Ultra-flexible flat cable wiring harness network for aerospace

A flat cable and aerospace technology, applied in the field of ultra-light and flexible flat cable harness nets for aerospace, can solve the problem of poor cable resistance to high and low temperature, weight, heat shrinkage and excellent mechanical properties, and lack of anti-salt spray, anti-humidity and heat resistance High-energy electron radiation characteristics, reliable energy and signal transmission cannot be guaranteed, etc., to achieve excellent heat shrinkage, excellent anti-high-energy electron radiation characteristics, and novel structural design effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

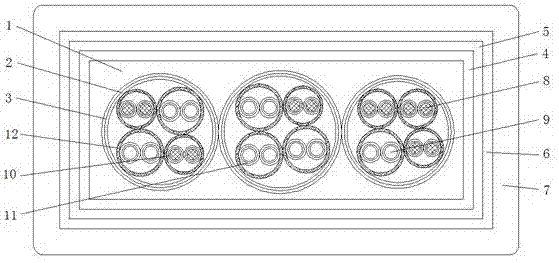

[0015] See attached picture:

[0016] Ultra-light and flexible flat cable wire harness net for aerospace, including wire harness 1, wire harness 2, wire harness 3 extruded in cross-linked ethylene-tetrafluoroethylene copolymer carrier layer 1, wire harness 1, wire harness 2, wire harness 3 are all 0.15mm Twisted shielded wires, 0.3mm twisted shielded wires are twisted into a bundle, and the outer circumference is sequentially provided with a braided seam layer 2, and a cross-linked ethylene-tetrafluoroethylene copolymer insulating layer 3, wherein the cross-linked ethylene-tetrafluoroethylene copolymer The carrier layer 1 is covered in turn with a double-sided semi-conductive rubber cloth wrapping layer 4, a polyolefin physical foam layer 5, a braided layer of carbon fiber filaments and aramid filaments 6, and a cross-linked ethylene-tetrafluoroethylene copolymer outer layer. Sheath layer 7.

[0017] The braided suture layer 2 is composed of 3×600D aramid yarn twisted into ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com