as monomer units, from 55 to 95 mass % of a vinyl aromatic hydrocarbon and from 5 to 45 mass % of a conjugated diene.

Owner:DENKA CO LTD

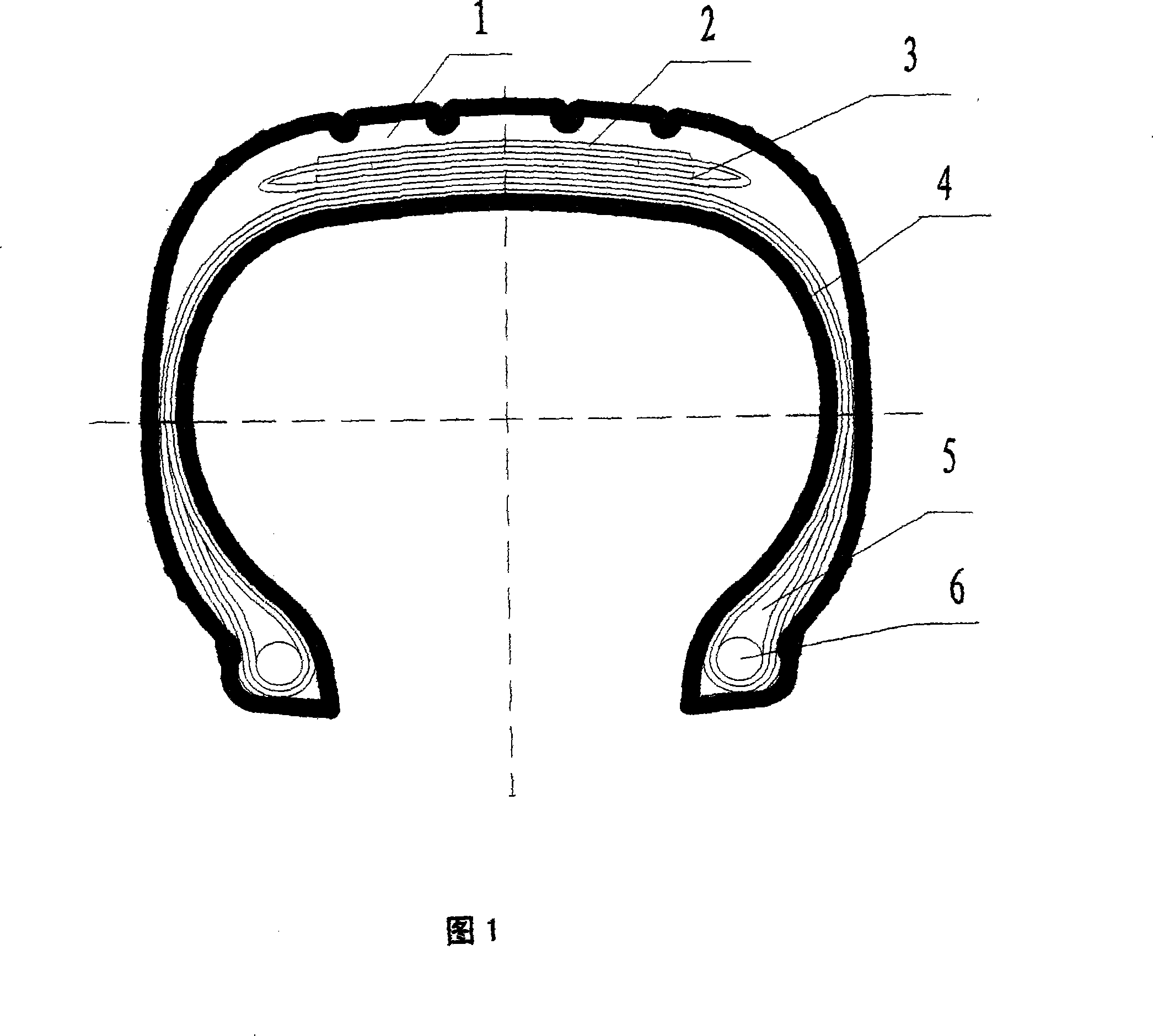

Meridian aviation tyre using nylon/aramid fiber composite cord as framework material

InactiveCN101200161AHeat shrinkableIncrease initial tensionPneumatic tyre reinforcementsInternal pressureAviation

The invention discloses a steel-belted aerial tire with the skeleton material of nylon-kelvar composite cord, which is mainly characterized in that the carcass ply is composed of multi-layer nylon 66 cords or nylon-kelvar composite cords. The belt structure layer is composed of at least more than two layers of nylon-kelvar composite cords. A tire tread structure layer is arranged above the belt structure layer, in which the nylon-kelvar composite cord is also applied. Both ends of the carcass ply cord layer are wound with a pair of left and right wire loops and counter wrapped upward. The belt structure layer is composed of the invert folded cords, in which the curling ends are all in the middle of the tread of tire. This aerial tire has the advantages that (1) the nylon-kelvar composite cord is taken as the skeleton material of the tire so that the fine characteristics of the nylon-kelvar composite cords are reflected, in which a good basis is laid in order to meet the using requirements of the steel-belted aerial tire. (2) With the belt structure layer of multi-layer nylon-kelvar composite cords, the high internal pressure, high-speed, high-load, large deformation and impact resistant use requirements of the steel-belted tire can be met.

Owner:中国化工集团曙光橡胶工业研究设计院有限公司

Trade mark paper and its preparing method

InactiveCN1986964AHeat shrinkableAvoid glue residueMechanical working/deformationSpecial paperTrademarkPulp and paper industry

A label paper with high stability is composed of a thermoshrinkable plastic film, a pressure-sensitive adhesive layer and a parting paper layer. Its preparing process is also disclosed.

Owner:ZHONGSHAN KINGLABEL ADHESIVE PRODS

Method for producing laminated film

ActiveCN103140298AHeat shrinkablePrevent precipitationLamination ancillary operationsLayered product treatmentOligomerSolvent

Owner:NITTO DENKO CORP

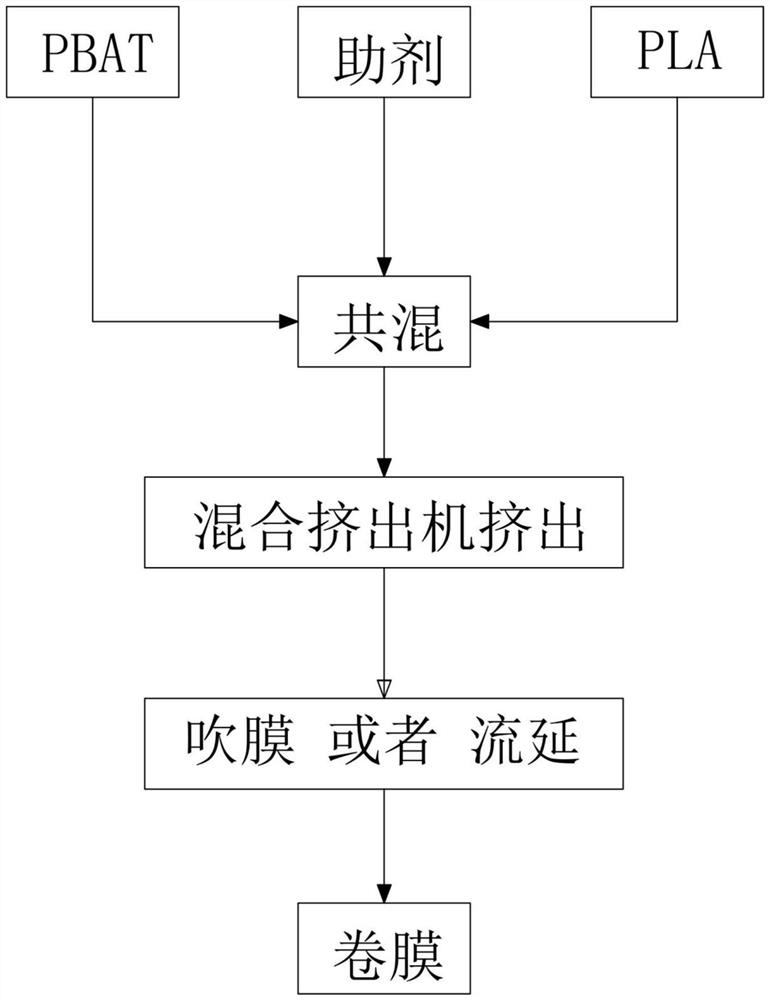

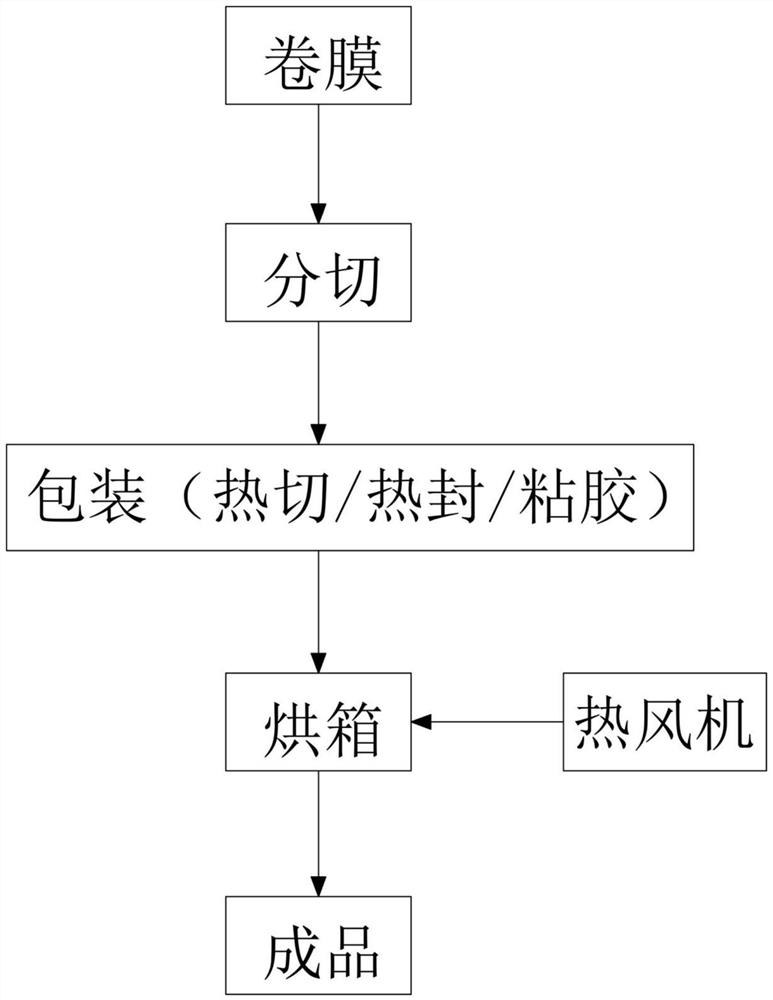

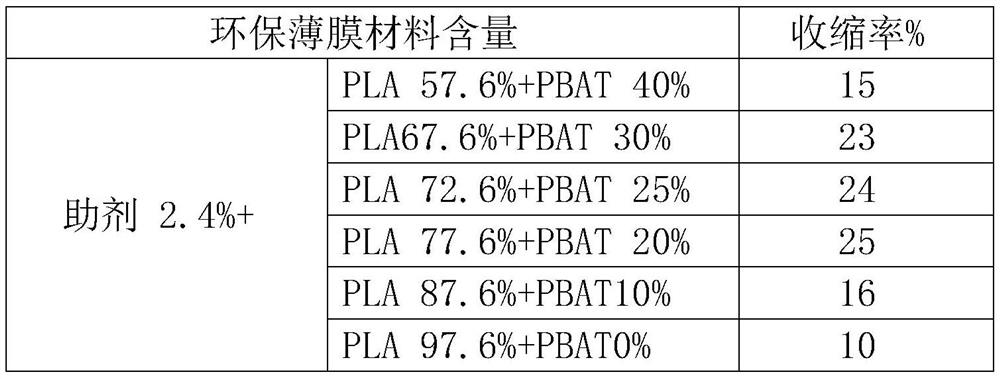

Heat-shrinkable degradable environment-friendly film material as well as preparation method and application method

