Insulation anti-corrosion heat shrinkable casing pipe material and preparation method thereof

A heat-shrinkable sleeve and insulating composite material technology, which is applied in the field of heat-shrinkable sleeve materials, can solve the problems of poor insulation performance, acid and alkali corrosion resistance and high temperature resistance, so as to solve the problems of poor insulation performance, wide application range, and improved mechanical properties. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

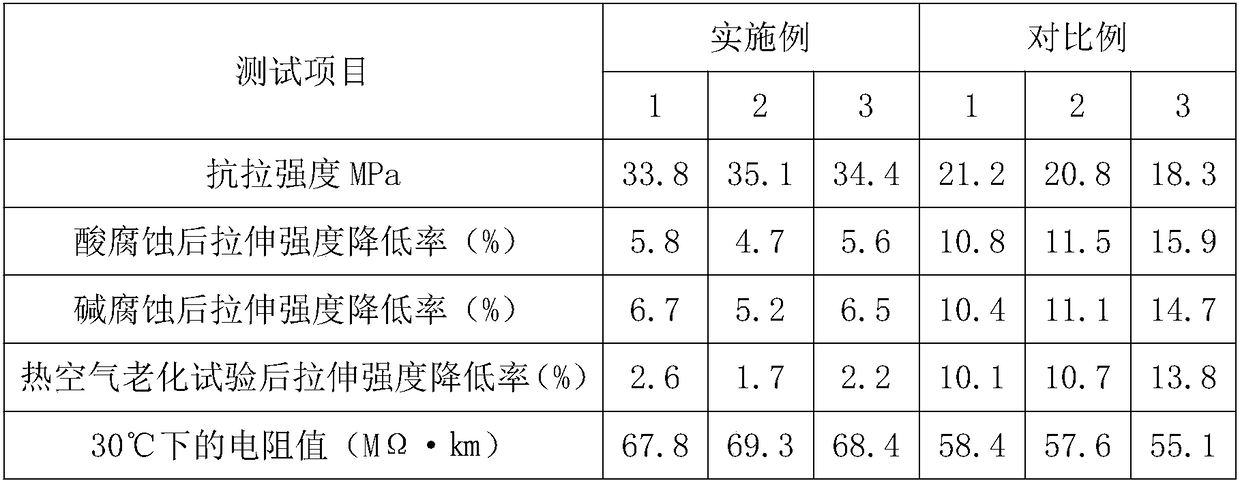

Examples

Embodiment 1

[0018] An insulating and anti-corrosion heat-shrinkable sleeve material, comprising the following raw materials in parts by weight:

[0019] 85 parts of polyvinyl chloride, 42 parts of pure thermosetting liquid polyimide resin, 5 parts of vapor phase growth nano-carbon fiber powder, 8 parts of insulating composite material, 3 parts of polytetrafluoroethylene micropowder, 3.2 parts of phthalic anhydride, silane coupling 4.2 parts of agent, 5 parts of epoxidized soybean oil, 5.5 parts of liquid paraffin, 4007.3 parts of polyethylene glycol, 0.7 part of maleic acid grafted PE; wherein, the preparation steps of the insulating composite material are as follows:

[0020] (1) In parts by weight, weigh 4 parts of expanded graphite, 2.2 parts of nano-silicon dioxide, 0.5 parts of nano-boron nitride and 2.8 parts of hydroxyl-terminated polybutadiene, mix and stir evenly, and then add 3.2 parts of perfluoropolyether Stir to mix well;

[0021] (2) Put the mixture obtained in step (1) int...

Embodiment 2

[0028] An insulating and anti-corrosion heat-shrinkable sleeve material, comprising the following raw materials in parts by weight:

[0029] 85 parts of polyvinyl chloride, 46 parts of pure thermosetting liquid polyimide resin, 6 parts of vapor phase growth nano-carbon fiber powder, 9 parts of insulating composite material, 2.8 parts of polytetrafluoroethylene micropowder, 3.2 parts of phthalic anhydride, silane coupling 4.6 parts of agent, 6 parts of epoxidized soybean oil, 6 parts of liquid paraffin, 4008 parts of polyethylene glycol, 0.8 part of maleic acid grafted ABS; wherein, the preparation steps of the insulating composite material are as follows:

[0030] (1) In parts by weight, weigh 4 parts of expanded graphite, 2.2 parts of nano-silicon dioxide, 0.5 parts of nano-boron nitride and 2.8 parts of hydroxyl-terminated polybutadiene, mix and stir evenly, and then add 3.2 parts of perfluoropolyether Stir to mix well;

[0031] (2) The mixture obtained in step (1) was grou...

Embodiment 3

[0038]An insulating and anti-corrosion heat-shrinkable sleeve material, comprising the following raw materials in parts by weight:

[0039] 90 parts of polyvinyl chloride, 43 parts of pure thermosetting liquid polyimide resin, 6 parts of vapor phase growth nano-carbon fiber powder, 8 parts of insulating composite material, 3 parts of polytetrafluoroethylene micropowder, 3 parts of phthalic anhydride, silane coupling 6 parts of epoxidized soybean oil, 6 parts of liquid paraffin, 4008 parts of polyethylene glycol, 0.8 part of maleic acid grafted PP; wherein, the preparation steps of the insulating composite material are as follows:

[0040] (1) In parts by weight, weigh 4 parts of expanded graphite, 2.2 parts of nano-silicon dioxide, 0.5 parts of nano-boron nitride and 2.8 parts of hydroxyl-terminated polybutadiene, mix and stir evenly, and then add 3.2 parts of perfluoropolyether Stir to mix well;

[0041] (2) Put the mixture obtained in step (1) into a ball mill and grind for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com