Adhesive for UV viscosity-reducing film and UV viscosity-reducing film thereof

A technology of adhesives and mucous membranes, applied in the direction of film/sheet adhesives, conductive adhesives, polymer adhesive additives, etc., can solve the problem that the adhesive layer does not have antistatic properties, and the process is complicated problems, to achieve excellent antistatic properties, simple process, and improve the effect of cross-linking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

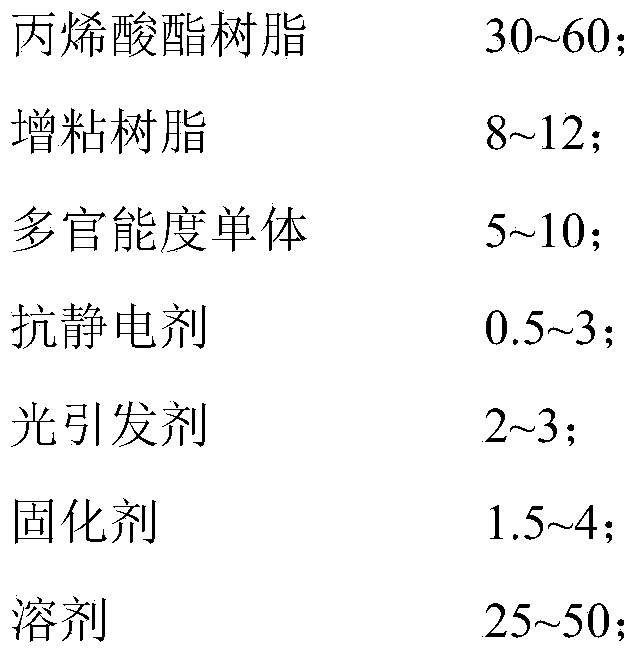

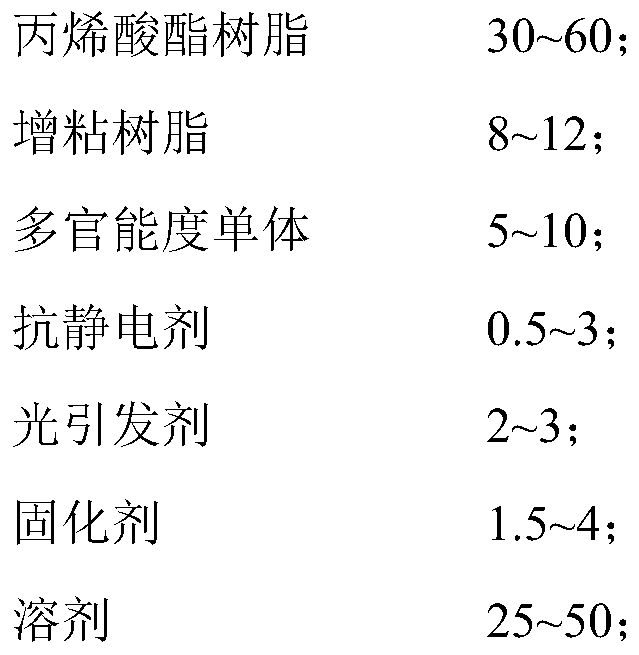

Method used

Image

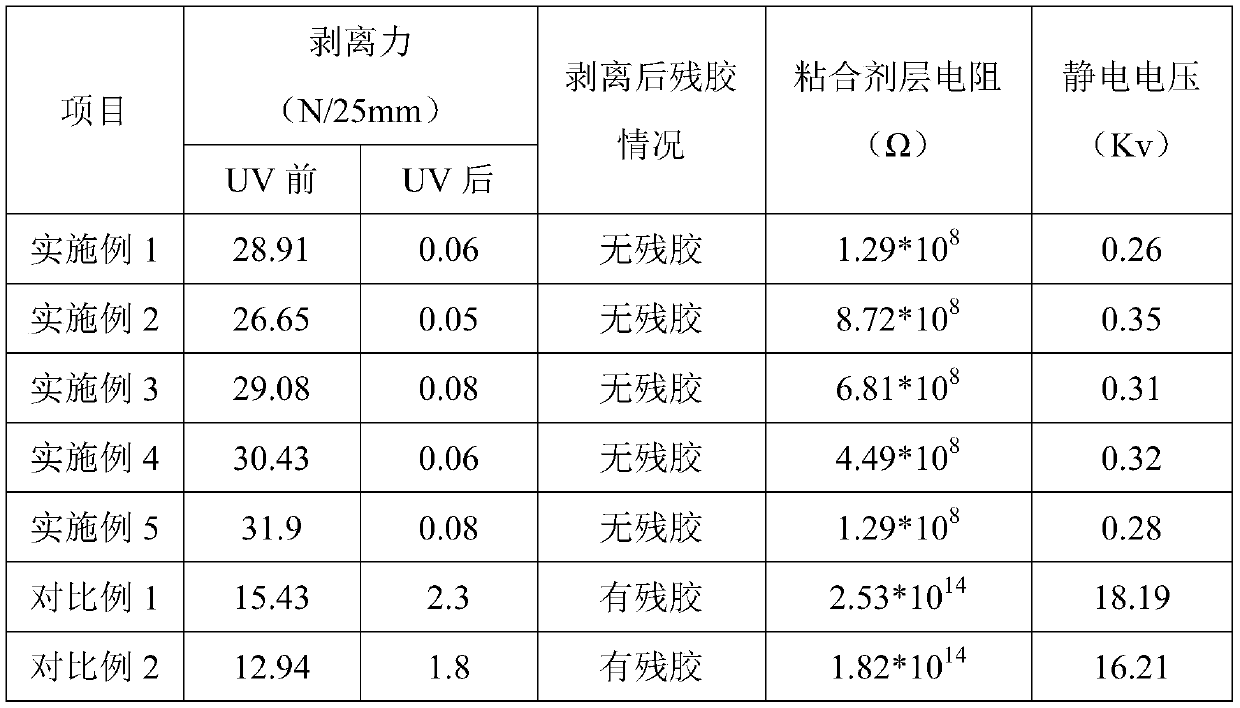

Examples

Embodiment 1

[0031] Weigh 10g methyl methacrylate, 20g vinyl acetate, 8g n-octyl acrylate, 10g butyl acrylate, 1.2g hydroxyethyl acrylate, 0.5g hydroxypropyl methacrylate, 0.8g hydroxyethyl acrylate, 1g formazan Hydroxypropyl acrylate, 1.5g diacetone acrylamide, 0.8g N,N-dimethylacrylamide to prepare acrylate resin, the preparation method of acrylate resin is the same as CN108611033A.

[0032] Weigh 40g of prepared acrylate resin, 37.5g of ethyl acetate, 12.5g of acetone and mix evenly, then add 5g of triallyl isocyanate, 8g of terpene resin, 2g of petroleum resin, 0.5g of zinc oxide with a particle size of 80nm, 1g Benzoin dimethyl ether, 1g 2-hydroxy-2-methyl-1-phenylacetone, 1g 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, 2g hexamethylene diisocyanate trimer Stir and mix evenly to obtain an adhesive for UV mucous-reducing film.

[0033] Coat the adhesive for UV adhesive film on the non-antistatic layer of polyester film with a thickness of 50 μm, put it in an oven at 100°C for 2 min...

Embodiment 2