PendingCN113045881ASimple equipment and processSuitable for large-scale industrial productionWrappers shrinkageFlexible coversThin membraneFilm material

The invention provides a heat-shrinkable degradable environment-friendly film material which is prepared by blending and modifying PBAT and PLA in proportion under the action of auxiliaries, wherein the auxiliaries comprise wax, a coupling agent, a chain extender, an anti-blocking agent and a slipping agent. According to the invention, the PBAT material with good biodegradability, biocompatibility and high elongation at break and the PLA material with high hardness, high transparency and low elongation rate are modified and mixed under the action of the auxiliaries to obtain the biodegradable compostable environment-friendly film material with thermal shrinkage performance. The process and equipment for preparing the environment-friendly film material are simple, and are very suitable for large-scale industrial production. The heat-shrinkable degradable environment-friendly film material can be used to prepare a packaging film with good blow molding effect, good thermal shrinkage, good stiffness and good toughness, and can also be applied to packaging films, industrial materials and the like.

Owner:珠海横琴辉泽丰包装科技有限公司

Block copolymer mixture and heat shrinkable film using it

ActiveUS7470747B2Improve balanceIncrease resistanceWrappers shrinkageShrinkage connectionsPolycyclic aromatic hydrocarbonPolymer science

A block copolymer mixture comprising block copolymers (A), (B) and (C) each block comprising vinyl aromatic hydrocarbon and conjugated diene monomer units:wherein block (A) comprises from 75 to 95 mass % of a vinyl aromatic hydrocarbon and from 5 to 25 mass % of a conjugated diene, and which has a block portion composed mainly of a vinyl aromatic hydrocarbon having a number average molecular weight of from 30,000 to less than 150,000:block (B) comprises from 50 to 80 mass % of a vinyl aromatic hydrocarbon and from 20 to 50 mass % of a conjugated diene, and which has a block portion composed mainly of a vinyl aromatic hydrocarbon having a number average molecular weight of from 20,000 to less than 120,000, andblock (C) comprises from 60 to 95 mass % of a vinyl aromatic hydrocarbon and from 5 to 40 mass % of a conjugated diene, which has at least one random copolymer block portion comprising, as monomer units, from 55 to 95 mass % of a vinyl aromatic hydrocarbon and from 5 to 45 mass % of a conjugated diene.

Owner:DENKA CO LTD

Thermal contracting directional memory polyvinyl chloride pipe and manufacture thereof

InactiveCN1614279AEasy to operateDoes not destroy performanceRigid pipesPolyvinyl chlorideEngineering

A polyvinyl chloride pipe with radial and / or longitudinal thermal directional shrinking memory function is prepared from polyvinyl chloride through shaping pipe, blocking both ends, arranging it in a limiter, filling high-pressure air in while heating it for expansion, cooling and releasing pressure.

Owner:徐益鑫

Hydrogenation Product of Block Copolymer or Sheet or Film of the Same

ActiveUS20090061248A1Heat shrinkableExcellent physical propertyBiocideFilm/foil adhesivesSolventConjugated diene

An object of the invention is to provide a block copolymer hydrogenation product suitable for a sheet and a heat shrinkable film which are excellent in solvent resistance, rigidity, elongation and transparency, which is excellent in a balance of physical properties such as solvent resistance, natural shrinkability, low-temperature shrinkability, rigidity, transparency and low-temperature elongation, and a composition thereof. The invention relates to a block copolymer hydrogenation product having a weight ratio of a vinyl aromatic hydrocarbon and a conjugated diene of 55 / 45 to 95 / 5, a number average molecular weight measured by gel permeation chromatography (GPC) of 30,000 to 500,000 and a hydrogenation rate of 30% or more, wherein the vinyl aromatic hydrocarbon incorporated into the hydrogenation product has a block rate of 60 to 98% by weight, wherein relative to the weight of the total vinyl aromatic hydrocarbon polymer blocks, the ratio of vinyl aromatic hydrocarbon polymer blocks having a molecular weight of 50,000 or less is 80% by weight or more and the ratio of vinyl aromatic hydrocarbon polymer blocks having a molecular weight of 15,000 or less is from 10 to 80% by weight, and wherein at least one peak temperature of function tan δ in a dynamic viscoelasticity measurement of the hydrogenation product is present within the range of exceeding −80° C. to lower than −10° C.

Owner:ASAHI KASEI CHEM CORP

Nylon-spandex covered yarn used for manufacturing super-soft mask stockings and production technology thereof

InactiveCN105113077ASoft touchIncrease elasticityYarnArtifical filament manufactureYarnPolymer science

The invention provides nylon-spandex covered yarn used for manufacturing super-soft mask stockings and a production technology thereof. The problems that nylon-spandex covered yarn produced through a traditional technology is poor in mechanical property, hard in handfeel, prone to water shrinkage and the like are solved. The covered yarn produced through the technology has the advantages of being soft in handfeel, good in elasticity, high in wear resistance and strength and the like and further has the advantages of moisture absorption and breathability of natural fibers.

Owner:JIANGSU BANGYUAN NEW MATERIAL

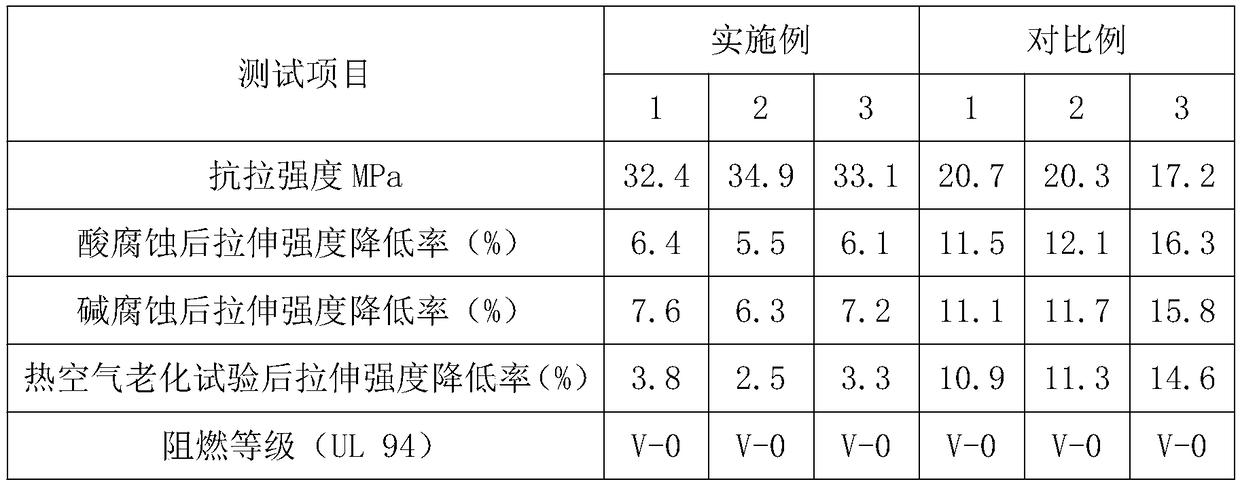

Reinforced flame-retardant PET (polyethylene terephthalate) heat shrink tube

InactiveCN107177177AImprove flame retardant performanceHeat shrinkableGlycidyl methacrylatePolymer science

The invention provides a flame-retardant PET heat-shrinkable sleeve, which is prepared from a reinforced flame-retardant PET material. The reinforced flame-resistant PET material is prepared by the following method: prepare raw materials according to the following ratio, PET 60-70 parts by weight of slices, 5-10 parts by weight of flame retardant, 1-3 parts by weight of antioxidant, 1-3 parts by weight of toughening agent, add in a high-speed mixer and mix uniformly, then add glass fiber as a reinforcing agent; The mixed material is sent into a twin-screw extruder for melt blending and extrusion, and the extruded material is water-cooled, drawn and stretched, and pelletized by a pelletizer to obtain a reinforced flame-retardant PET material; wherein the flame retardant is A compound of decabromodiphenyl ether and antimony trioxide; the toughening agent is ethylene-butyl acrylate-glycidyl methacrylate trisalt copolymer; the PET chips are pre-dried at 120°C 4h; the flame retardant and glass fiber are pre-dried at 120°C for 1h. The invention has the following technical effects: it has heat shrinkability and enhanced flame retardancy at the same time.

