Wafer processing method and wafer obtained by the wafer processing method

A processing method and wafer technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of wafer glue residue, inability to properly maintain the wafer itself, etc., to prevent glue residue and achieve good results. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0069] [Manufacturing Example 1] Preparation of Adhesive Composition

[0070] For 100 parts of resin component (manufactured by TORAY COATEX CO., LTD., trade name: Rheocoat R-1020), 3 parts of isocyanate-based cross-linking agent (manufactured by Nippon Polyurethane Industry Co., Ltd., trade name: CORONATE L) as a cross-linking agent , 3 parts of photopolymerization initiators (manufactured by BASF, brand name: IRGACURE651), and 70 parts of UV curable oligomers (manufactured by Nippon Kayaku Co., Ltd., brand name: KAYARAD DPHA) were stirred to obtain an adhesive composition.

manufacture example 2

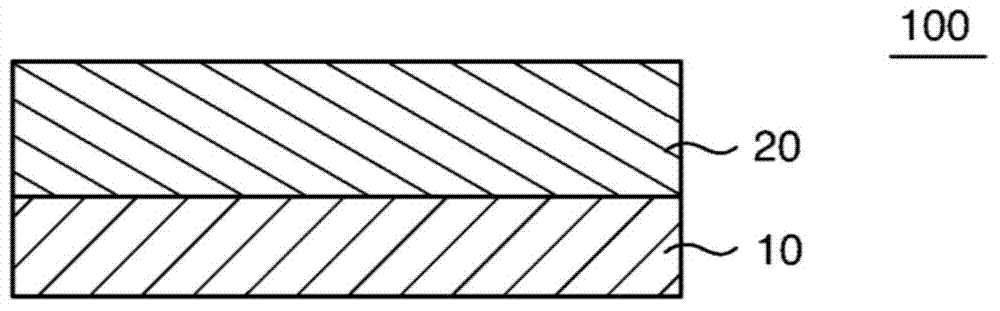

[0071] [Manufacturing example 2] Production of adhesive sheet for wafer processing

[0072] The adhesive composition obtained in Production Example 1 was applied to the release-treated surface of a release-treated film with a thickness of 38 μm so that the thickness after drying was 20 μm, and dried at 120° C. for 2 minutes using a drier. , forming an adhesive layer. This pressure-sensitive adhesive layer was bonded to a substrate (polyethylene film) to obtain a pressure-sensitive adhesive sheet for semiconductor wafer processing.

Embodiment 1

[0074] The PET film was peeled off from the adhesive sheet for wafer processing obtained in Production Example 2, and the wafer and the ring for wafer processing were simultaneously bonded together using a bonding device. Next, from the adhesive layer side of the wafer processing adhesive sheet (the side on which the wafer and the wafer processing ring are laminated), ultraviolet rays are irradiated under the following conditions so that the adhesive layer does not come into contact with the wafer and the wafer processing ring. Partial crosslinking of ring contacts for wafer processing. Next, methanol as a solvent was sprayed from the wafer and wafer processing ring side of the laminate of the wafer processing adhesive sheet, the wafer, and the wafer processing ring to clean the wafer. Then, ultraviolet rays were irradiated from the substrate side under the following conditions to peel the adhesive sheet for wafer processing from the wafer.

[0075]

[0076] Device: Nitto S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com