Ammonia dyeing technology and equipment

A technology, the technology of dyeing kettle, applied in the direction of dyeing method, equipment configuration for processing textile materials, textiles and papermaking, etc., can solve the problems of increased expenditure, environmental pollution, etc., and achieve easy operation, reduced production costs, simple and practical equipment and processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

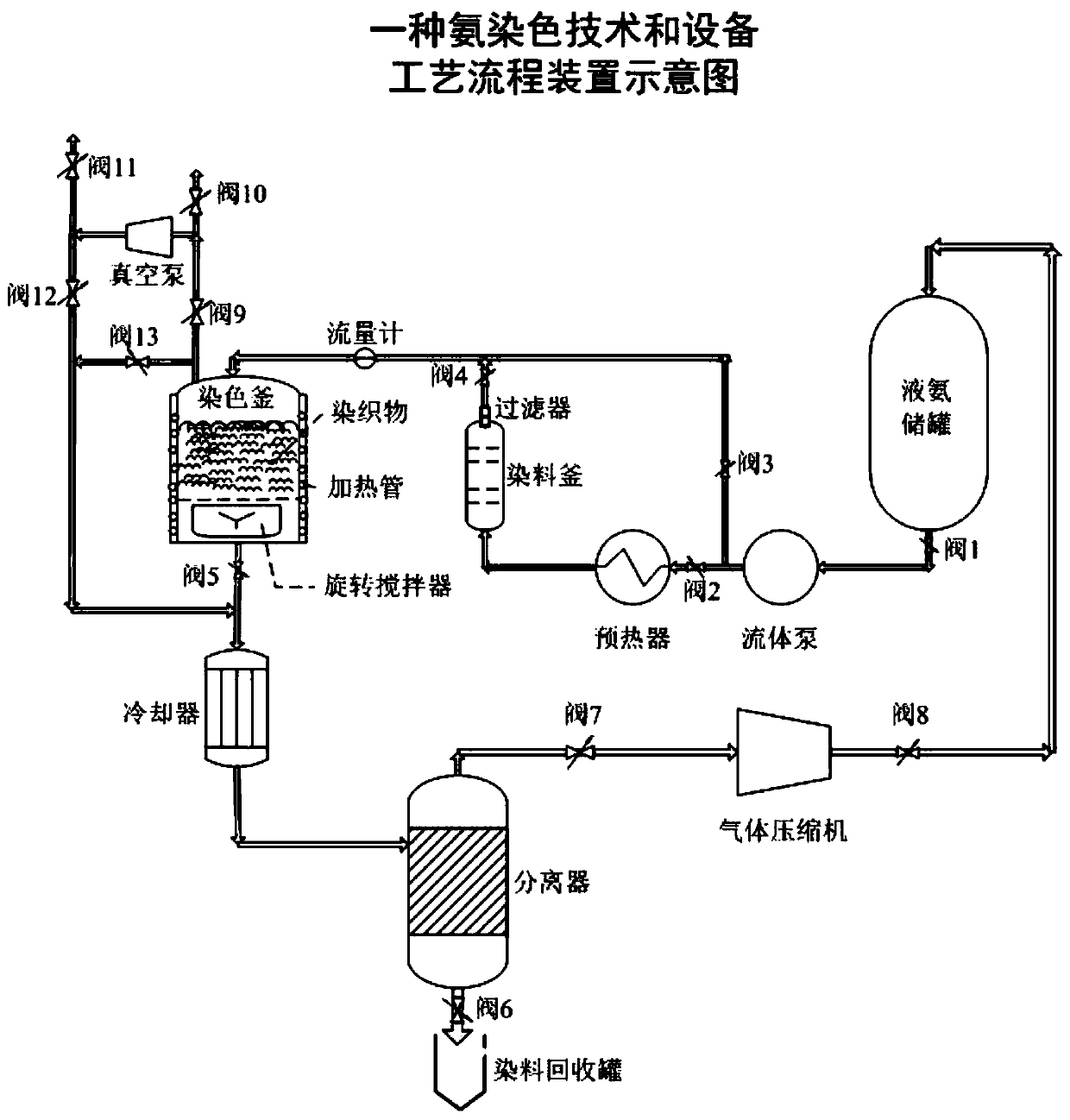

[0040] Step (1): The precondition is attached figure 1 All valves and kettle bodies in the tank are closed;

[0041] Step (2): open the lid of the dyeing still, put 25g white viscose cloth with a moisture content of 10% into the dyeing still, the still is airtight, put 1.2g reactive Yuanqing B150 dye into the dye still, and the still is airtight;

[0042] Step (3): Open valve 4, valve 5, valve 9, and valve 11, start the vacuum pump, vacuumize the preheater, dyeing kettle, dye kettle, cooler, and separator, and the vacuum degree is ≥ 5Pa to turn off the vacuum pump, and at the same time Close all the above valves;

[0043] Step (4): Open valve 1 and valve 2, turn on the preheater and fluid pump, inject 500mL of liquid ammonia heated to 40°C into the dye kettle, and let it stand for 2 minutes; then open valve 4, and pour the liquid ammonia that dissolves the dye The dyeing solution is poured into the dyeing kettle, and then the preheater and the fluid pump are turned off, and ...

Embodiment 2

[0052] Step (1): The precondition is attached figure 1 All valves and kettle bodies in the tank are closed;

[0053] Step (2): Open the kettle lid of the dyeing kettle, put 250g white loose cotton fibers with a moisture content of 8% into the dyeing kettle, keep the kettle airtight, and put 1.2g of the reactive blue EC-R dyestuff of Noviclon brand into the dyeing kettle In the kettle, the kettle is sealed;

[0054] Step (3): Open valve 4, valve 5, valve 9, and valve 11, start the vacuum pump, vacuumize the preheater, dyeing kettle, dye kettle, cooler, and separator, and the vacuum degree is ≥ 5Pa to turn off the vacuum pump, and at the same time Close all the above valves;

[0055] Step (4): Open valve 1 and valve 2, turn on the preheater and fluid pump, inject 500mL of liquid ammonia heated to 35°C into the dye kettle, and let it stand for 3 minutes; then open valve 4, and pour the liquid ammonia that dissolves the dye The dyeing solution is poured into the dyeing kettle, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com