A kind of antistatic wafer cutting protective film and preparation method thereof

A protective film and anti-static technology, which is applied in the direction of circuits, electrical components, film/sheet adhesives, etc., can solve the problem of inability to achieve high-accuracy fixing and efficient picking, contamination of attached objects, and peeling off Low strength peel strength and other problems, to improve the effect of fixing and picking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

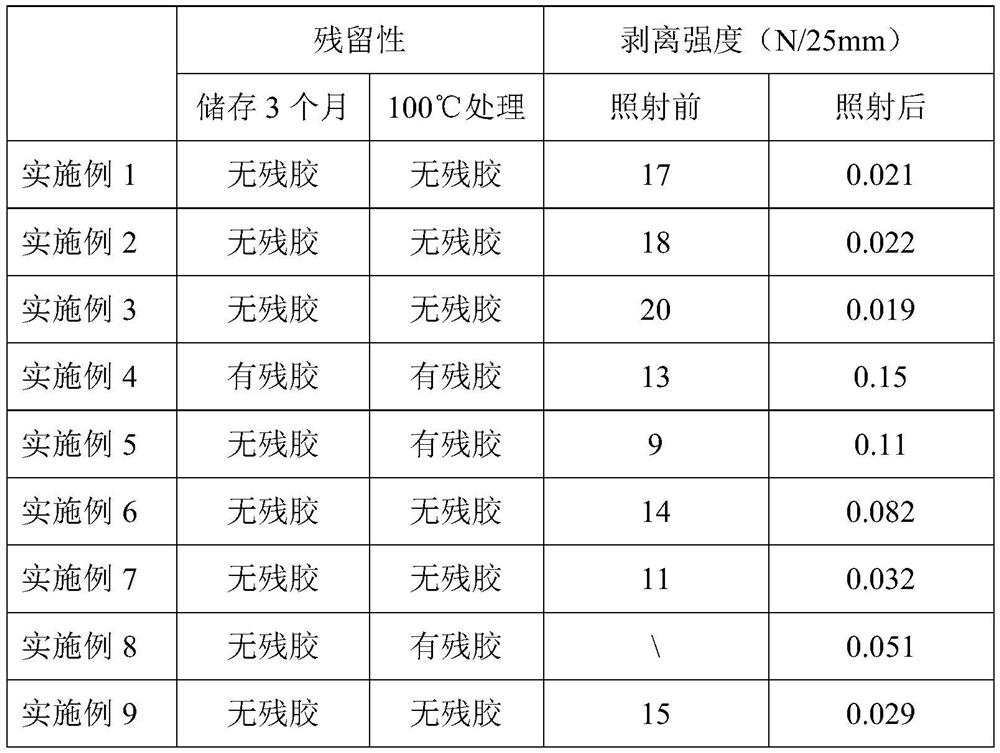

Examples

preparation example Construction

[0042] A second aspect of the present invention provides a method for preparing the antistatic wafer dicing protective film, comprising the following steps:

[0043] (1) the first antistatic layer is bonded to one side of the substrate film, and the second antistatic layer is bonded to the other side of the substrate film;

[0044] (2) Coating the raw materials of the adhesion-reducing layer on the surface of the second antistatic layer, pre-baking, laminating with the release film layer, and curing to obtain the wafer dicing protective film.

[0045] Preferably, the preparation method of the antistatic wafer cutting protection film comprises the steps of:

[0046] (1) Laminate the first antistatic layer with the substrate film, and then with the second antistatic layer;

[0047] (2) Coating the treated raw material of the adhesion-reducing layer on the surface of the second antistatic layer, pre-baking, laminating with the release film layer, and curing to obtain the wafer d...

Embodiment 1

[0052] Embodiment 1 of the present invention provides an antistatic wafer dicing protective film, which sequentially includes a first antistatic layer, a substrate layer, a second antistatic layer, an adhesion-reducing layer, and a release film layer;

[0053] The debonding layer includes the following raw materials in parts by weight: 22 parts of acrylate monomers, 11 parts of acrylate oligomers containing active reactive groups, 1.0 parts of photoinitiators, 5 parts of fillers and 26 parts of solvents;

[0054] The acrylate monomers are butyl acrylate, lauric acrylate and 1,4-butanediol diacrylate, and the molar ratio of butyl acrylate, lauric acrylate and 1,4-butanediol diacrylate is 1: 0.21:0.32;

[0055] The raw materials for the preparation of the acrylate oligomer containing active reactive groups include hydroxyl-containing acrylate monomers and polyisocyanates, and the molar ratio of the hydroxyl groups in the hydroxyl-containing acrylate monomers to the isocyanate gr...

Embodiment 2

[0069] Embodiment 2 of the present invention provides an antistatic wafer dicing protective film, which sequentially includes a first antistatic layer, a substrate layer, a second antistatic layer, an adhesion-reducing layer, and a release film layer;

[0070] The debonding layer includes the following raw materials in parts by weight: 38 parts of acrylate monomers, 19 parts of acrylate oligomers containing active reactive groups, 4.0 parts of photoinitiators, 15 parts of fillers and 53 parts of solvents;

[0071] The acrylate monomers are butyl acrylate, lauric acrylate and 1,4-butanediol diacrylate, and the molar ratio of butyl acrylate, lauric acrylate and 1,4-butanediol diacrylate is 1: 0.35:0.49;

[0072] The raw materials for the preparation of the acrylate oligomer containing active reactive groups include hydroxyl-containing acrylate monomers and polyisocyanates, and the molar ratio of the hydroxyl groups in the hydroxyl-containing acrylate monomers to the isocyanate g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com