Corrosion-resistant heat shrinkable sleeve material and preparation method thereof

A heat-shrinkable sleeve and corrosion-resistant technology, which is applied in the field of corrosion-resistant heat-shrinkable sleeve materials and its preparation, can solve the problems of poor acid and alkali corrosion resistance and high temperature resistance, and achieve poor high temperature resistance and impact strength. Large, the effect of increasing the reproduction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

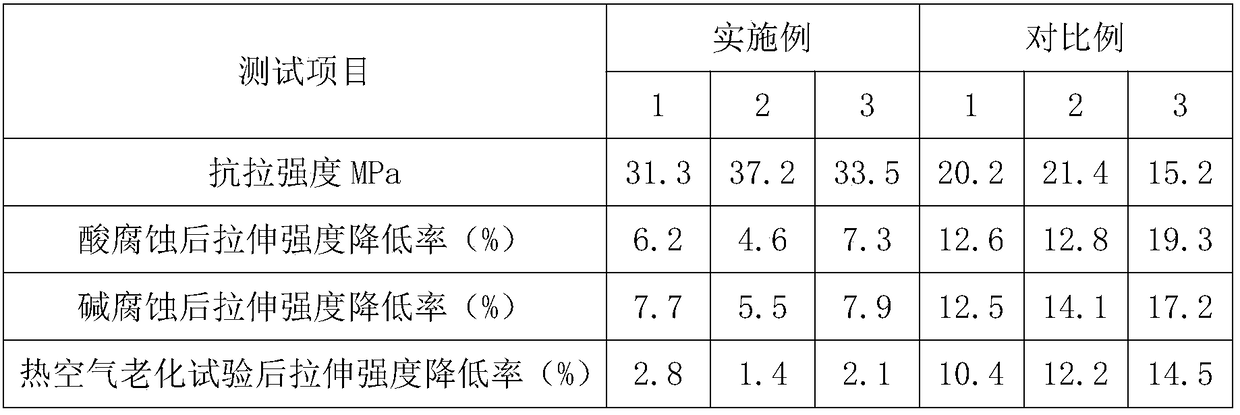

Examples

Embodiment 1

[0018] A corrosion-resistant heat-shrinkable sleeve material proposed by the present invention includes the following raw materials in parts by weight: 90 parts of high-density polyethylene, 20 parts of acrylonitrile-butadiene-styrene copolymer, 5 parts of glass fiber, polytetrafluoroethylene 1 part of ethylene micropowder, 1 part of phthalic anhydride, 2 parts of silane coupling agent, 3 parts of turpentine oil, 5 parts of liquid paraffin, 4005 parts of polyethylene glycol, 2 parts of tris(2,3-dichloropropyl) phosphate part, 0.3 part of compatibilizer; compatibilizer is maleic acid grafted ABS;

[0019] Its preparation method comprises the following steps:

[0020] S1. According to 90 parts of high-density polyethylene, 20 parts of acrylonitrile-butadiene-styrene copolymer, 5 parts of glass fiber, 1 part of polytetrafluoroethylene micropowder, 1 part of phthalic anhydride, and 2 parts of silane coupling agent 3 parts of turpentine, 5 parts of liquid paraffin, 4005 parts of p...

Embodiment 2

[0025] A corrosion-resistant heat-shrinkable sleeve material proposed by the present invention comprises the following raw materials in parts by weight: 100 parts of high-density polyethylene, 30 parts of acrylonitrile-butadiene-styrene copolymer, 10 parts of glass fiber, polytetrafluoroethylene 2 parts of ethylene micropowder, 2 parts of phthalic anhydride, 3 parts of silane coupling agent, 6 parts of turpentine oil, 8 parts of liquid paraffin, 4008 parts of polyethylene glycol, 3 parts of tris(2,3-dichloropropyl) phosphate part, 0.6 part of compatibilizer; compatibilizer is maleic acid grafted PE;

[0026] Its preparation method comprises the following steps:

[0027] S1, according to 100 parts of high-density polyethylene, 30 parts of acrylonitrile-butadiene-styrene copolymer, 10 parts of glass fiber, 2 parts of polytetrafluoroethylene micropowder, 2 parts of phthalic anhydride, 3 parts of silane coupling agent 6 parts, 6 parts of turpentine, 8 parts of liquid paraffin, 40...

Embodiment 3

[0032] A corrosion-resistant heat-shrinkable sleeve material proposed by the present invention includes the following raw materials in parts by weight: 110 parts of high-density polyethylene, 40 parts of acrylonitrile-butadiene-styrene copolymer, 15 parts of glass fiber, polytetrafluoroethylene 4 parts of ethylene micropowder, 4 parts of phthalic anhydride, 6 parts of silane coupling agent, 8 parts of turpentine, 10 parts of liquid paraffin, 40010 parts of polyethylene glycol, 5 parts of tris(2,3-dichloropropyl) phosphate part, 0.6 part of compatibilizer; compatibilizer is maleic acid grafted PP;

[0033] Its preparation method comprises the following steps:

[0034] S1. According to 110 parts of high-density polyethylene, 40 parts of acrylonitrile-butadiene-styrene copolymer, 15 parts of glass fiber, 4 parts of polytetrafluoroethylene micropowder, 4 parts of phthalic anhydride, and 6 parts of silane coupling agent 8 parts of turpentine, 10 parts of liquid paraffin, 40010 par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com