Patents

Literature

46 results about "Butanediol diacrylate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Packaging 1 L in glass bottle 25, 100 mL in glass bottle Application 1,4-Butanediol diacrylate may be used as a multifunctional crosslinker.

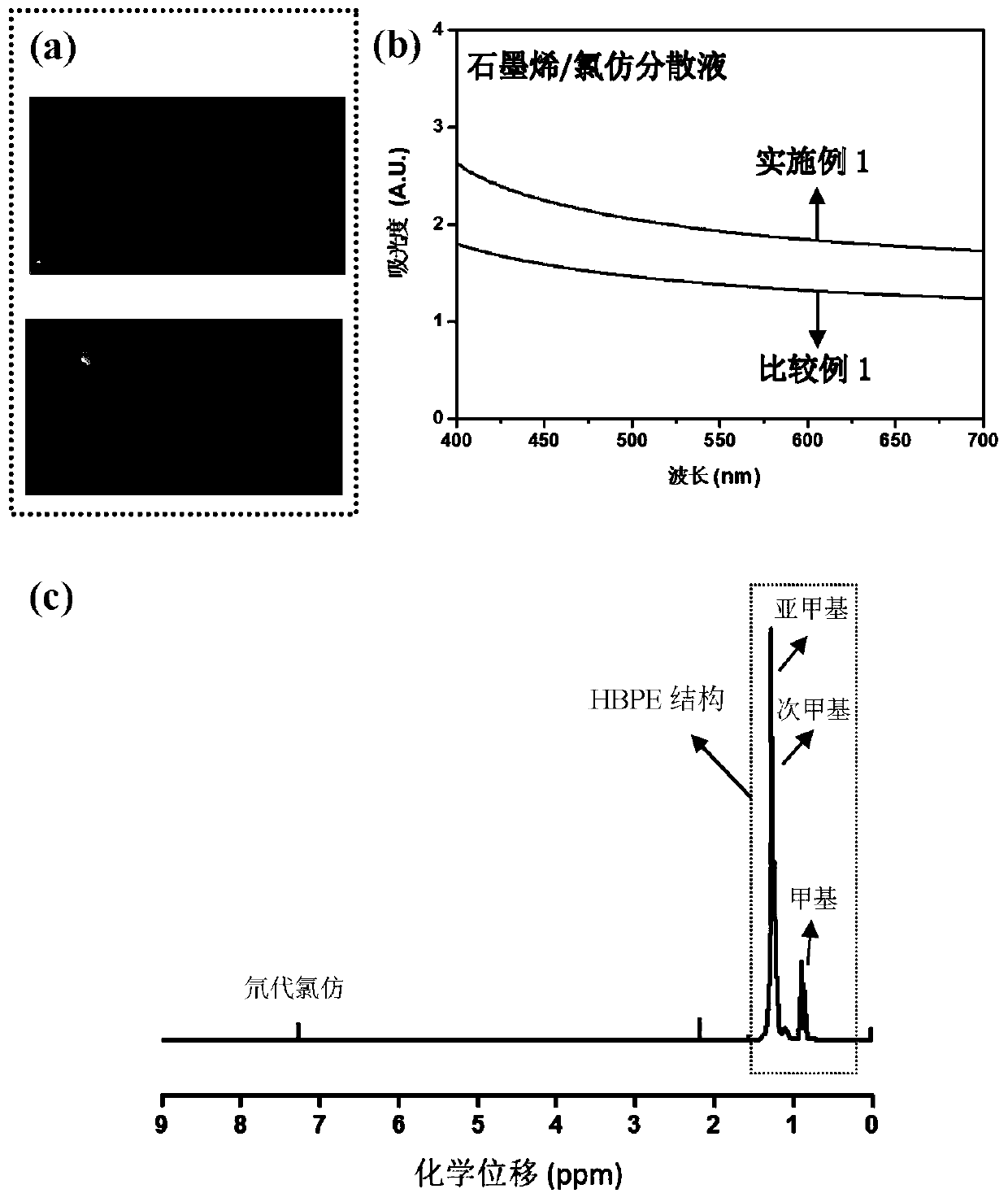

Preparation method of ultraviolet-curable graphene dispersion liquid

ActiveCN106519737AQuality improvementReduce defectsPigment treatment with macromolecular organic compoundsPigment physical treatmentFlexible electronicsCopolymer

