Epoxy powder for packaging medium-low-voltage bus bar

A technology of epoxy powder and low-voltage busbar, which is applied in the field of packaging materials, can solve the problems of not being able to meet environmental protection and flame retardancy at the same time, unfavorable cost saving, long curing time, etc., achieve fluidized state effect and excellent durability of use, and filler Reasonable particle size matching and short curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

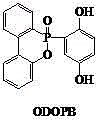

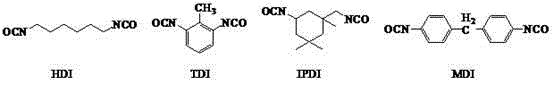

[0037] The synthesis method of the described phosphorus-containing silicon-containing polyurethane type epoxy resin comprises the following steps: firstly utilize the reaction type phosphorus compound and organic silicon resin to react with isocyanate to obtain the phosphorus-containing silicon-containing polyurethane prepolymer whose terminal group is isocyanate , and then use the reaction between isocyanate and epoxy resin to introduce the prepolymer into the molecular chain of epoxy resin to obtain a polyurethane epoxy resin containing phosphorus and silicon at the same time.

[0038] Specifically include the following steps:

[0039] (1) Under the protection of nitrogen, add isocyanate and catalyst into the reaction kettle with heating device, stirrer and thermometer, raise the temperature to 50~150°C, stir to mix isocyanate and catalyst evenly;

[0040] (2) Slowly add the reactive phosphorus-containing compound into the reaction kettle in (1) under stirring, and keep it w...

Embodiment 1

[0110] (1) First crush the raw materials that need to be crushed with a pulverizer;

[0111] (2) After the raw materials are baked and dried separately, set aside;

[0112] (3) Weigh the filler and coupling agent according to the weight in Table 1, microsilica powder DRG800 25kg, coupling agent SG-TPT 0.5kg, put them into a stainless steel mixer and mix vigorously for 10 minutes, and perform surface modification on the filler;

[0113] (4) 40kg of phosphorus-containing silicon-containing polyurethane epoxy resin A, 20kg of curing agent KD402, 2.5kg of toughening agent MBS, 0.5 kg of flame retardant aluminum hydroxide, and a compound of curing accelerator triphenylphosphine and imidazole 0.5kg, leveling agent GLP503 0.5kg, anti-scratch agent carnauba wax 0.5kg, pigment phthalocyanine blue 0.5kg, weighed according to the amount, put into a stainless steel mixer, and mix vigorously for 10 minutes until uniform;

[0114] (5) Melt, knead and extrude the mixed raw materials with a ...

Embodiment 2

[0118] The epoxy powder was prepared according to the steps described in Example 1, the components and their addition amounts are shown in Table 1, and the test performance of the product is shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com