Flame-ablation-resistant silicone rubber heat-shrinkable material, preparation method thereof and silicone rubber heat-shrinkable tube

A silicone rubber, ablation-resistant technology, applied in the field of materials, can solve problems such as tensile fracture, inconvenient pipe body piercing and connection, and large inner layer friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The present invention also provides a method for preparing the flame ablation-resistant silicone rubber heat-shrinkable material described in the above technical solution, comprising the following steps:

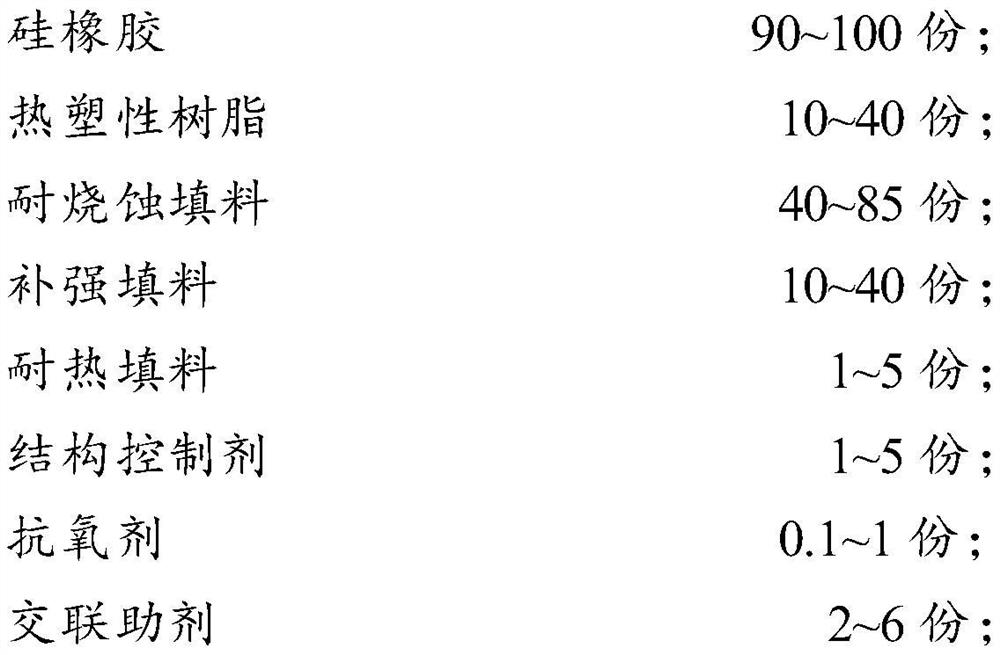

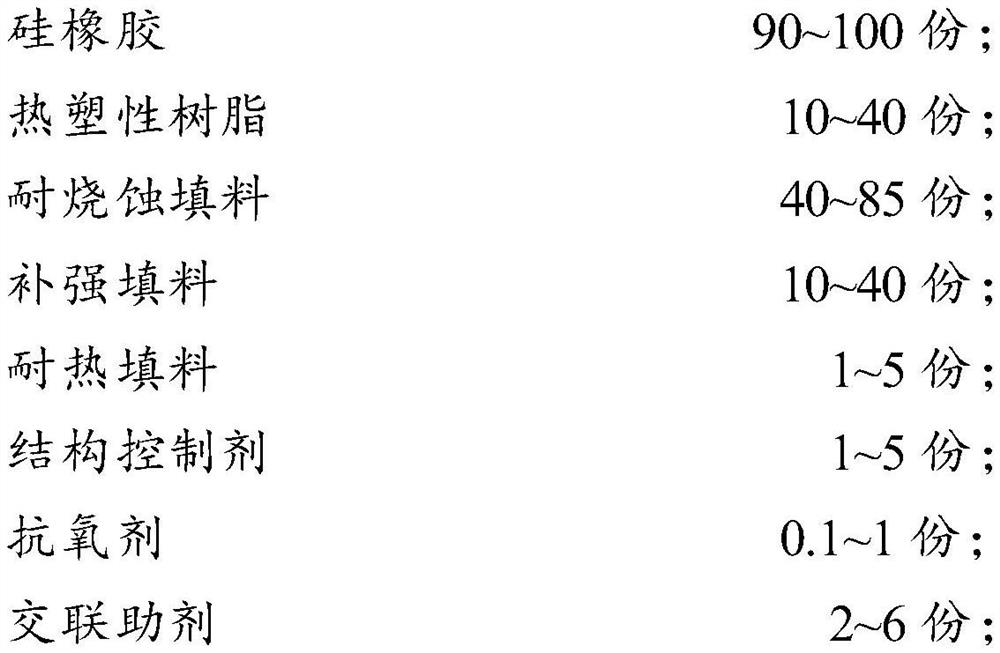

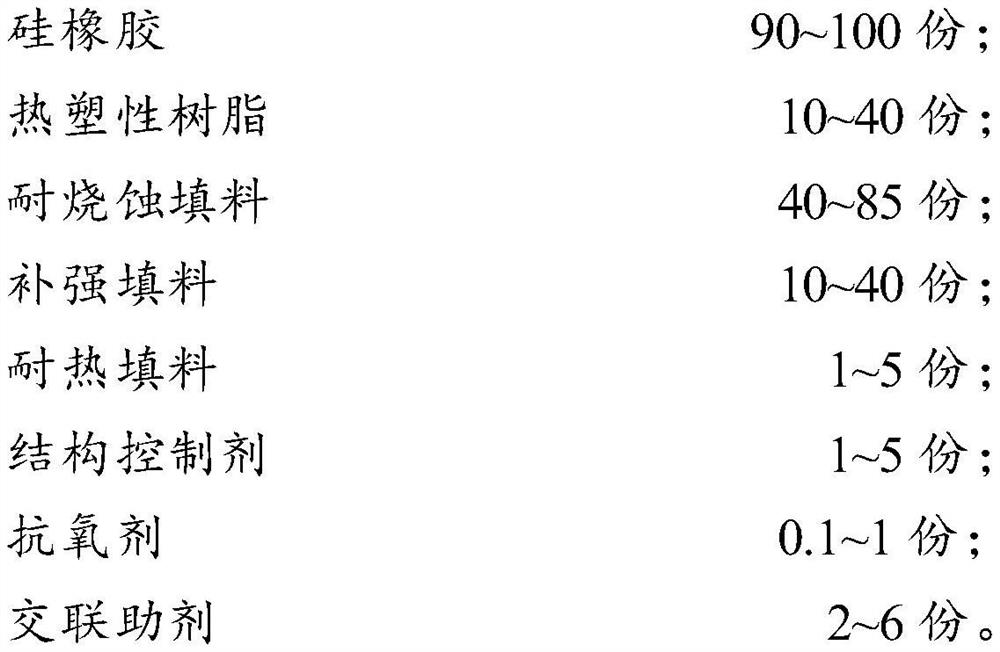

[0055] a) 90-100 parts by mass of silicone rubber, 10-40 parts by mass of thermoplastic resin, 40-85 parts by mass of anti-ablation filler, 10-40 parts by mass of reinforcing filler, 1-5 parts by mass of heat-resistant mixing fillers, 1-5 parts by mass of a structure control agent, 0.1-1 parts by mass of an antioxidant, and 2-6 parts by mass of a crosslinking aid to obtain a rubber-plastic compound;

[0056] b) Preforming the rubber-plastic compounded rubber material to obtain a silicone rubber preform;

[0057] c) subjecting the silicone rubber preform to cross-linking modification treatment to obtain a vulcanized silicone rubber material;

[0058] d) expanding and shaping the vulcanized silicone material to obtain a flame-ablation-resistant silicone rubber heat-shr...

Embodiment 1

[0072] Modification of ablation-resistant filler:

[0073] Due to the weak interfacial bonding force and incompatibility between the inorganic filler and the silicone rubber matrix, it is easy to agglomerate in the system when a high content is introduced, resulting in poor mechanical properties, low expansion yield, and unstable flame ablation resistance. In order to further improve The dispersion of ablation-resistant fillers in the silicone rubber system requires organosiliconization on the surface; at the same time, due to wollastonite, low-melting glass powder, ZrO 2 Inorganic fillers such as -OH have -OH on the surface, which is easy to react with the hydrolyzed silane coupling agent. The matrix used in the subsequent preparation of heat shrinkable tubes is addition-type silicone rubber, and the surface-modified coupling agent is mainly vinyl; therefore, the selected The specific modification process is as follows:

[0074] (1) Add 100g wollastonite (ultra-fine acicular...

Embodiment 2

[0079] A flame-ablation-resistant silicone rubber heat-shrinkable tube, its specific formula is as follows in parts by mass: 90 parts of methyl vinyl silicone rubber, 10 parts of methyl vinyl phenyl silicone rubber, 25 parts of ethylene-vinyl acetate copolymer Parts, modified wollastonite 50 parts, modified ZrO 2 10 parts, 5 parts of modified low-melting glass powder, 30 parts of fumed silica modified by hexamethyldisilazane, CeO 2 (Particle size 30-50nm) 2 parts, 3.5 parts of hydroxy silicone oil, 0.3 parts of tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, trimethylolpropane trimethyl 4 parts of acrylic acid ester; wherein, the methyl vinyl silicone rubber is a methyl-terminated structure, the vinyl content is 0.05 to 0.13 wt%, and the number average molecular weight is 60 to 650,000; the methyl vinyl phenyl silicone rubber The rubber is a methyl-terminated structure, with a vinyl content of 0.05-0.13 wt%, a phenyl content of 5-8 wt%, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com