Owner:NANTONG DINGSHANG ELECTRONICS MATERIAL CO LTD

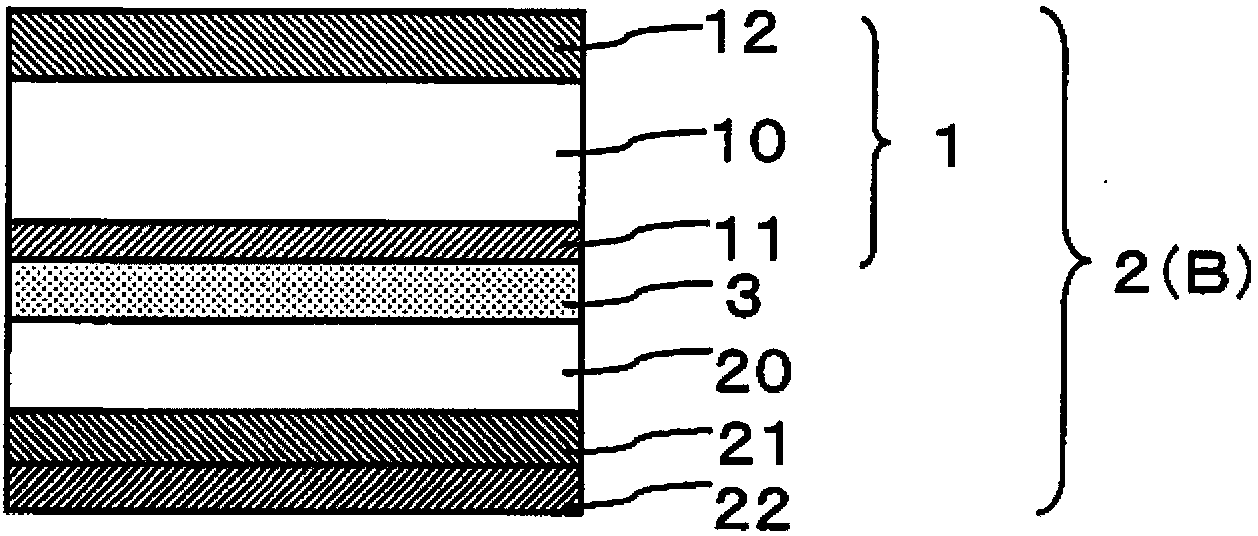

A kind of polysulfone nanofiber separator for lithium battery and preparation method thereof

The invention relates to a polysulfone nano-fiber diaphragm for a lithium battery and a preparation method of the polysulfone nano-fiber diaphragm, and belongs to the technical field of lithium battery diaphragms. The polysulfone nano-fiber diaphragm for the lithium battery is prepared by the steps of dissolving one or more polysulfones with any proportion in a polar organic solvent and then performing electrostatic spinning. The polysulfone nano-fiber diaphragm is characterized in that the thickness is 10-50Mum, the diameter is 100-300nm, the elongation at break is 15-25%, the thermal decomposition temperature is 250-350 DEG C, the porosity is 20-90%, the mechanical tensile strength is 15-20MPa, and the electric breakdown strength is 1*107-1.5*107v / m. The polysulfone nano-fiber diaphragm for the lithium battery has the advantages of resisting to tearing, thermal contraction, high temperature and high-voltage large-current overcharge (electricity), and also has good homogeneity and high porosity.

