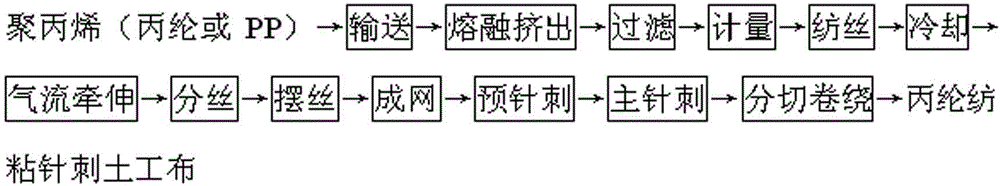

Production method for polypropylene spun-bonded needle-punched geotextile

A technology of polypropylene spunbonding and production methods, which is applied in the direction of non-woven fabrics, textiles, and papermaking, and can solve the problem of cloth surface tensile strength and elongation at break (the influence of elongation, the long production process of staple fiber polypropylene geotextiles, and the restriction of polypropylene geotextiles) Geotextile performance indicators and other issues, to achieve the effect of shortening the production process, stabilizing various indicators, and stabilizing heat shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The polypropylene raw material is transported into the screw extruder for melt extrusion. The screw extruder has a large length-to-diameter ratio, that is, a polypropylene screw extruder with a length-to-diameter ratio of 29:1. The temperature of each zone: 165°C, 200°C, 230°C, 250°C ℃, 250℃, 260℃, 265℃, 265℃. After the melt passes through the filter, the pressure is 11Mpa, and then enters the spinning box, and is sprayed out from the spinneret after metering. The component pressure is 15Mpa, the spinning temperature is 265°C, the single-filament fineness is controlled at 6dpf, and the single-filament strength is greater than 4.2CN / dtex. The spun filaments are cooled by side blowing, the wind speed of the side blowing: 0.7m / s, the temperature of the side blowing: 17°C, and the humidity of the side blowing: above 70%. The cooled filaments are air-drawn by a tubular air-flow drawing device, and the air-flow drawing speed is 5000m / min. The drawing pressure is 0.60 Mpa. ...

Embodiment 2

[0022] The PP raw material is conveyed into the screw extruder for melt extrusion. The screw extruder has a large aspect ratio, that is, a polypropylene screw extruder with an aspect ratio of 30:1. The temperature of each zone: 165°C, 200°C, 240°C, 255°C ℃, 255℃, 260℃, 270℃, 270℃. After the melt passes through the filter, the pressure is 12Mpa, and then enters the spinning box, and is sprayed out from the spinneret after metering. The component pressure: 16Mpa, the spinning temperature: 270°C, the monofilament fineness is controlled at 8dpf, and the monofilament strength is greater than 4.2CN / dtex. The spun filaments are cooled by the side blowing, the wind speed of the side blowing: 0.9m / s, the temperature of the side blowing: 16°C, and the humidity of the side blowing: above 70%. The cooled filaments are air-drawn by a tubular air-flow drawing device, and the air-flow drawing speed is 4600m / min. The drawing pressure is 0.65 Mpa. After spinning, the frequency of the spinn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com