Acrylate prepolymer as well as preparation method and application thereof

A technology of acrylate and alkyl acrylate, applied in the field of acrylate prepolymer and preparation, can solve the problem of few optical adhesives, etc., and achieve the effects of promoting cross-linking reaction, increasing tensile elasticity, and promoting the complete degree of curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

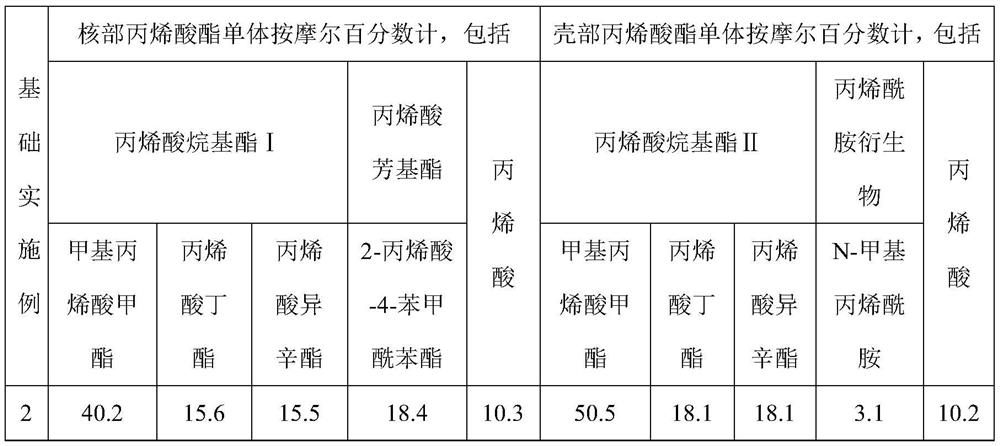

[0097] Basic Example 1 A kind of acrylate prepolymer and its preparation method

[0098]

[0099] Wherein, the molar ratio of the alkyl acrylate I to the alkyl acrylate II is 1:10.

[0100] Preparation:

[0101] Add the core acrylate monomer, initiator and chain transfer agent into the solvent, react at 70°C for 0.5h, then add dropwise the alkyl acrylate II and acrylic acid in the shell acrylate monomer, and finally add dropwise acrylamide to derivatize Material, reflux reaction, obtains described prepolymer;

[0102] The initiator is dibenzoyl peroxide, and the initiator accounts for 0.3wt% of the total weight of the core acrylate monomer and the shell acrylate monomer;

[0103] The chain transfer agent is dodecyl mercaptan, and the chain transfer agent accounts for 0.015wt% of the total weight of the core acrylate monomer and the shell acrylate monomer;

[0104] The solvent is ethyl acetate, and the solid content of the prepolymer is 50wt%.

[0105] Basic Example 2 A ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com