Owner:DONGFANG ELECTRIC CORP LTD

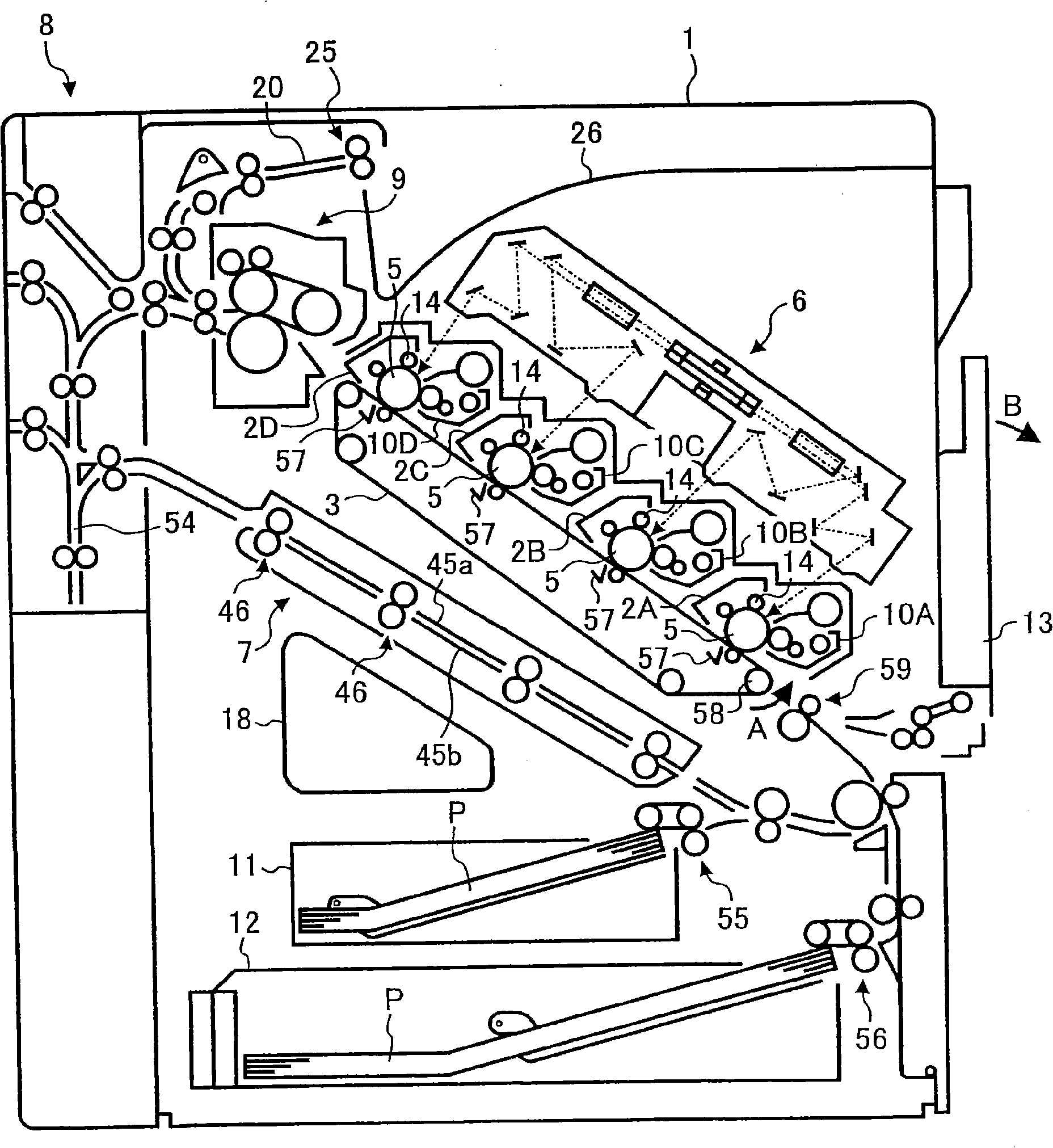

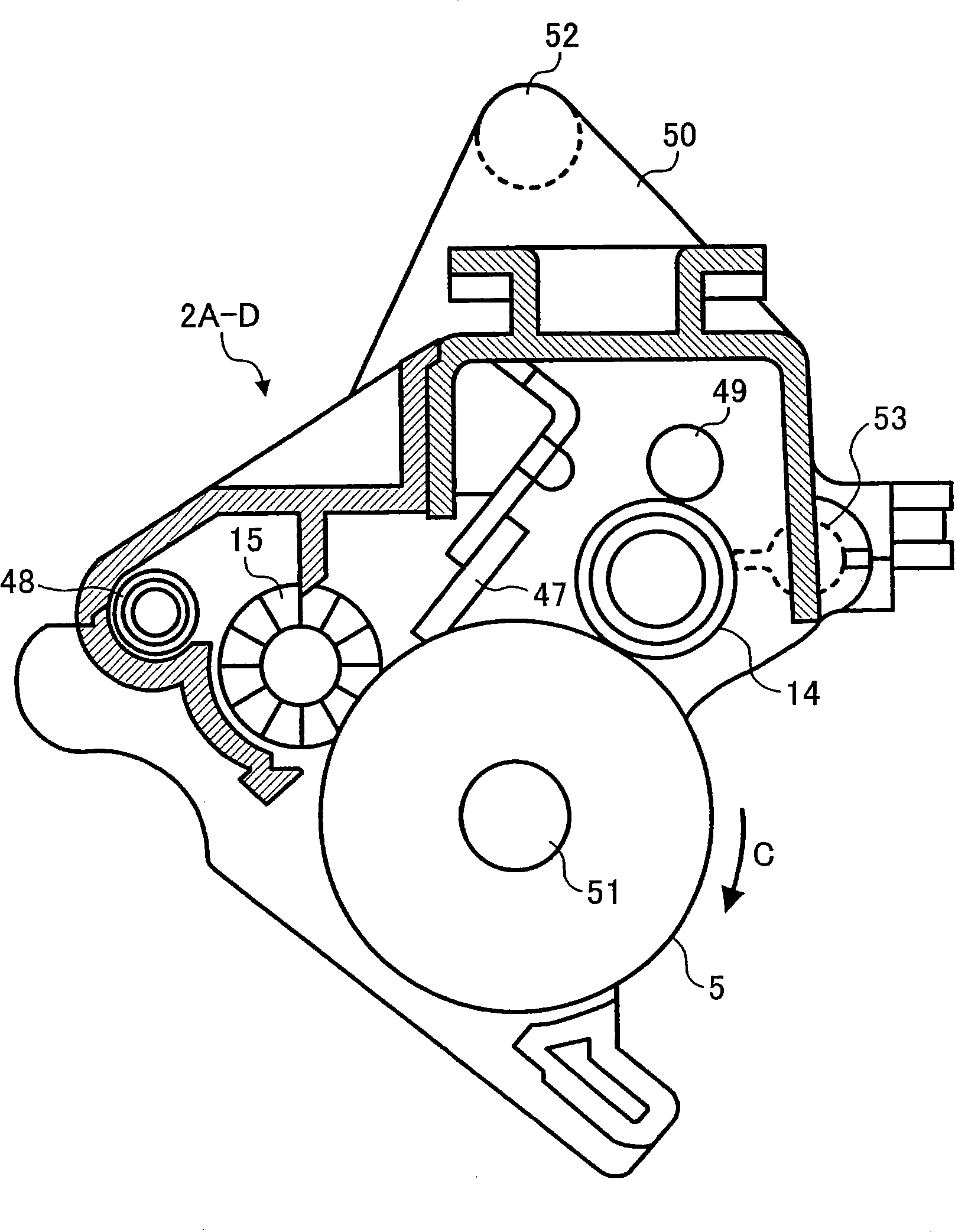

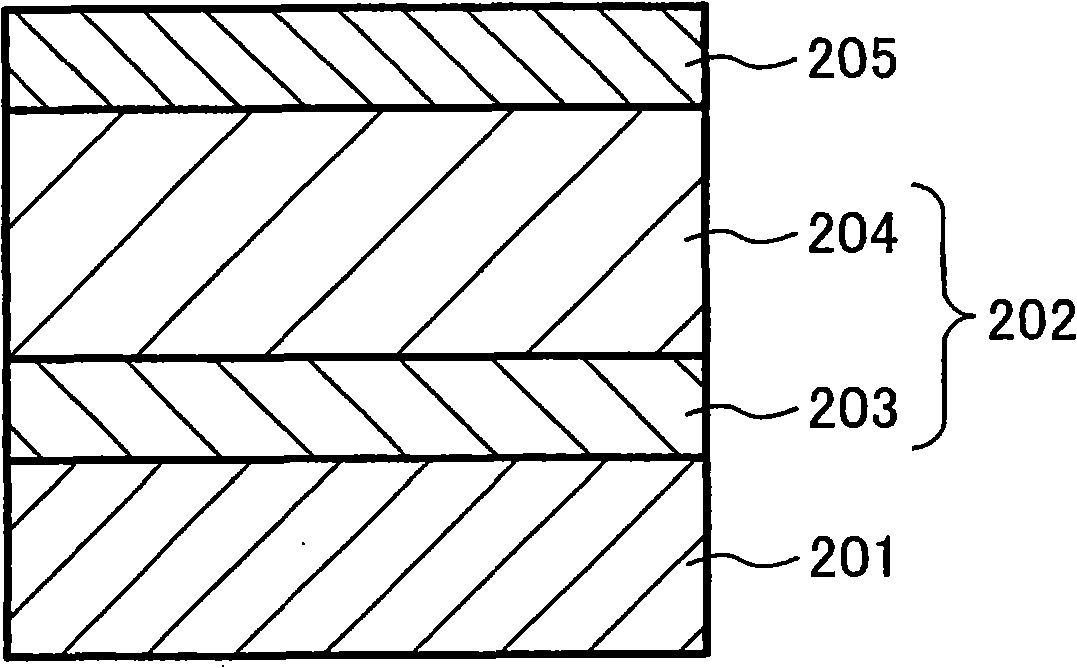

Electrifying device, process cartridge and image forming apparatus

InactiveCN101320238ALittle environmental changeLow costShaft and bearingsElectrographic process apparatusMeasurement deviceCharge layer

The invention relates to image forming devices such as a copier, a printer, a fax machine and a plotter, a charging unit used in the image forming devices and a manufacturing method for the charging unit, a processing cartridge and a setting method for charge gap. A charging roller 14 comprises a metal core 101 as a conductive support, a charging layer 102 made of conductive resin material, sheet-like gap holding component 103 provided between two ends of the charging layer 102. The gap holding component 103 is connected with a photosensitive layer 5b out of an image region 5a of a photoreceptor 5. Average value of the charging gaps when environmental temperature is 10 DEG C, 20 DEG C or 30 DEG C are respectively set as G10, G20, G30, satisfying the following condition: |G30-G10| X 5 is less than G20. Even in the event that a measurement device and a regulation device for the charging gaps are not provided, environmental variation of the charging gaps can still be reduced to realize high durability at low cost.

Owner:RICOH KK

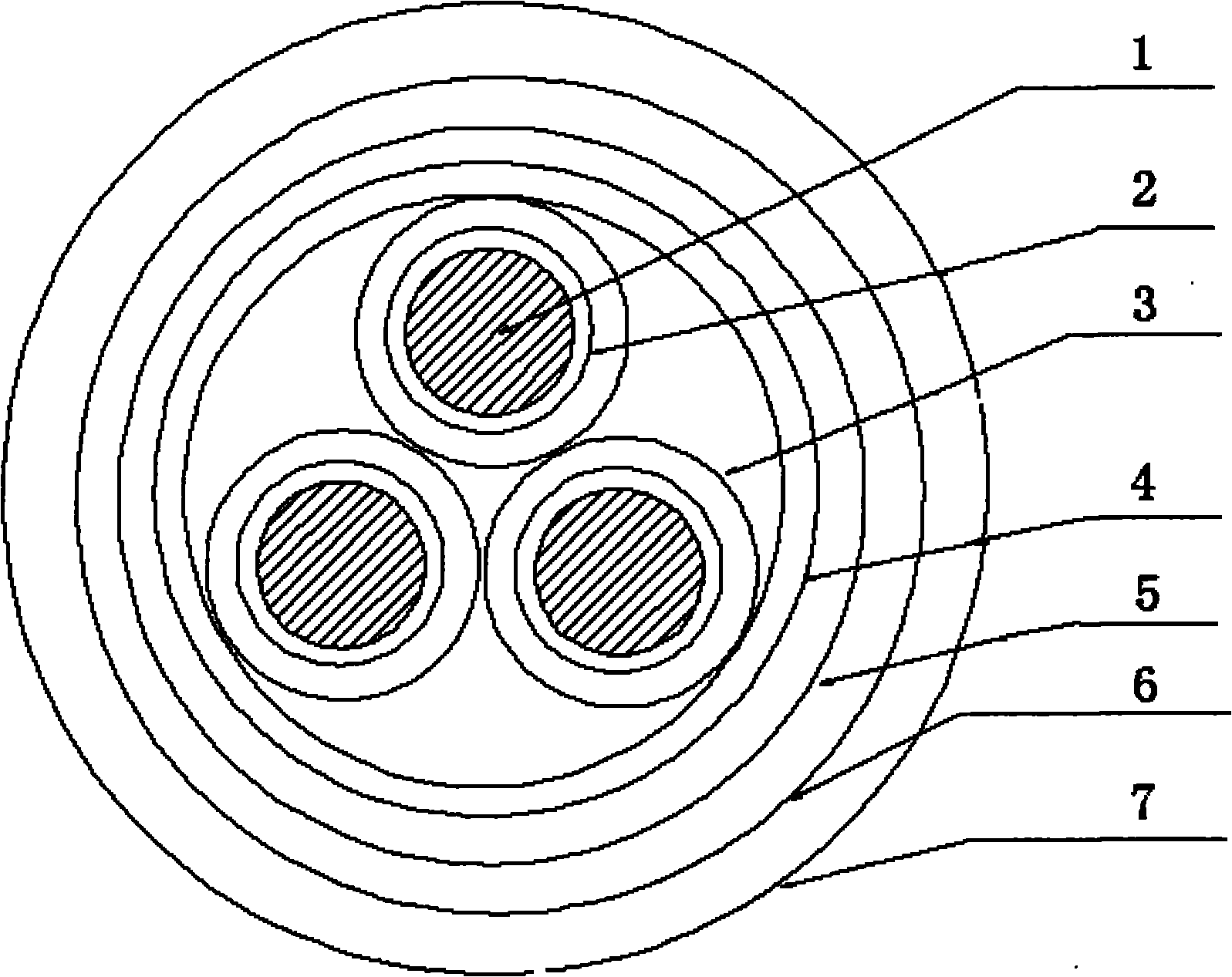

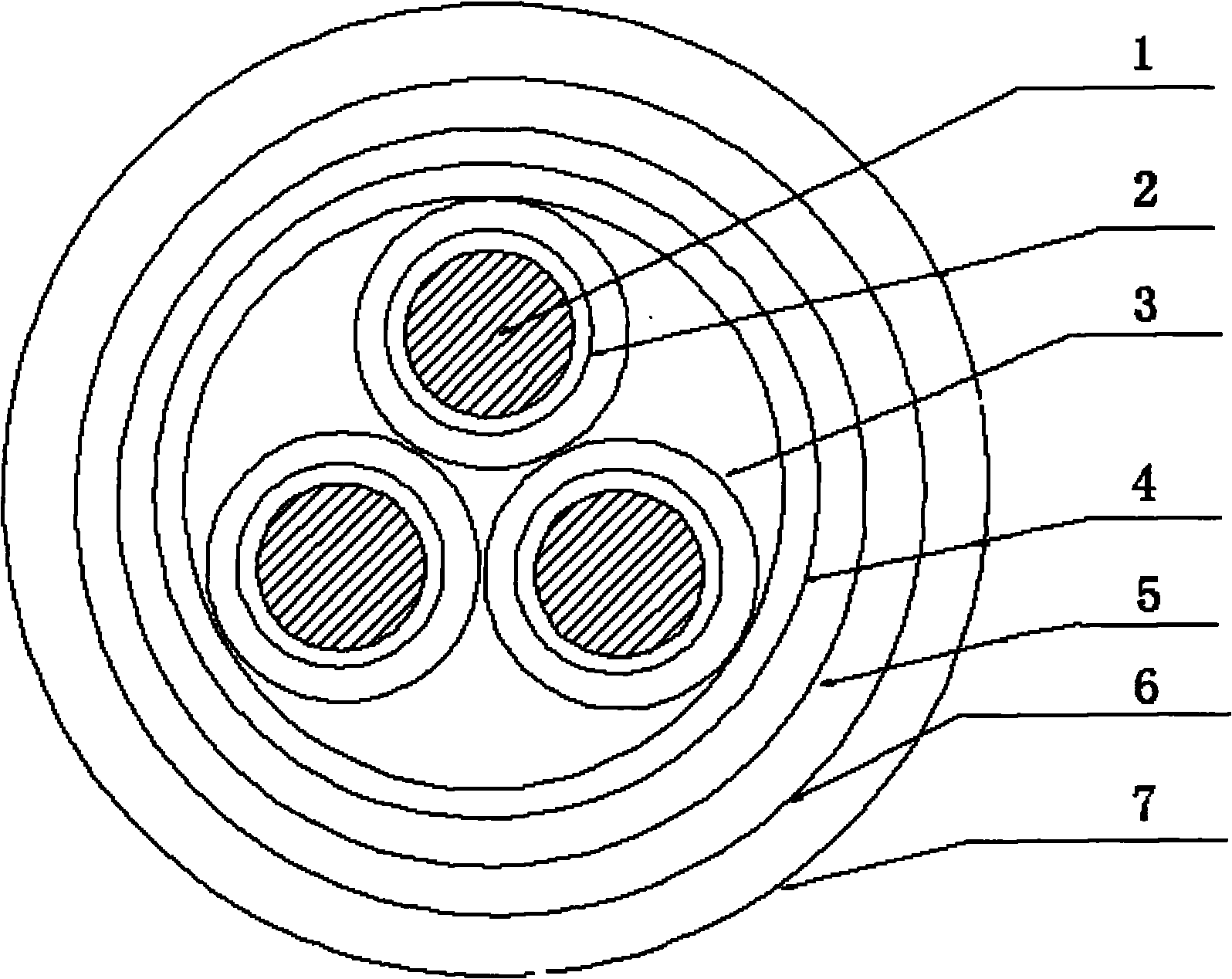

Shield control soft cable for ship engine

InactiveCN101794642ACompact structureHeat shrinkableFlexible cablesFlexible conductorsTemperature resistanceMica

The invention relates to a shield control soft cable for a ship engine, which is characterized in that a cable conductor adopts a fifth tinned conductor in GB3956, a refractory insulating layer, i.e. a mica tape is coated on the surface of the conductor, an insulator adopts an FEP insulating material which resists the high temperature of plus 250 DEG C, a layer of electricity isolated paper is longitudinally coated before cable shield weaving and performs the action of antistatic interference, and the shield control soft cable has the characteristics of cold resistance, high temperature resistance, acid and alkali and corrosive gas resistance, water prevention and the like and has the advantages of compact structure, softness, wearing resistance, flame retardance and the like.