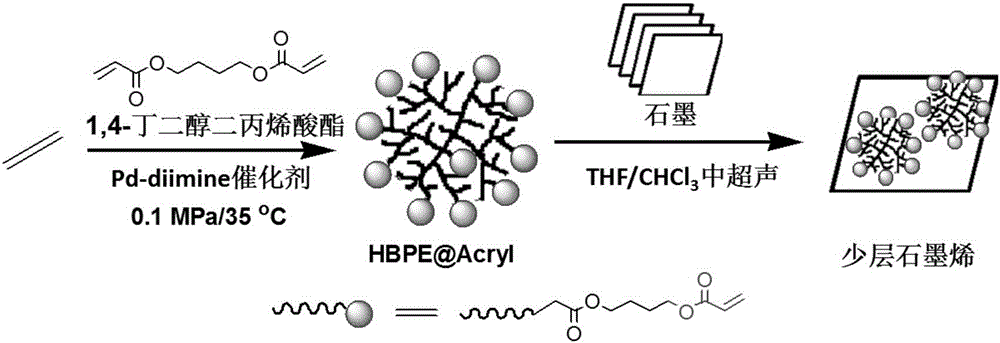

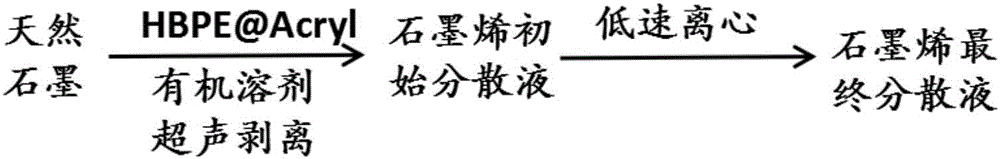

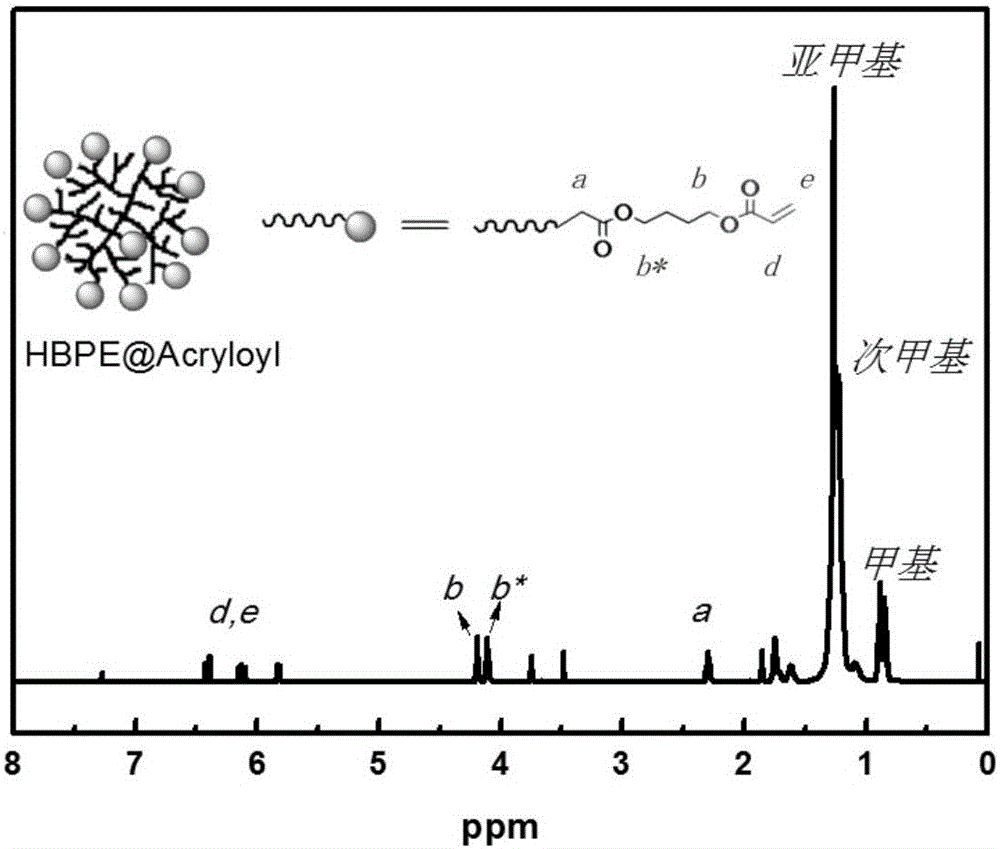

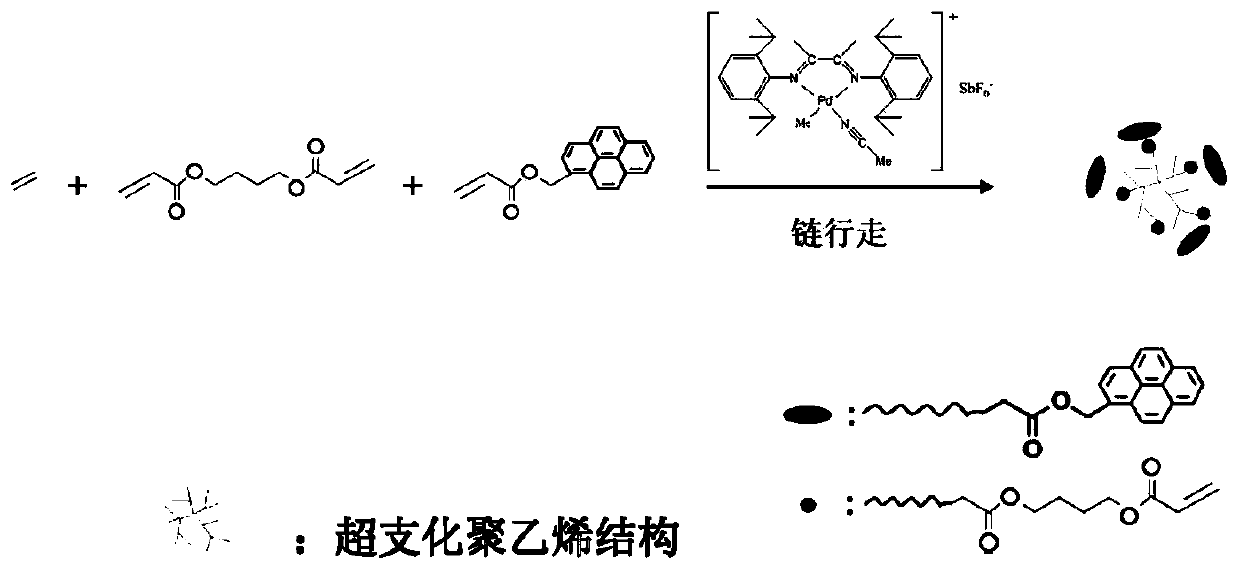

The invention discloses a preparation method of ultraviolet-curable graphene dispersion liquid. The preparation method comprises the following steps: catalyzing ethylene and 1,4-butylene glycol diacrylate through a Pd-diimine catalyst for chain 'walking' copolymerization, and introducing a reactable acryloyl group into hyperbranched polyethylene (HBPE); carrying out CH-Pi action on the tail ends of multiple branch chains of an acryloyl-grafted hyperbranched polyethylene copolymer (HBPE@Acryl) and the surface of graphene, wherein the HBPE@Acryl can be effectively adsorbed to the surface of a graphene slice layer, so that the graphene can be uniformly dispersed in an organic solvent without being aggregated. The preparation method disclosed by the invention is simple in process, mild in condition and relatively small in environmental pollution; the prepared ultraviolet-curable graphene dispersion liquid has the advantages of high quality, low defect and long-time stable dispersion, can be used for preparing a flexible electronic device, an energy storage material, a sensing device and the like, and has a relatively good application prospect in the aspects of ultraviolet curing coating, functional conductive ink and the like.

Owner:宁波聚泰新材料科技有限公司

Environment-friendly textile sizing agent

InactiveCN104975507AGood film formingImprove permeabilityFibre treatmentCelluloseHydroxyethyl cellulose

An environment-friendly textile sizing agent is composed of the following raw materials in parts by weight: 3 to 4 parts of crease resistant agent, 8 to 15 parts of acrylate, 5 to 7 parts of maleic anhydride, 10 to 16 parts of butanediol diacrylate, 2 to 4 parts of hydroxyethyl cellulose, 8 to 14 parts of glycol, 7 to 15 parts of butyl acrylate, 6 to 10 parts of aqueous polymerized ether-ester, 2 to 4 parts of protein amino acid, 2 to 4 parts of polyacrylate, 12 to 26 parts of acetylated distarch phosphate, 2 to 4 parts of wax sheet, 10 to 15 parts of protein slurry, 3 to 5 parts of modified silicone oil antifoaming agent, 2 to 4 parts of sodium sulfamate, 7 to 12 parts of cassava starch, and 9 to 13 parts of modified starch. The provided environment-friendly textile sizing agent has a good film-forming property and permeability, can reduce the pollution, has a simple preparation technology, and is accord with the environment protection requirements.

Owner:QINGDAO ENGAO MOTION CONTROL TECH

Novel disperse print thickening agent and preparation method thereof

The invention discloses a novel disperse print thickening agent. The novel disperse print thickening agent includes hydroxymethyl cellulose, sucrose fatty acid ester, an unsaturated acidic monomer, long-chain fatty alcohol-polyoxyethylene ether acrylic acid salt, polyacrylic acid, 3-propyl-2- acryloyloxy propane-1-sodium sulfonate, butanediol diacrylate, diethylene glycol diacrylate, an initiator, inorganic thickening powder, a phase inversion agent and deionized water. The disperse print thickening agent has a very good thickening effect and high viscosity, is resistant to electrolyte, can reduce the using amount of pigment printing slurry and has no adverse effect on the color brilliance, washable fastness and soft hand feel of printed fabrics.

Owner:湖州市千金丝织厂(普通合伙)

Preparation method of PET polyester based on emulsion polymerization process

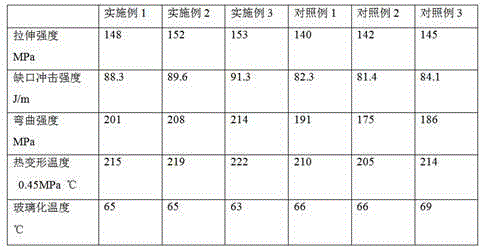

InactiveCN104356614ALower glass transition temperatureHigh mechanical strengthPolyesterPolymer science

The invention relates to a preparation method of PET polyester based on an emulsion polymerization process, belonging to the technical field of high polymer materials. The preparation method comprises the following steps: adding water and an emulsifier into a reactor, uniformly stirring, then, adding acrylic acid, hydroxyethyl acrylate and methyl methacrylate, uniformly stirring, then, adding an initiator, heating to perform polymerization reaction, adding ferric oxide, glass fiber and silicon oxide powder, uniformly stirring, carrying out suction filtration to obtain a polymer, washing a filter cake by using alcohol, and drying the filter cake to obtain a prepolymer; uniformly mixing the prepolymer, polyethylene glycol terephthalate, butanediol diacrylate, a nucleating agent, an antioxidant, a silane coupling agent and a lubricant to obtain a mixture; and feeding the mixture into a twin-screw extruder, and extruding and pelletizing. According to the polyester material provided by the invention, the glass fiber is prepared into the prepolymer by virtue of an emulsion coating manner, and the prepolymer and the polyester are extruded to obtain the polymer material, so that the glass transition temperature of the polyester is lowered and the mechanical strength of the polyester is improved.

Owner:广州格兰德塑胶科技有限公司

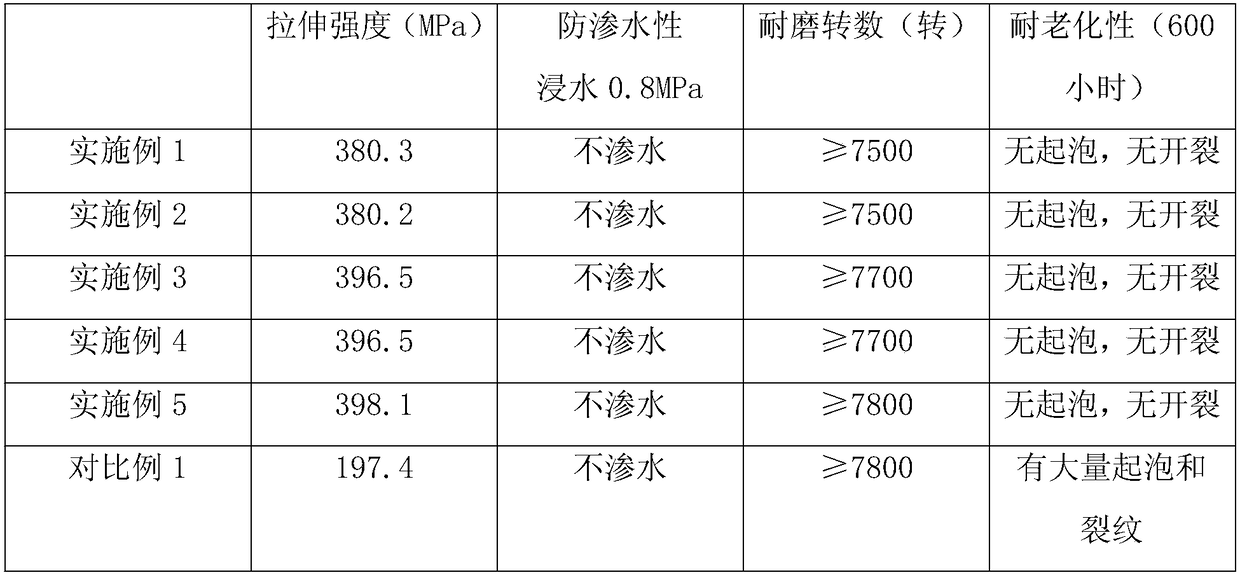

Composite for fire hoses and preparation method of composite

InactiveCN108102265AImprove mechanical propertiesImprove waterproof performancePolyvinyl alcoholPolyvinyl chloride

The invention provides a composite for fire hoses and a preparation method of the composite. The composite is prepared from components in parts by weight as follows: 100 parts of sucrose polyester modified polyvinyl chloride resin, 60-70 parts of a fluorine-containing organosilicone modified polyurethane polymer, 40-50 parts of bisphenol A polycarbonate, 30-40 parts of polyphenyl ether, 10-15 parts of polyacrylamide, 10-15 parts of acrylate, 10-12 parts of medium chain triglyceride, 8-12 parts of polyvinyl acetal, 8-12 parts of dibutyl phthalate, 2-3 parts of calcium stearate, 2-3 parts of cadmium stearate, 1-2 parts of 1,4-butanediol diacrylate and 1-2 parts of dibutyltin dilaurate. Main raw materials comprise sucrose polyester modified polyvinyl chloride resin, the fluorine-containing organosilicone modified polyurethane polymer, bisphenol A polycarbonate and polyphenyl ether, and the composite has good mechanical performance, water resistance, wear resistance and aging resistance through cooperation of the four raw materials and the auxiliary function of auxiliary materials.

