Antibacterial fabric and preparation method thereof

A technology of antibacterial fabric and antibacterial agent, which is applied in the field of antibacterial fabric and its preparation, can solve problems such as hindering the normal division of bacteria, and achieve the effect of excellent antibacterial properties and good flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

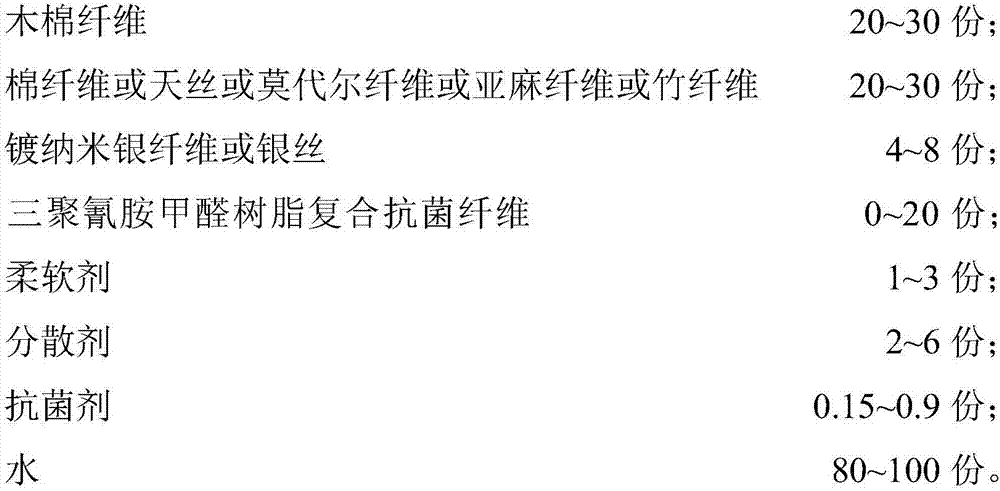

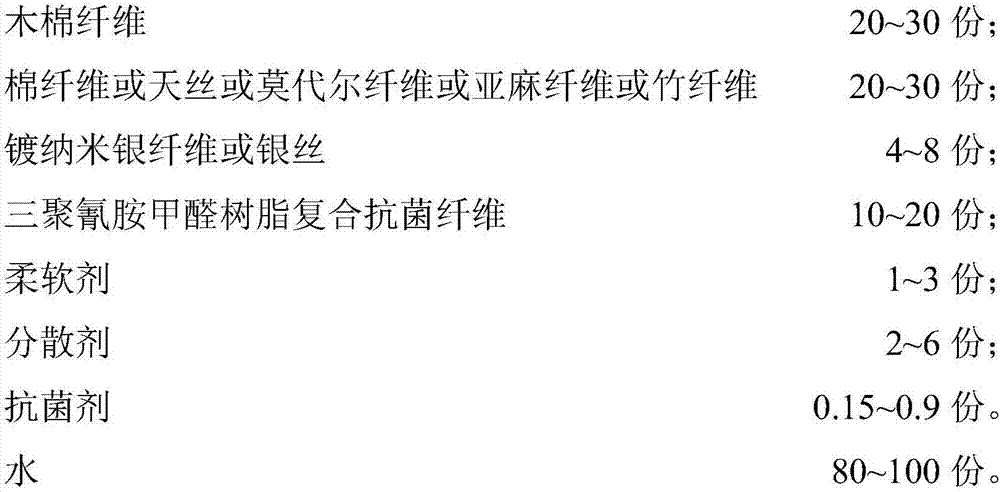

Method used

Image

Examples

preparation example Construction

[0052] The preparation method of melamine formaldehyde resin composite antibacterial fiber:

[0053] Add 23.0g of melamine formaldehyde resin and 0.4g of hexadecyltrimethylammonium bromide into 73g of water and stir for 30min at a speed of 200r / min, and keep it in the dark for 12h; add 1.0g of Cu(NO 3 ) 2 , 1.0gAgNO 3 1.6 g of polydimethyl diallyl ammonium chloride was stirred at 50° C. for 8 h to obtain a melamine formaldehyde resin spinning stock solution.

[0054] The above-mentioned melamine-formaldehyde resin spinning stock solution is filtered under pressure at 60°C, defoamed, and transported to the spinneret hole with a pore size of 0.08mm through a metering pump, and the stock solution is sprayed into the spinneret in a thin stream at a temperature of 500°C and a pH= 3. The saturated sodium sulfate aqueous solution is solidified and formed, and the as-spun fiber is stretched 3 times and sent to a steam oven at a temperature of 100°C for 15 minutes of wet heat treatme...

Embodiment 1

[0058] A kind of preparation method of antibacterial fabric, is characterized in that, comprises the following steps:

[0059] a). 20 parts by weight of spandex, 30 parts by weight of kapok fiber, and 30 parts by weight of cotton fiber are placed in the mixer, and stirred for 30 minutes at a speed of 500 rpm; then add 2 parts by weight of softening agent, 4 parts by weight of dispersant, 100 parts by weight of water were stirred twice, and stirred for 10 minutes at a speed of 500 rpm to obtain a mixture;

[0060] b). After the above-mentioned mixture is dried in the air, after conventional roving, spun yarn, winding, steaming and doubling treatment, 40D blended yarn is obtained;

[0061] c). The above-mentioned blended yarn and 8 parts by weight of silver wire are woven into cloth on the HT11 small-scale automatic loom (Changyi Haotian Textile Machinery Co., Ltd.); the warp density of the cloth is 100 threads / cm , The weft thread density is 60 threads / cm;

[0062] d). Soak t...

Embodiment 2

[0068] A kind of preparation method of antibacterial fabric, is characterized in that, comprises the following steps:

[0069] a). 20 parts by weight of spandex, 30 parts by weight of kapok fiber, and 30 parts by weight of tencel are placed in a mixer, and stirred for 30 minutes at a speed of 500 rpm; then add 2 parts by weight of softening agent, 4 parts by weight of dispersant, 100 parts by weight of water were stirred twice, and stirred for 10 minutes at a speed of 500 rpm to obtain a mixture;

[0070] b). After the above-mentioned mixture is dried in the air, after conventional roving, spun yarn, winding, steaming and doubling treatment, 40D blended yarn is obtained;

[0071] c). The above-mentioned blended yarn and 8 parts by weight of silver wire are woven into cloth on the HT11 small-scale automatic loom (Changyi Haotian Textile Machinery Co., Ltd.); the warp density of the cloth is 100 threads / cm , The weft thread density is 60 threads / cm;

[0072] d). Soak the prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber denier | aaaaa | aaaaa |

| Fiber denier | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com