Adhesive sheet for supporting and protecting semiconductor wafer, back grinding method for semiconductor wafer

A technology of semiconductors and adhesive sheets, which is applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, adhesive types, etc., can solve the problems of residual glue, insufficient follow-up of sheets, processing errors, etc., and achieve the goal of preventing glue residue Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

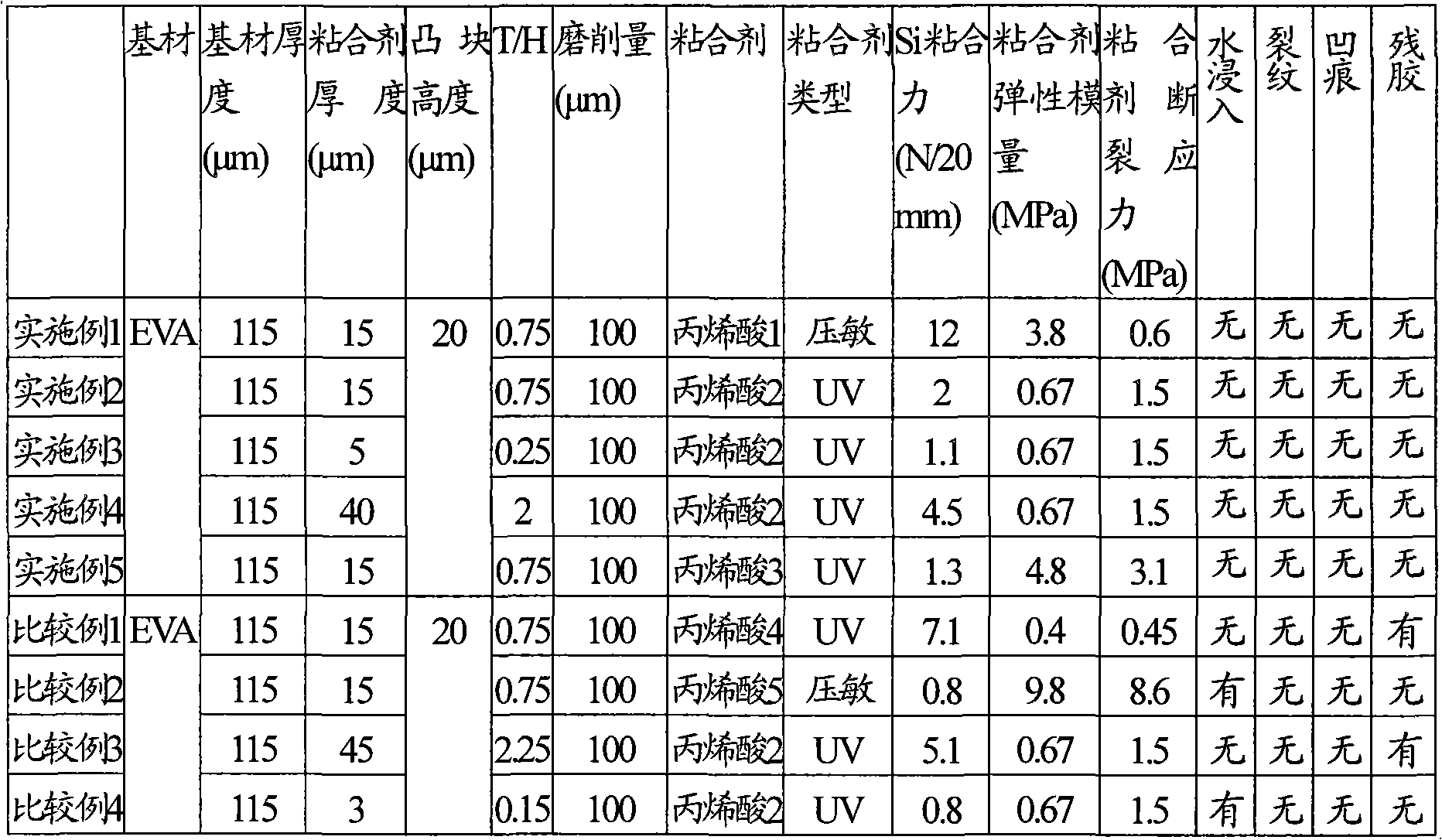

[0161] As the substrate layer, an ethylene-vinyl acetate copolymer (EVA) film with a thickness of 115 μm was used.

[0162] A pressure-sensitive adhesive layer (thickness: 15 μm) was formed thereon.

[0163] For the pressure-sensitive adhesive layer, the adhesive solution of the above-mentioned acrylic adhesive 1 was applied to a silicone release-treated polyester film with a thickness of 38 μm to a thickness of 50 μm after drying, and dried at 120°C 2 minutes.