Owner:FOSHAN SHIRUI LEADING MATERIAL RES INST GENERAL PARTNERSHIP

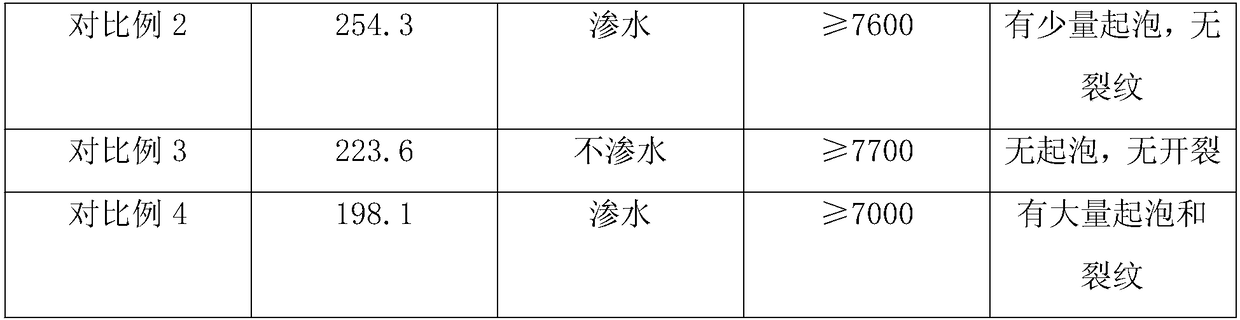

Preparation method of high-impact-resistant waterproof type epoxy resin toughening agent

The invention discloses a preparation method of a high-impact-resistant waterproof type epoxy resin toughening agent, and belongs to the technical field of preparation of toughening agents. The methoddisclosed by the invention is characterized in that butyl acrylate, 1,4-butanediol diacrylate, allyl methacrylate, distilled water, sodium dodecyl benzene sulfonate and potassium persulfate are subjected to heating reaction to prepare a home-made seed emulsion, and the home-made seed emulsion is mixed with butyl acrylate, methyl methacrylate, a cross-linking agent, an emulsifying agent, an initiating agent and a grafting agent together to prepare a core layer emulsion and a shell layer emulsion; divinyl benzene is an oil-soluble initiating agent and mainly swells in emulsion particles, and only a small amount of divinyl benzene is dissolved in a water phase, thereby improving the impact-resistance strength of the toughening agent; and nano silicon dioxide is added to a polyacrylate emulsion with better water resistance and physical and mechanical properties to enable the polymer to have high water absorbing capacity, and resin can be cured in a humid environment or even underwater andcan keep good water resistance, thereby improving the water resistance of the toughening agent.

Owner:常州市万昌化工有限公司

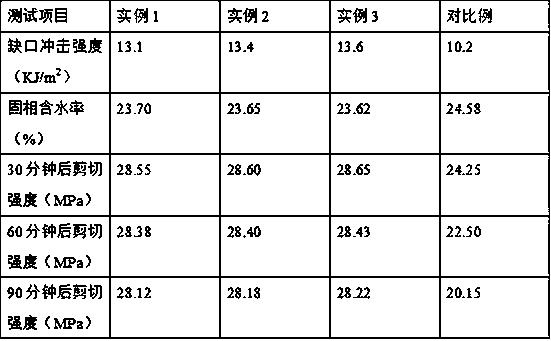

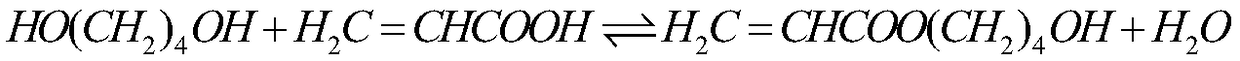

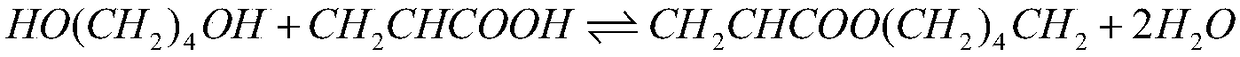

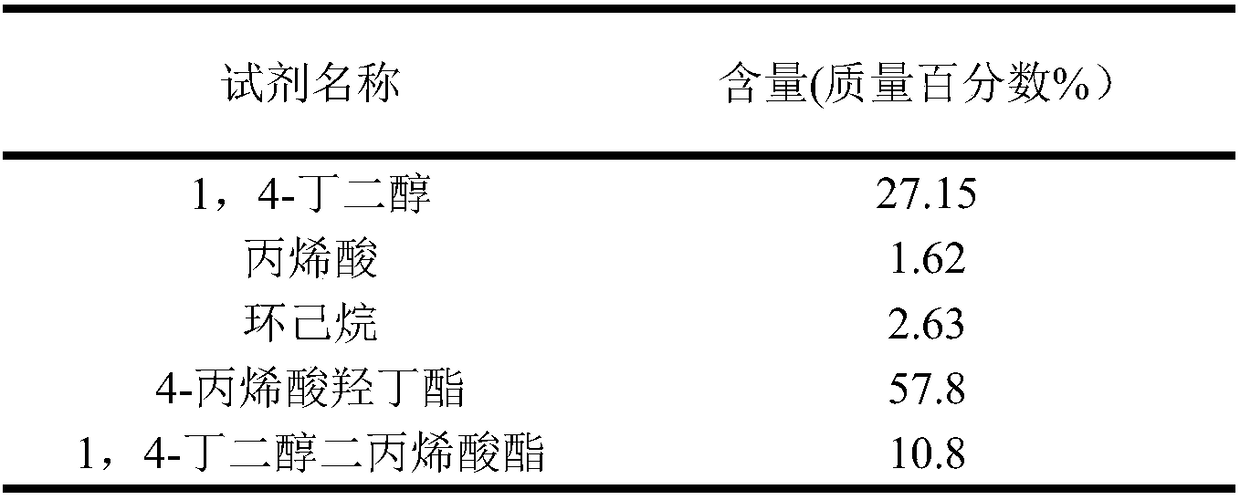

Production technology and equipment for preparing 4-hydroxybutyl acrylate through extraction separation

InactiveCN109053449AReduce equipment investmentReduce energy consumptionOrganic compound preparationCarboxylic acid esters separation/purificationDiacrylate esterDistillation

The invention relates to a production technology and equipment for preparing 4-hydroxybutyl acrylate through extraction separation. The production technology comprises the steps: reacting 1,4-butanediol with acrylic acid under the existence of a catalyst, a polymerization inhibitor and a solvent to obtain main products of 4-hydroxybutyl acrylate and 1,4-butanediol diacrylate; choosing cyclohexaneto extract 1,4-butanediol diacrylate from a water phase at first, then choosing dichloromethane to extract 4-hydroxybutyl acrylate from the water phase and finally obtaining a finished product throughreduced pressure distillation. The production technology disclosed by the invention has the beneficial effects: a set of technological process is designed for the characteristics of physical properties, contents and the like of all the ingredients of a reaction workshop section and a separation workshop section, the final product 4-hydroxybutyl acrylate is obtained through the technological process, and the purity can completely meet an industrial production requirement. The production technology disclosed by the invention has the advantages of simple technology, low required energy consumption and low production cost, and the prepared product has the advantages of high purity, high product yield and good quality.

Owner:QINGDAO UNIV OF SCI & TECH

Biodegradable waterproof polycarbonate composite material and preparation method therefor

The present invention discloses a biodegradable waterproof polycarbonate composite material and a preparation method therefor. The biodegradable waterproof polycarbonate composite material is prepared by using the following components in parts by weight: 80-90 parts of polycarbonate, 20-30 parts of polyvinyl acetate resin, 11-16 parts of hydroxypropyl methylcellulose, 8-15 parts of polyvinyl butyral, 3-7 parts of zirconium fluoride, 3-6 parts of 1,4-butanediol diacrylate, 2-5 parts of ethylene tetrafluoroethylene copolymer, 1-2 parts of 4,4'-bi (2, 2-epoxy propoxylated) octafluorobiphenyl, 1-2 parts of dibutyltin dilaurate, and 0.2-1 parts of polydimethyl amino thiazole. The present invention also provides a preparation method for the biodegradable waterproof polycarbonate composite material.

Owner:JIN BAOLI TECH SUZHOU

Heat-resistant crack-resistant organic glass and preparation method thereof

InactiveCN107057254AIncrease steric hindranceImprove molecular weightEthyl hydroxybenzoateMethacrylate

The invention discloses heat-resistant crack-resistant organic glass and a preparation method thereof; the heat-resistant crack-resistant organic glass comprises, by weight, methyl methacrylate, polycyclic norbornene methacrylate, butanediol diacrylate, epoxidized soybean oil acrylate, an impact modifier, 1-dodecanethiol, polyacrylamide, rubber particles, poly(butyl acrylate), nylon terpolymer, rare earth, azobisisobutyronitrile, dicumyl peroxide, diisobutyl phthalate, and ethyl 4-hydroxybenzoate. The heat-resistant crack-resistant organic glass and the preparation method thereof are provided herein; the organic glass has high glass transition temperature, good heat resistance and good mechanical properties, rarely cracks and has good economic benefit.

Owner:蚌埠承永玻璃制品有限公司

Method for preparing 1,4-butanediol diacrylate

InactiveCN101462955AWide variety of sourcesReduce corrosionOrganic compound preparationCarboxylic acid esters preparationButanediolSolvent

The invention belongs to a method for preparing 1, 4-butanediol diacrylate ester, comprising the steps as follows: (1) 1, 4-butanediol, acrylic acid, catalyst, solvent and polymerization inhibitor are put into a reaction kettle to be fully mixed and stirred, so as to form a mixture; (2) a steam valve of the reaction kettle is opened to slowly heat the mixture, the temperature is controlled and maintained at 70-90 DEG C for a 20-40min reaction; (3) the mixture is continued to be heated to react for 3-4h, then reflow is carried out for 5-7h and then the reaction is finished; (4) soda water solution and sodium chloride water solution are added into the mixture and after washing the upper organic phase is extracted; (5) the upper organic phase is separated from the solvent; (6) then cooling and pressing are carried out to obtain the end product. The method is simple in process, produces few by-products or little waste water, has good activity and flexibility, low color intensity, acidity, viscosity and shrinking percentage, high yield coefficient and good quality.

