Heat-shrinkable degradable environment-friendly film material as well as preparation method and application method

A film material and application method technology, applied in the direction of packaging paper shrinkage, sustainable manufacturing/processing, sustainable packaging industry, etc., can solve equipment research and development, operation, maintenance, increased use costs, unfavorable wide use of enterprises, and low shrinkage rate Advanced problems, to achieve the effect suitable for large-scale industrial production, good blow molding effect, simple process and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

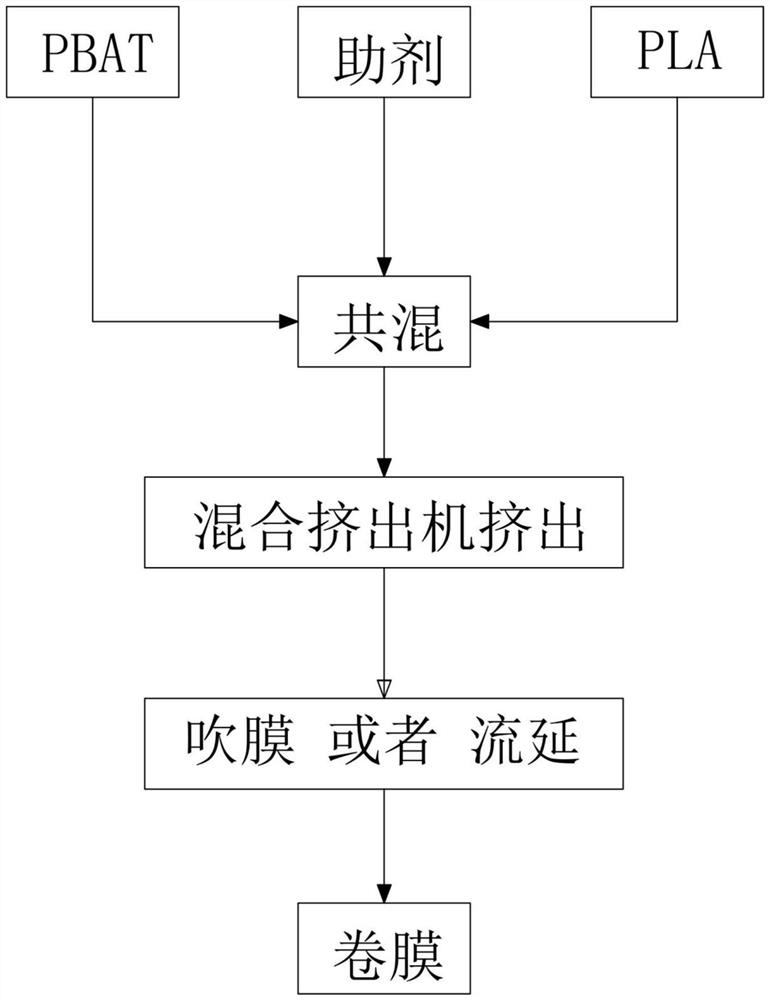

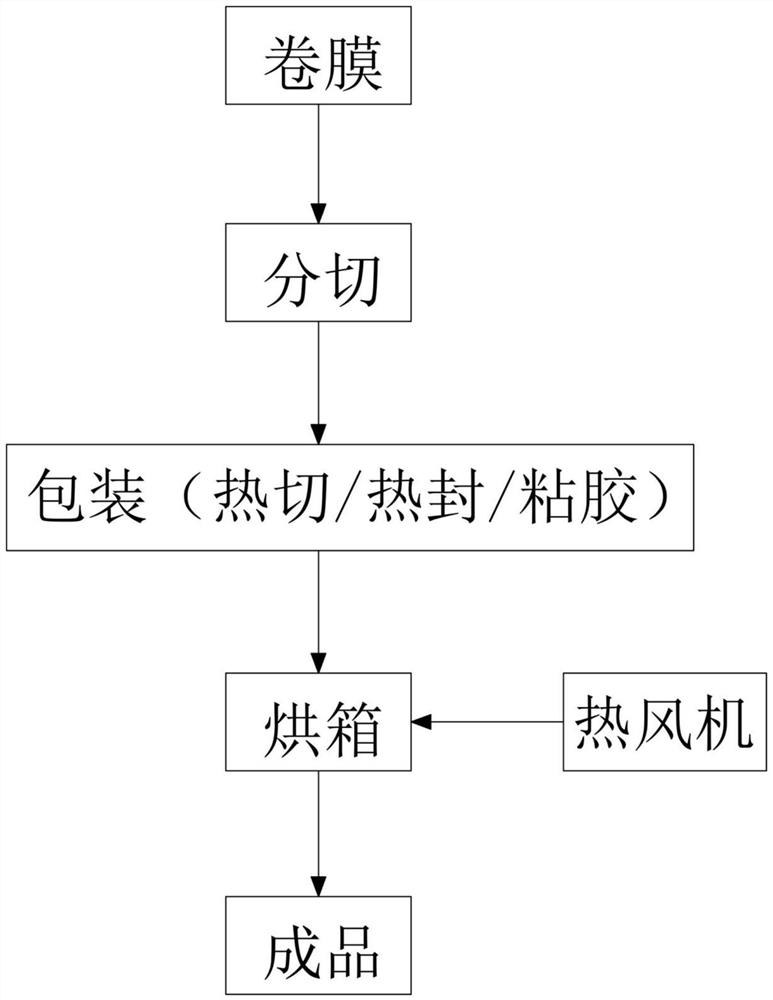

Method used

Image

Examples

Embodiment 1

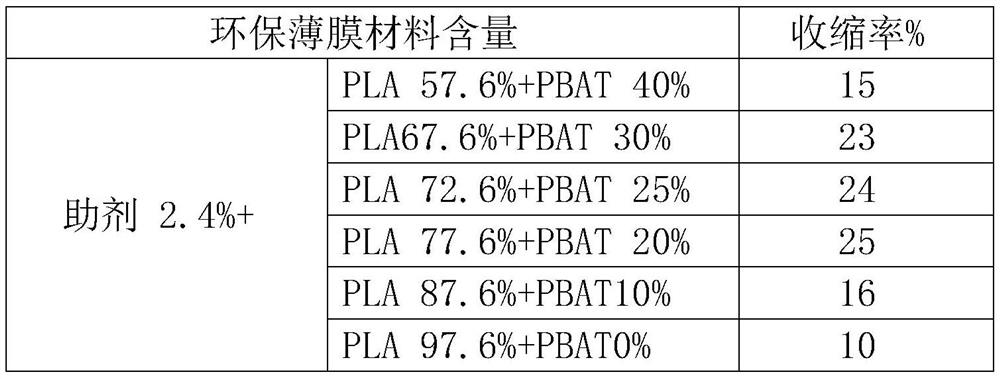

[0024] A heat-shrinkable and degradable environmental protection film material described in this embodiment, the environmental protection film material is modified by blending and modifying PBAT and PLA in proportion under the action of additives, and the percentage by weight of the environmental protection film material is The PBAT is 10%-30%, the PLA is 65%-85%, and the additive is 0.2-5%.

[0025] The auxiliary agent includes wax, coupling agent, chain extender, opening agent and smooth agent, and the wax is 0-1%, the coupling agent is 0-1%, and the chain extender is 0-1% by weight. 0.1-1%, the opening agent is 0.1-1%, and the slippery agent is 0-1%.

[0026] Wherein the PLA (polylactic acid) is a new type of bio-based, renewable biodegradable material, which is made from starch raw materials proposed by renewable plant resources (such as corn, cassava, etc.). The starch raw material is saccharified to obtain glucose, and then fermented by glucose and certain strains to pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com