Cutting and laminating machine and application method thereof

A laminating machine and cutting technology, which is applied in the field of film processing, can solve the problems of low efficiency of manual film lamination, complicated equipment and process, etc., and achieve the effect of reducing manpower, simple equipment and process, high production efficiency and production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

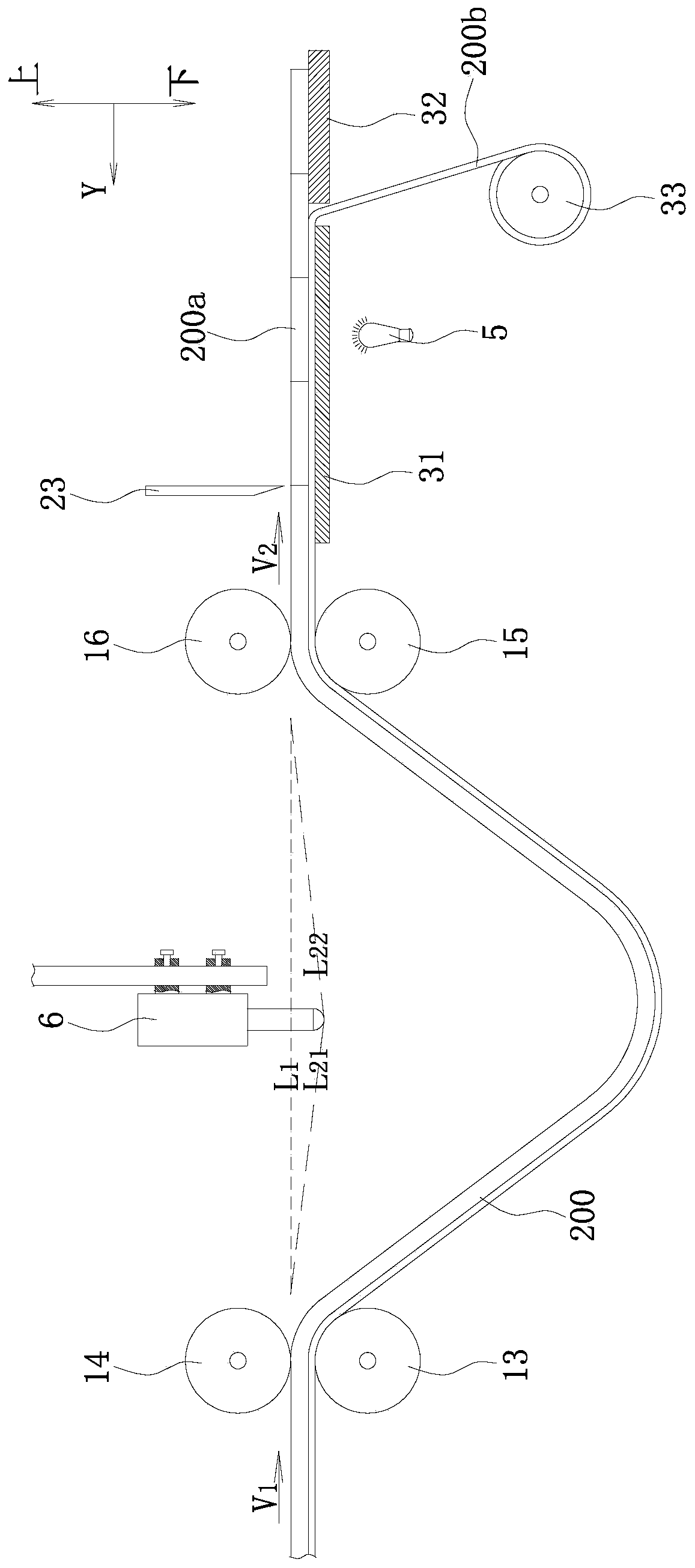

[0038] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings. For convenient feeding, the starting end of the raw material belt 200 is a section of master belt 200b without membrane 200a; and the gap between the second platform 32 to complete the supplementary installation of new raw materials. Lesser configurations are to peel off one end of the film 200a at the beginning of the raw material tape 200, wasting this section of film 200a, and obtain a section of master tape 200b without the film 200a.