Owner:曹洪波

Thermo-shrinkable polyester mono-layer film

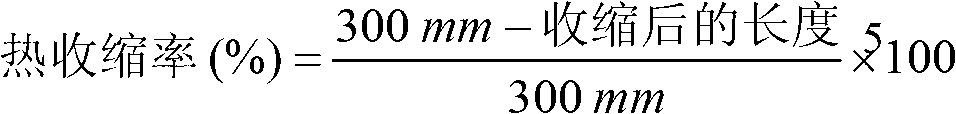

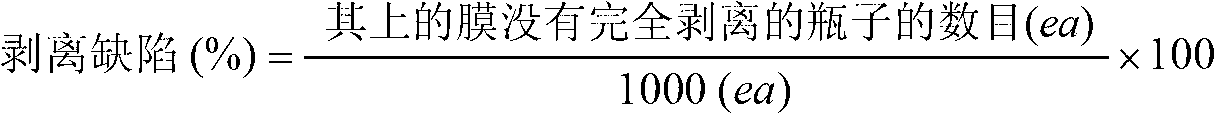

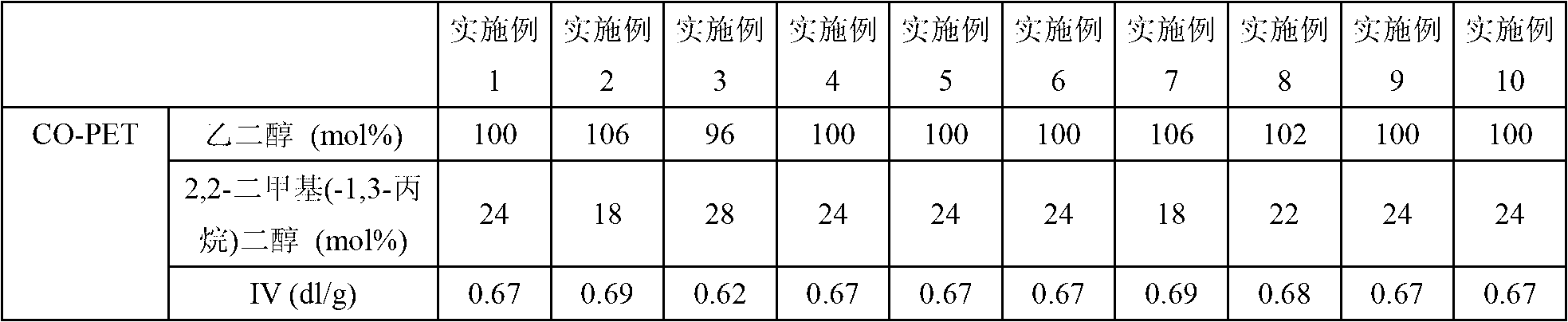

The present invention relates to a heat-shrinkable polyester-based single-layer film which has superior shrinkability and color, and thus provides aesthetic enhancement to the product to which the film is attached when the film is printed. Therefore, the polyester-based single-layer film of the present invention can be valuably used as a label film as it can replace labels made of paper, and can be easily peeled off by means of hot water, thus contributing to the recycling of bottles.

Owner:KOLON IND INC

Method for Extending the Life of Golf Course Equipment

InactiveUS20090211686A1Easy to replaceHeat shrinkableLaminationLamination apparatusGolf course turfEngineering

Owner:INSULTAB

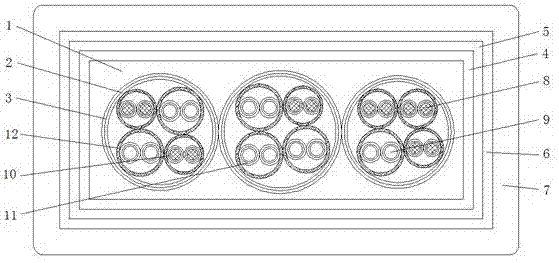

Ultra-flexible flat cable wiring harness network for aerospace

InactiveCN107103942ASoftWith bending resistanceQuad constructionsClimate change adaptationAviationPolyolefin

The invention discloses an ultra-flexible flat cable wiring harness network for aerospace. The ultra-flexible flat cable wiring harness network comprises a first wiring harness, a second wiring harness and a third wiring harness, which are formed in a crosslinked ethylene-tetrafluoroethylene copolymer carrier layer by extrusion molding, wherein the first wiring harness, the second wiring harness and the third wiring harness are formed by twisting 0.15mm pair twisted shielded wires and 0.3mm pair twisted shielded wires into beams and each beam is sequentially coated with a woven suture layer and an anti-tear silicone rubber protection layer on the periphery, wherein a wrapping layer, a polyolefin physical foaming layer, a woven layer and a crosslinked ethylene-tetrafluoroethylene copolymer outer sheath layer are coated at the outside of the crosslinked ethylene-tetrafluoroethylene copolymer carrier layer in sequence. The ultra-flexible flat cable wiring harness network disclosed by the invention is novel in structural design, the cable has flexibility and bending resistance, the operation of branch welding and other subsequent procedures is implemented easily, and the ultra-flexible flat cable wiring harness network has the advantages of high and low temperature resistance, weight, thermal shrinkage, excellent mechanical properties, salt mist resistance, dampness and heat resistance, excellent high-energy electron radiation resistance, and can improve the reliable energy and signal transmission in harsh environments.

Owner:HUAINAN WENFENG AEROSPACE CABLE CO LTD

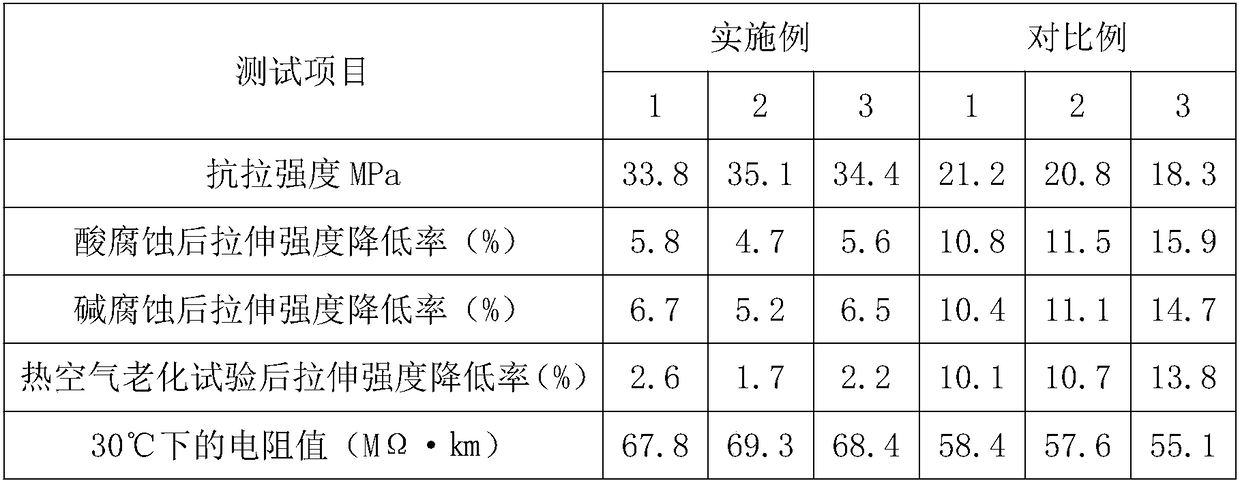

Insulation anti-corrosion heat shrinkable casing pipe material and preparation method thereof

The invention provides an insulation anti-corrosion heat shrinkable casing pipe material and a preparation method thereof. The heat shrinkable casing pipe material is prepared from 70 to 95 parts by weight of polyvinyl chloride, 30 to 50 parts by weight of thermosetting liquid polyimide pure resin, 4 to 7 parts by weight of vapor phase growth nano-carbon fiber powder, 6 to 10 parts by weight of aninsulating composite material, 2 to 4 parts by weight of polytetrafluoroethylene micropowder, 2 to 4 parts by weight of phthalic anhydride, 3 to 6 parts by weight of a silane coupling agent, 3 to 7 parts by weight of epoxy soybean oil, 4 to 7 parts by weight of liquid paraffin, 5 to 9 parts by weight of polyethylene glycol 400 and 0.5 to 0.9 parts by weight of a compatibilizer. The preparation method comprises: S1, raw material preparation, S2, premixing of the polytetrafluoroethylene micropowder, phthalic anhydride, silane coupling agent, vapor phase growth nano-carbon fiber powder and insulating composite material, S3, mixing, and S4, extrusion, molding and drying. The heat shrinkable casing pipe material is excellent in insulation, corrosion resistance, high temperature resistance andthermal expansion and contraction performance.

