Micro-lens manufacturing method based on CO2 laser melting assisted by high-pressure gas

A high-pressure gas and laser melting technology, which is applied in the direction of lenses, optics, optical components, etc., can solve the problems that ultra-precision machining is difficult to process with micro-lenses, reduce the overall uniformity of micro-lenses, and take a long time for ultra-precision cutting. Avoid mask difficulties, eliminate the limitation of grinding wheel size and wear, and have a large processing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] A high-pressure gas-assisted CO 2 The microlens manufacturing method of laser fusion is characterized in that, comprising the following steps:

[0023] Step 1: Manufacturing a preform, using a machining method to manufacture a preform suitable for the designed microlens structure;

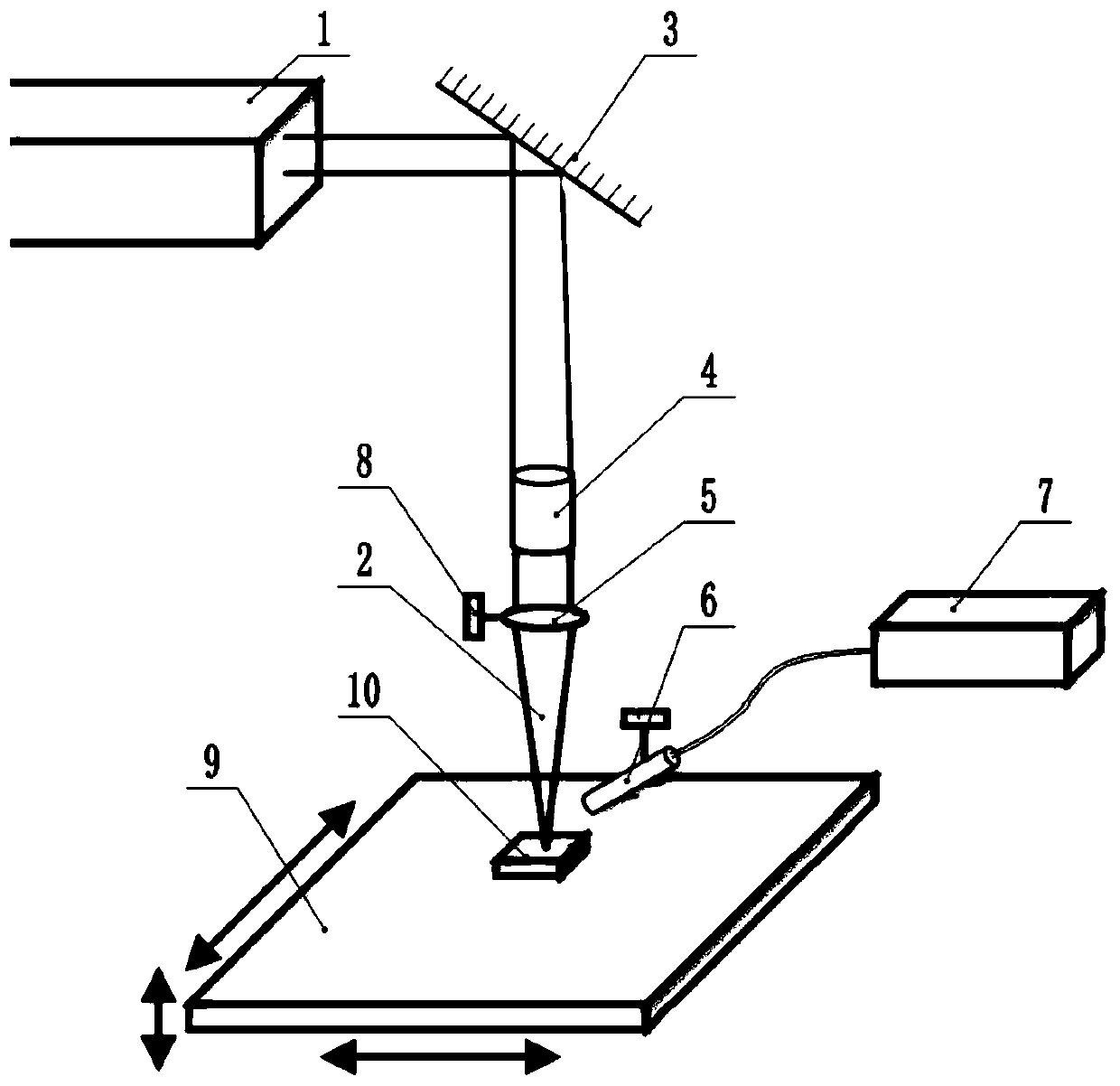

[0024] Step 2: CO 2 Laser 2 remodeling, using CO 2 Laser 1 emits CO 2 The laser light 2 is reflected to the surface of the preform by the reflector 3, and the CO 2 The laser 2 is focused on the surface of the preform to generate a high-temperature region, and the temperature is higher than the melting temperature or softening temperature of the material (for example, for quartz materials, a high-temperature region above 2000°C is generated), and then the nozzle 6 is used to spray high-pressure gas to the softening region. Reshaping; the nozzle 6 is connected to the high-pressure air pump 7 through the air pipe, and the shape of the remodeling can be controlled by controlling the shape of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com