Meridian aviation tyre using nylon/aramid fiber composite cord as framework material

A technology of aviation tires and composite cords, which is applied to tire parts, reinforcement layers of pneumatic tires, transportation and packaging, etc., can solve problems such as heat resistance, high heat generation, and low rigidity of tread parts, and meet high requirements. Effects of internal pressure and high speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

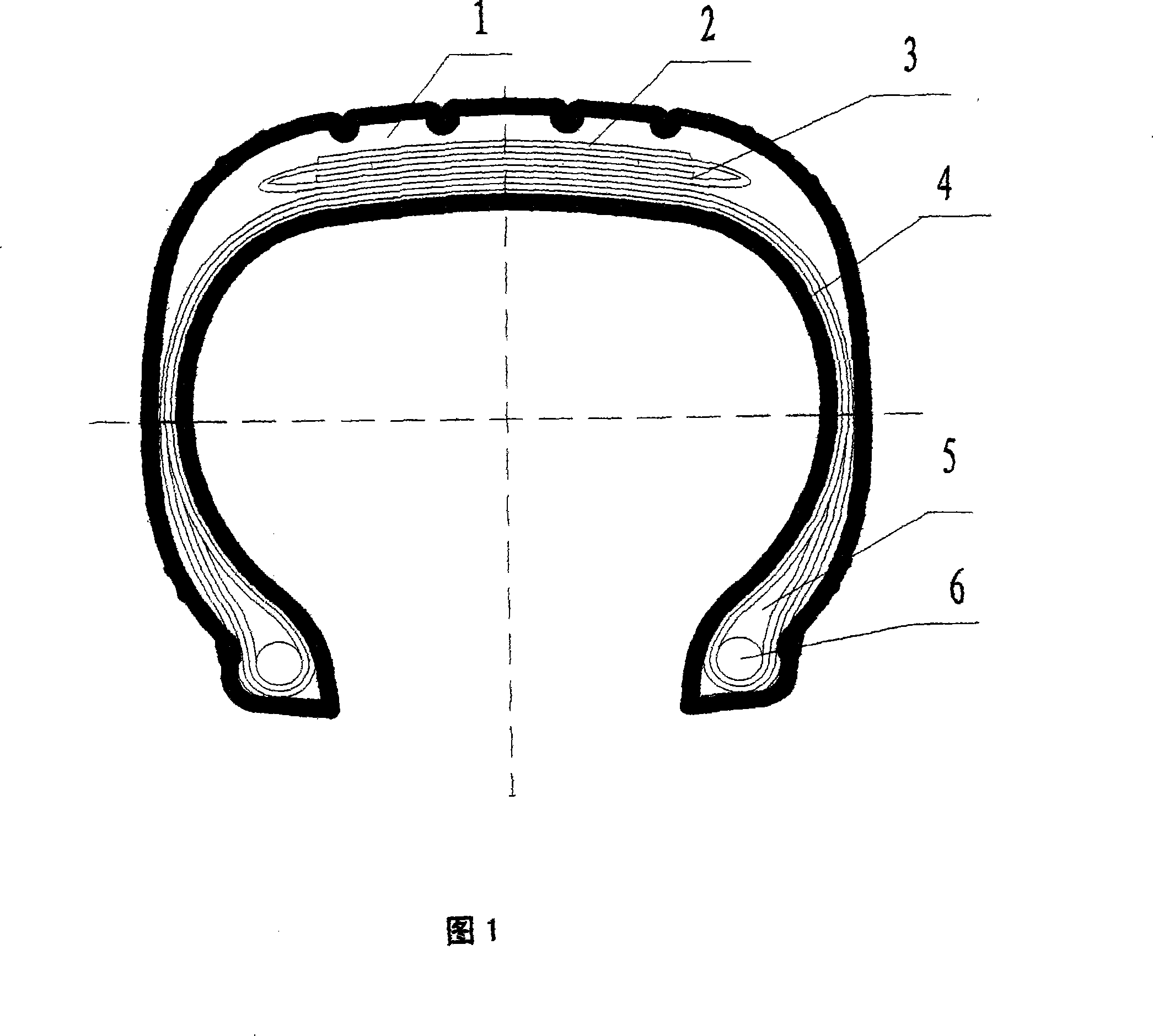

[0009] Referring to Fig. 1, the radial aviation tire of the present invention comprises a tread 1, a cap structure layer 2, a belt structure layer 3, a carcass 4, a filling rubber 5, and a traveler 6. The ply of the carcass 4 is composed of multiple layers of organic fiber ply, and the steel ring 6 is turned up from the inside to the outside. At least one layer of organic fiber ply wraps the steel ring 6 from the outside to the inside. The included angle is 60°~90°. The belt structure layer 3 and the cap structure layer 2 are arranged at the crown of the tire. The belt structure layer 3 is composed of at least two layers of cords, and the angle between the cords of the belt structure layer and the circumferential direction of the tire is 0° to 30°. In order to reduce the interlayer shear stress concentration at the end of the belt structure layer, at least one belt layer has a wrapping structure, and the curling ends of the belt structure layer are all in the middle of the cro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com