Thermo-shrinkable polyester mono-layer film

一种聚酯类、热收缩的技术,应用在聚酯类单层膜领域,能够解决不合意、热收缩膜低隐藏能力、降低广告效果等问题,达到良好印刷外观、防止废水、高隐藏能力的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

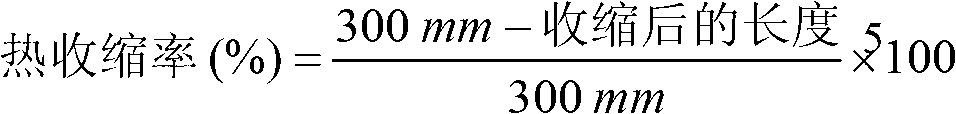

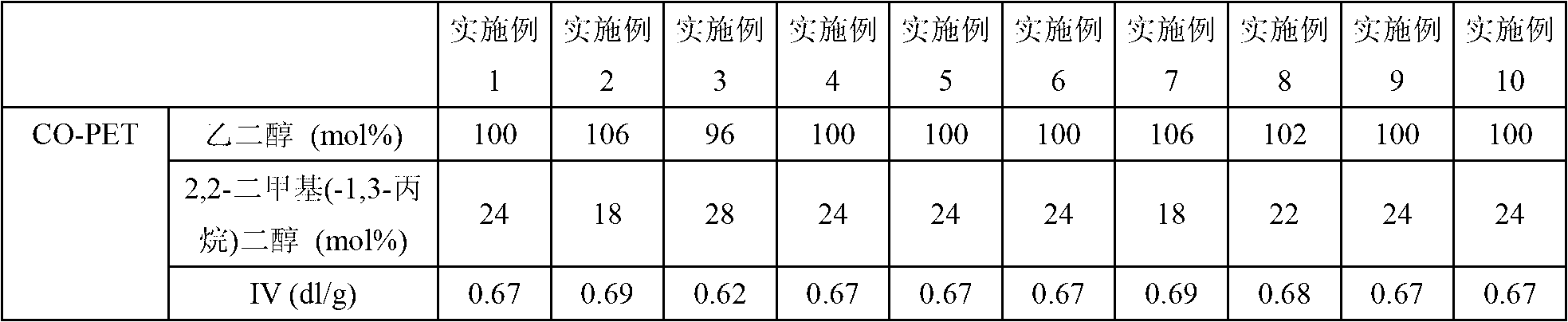

[0105] (1) 100mol% of terephthalic acid as a dibasic acid component, 100mol% of ethylene glycol as a dibasic alcohol component, and 24mol% of 2,2-dimethyl (-1,3 -propane) diol, and 0.05 mol of antimony trioxide (for the acid component) as a catalyst for polycondensation, thereby producing 2,2-dimethyl (-1,3-propane) diol copolyester.

[0106] (2) Put a mixture of 2,2-dimethyl(-1,3-propane)diol copolyester and titanium dioxide particles (particle size: 0.5 μm) into a twin-screw extruder or kneader, and melt it and mixed to obtain polyester-based masterbatch chips containing particles. The above-mentioned masterbatch slices containing particles are then subjected to an anti-sticking treatment using a grinder equipped with a screw such that an extremely small roughness. As such, milling was performed at room temperature, 1750 rpm, 45A, and a rate of 2 ton / hr.

[0107] The prepared masterbatch chips were precrystallized at 130°C and dried at 160°C to dehydrate them. Thus, the...

Embodiment 2~10

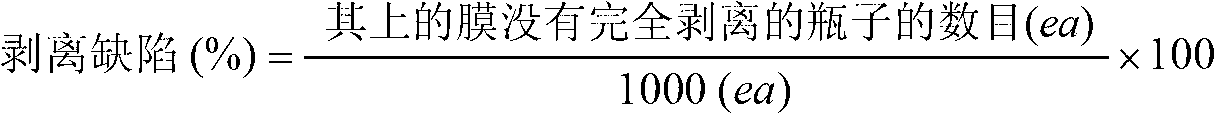

[0115] Except changing the mole % of 2,2-dimethyl(-1,3-propane)diol in 2,2-dimethyl(-1,3-propane)diol copolyester as shown in Table 1 below , the size of the particles used in the masterbatch chips, the amount of particles in the film, the TD stretching temperature, and the heat treatment temperature, a heat-shrinkable film was prepared in the same manner as in Example 1. The properties of these films are shown in Table 3 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| turbidity | aaaaa | aaaaa |

| turbidity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com