Owner:WUHU EXCELLENCE WIRE HARNESS SYST

Thermal contracting directional memory polyvinyl chloride pipe and manufacture thereof

InactiveCN1327154CEasy to operateDoes not destroy performanceRigid pipesPolyvinyl chlorideEngineering

Owner:徐益鑫

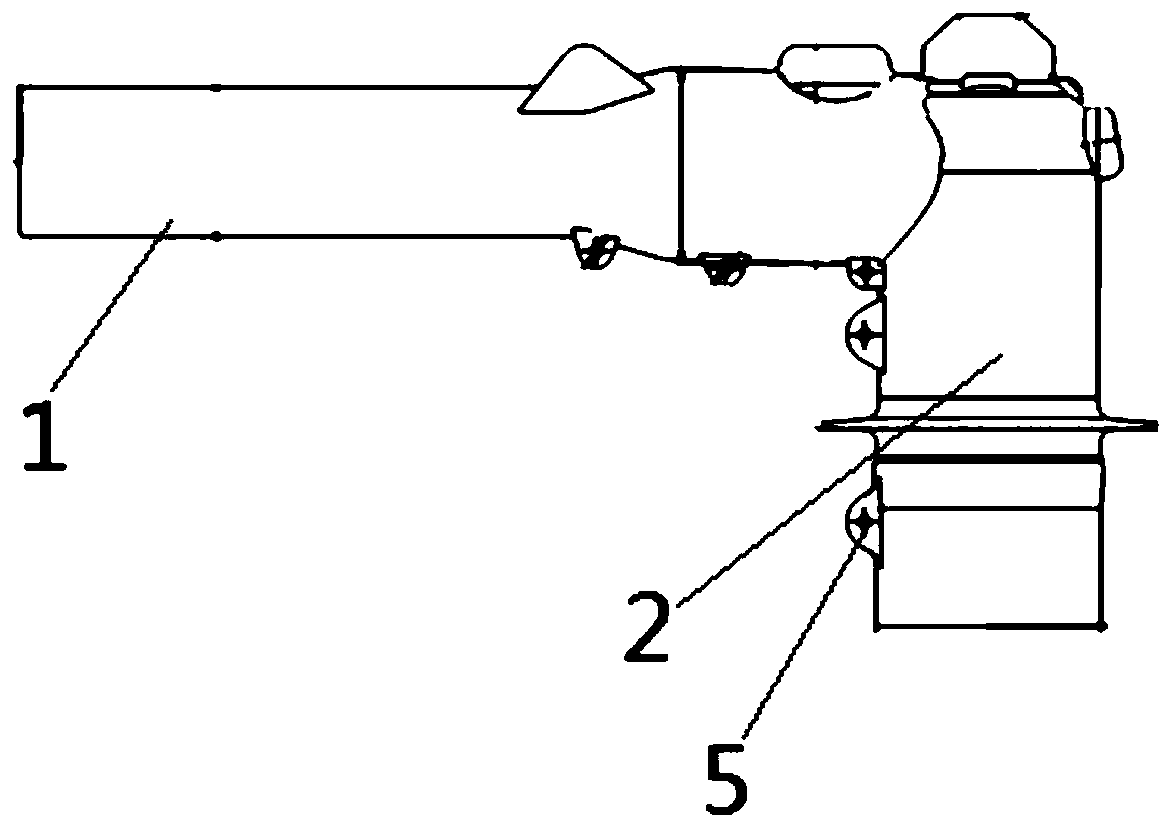

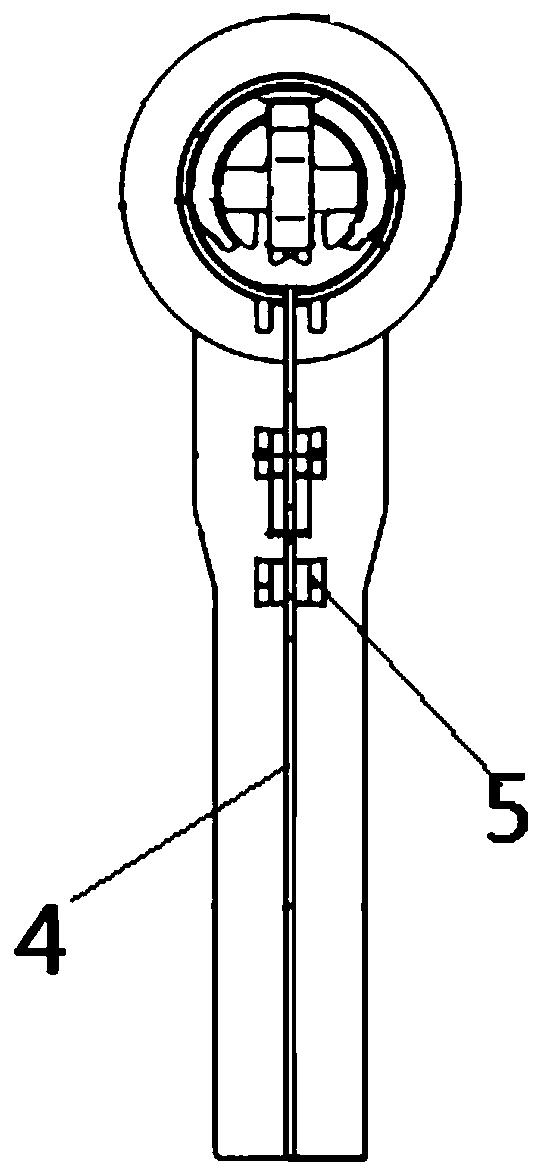

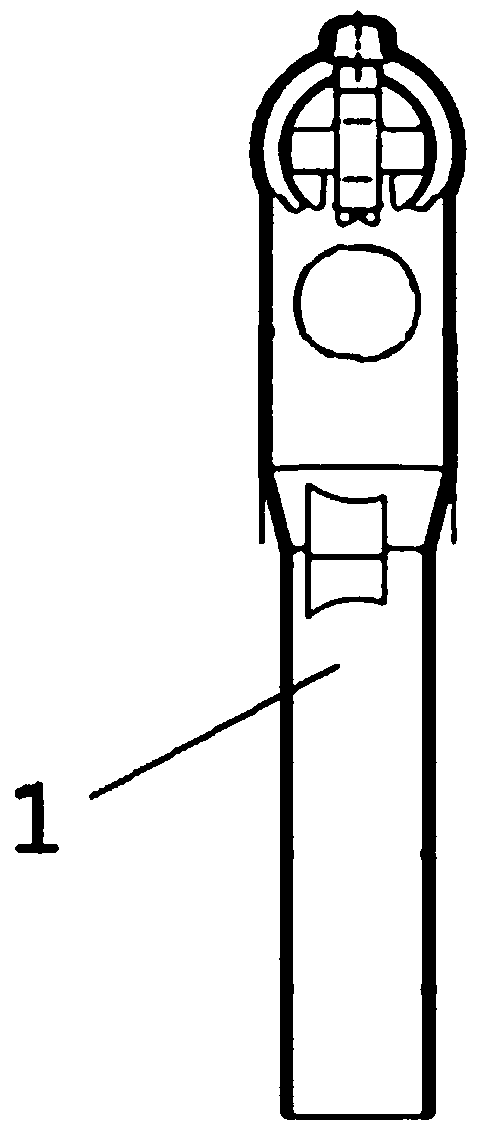

Pole-mounted transformer cable elbow-shaped head waterproof cover

InactiveCN111564816ADelay agingEasy dischargeTransformers/inductances coils/windings/connectionsCable junctionsTransformerSevere weather

The invention discloses a pole-mounted transformer cable elbow-shaped head waterproof cover which comprises a waterproof cover shell, the waterproof cover shell comprises a transverse sleeve and a vertical sleeve which are integrally formed, the transverse sleeve is used for being arranged on the transverse part of a cable elbow-shaped head in a sleeving mode, and the vertical sleeve is used for being arranged on the vertical part of the cable elbow-shaped head in a sleeving mode. The waterproof cover is additionally arranged on the cable elbow-shaped head, so that the cable elbow-shaped headcan be effectively protected, the aging of the cable elbow-shaped head is delayed, and the problem of discharge of the cable elbow-shaped head due to damp is reduced in severe weather such as rain andsnow. A plurality of circles of rain skirts protruding outwards are arranged in the lower part of the outer wall of the vertical sleeve; the cable elbow-shaped head can be further protected, and water is prevented from entering the lower portion of the cable elbow-shaped head in rainy and snowy days. A tail end pipe hoop is arranged at an opening of the transverse sleeve and fastens the transverse sleeve to the wire end of the cable elbow-shaped head, and water is further prevented from entering the transverse sleeve.

Owner:STATE GRID BEIJING ELECTRIC POWER +2

Corrosion-resistant heat shrinkable sleeve material and preparation method thereof

InactiveCN108794860AExcellent high temperature resistance and thermal expansion and contraction performanceWide range of useParaffin waxCorrosion resistant

The invention provides a corrosion-resistant heat shrinkable sleeve material and a preparation method thereof. The corrosion-resistant heat shrinkable sleeve material comprises the following raw materials by weight: 90-110 parts of high-density polyethylene, 20-40 parts of acrylonitrile-butadiene-styrene copolymer, 5-15 parts of glass fiber, 1-4 parts of polytetrafluoroethylene micropowder, 1-4 parts of phthalic anhydride, 2-6 parts of silane coupling agent, 3-8 parts of turpentine, 5-10 parts of liquid paraffin, 5-10 parts of polyethylene glycol 400, 2-5 parts of tris(2,3-dichloropropyl)phosphate and 0.3-0.8 part of compatibilizer. The preparation method includes the following steps: the step S1 of preparation of raw materials; the step S2 of pre-mixing of the polytetrafluoroethylene micropowder, the phthalic anhydride, the silane coupling agent and the glass fiber; the step S3 of mixing; the step S4 of extrusion, molding and drying. The heat shrinkable sleeve material is excellent incorrosion resistance, high temperature resistance and thermal expansion and contraction performance.

Owner:WUHU EXCELLENCE WIRE HARNESS SYST

Enhanced flame-retarding PET heat-shrinkable bush

The invention provides a flame-retardant PET heat-shrinkable sleeve, which is prepared from a reinforced flame-retardant PET material. The reinforced flame-resistant PET material is prepared by the following method: prepare raw materials according to the following ratio, PET 65-75 parts by weight of slices, 1-5 parts by weight of reinforcing agent, 1-5 parts by weight of flame retardant, 1-3 parts by weight of antioxidant, add in a high-speed mixer and mix uniformly; send the compound into a twin-screw extruder Melt blending and extruding, the extruded strips are water-cooled, drawn and stretched, and pelletized by a pelletizer to obtain a reinforced flame-retardant PET material; wherein, the reinforcing agent is a mixture of nano-barium sulfate and nano-montmorillonite ; The flame retardant is microcapsule red phosphorus; the PET chips, reinforcing agent and flame retardant are pre-dried at 100° C. for 10 h. The invention has the following technical effects: it has heat shrinkability and enhanced flame retardancy at the same time.