Owner:TIANJIN CHEM REAGENT RES INST

High-adhesion pearized silver printing ink and preparation method thereof

The invention relates to high-adhesion pearized silver printing ink which comprises the following components in parts by weight: 50 parts of pearl powder, 35 parts of silver powder, 52 parts of hydroxy fluorosilicone resin, 20 parts of 1,4-butanediol diacrylate, 6 parts of diammonium citrate, 6 parts of butyl glycidyl ethe, 0.8 parts of octaphenyl polyoxyethyiene, 0.5 parts of antioxidant 1010 and 80 parts of mixed solvent. The environment-friendly printing ink adopts the mixed solvent of dimethyl carbonate and trimethylolpropane polyether with the molecular weight of 400-1000, is basically free of toxic chemicals such as benzene and methylbenzene, is very excellent in environment-friendly property, and has excellent dissolving and dispersing properties for resin and a pigment; good durability is endowed for the printing ink; very good printing quality is represented; the environment-friendly printing ink is suitable for silk-screen printing of the surfaces of glass and a PMMA (polymethyl methacrylate) substrate; and after the printing ink is dried, the printing ink is bright in color, stable in adhesivity, and good in oil resistance and alcohol resistance.

Owner:SUZHOU ANJIE TECH

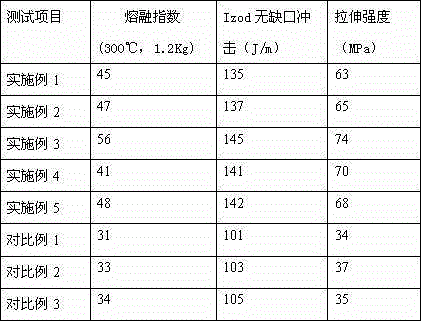

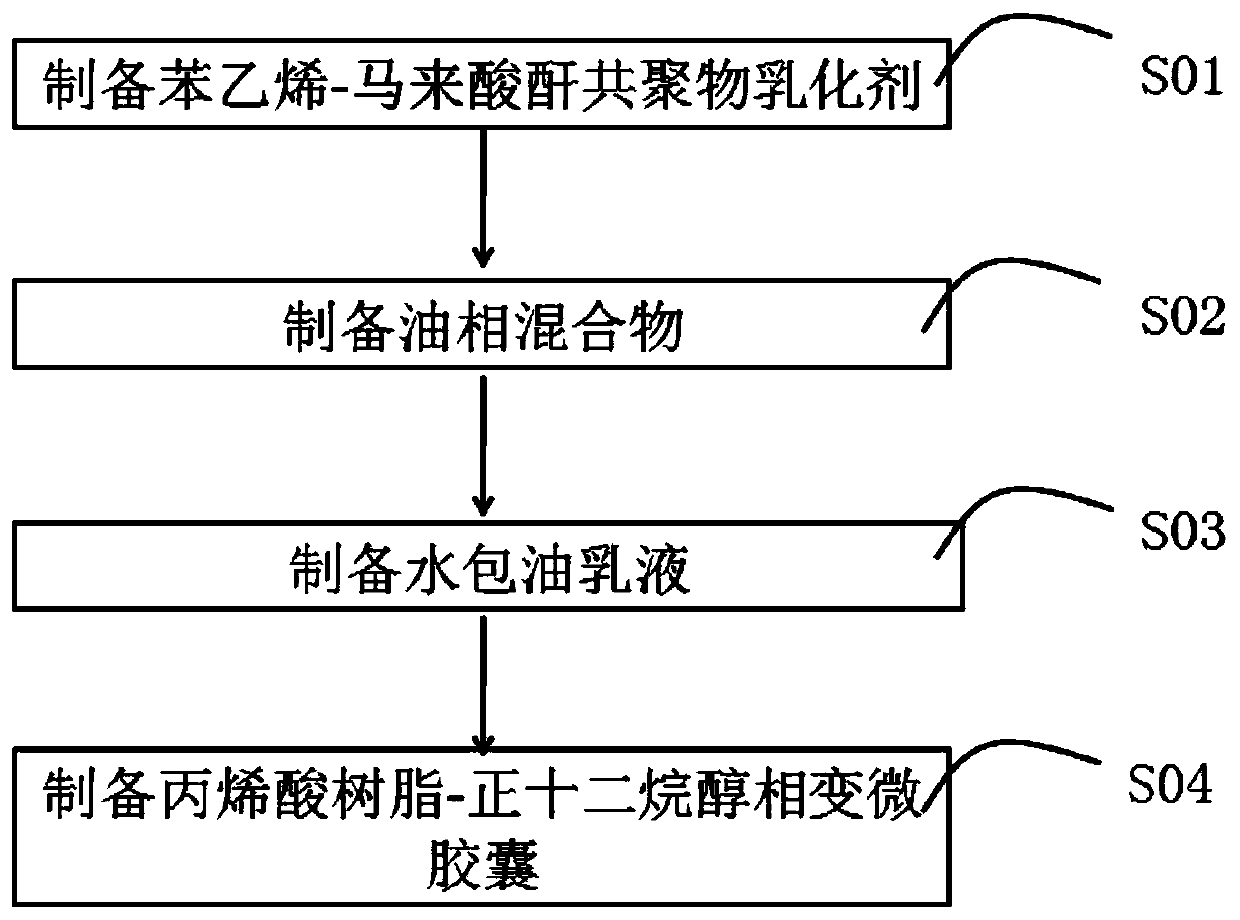

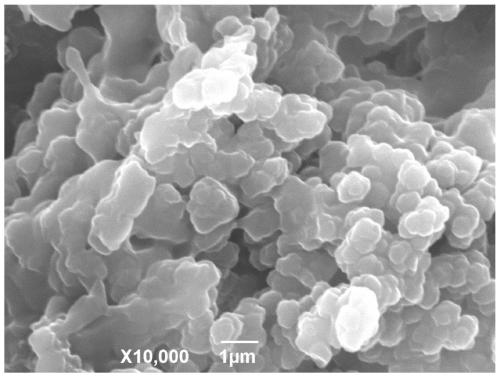

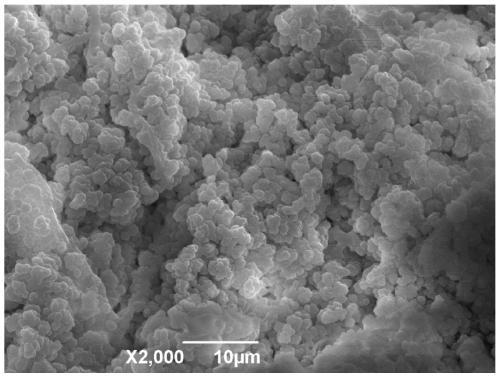

Phase change microcapsule based on ultrasound wave irradiation technology and preparing method

InactiveCN109825256AThe particle surface is uniform and smoothSmall particle sizeHeat-exchange elementsOil phaseSpherical shaped

The invention discloses a preparing method of a phase change microcapsule. The method includes the steps of preparing a styrene-maleic anhydride copolymer emulsifier, preparing an oil phase mixture, preparing an oil-in-water emulsion, and preparing the phase change microcapsule. The phase change microcapsule based on the ultrasound wave irradiation technology comprises a shell and a phase change material arranged in the shell. The shell comprises polyurethane acrylate, 1,4-butanediol diacrylate, acrylic acid and azodiisobutyronitrile. The phase change material is dodecyl alcohol. The phase change microcapsule presents the complete spherical shape, is smooth and uniform in surface, large in melting phase change latent heat, high in coating rate and high in temperature change response speedand is widely applied in the fields of building materials and air conditioning refrigeration.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

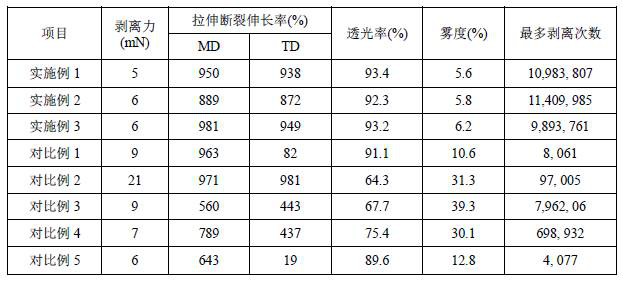

Three-layer composite release film for 3D printing process and preparation method of three-layer composite release film

ActiveCN114603955ARelease stabilityHigh mechanical strengthManufacturing platforms/substratesSynthetic resin layered productsPolymer scienceButanediol

The invention discloses a three-layer composite release film for a 3D printing process and a preparation method of the three-layer composite release film. The three-layer composite release film comprises a layer B and layers A arranged on the two sides of the layer B, the component of the layer A is poly (4-methyl-1-pentene); the component of the layer B is long-chain branch modified poly (4-methyl-1-pentene); the ratio of the total mass of the layer A to the mass of the layer B is 10: (1-5); the preparation method of the long-chain branch modified poly (4-methyl-1-pentene) comprises the following steps: mixing poly (4-methyl-1-pentene), a grafting monomer and an initiator, and carrying out melt extrusion to obtain the long-chain branch modified poly (4-methyl-1-pentene), and the grafting monomer comprises 1, 4-butanediol diacrylate and maleic anhydride. According to the invention, the poly (4-methyl-1-pentene) and the long-chain-chain modified poly (4-methyl-1-pentene) are respectively used as the surface layer and the middle layer, so that the prepared release film has excellent release property under the condition that a release agent is not added, and the film is high in light transmittance and good in mechanical property and can meet the use requirements in the 3D printing process.