[0164] Thereafter, a 115 μm EVA film was laminated as a base material to prepare an adhesive sheet for holding and protecting a semiconductor wafer.

[0165] The obtained adhesive sheet for holding and protecting the semiconductor wafer was heated at 50° C. and aged for 1 day or more to obtain an adhesive sheet.

[0166] When the adhesive force of the obtained adhesive sheet to the silicon wafer was measured, it was 12 N / 20 mm.

Embodiment 2~5 and comparative example 1~4

[0168] As the substrate layer, an ethylene-vinyl acetate copolymer (EVA) film having a thickness of 115 μm was used in the same manner as in Example 1.

[0169] Using the adhesives shown in Table 1, according to Example 1, an adhesive layer was formed on the substrate layer with the thickness in Table 1.

[0170] The adhesive strengths of the obtained adhesive sheets to silicon wafers were measured, respectively. The results are shown in Table 1.

[0171] Each of the obtained adhesive sheets was adhered to a silicon wafer, ground, peeled off the adhesive sheet, "water immersion", "wafer crack after grinding", "wafer dent" and " Wafer Contamination” evaluation. Moreover, 25 adhesive sheets of each Example and a comparative example were prepared and evaluated. The results are shown in Table 1.

[0172] paste

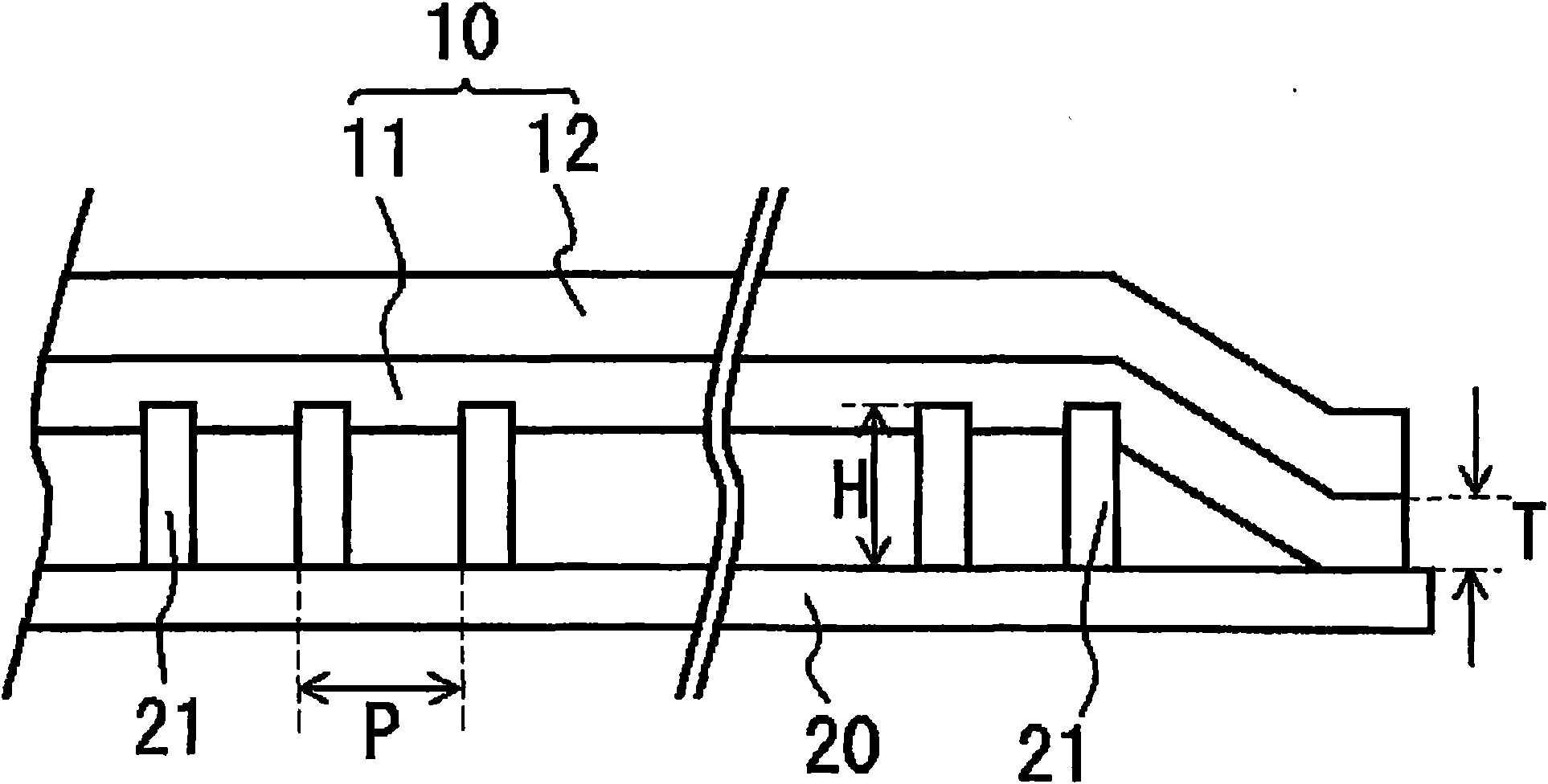

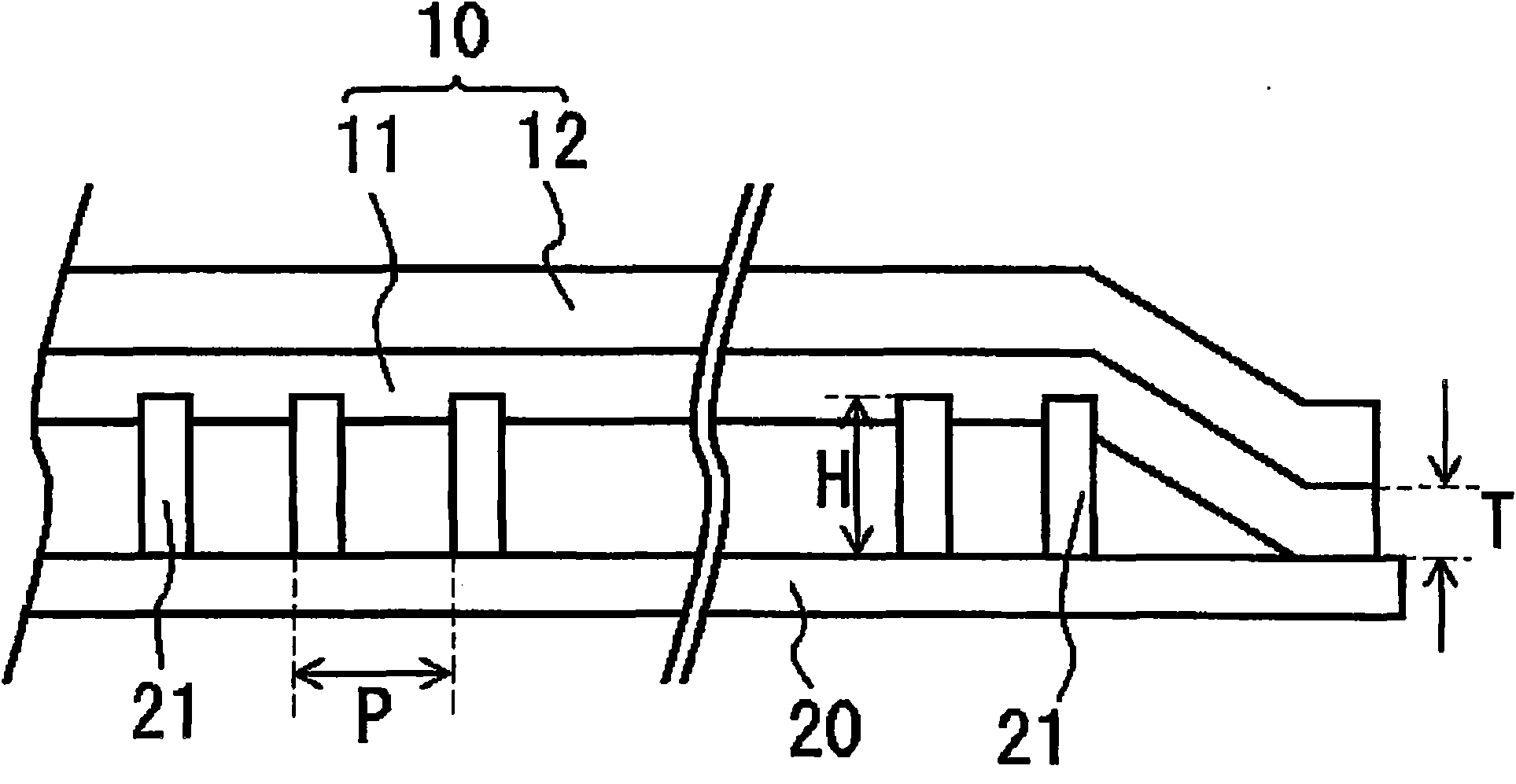

[0173] Each adhesive sheet was pasted so that the adhesive layer 11 was disposed on the surface side of the 6-inch silicon wafer 20 on which the bump electrode 21 w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com