Owner:NANTONG DINGSHANG ELECTRONICS MATERIAL CO LTD

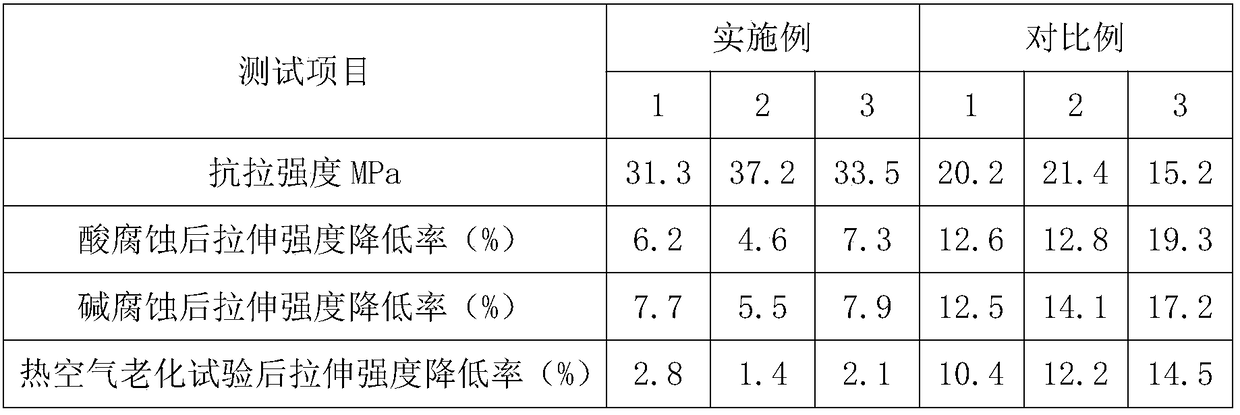

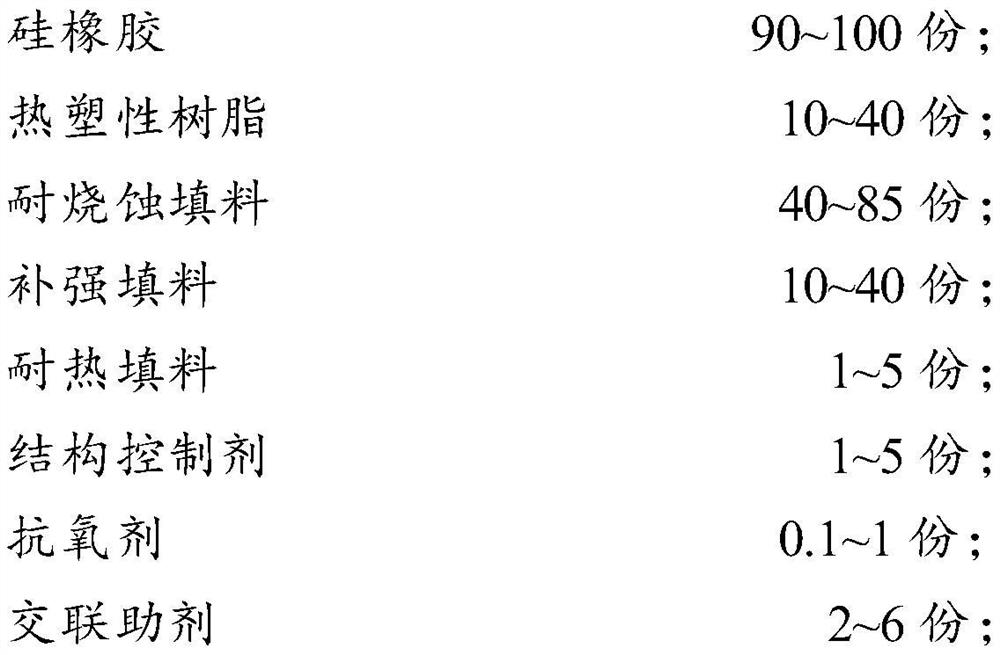

Flame-ablation-resistant silicone rubber heat-shrinkable material, preparation method thereof and silicone rubber heat-shrinkable tube

The invention belongs to the field of materials, and particularly relates to a flame-ablation-resistant silicone rubber heat-shrinkable material, a preparation method thereof and a silicone rubber heat-shrinkable tube. The silicone rubber heat-shrinkable material provided by the invention is prepared from raw materials through mixing, pre-forming, cross-linking modification and expansion shaping; and the raw materials comprise the following components in parts by mass: 90-100 parts of silicone rubber, 10-40 parts of thermoplastic resin, 40-85 parts of ablation-resistant filler, 10-40 parts of reinforcing filler, 1-5 parts of heat-resistant filler, 1-5 parts of a structure control agent, 0.1-1 part of an antioxidant and 2-6 parts of a cross-linking aid. The silicone rubber heat-shrinkable material provided by the invention has good mechanical properties and flame ablation resistance, can effectively isolate flame burning and thermal radiation, is simple in construction process, can tightly bind a protected sample after being heated, and is not easy to fall off.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

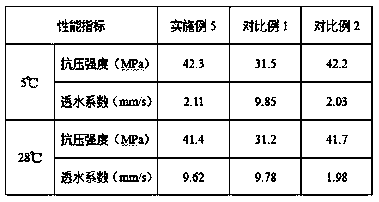

Pervious concrete for sponge city pavement and preparation method

The invention relates to the technical field of building materials, and provides pervious concrete for a sponge city pavement and a preparation method. The pervious concrete is prepared by mixing heatshrinkable particles, cement, coarse aggregate, fly ash, a water reducing agent, a tackifier and water, wherein the heat shrinkable particles are prepared by coating a heat-shrinkable polymer with acoupling agent. When the pervious concrete is used as the sponge city pavement, the pervious concrete has high strength in winter with low requirements on pervious capacity, and has high strength andhigh water permeability in summer with high requirements on pervious capacity.

Owner:成都其其小数科技有限公司

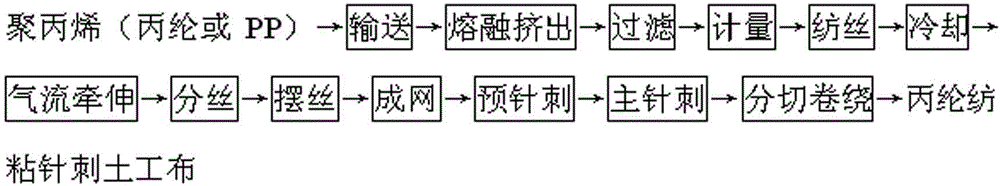

Production method for polypropylene spun-bonded needle-punched geotextile

ActiveCN103074739BReduce production processReduce manufacturing costNon-woven fabricsCardingEngineering

A production method for a polypropylene spun-bonded needle-punched geotextile mainly includes the following steps: polypropylene chips are conveyed into a screw extruder and extruded out, the melt enters a spinning manifold via a filter, and is measured and extruded into filaments by a spinneret plate, the filaments are cooled by cross wind, drafted by duct airflow, then separated, swayed and formed into a web on a lapper, the web is outputted to a needle machine and needled to be bound, and after tension is adjusted, the web is trimmed and rolled, so that the polypropylene spun-bonded needle-punched geotextile is formed. Various processes after spinning, such as bundle stretching, rolling, drying, shaping, cutting off, packing, unpacking, blending, carding and web forming, are dispensed, consequently, the production process is greatly shortened, the production cost is lower, and the production efficiency is higher; the product has higher strength and better uniformity, thermal shrinkage and various indexes are more stable, and the product is incomparable with polypropylene staple geotextile and the like.

Owner:DALIAN HUAYANG NEW MATERIALS TECH CO LTD

A shaping method for skin-core composite low-melting-point fiber

ActiveCN106283231BEasy to adjust sensitivelyReduce stickingArtificial filament heat treatmentTime rangePolyester

The invention relates to a chemical fiber setting technology, in particular to a low-melting-point polyester setting technology. Low-temperature thermal shrinkage setting and strong-wind cooling are adopted in a sheath-core composite low-melting-point fiber setting method, wherein the thermal shrinkage temperature ranges from 50 DEG C to 70 DEG C, the thermal shrinkage time ranges from 15 min to 45 min, and fibers are subjected to rapid cooling by a strong-cold fan after leaving a setting area. The surfaces of low-melting-point polyester staple fibers obtained according to the technology are smooth to a certain degree, good in dispersibility, small in specific resistance and stable in thermal shrinkage, and the low-melting-point polyester staple fibers treated by the method can be used at 150-210 DEG C and can be used for producing sound insulation, thermal insulation and waterproof materials such as hard cotton, needle punched non-woven fabric, hot-air bonded nonwoven fabric, silk-like cotton, palm / coconut palm mattresses, shoe materials and the like.

Owner:余姚大发化纤有限公司

Method for producing laminated film

ActiveCN103140298BHeat shrinkablePrevent precipitationLamination ancillary operationsLayered product treatmentOligomerSolvent

