Flame-retardant anti-corrosion heat shrinkable tube material and preparation method thereof

A heat-shrinkable sleeve and flame-retardant composite material technology, which is applied in the field of heat-shrinkable sleeve materials, can solve the problems of flame retardant performance, poor acid and alkali corrosion resistance and high temperature resistance, and achieves poor flame retardant performance and a wide range of applications. , Improve the effect of flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

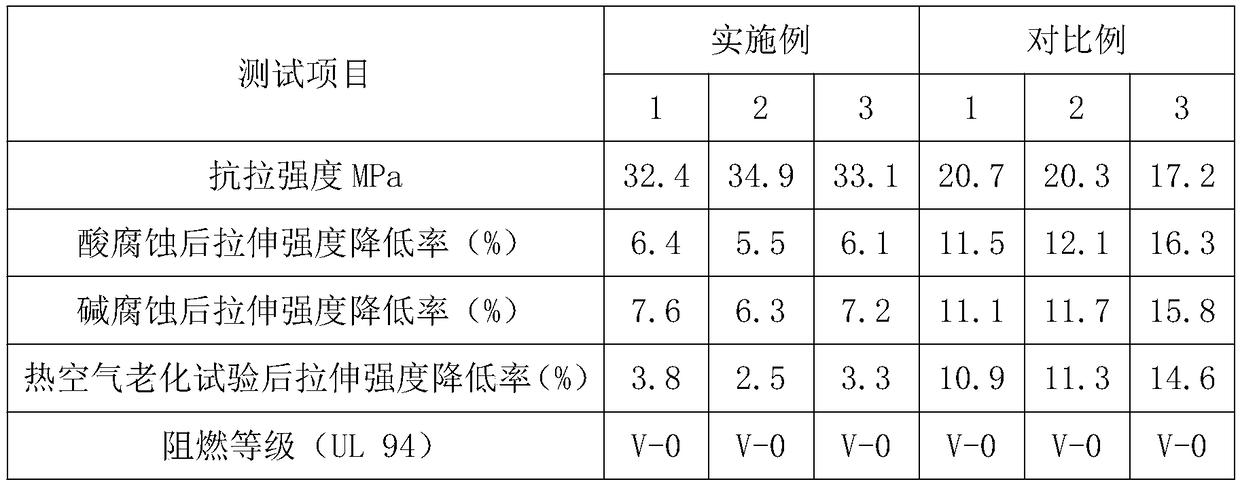

Examples

Embodiment 1

[0018] A flame-retardant and anti-corrosion heat-shrinkable sleeve material, comprising the following raw materials in parts by weight:

[0019] 85 parts of EVA resin, 42 parts of pure thermosetting liquid polyimide resin, 5 parts of vapor phase growth nano-carbon fiber powder, 8 parts of flame-retardant composite material, 3 parts of polytetrafluoroethylene micropowder, 3 parts of phthalic anhydride, silane coupling 5.6 parts of chlorinated paraffin, 5 parts of chlorinated paraffin, 6 parts of liquid paraffin, 4007 parts of polyethylene glycol, and 0.7 part of maleic acid grafted ABS; wherein, the preparation steps of the flame-retardant composite material are as follows:

[0020] (1) In parts by weight, take 4 parts of expanded graphite, 2.3 parts of nano-zinc borate, 0.6 parts of nano-alumina and 3.2 parts of ammonium polyphosphate, mix and stir evenly, then add 3.6 parts of perfluorobutylsulfonate potassium and stir well mixed;

[0021] (2) Put the mixture obtained in ste...

Embodiment 2

[0028] A flame-retardant and anti-corrosion heat-shrinkable sleeve material, comprising the following raw materials in parts by weight:

[0029] 90 parts of EVA resin, 48 parts of pure thermosetting liquid polyimide resin, 5 parts of vapor phase growth nano-carbon fiber powder, 9 parts of flame-retardant composite material, 3 parts of polytetrafluoroethylene micropowder, 3.6 parts of phthalic anhydride, silane coupling 6 parts of chlorinated paraffin, 6 parts of liquid paraffin, 4008 parts of polyethylene glycol, 0.8 part of maleic acid grafted PP; wherein, the preparation steps of the flame-retardant composite material are as follows:

[0030] (1) In parts by weight, take 4 parts of expanded graphite, 2.3 parts of nano-zinc borate, 0.6 parts of nano-alumina and 3.2 parts of ammonium polyphosphate, mix and stir evenly, then add 3.6 parts of perfluorobutylsulfonate potassium and stir well mixed;

[0031] (2) Put the mixture obtained in step (1) into a ball mill and grind it fo...

Embodiment 3

[0038] A flame-retardant and anti-corrosion heat-shrinkable sleeve material, comprising the following raw materials in parts by weight:

[0039] 90 parts of EVA resin, 42 parts of pure thermosetting liquid polyimide resin, 5 parts of vapor phase growth nano-carbon fiber powder, 8 parts of flame-retardant composite material, 3 parts of polytetrafluoroethylene micropowder, 3 parts of phthalic anhydride, silane coupling 5 parts of chlorinated paraffin, 6 parts of liquid paraffin, 4007 parts of polyethylene glycol, 0.8 part of maleic acid grafted PE; wherein, the preparation steps of the flame-retardant composite material are as follows:

[0040] (1) In parts by weight, take 4 parts of expanded graphite, 2.3 parts of nano-zinc borate, 0.6 parts of nano-alumina and 3.2 parts of ammonium polyphosphate, mix and stir evenly, then add 3.6 parts of perfluorobutylsulfonate potassium and stir well mixed;

[0041] (2) Put the mixture obtained in step (1) into a ball mill and grind it for 5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com