Owner:NINGBO CHANGYANG TECH

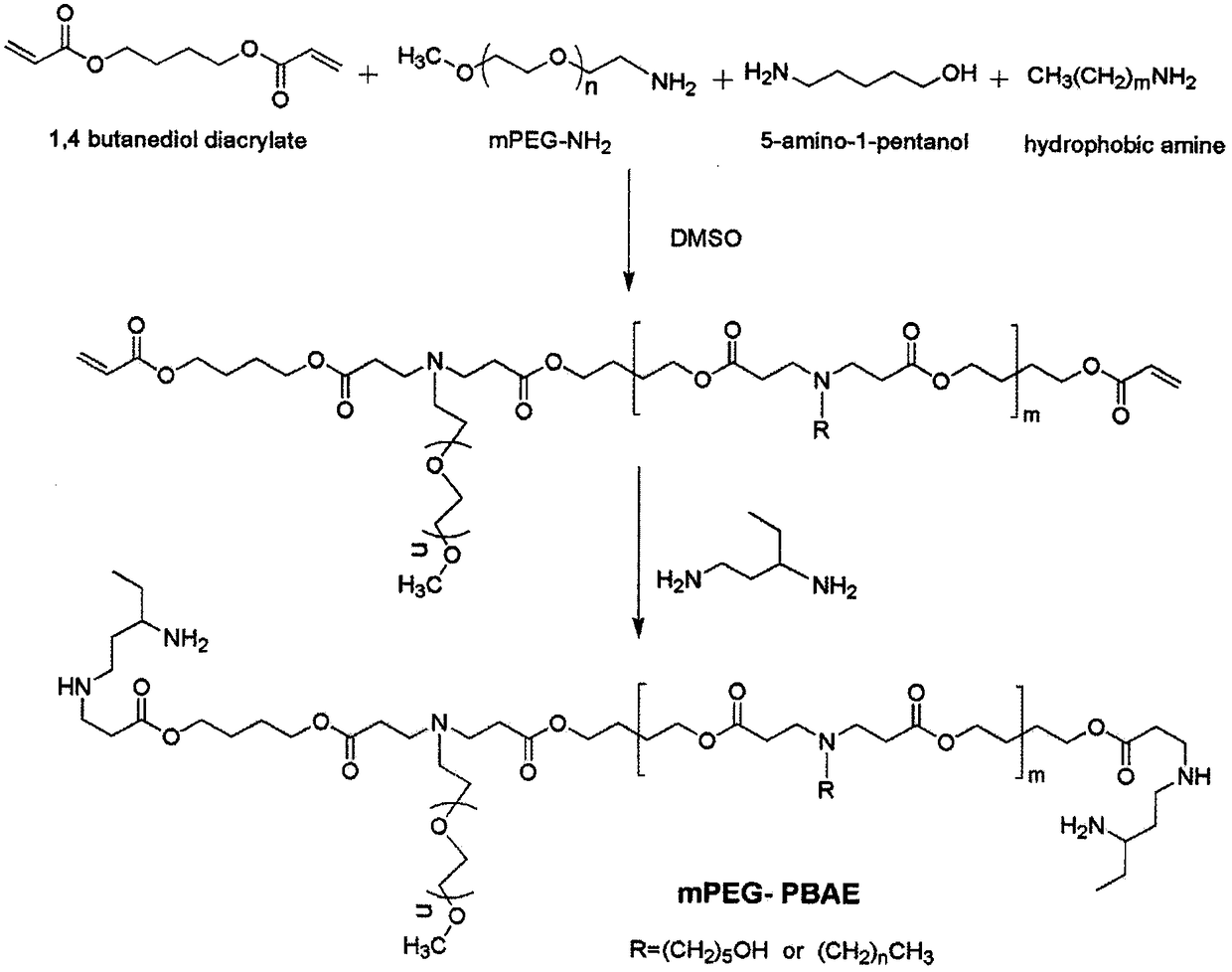

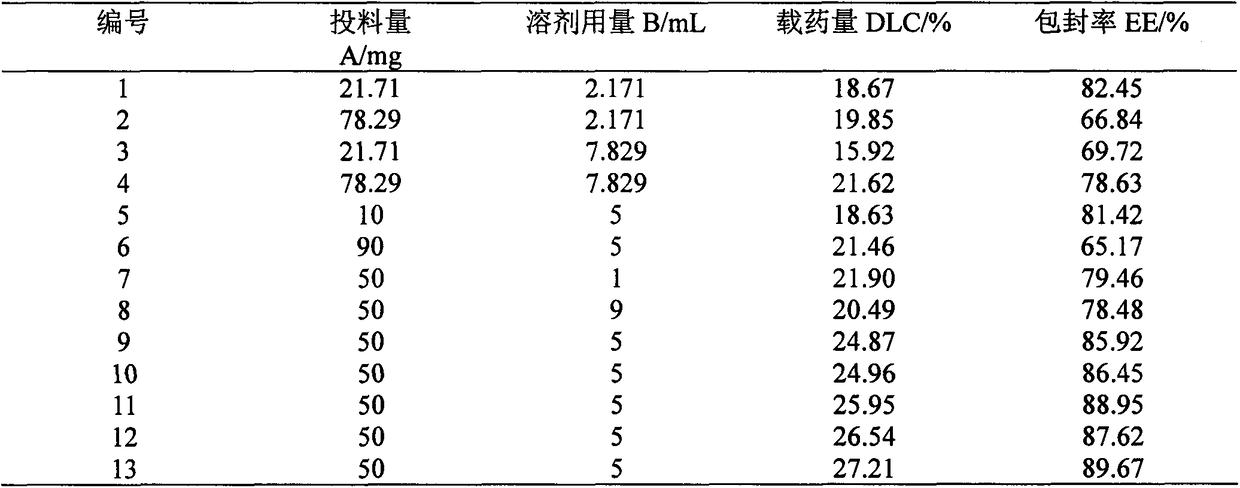

Preparation method of urushiol-loading pH responsive amphiphilic copolymer micelle

ActiveCN109303768ALow CMC valueImprove stabilityHydroxy compound active ingredientsPharmaceutical non-active ingredients1-PentanolPolyethylene glycol

The invention relates to a preparation method of urushiol-loading pH responsive amphiphilic copolymer micelle. The preparation method comprises the following steps: firstly, dissolving a certain amount of mPEG, hydrophobic amine monomer, 5-amino-1-pentanol and 1,4-butanediol diacrylate in DMSO to prepare a reaction solution with a certain concentration, performing polyreaction for 20-48h, then adding a certain amount of 1,3-pentanediamine, and continuing the reaction for 24h to synthesize polyethylene glycol-poly-beta-amino ester amphiphilic copolymer (mPEG-PBAE); and then taking and dissolving a certain amount of mPEG-PBAE and urushiol in DMF, performing uniform ultrasonic mixing, and performing dialyzing, centrifuging and filtering to obtain the urushiol-loading pH responsive amphiphiliccopolymer micelle. The drug-loading micelle has an average particle diameter of 140-160nm, good stability, obvious pH responsive drug-release property, good biocompatibility, and good targeting anti-tumor activity, can be applied to clinical targeting anti-tumor drugs, has very high added value, and can become a new technique for clinically developing urushiol targeting anti-tumor drugs.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Modified plate and preparation method thereof

The invention relates to a modified plate which comprises the following raw materials by mass percent: 75-80% of homopolymerized PP (propene polymer), 19-25% of PE (polyethylene) and 1-3% of assistant, wherein the assistant consists of dicumyl peroxide, an antioxidant 1010, styrene and 1,4-butylene glycol diacrylate. The invention further provides a preparation method of the modified plate. The plate is formed by melting and blending the raw materials and pressing. The plate is relatively ideal in properties such as tensile strength, elongation at break, flexural modulus and tearing strength, is particularly higher in shock resistance, and can be applied to an occasion with frequent shocks.