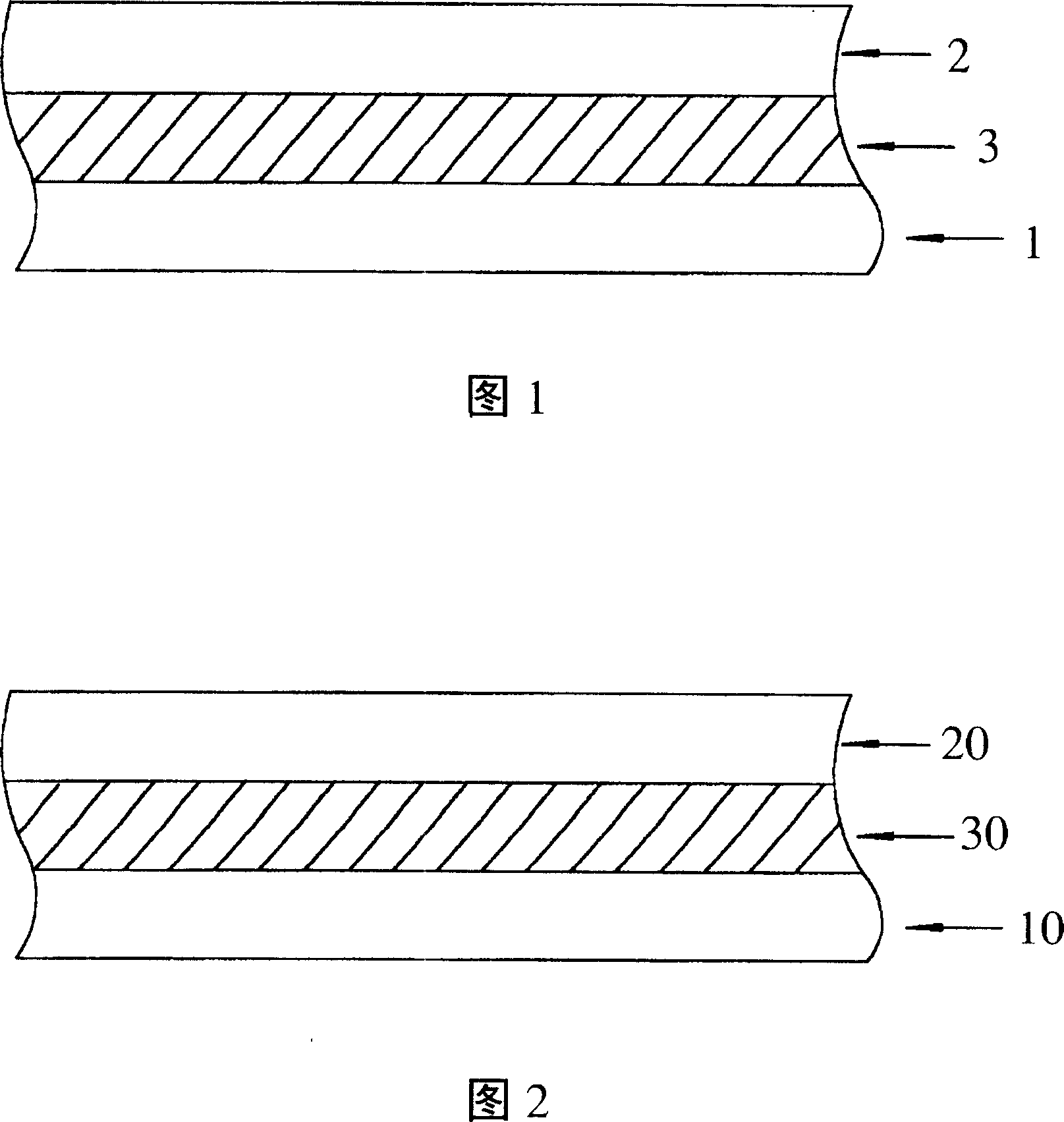

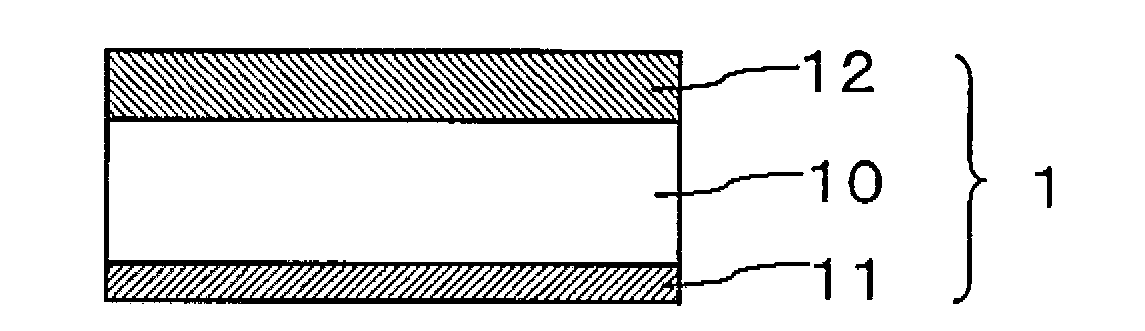

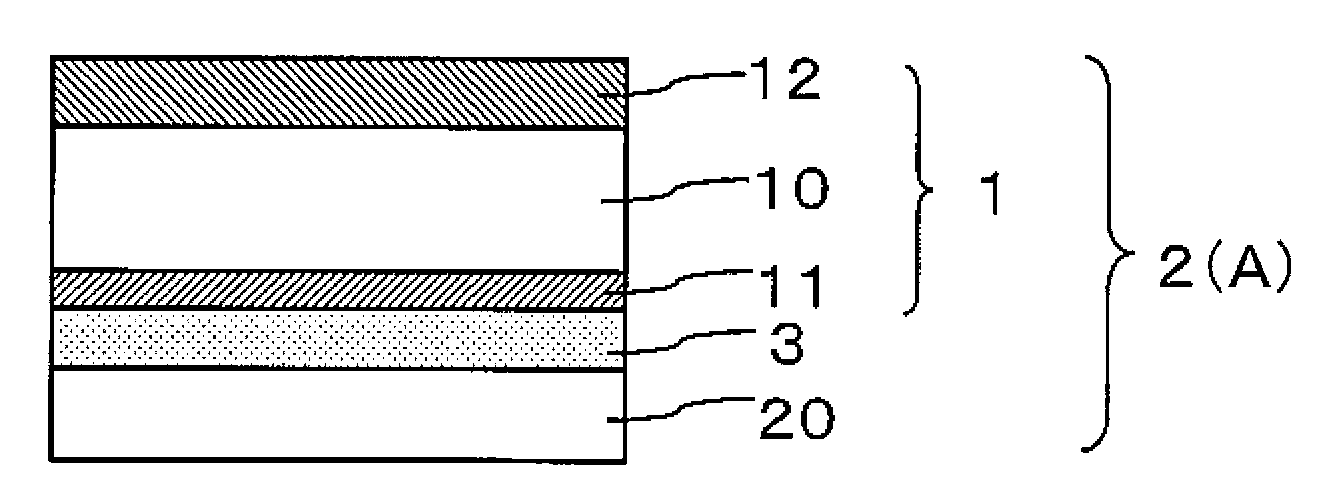

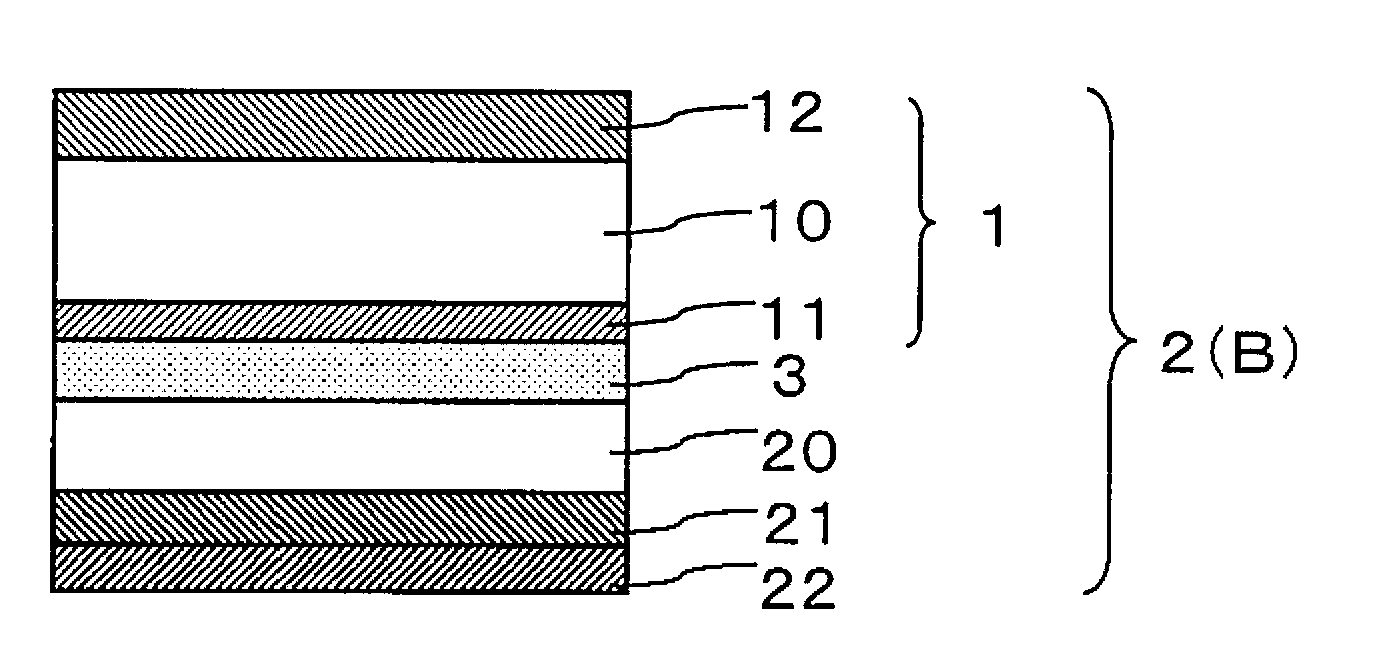

A process including (1) applying a solution composition to one or both sides of a first transparent resin film to form a coating layer or layers, wherein the solution composition contains an active energy ray-curable compound, a photopolymerization initiator, and a solvent, wherein the photopolymerization initiator has a 10% weight loss temperature of 170° C. or more as measured by a loss-on-heating test; (2) removing, after the coating step (1), a solvent from the coating layer or layers by drying under such temperature conditions that the first laminated film obtained has a thermal shrinkage of 0.5% or less when heated at 150° C. for 1 hour, and (3) curing the coating layer or layers after the heat-treating step (2). A second laminated film produced with the first laminated film makes it possible to suppress curling and to prevent oligomer precipitation.

Owner:NITTO DENKO CORP

A processing method for improving the non-ironing property of moisture-crosslinked yarn-dyed fabrics

ActiveCN108457082BAdequate responseGood flatness effectHeating/cooling textile fabricsWrinkle resistant fibresEngineeringOceanography

The invention belongs to the technical field of textile dyeing and finishing, and in particular relates to a processing method for improving the non-ironing property of moisture-crosslinked and finished yarn-dyed fabrics. The process flow is singeing → desizing → mercerizing → liquid ammonia → pre-softening → wet cross-linking rolling → wet cross-linking → baking → primary washing → secondary washing → tenter → finished product inspection; It is carried out on a baking machine, the baking temperature is 120-140°C, and the baking time is 3-5 minutes. The invention creatively adopts two times of cross-linking, the water shrinkage and thermal shrinkage of the fabric are more stable, the pre-shrinking process is omitted, and the production cost of the fabric is reduced; The setting time is 6-12 hours, which reduces the amount of resin and catalyst by 20% to 50% compared with the traditional moisture cross-linking process; improves the non-ironing performance of the dyed fabrics finished by moisture cross-linking to 0.2-0.5 level, washable for 50 times, and non-ironing property Above level 4.0.

Owner:LUTAI TEXTILE

Flame-retardant anti-corrosion heat shrinkable tube material and preparation method thereof

InactiveCN108794876AGood flame retardant performanceGood high temperature resistancePolytetrafluoroethyleneParaffin oils

The invention provides a flame-retardant anti-corrosion heat shrinkable tube material and a preparation method thereof. The heat shrinkable tube material comprises the following raw materials by weight: 70-100 parts of EVA resin, 30-50 parts of thermosetting liquid polyimide pure resin, 4-6 parts of vapor phase growth nano carbon fiber powder, 6-10 parts of flame-retardant composite material, 2-4parts of polytetrafluoroethylene micropowder, 2-4 parts of phthalic anhydride, 3-6 parts of silane coupling agent, 3-7 parts of chlorinated paraffin, 4-7 parts of liquid paraffin, 5-9 parts of polyethylene glycol 400 and 0.5-0.9 part of compatibilizer. The preparation method comprises the following steps: the step S1 of preparing raw materials; the step S2 of premixing of the polytetrafluoroethylene micropowder, the phthalic anhydride, the silane coupling agent, the vapor phase growth nano carbon fiber powder and the flame-retardant composite; the step S3 of mixing; the step S4 of extrusion, molding and drying. The heat shrinkable tube material is excellent in flame retardancy, corrosion resistance, high temperature resistance and thermal stretching performance.

Owner:WUHU EXCELLENCE WIRE HARNESS SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com