[0035] Weigh 15g methyl methacrylate, 18g vinyl acetate, 5g n-octyl acrylate, 8g butyl acrylate, 0.5g hydroxyethyl acrylate, 0.8g hydroxypropyl methacrylate, 1g hydroxyethyl acrylate, 0.5g formazan Hydroxypropyl acrylate, 1.2g diacetone acrylamide, 1.2g N,N-dimethylacrylamide to prepare acrylate resin, the preparation method of acrylate resin is the same as CN108611033A.

[0036] Weigh 50g of the prepared acrylate resin, 29.2g of ethyl acetate, 8.3g of acetone and mix evenly, then add 2.5g of triallyl isocyanate, 5g of 1,3-diallyl urea, 9g of terpene resin, 3g of petroleum resin , 0.8g of zinc oxide with a particle size of 50nm, 1g of tin oxide with a particle size of 40nm, 2.5g of 2-hydroxy-2-methyl-1-phenylacetone, 1g of hexamethylene diisocyanate trimer, 1.8g The isophorone diisocyanate trimer is stirred and mixed evenly to obtain an adhesive for UV film reduction.

[0037] Coat the adhesive for UV adhesive film on the non-antistatic layer of optical-grade polyester film w...

Embodiment 3

[0039] Weigh 20g methyl methacrylate, 10g vinyl acetate, 7g n-octyl acrylate, 6g butyl acrylate, 1g hydroxyethyl acrylate, 1g hydroxypropyl methacrylate, 0.5g hydroxyethyl acrylate, 1.2g methyl Hydroxypropyl acrylate, 0.8g of diacetone acrylamide, and 1.5g of N,N-dimethylacrylamide are used to prepare acrylate resin, and the preparation method of acrylate resin is the same as that of CN108611033A.

[0040] Weigh 30g of prepared acrylate resin, 24g of ethyl acetate, 6g of acetone and mix evenly, then add 5g of triallyl isocyanate, 5g of 1,3-diallyl urea, 7.9g of terpene resin, 3.1g of petroleum resin, 1g of tin oxide with a particle size of 20nm, 1.5g of benzoin dimethyl ether, 0.5g of 2,4,6-trimethylbenzoyl-diphenylphosphine oxide, and 1.5g of isophorone diisocyanate trimer were stirred and mixed Evenly, an adhesive for UV mucous-reducing film is obtained.

[0041] Coat the adhesive for UV adhesive film on the non-antistatic layer of optical-grade polyester film with a thicknes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com