Owner:惠州市峄董塑胶科技有限公司

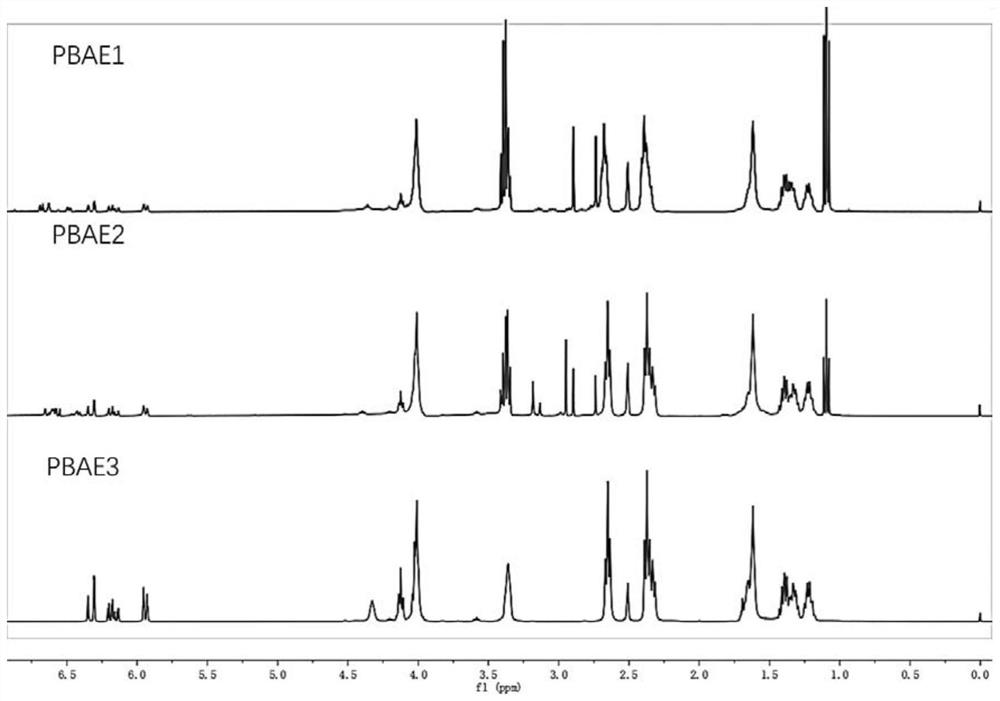

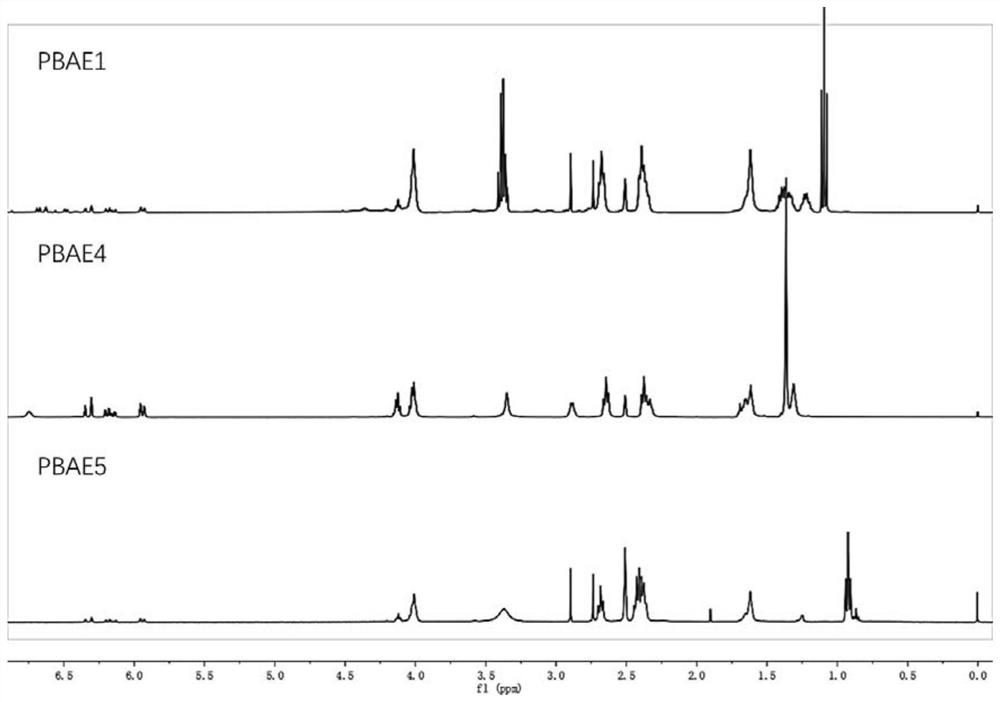

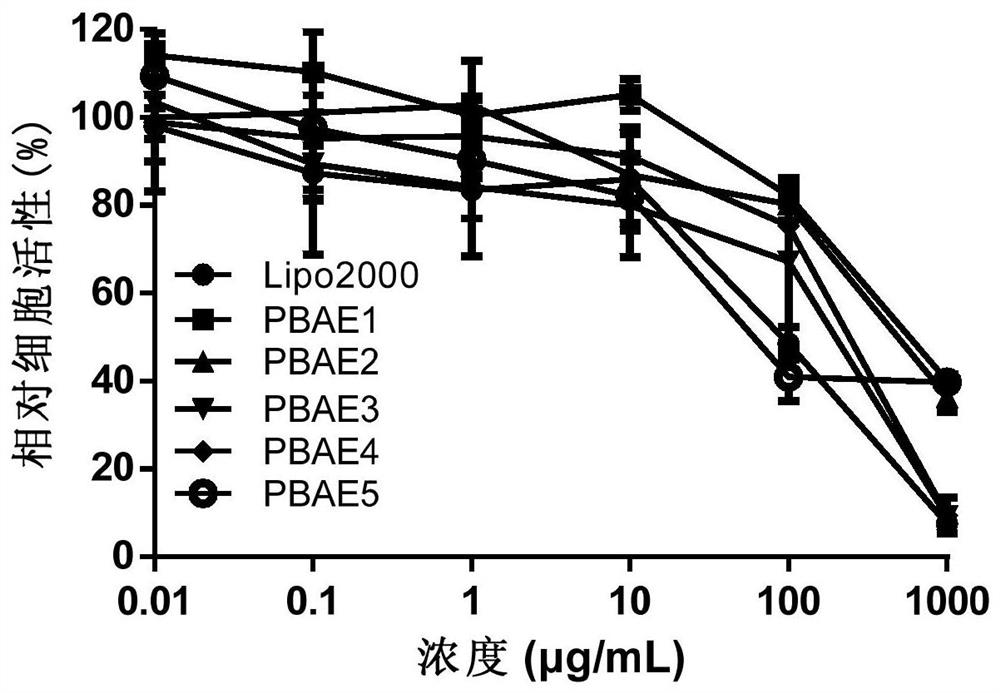

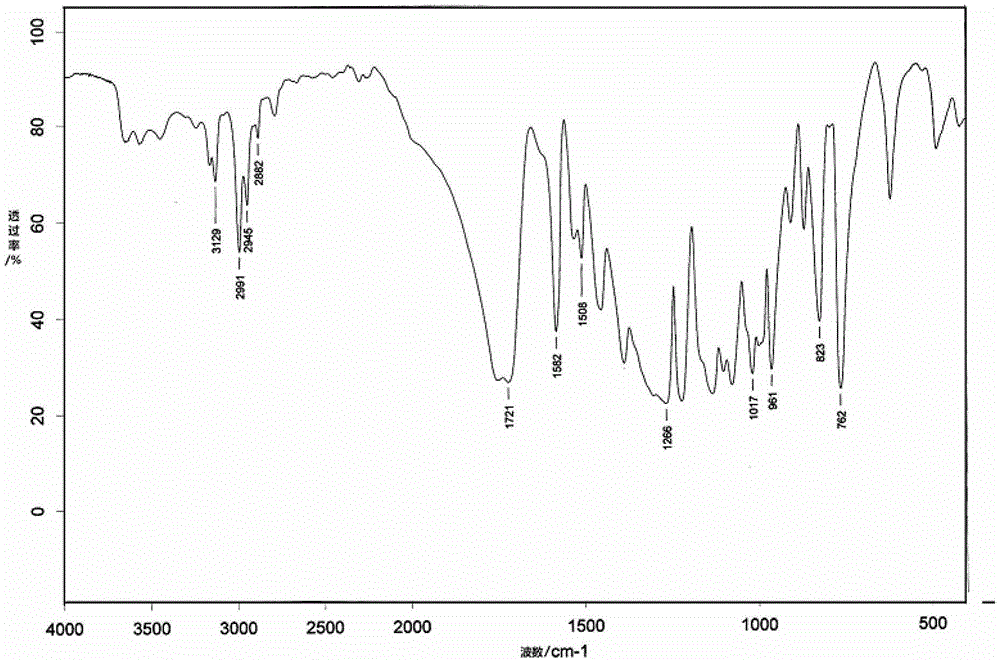

Dopamine functionalized poly(beta-amino ester) as well as preparation method and application thereof

ActiveCN112876677AImprove stabilityHigh transfection efficiencyOther foreign material introduction processesAmino estersCytotoxicity

The invention relates to the technical field of biology, and discloses dopamine functionalized poly(beta-amino ester) as well as a preparation method and application thereof. The structural formula of the poly(beta-amino ester) is shown in the specification, and the preparation method of the poly(beta-amino ester) comprises the steps: carrying out a polymerization reaction on 1,4-butanediol diacrylate and an amino-containing monomer; carrying out end capping on the polymer by adopting small molecular amine; and finally, carrying out deprotection on the phenolic hydroxyl group of dopamine to obtain the dopamine functionalized poly(beta-amino ester). Dopamine is introduced into PBAE, and ferric ions are complexed with the PBAE to form an encapsulated nanoparticle structure, so that the stability of a compound is improved, and a gene transfection vector with high transfection efficiency and low cytotoxicity is obtained, so that the gene transfection vector has potential clinical application value in the aspect of non-viral gene vectors.

