Protective film for automotive wheel

A technology for protecting films and wheels, applied to wheels, pressure-sensitive films/sheets, film/sheet-like adhesives, etc., to prevent rust, scratches, and glue residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

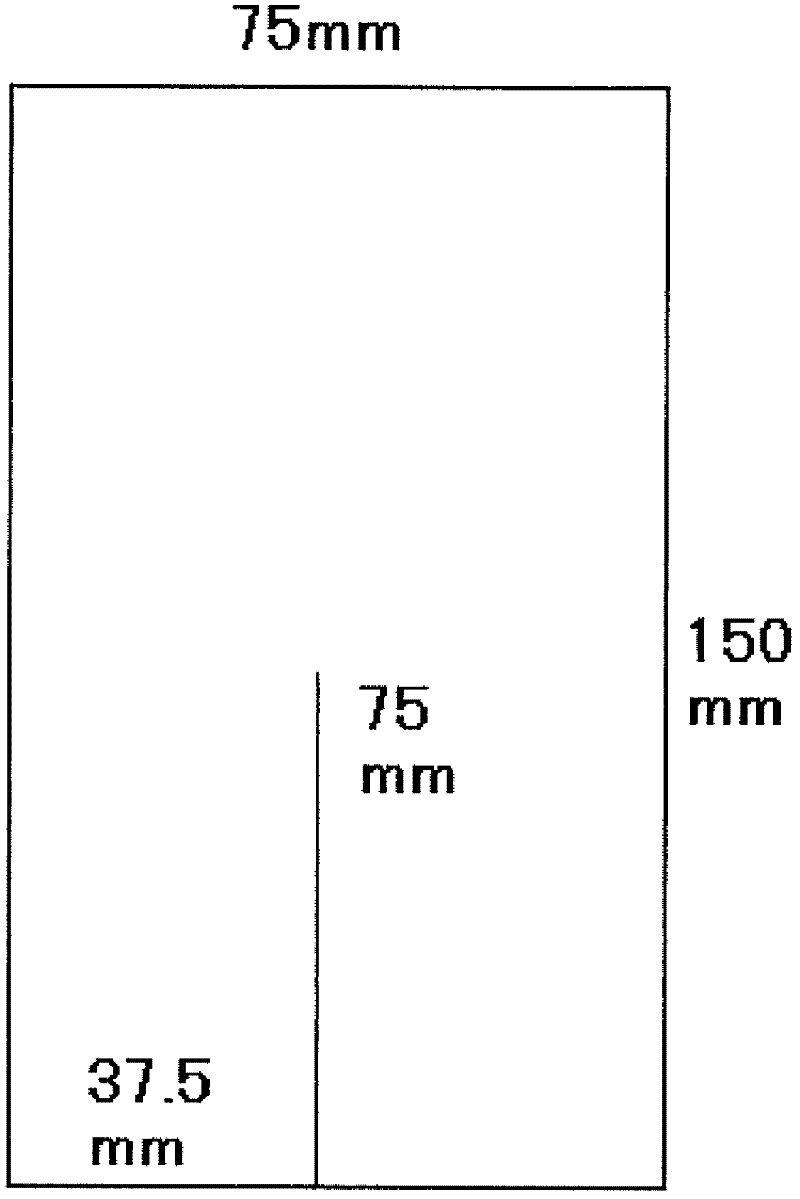

Image

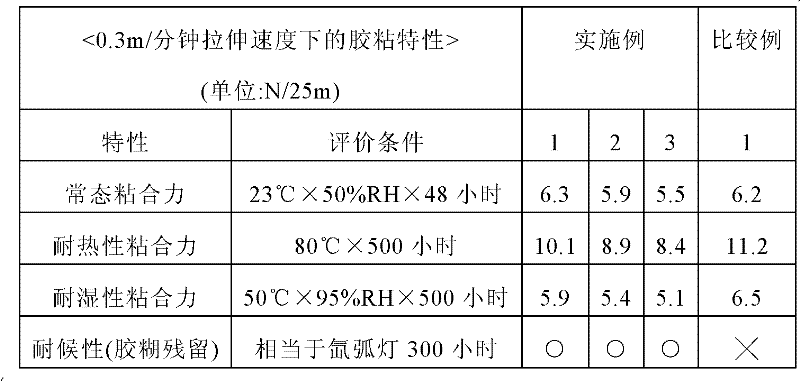

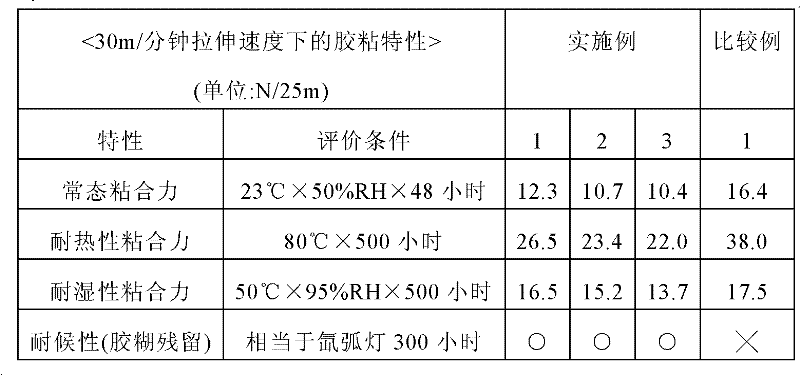

Examples

Embodiment 1

[0113] (Preparation of (meth)acrylic polymer)

[0114] In a four-neck flask with a stirring blade, a thermometer, a nitrogen inlet tube, and a condenser, add 30 parts by weight of 2-ethylhexyl acrylate, 70 parts by weight of ethyl acrylate, 5 parts by weight of methyl methacrylate, 4 parts by weight of Parts of 2-hydroxyethyl acrylate, 0.2 parts by weight of 2,2'-azobisisobutyronitrile and 200 parts by weight of ethyl acetate as a polymerization initiator, introduce nitrogen while slowly stirring, and keep the liquid temperature in the flask Polymerization was carried out at about 65° C. for about 6 hours to prepare a (meth)acrylic polymer solution (35% by weight). The glass transition temperature (Tg) of the (meth)acrylic polymer was -29°C.

[0115] (Preparation of binder solution)

[0116] The (meth)acrylic polymer solution (35% by weight) was diluted to 20% by weight with ethyl acetate, and 0.6 wt. Parts of isocyanate compound (coronet L, manufactured by Nippon Polyureth...

Embodiment 2

[0120] Except for using the (meth)acrylic adhesive solution (B) obtained by blending 0.8 parts by weight of the isocyanate compound (Coronet L, manufactured by Nippon Polyurethane Industry Co., Ltd.), the same operation as in Example 1 was performed to produce an automobile Protective film for wheels.

Embodiment 3

[0122] Except for using the (meth)acrylic adhesive solution (C) obtained by blending 1.0 parts by weight of the isocyanate compound (Coronet L, manufactured by Nippon Polyurethane Industry Co., Ltd.), the same operation as in Example 1 was performed to produce an automobile Protective film for wheels.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com