Pervious concrete for sponge city pavement and preparation method

A technology for permeable concrete and sponge city, which is applied in the field of permeable concrete for sponge city pavement and its preparation, can solve problems such as hindering the popularization and application of permeable concrete, poor concrete compactness and small addition amount, etc., so as to prevent waterlogging and heat island effect and improve strength. , the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

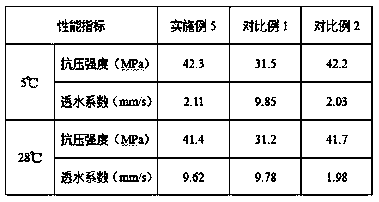

Examples

Embodiment 1

[0026] Coarse aggregate is crushed stone with a particle size of 5-10mm; the water reducer is calcium lignosulfonate; the tackifier is carboxymethyl cellulose; the heat shrinkable polymer is cross-linked heat shrinkable polyethylene, and its Tg after testing is 20°C; the coupling agent is silane coupling agent kh550; the cement is ordinary Portland cement 42.5;

[0027] The mass ratio of heat-shrinkable particles, cement, coarse aggregate, fly ash, water reducer, tackifier, and water is 15:26:100:11:1.3:0.7:33;

[0028] The mass ratio of the coupling agent in the heat-shrinkable particles to the heat-shrinkable polymer is 4:100;

[0029] Preparation steps:

[0030] (1) Crush the heat-shrinkable polymer in a plastic crusher until the particle size is not greater than 3mm, then add it to a high-speed mixer, add a coupling agent, heat to 80°C, stir and mix at a speed of 500r / min for 20min, stop Stir and cool naturally to room temperature to obtain heat-shrinkable particles;

...

Embodiment 2

[0033] The coarse aggregate is pebbles with a particle size of 5~10mm; the water reducer is sodium lignosulfonate; the tackifier is hydroxypropyl methylcellulose; the heat shrinkable polymer is heat shrinkable polyurethane, and its Tg is 22°C after testing ; The coupling agent is silane coupling agent kh570; the cement is ordinary Portland cement 42.5;

[0034] The mass ratio of heat shrinkable particles, cement, coarse aggregate, fly ash, water reducing agent, tackifier, and water is 20:28:100:13:1:0.8:30;

[0035] The mass ratio of the coupling agent in the heat-shrinkable particles to the heat-shrinkable polymer is 3:100;

[0036] Preparation steps:

[0037] (1) Crush the heat-shrinkable polymer in a plastic crusher until the particle size is not greater than 3mm, then add it to a high-speed mixer, add a coupling agent, heat to 90°C, stir and mix at a speed of 300r / min for 20min, stop Stir and cool naturally to room temperature to obtain heat-shrinkable particles;

[003...

Embodiment 3

[0040] The coarse aggregate is pebbles with a particle size of 5~10mm; the water reducing agent is magnesium lignosulfonate; the tackifier is hydroxypropyl methylcellulose; Its Tg is 24°C; the coupling agent is silane coupling agent kh570; the cement is ordinary Portland cement 42.5;

[0041] The mass ratio of heat-shrinkable particles, cement, coarse aggregate, fly ash, water reducer, tackifier, and water is 16:30:100:10:1.2:0.7:35;

[0042] The mass ratio of the coupling agent in the heat-shrinkable particles to the heat-shrinkable polymer is 3:100;

[0043] Preparation steps:

[0044] (1) Crush the heat-shrinkable polymer in a plastic crusher until the particle size is not greater than 3mm, then add it to a high-speed mixer, add a coupling agent, heat to 85°C, stir and mix at a speed of 400r / min for 30min, stop Stir and cool naturally to room temperature to obtain heat-shrinkable particles;

[0045](2) First add heat-shrinkable particles, coarse aggregate, and half of wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tg | aaaaa | aaaaa |

| Tg | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com