Owner:ZHEJIANG UNIV HANGZHOU GLOBAL SCI & TECH INNOVATION CENT

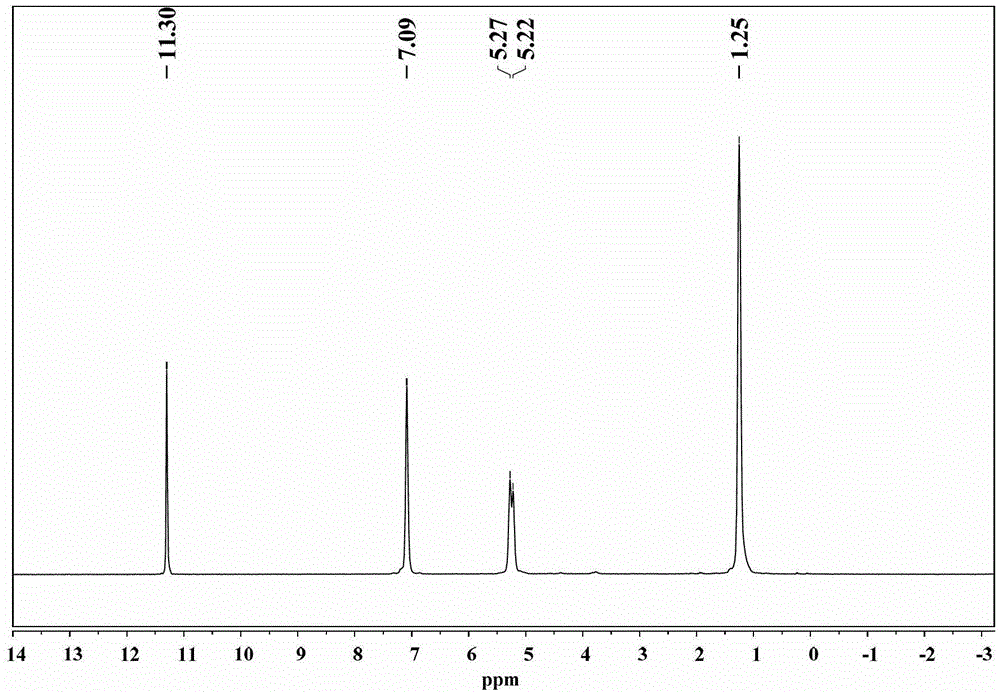

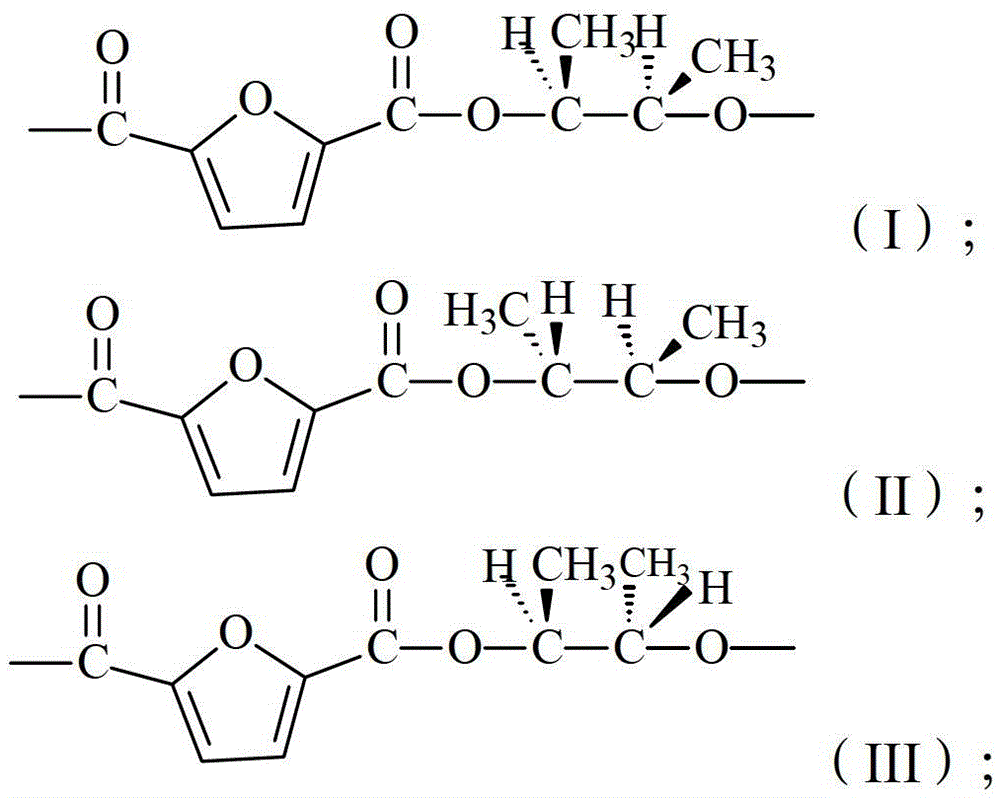

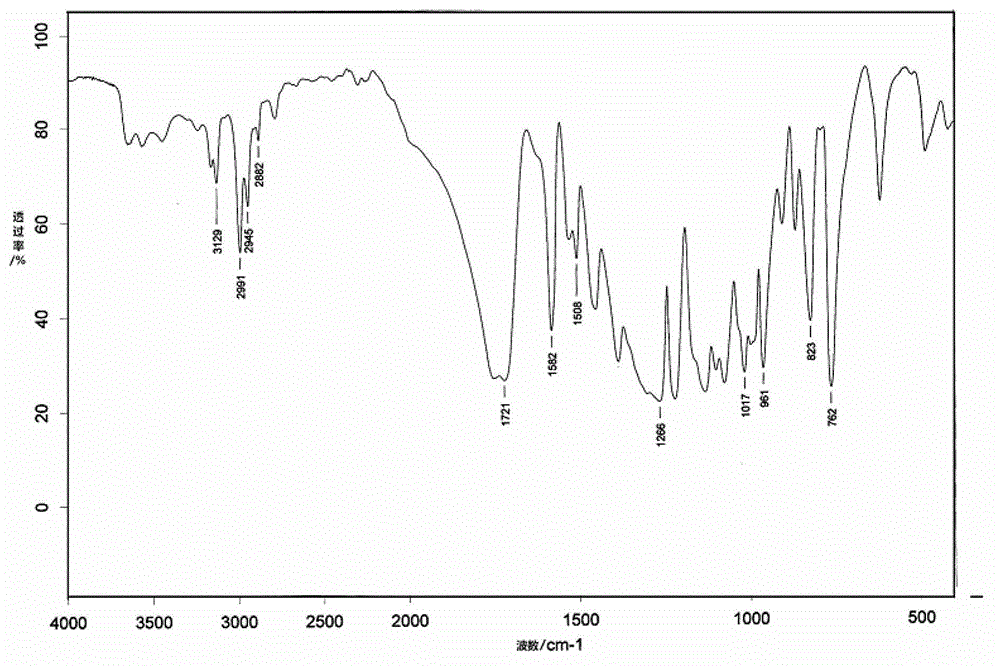

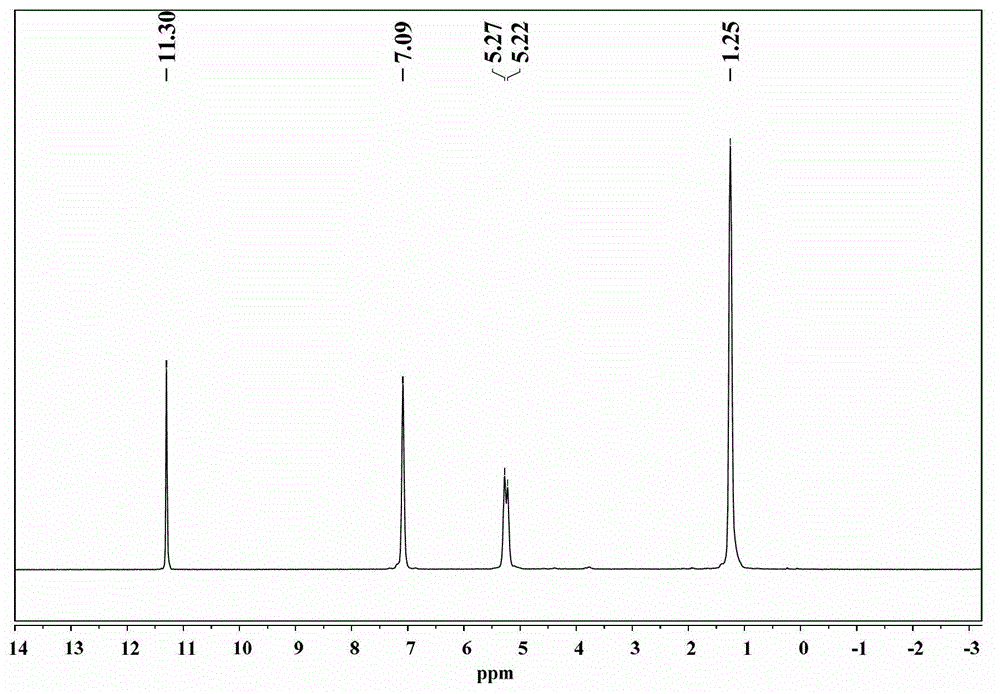

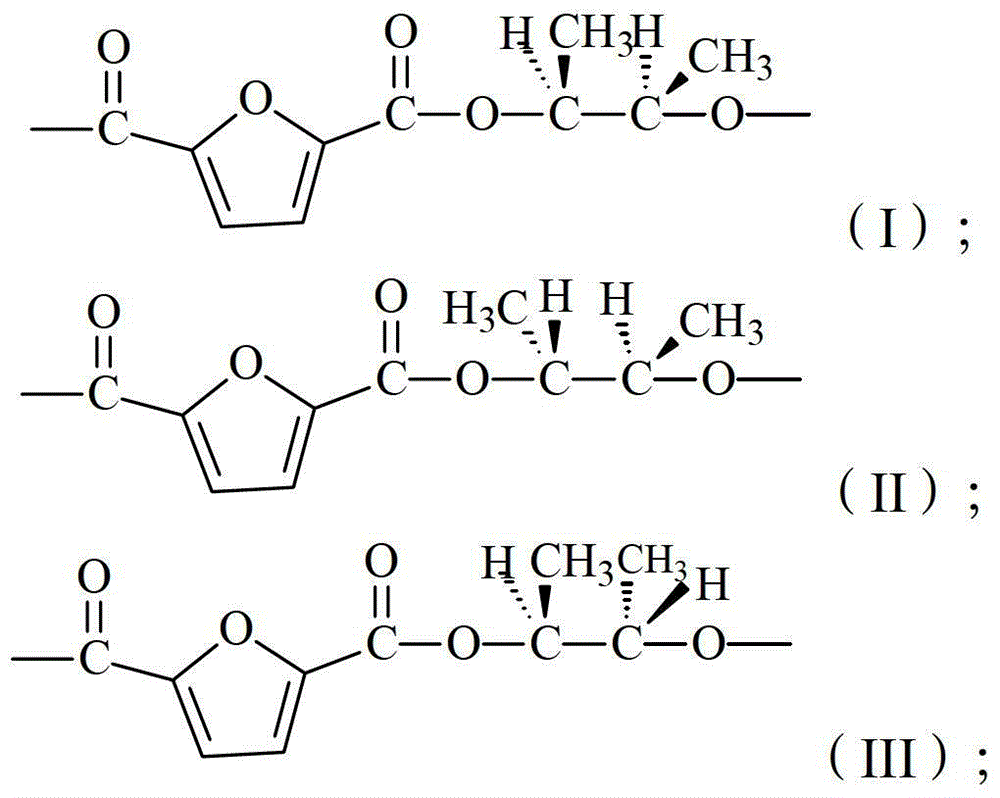

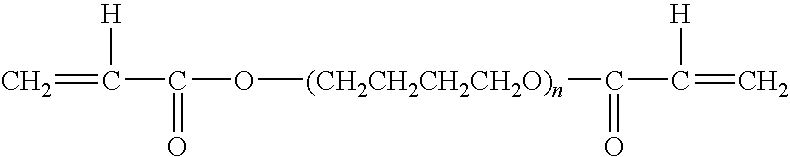

Poly furan-2,5-dicarboxylic acid-2,3-butanediol diacrylate and preparation method thereof

The invention provides poly furan-2,5-dicarboxylic acid-2,3-butanediol diacrylate and a preparation method thereof. The method comprises the following steps of reacting furan-2,5-dicarboxylic acid with 2,3-butanediol under the action of a tetravalent titanium compound catalyst, performing condensation polymerization on obtained intermediate products under the pressure of 10Pa-70Pa to obtain the product poly furan-2,5-dicarboxylic acid-2,3-butanediol diacrylate, wherein the tetravalent titanium compound catalyst comprises organic modifier-modified mesoporous silica and a tetravalent titanium compound which is loaded onto the mesoporous silica, wherein an organic modifier is a titanate coupling agent or a silane coupling agent. The product has at least one of first repeating unit shown by a formula (I), a second repeating unit shown by a formula (II) and a third repeating unit shown by a formula (III), and the intrinsic viscosity of the product is not lower than 0.5 deciliter per gram (0.5dL / g). Moreover, the preparation method is environmentally friendly and simple.

