Highly heatproof polyurethane hot melt adhesive and three layer heat-sealing adhesive tape

A polyurethane hot-melt adhesive, high heat-resistant technology, applied in polyurea/polyurethane adhesives, adhesives, non-polymer adhesive additives, etc., can solve the problem of poor adhesion and water absorption without polyurethane hot-melt adhesives and other problems, to achieve excellent heat resistance and UV resistance, improve adhesion, and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

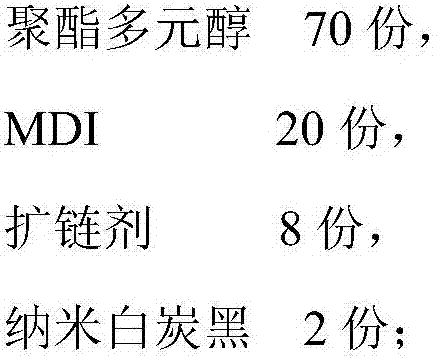

[0036] A high heat-resistant polyurethane hot-melt adhesive, comprising the following raw materials in parts by weight:

[0037]

[0038] Wherein, the polyester polyol is formed by dehydration polycondensation of terephthalic acid and ethylene glycol in a molar ratio of 1.2:1 through a vacuum melting method, and in the vacuum melting method, the raw materials of the above ratio are first React at 80°C for 0.5h, then raise the temperature to 120°C for 1h, then raise the temperature to 250°C until the polyester polyol has a hydroxyl value of 100mgKOH / g and an acid value of 2mgKOH / g.

[0039] The chain extender is a mixture of alcohol amine chain extender and polyol chain extender with a molar ratio of 1:1; wherein the alcohol amine chain extender is triisopropanolamine and ethylene glycol amine. The molar ratio is a mixture of 1:0.8; the polyol chain extender is ethylene glycol, glycerol and pentaerythritol in a weight ratio of 1:1:1.

[0040] The preparation method of above...

Embodiment 2

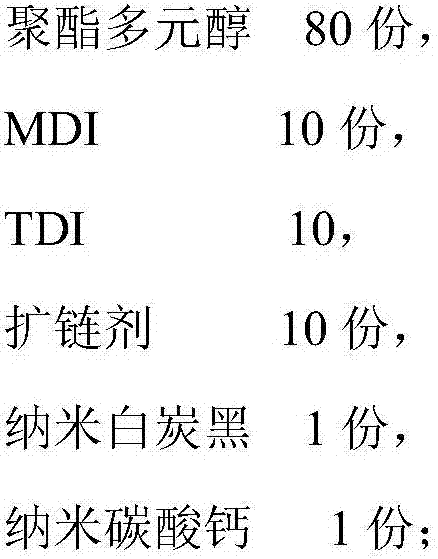

[0045] A high heat-resistant polyurethane hot-melt adhesive, comprising the following raw materials in parts by weight:

[0046]

[0047] Wherein, the polyester polyol is formed by dehydration polycondensation of terephthalic acid and ethylene glycol in a molar ratio of 1.01:1 through a vacuum melting method, and in the vacuum melting method, the raw materials of the above ratio are first React at 80°C for 0.5h, then raise the temperature to 150°C for 1h, then raise the temperature to 190°C until the polyester polyol has a hydroxyl value of 80mgKOH / g and an acid value of 1.8mgKOH / g.

[0048] The chain extender is a mixture of alcohol amine chain extender and polyol chain extender with a molar ratio of 1:1.2; wherein the alcohol amine chain extender is triisopropanolamine and ethylene glycol amine. The molar ratio is a mixture of 1:1; the polyol chain extender is ethylene glycol, glycerol and pentaerythritol in a weight ratio of 1:2:1.

[0049] The preparation method of abo...

Embodiment 3

[0054] A high heat-resistant polyurethane hot-melt adhesive, comprising the following raw materials in parts by weight:

[0055]

[0056]

[0057] Wherein, the polyester polyol is made of terephthalic acid and ethylene glycol in a molar ratio of 1.35:1, and is formed by dehydration and polycondensation of a dealcoholizing agent through a vacuum melting method. React at 100°C for 0.5h, then raise the temperature to 170°C for 1h, then raise the temperature to 200°C until the polyester polyol has a hydroxyl value of 120mgKOH / g and an acid value of 2.1mgKOH / g.

[0058] The chain extender is a mixture of alcohol amine chain extender and polyol chain extender with a molar ratio of 1:0.8; wherein the alcohol amine chain extender is triisopropanolamine and ethylene glycol amine. The molar ratio is a mixture of 1:1.2; the polyol chain extender is ethylene glycol, glycerol and pentaerythritol in a weight ratio of 1:1:2.

[0059] The preparation method of above-mentioned high heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com