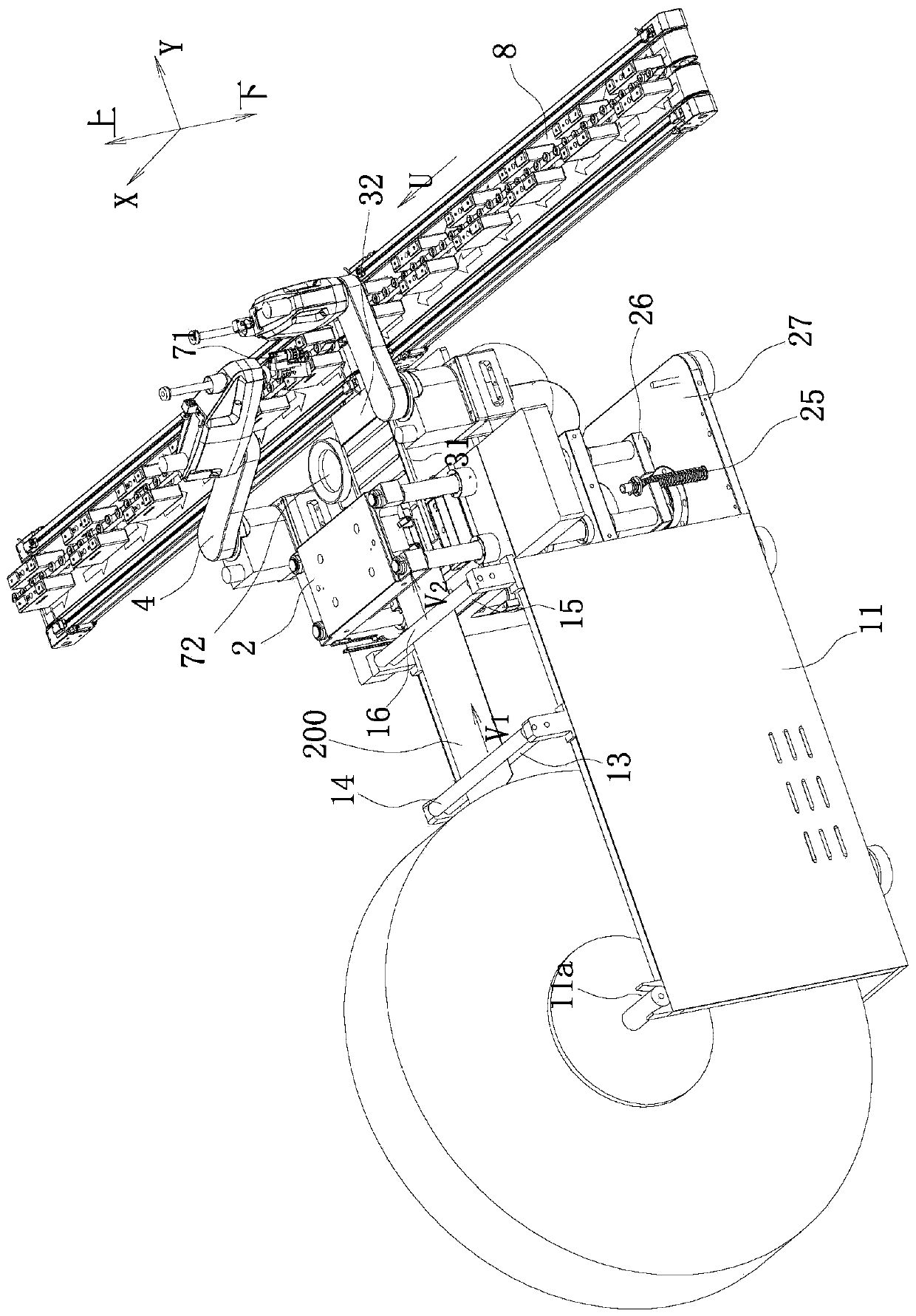

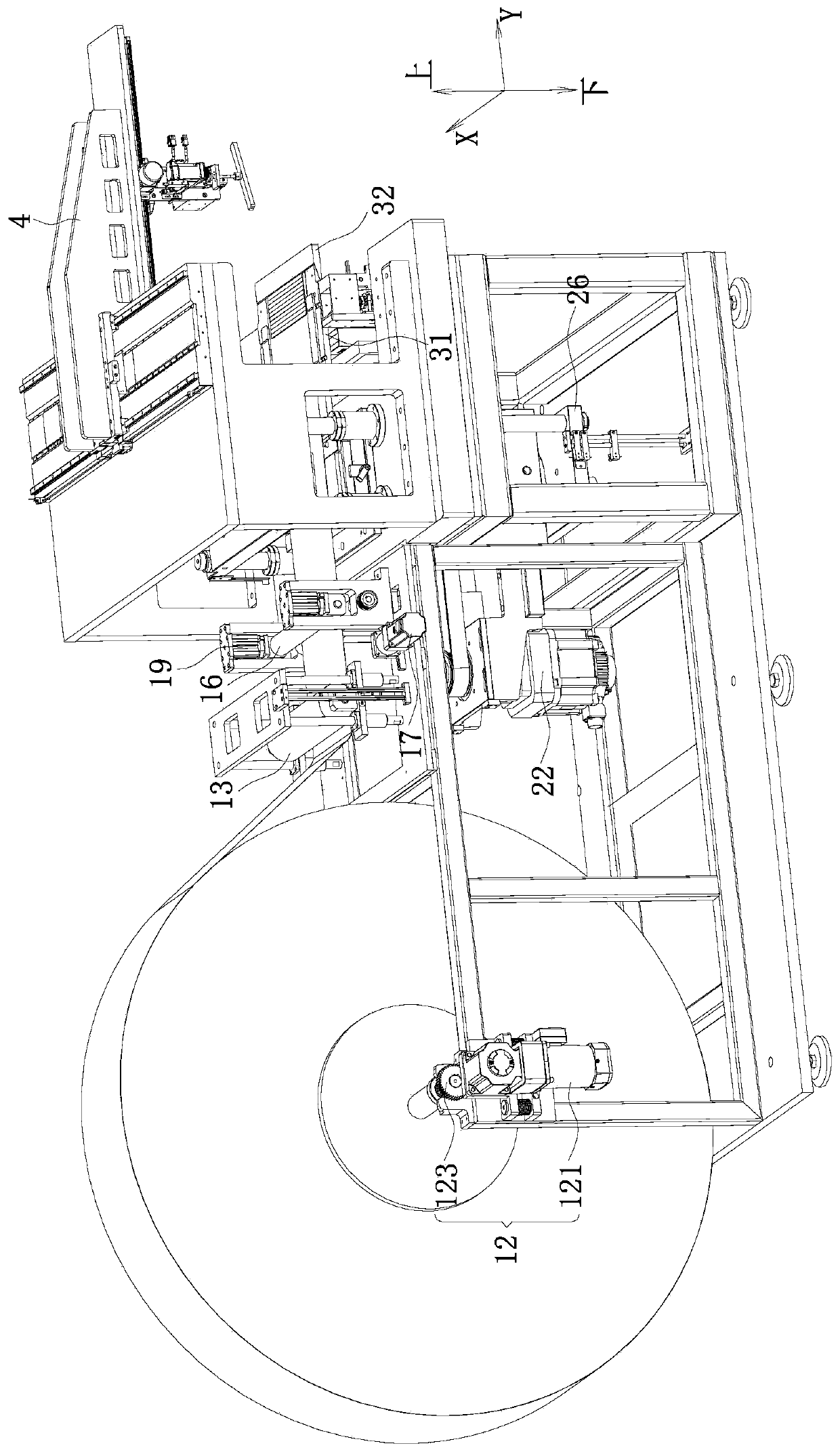

[0039] Such as Figure 1 to Figure 3 As shown, a cutting and laminating machine includes a frame, a feeding device, a punching assembly 2, a first platform 31, a second platform 32, a transfer device 4 and a transmission assembly 8; a feeding device, a punching assembly 2 and the first platform 31 are arranged in sequence along the material transmission direction, the punching assembly 2 can cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com