Owner:芜湖万隆新材料有限公司

Color-fixing printing sizing agent

InactiveCN104928949AGood color fixation and adhesionImprove adhesionDyeing processHydroxyethyl starchTextile printer

A color-fixing printing sizing agent comprises, by weight, 9-14 parts of dimethyl distearylammonium chloride, 7-9 parts of citric acid, 6-8 parts of emulgators, 10-15 parts of acetyl tributyl citrate, 4-9 parts of 4,4'-oxydibenzenesulfonyl hydrazide, 2-7 parts of antimonous oxide, 1-4 parts of plasticizers, 2-4 parts of antifreezes, 7-10 parts of hydroxyethyl starch ether, 3.2-7 parts of maleic anhydride, 4-6 parts of guar gum, 2-7 parts of organic silicon defoamers, 7-8 parts of butanediol diacrylate, 1-4 parts of protein sizing agents, 6-11 parts of PVA sizing agents and 3-8 parts of dye. The color-fixing printing sizing agent has the advantages that the printing sizing agent is good in color fixation and cohesiveness performance, capable of being well adhered to cloth, poisonless and harmless.

Owner:QINGDAO JINGSHITONG PRECISION MACHINERY MFG

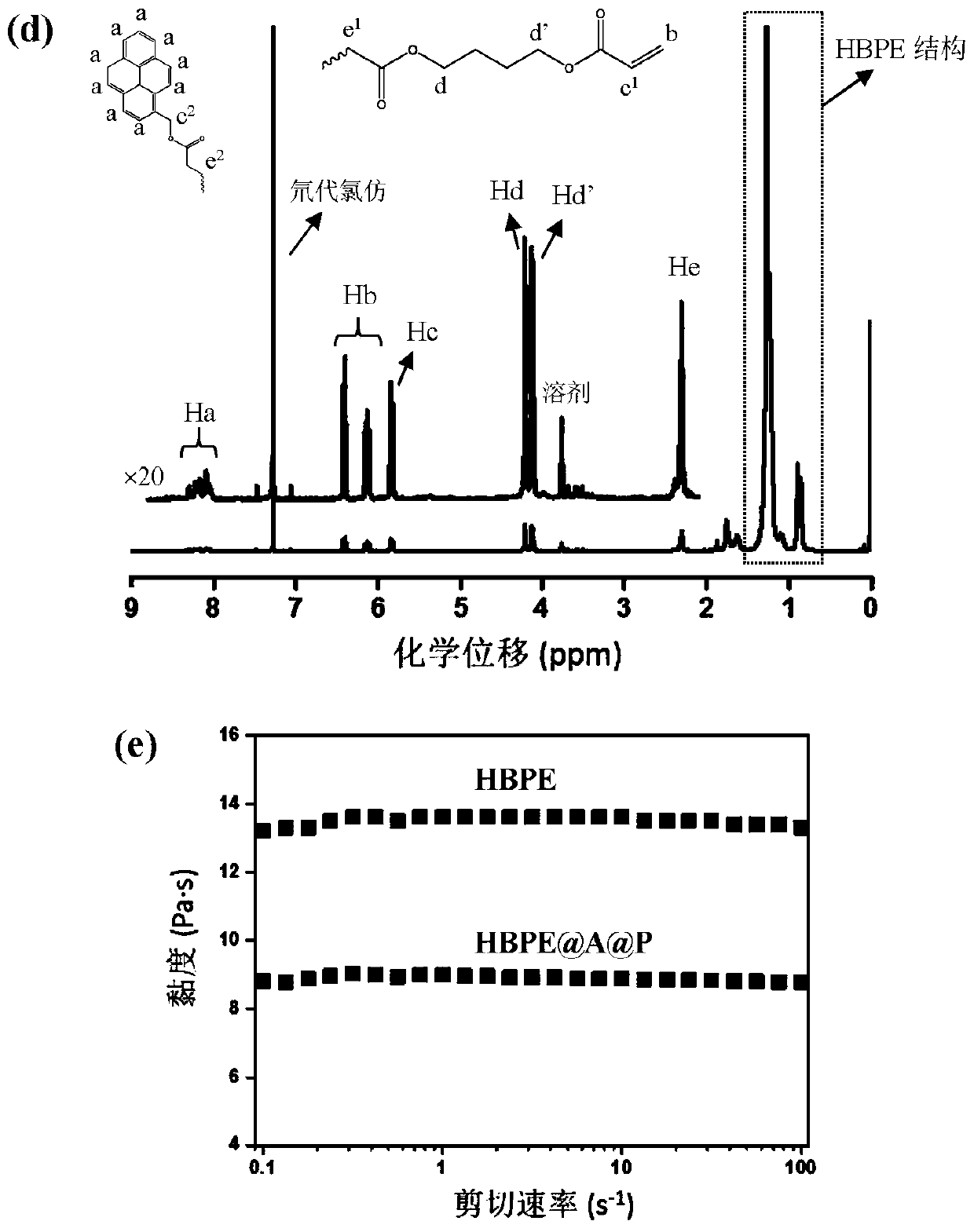

Functional hyperbranched polyethylene and preparation thereof, and application thereof in preparation of high-stability flexible conductive/electro-thermal film

InactiveCN111320718AImprove production efficiencyImprove stabilityBulk chemical productionPolymer sciencePtru catalyst

The invention discloses functional hyperbranched polyethylene and application thereof in the preparation of a high-stability flexible conductive / electro-thermal film. The functional hyperbranched polyethylene is obtained by catalyzing 1,4-butanediol diacrylate shown as a formula (I), a pyrene-containing monomer shown as a formula (II) and ethylene through a Pd-diimine catalyst according to a one-step chain transfer copolymerization mechanism. The invention provides an application of functional hyperbranched polyethylene in the preparation of a flexible conductive / electro-thermal film. The preparation method specifically comprises the following steps: (1) stripping graphite from the functional hyperbranched polyethylene by virtue of ultrasonic waves to obtain a graphene dispersion liquid; (2) painting the functional HBPE containing graphene dispersion liquid prepared in the step (1) on a flexible substrate; and (3) carrying out an ultraviolet curing treatment on a graphene layer containing filter membrane obtained in the step (2) to obtain the flexible conductive / electro-thermal film. The graphene dispersion liquid is obtained by utilizing the functional hyperbranched polyethylene,and the flexible conductive / electro-thermal film prepared from the graphene dispersion liquid has excellent stability.

Owner:ZHEJIANG UNIV OF TECH +1

Co-crosslinking immobilization method of penicillin G acylase

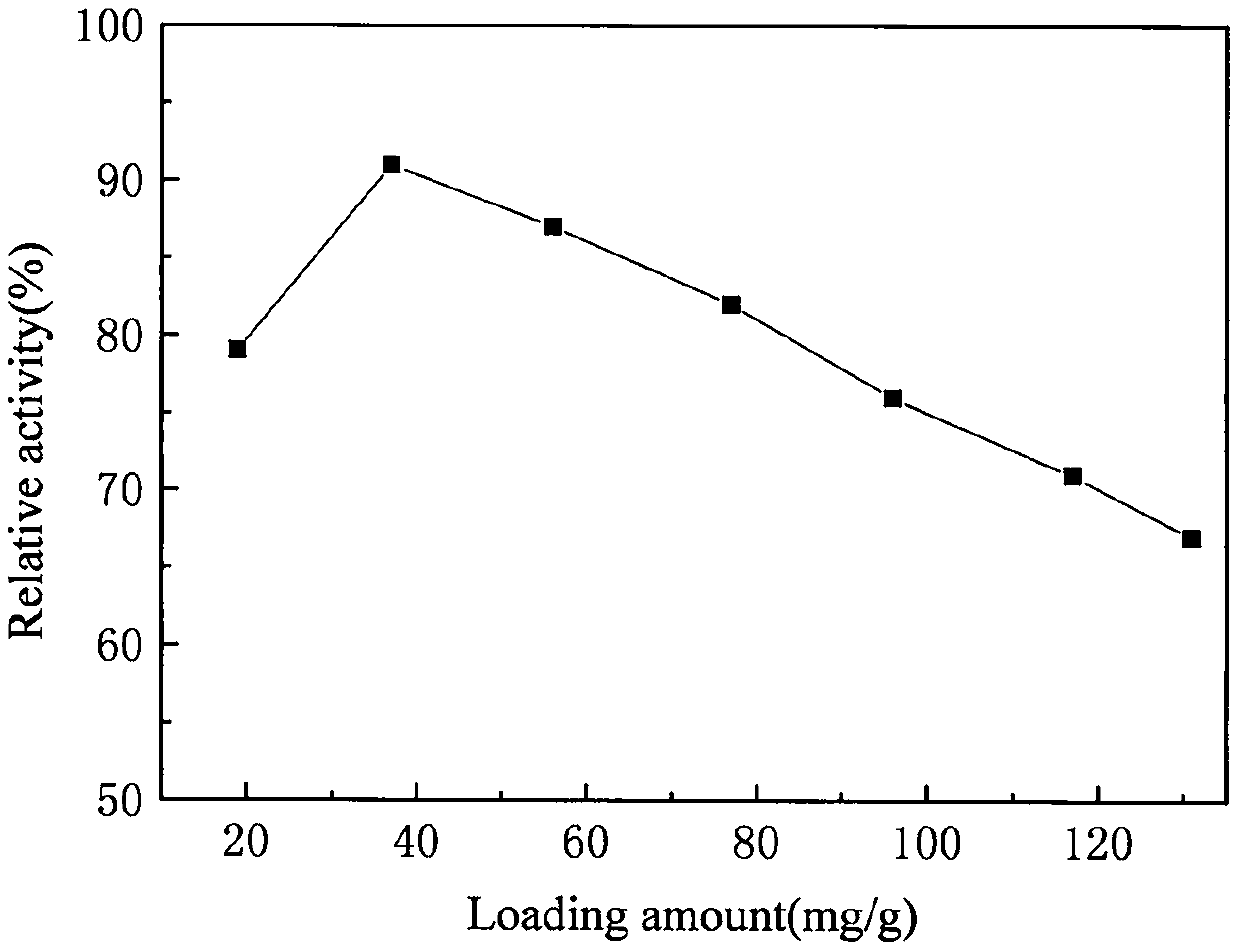

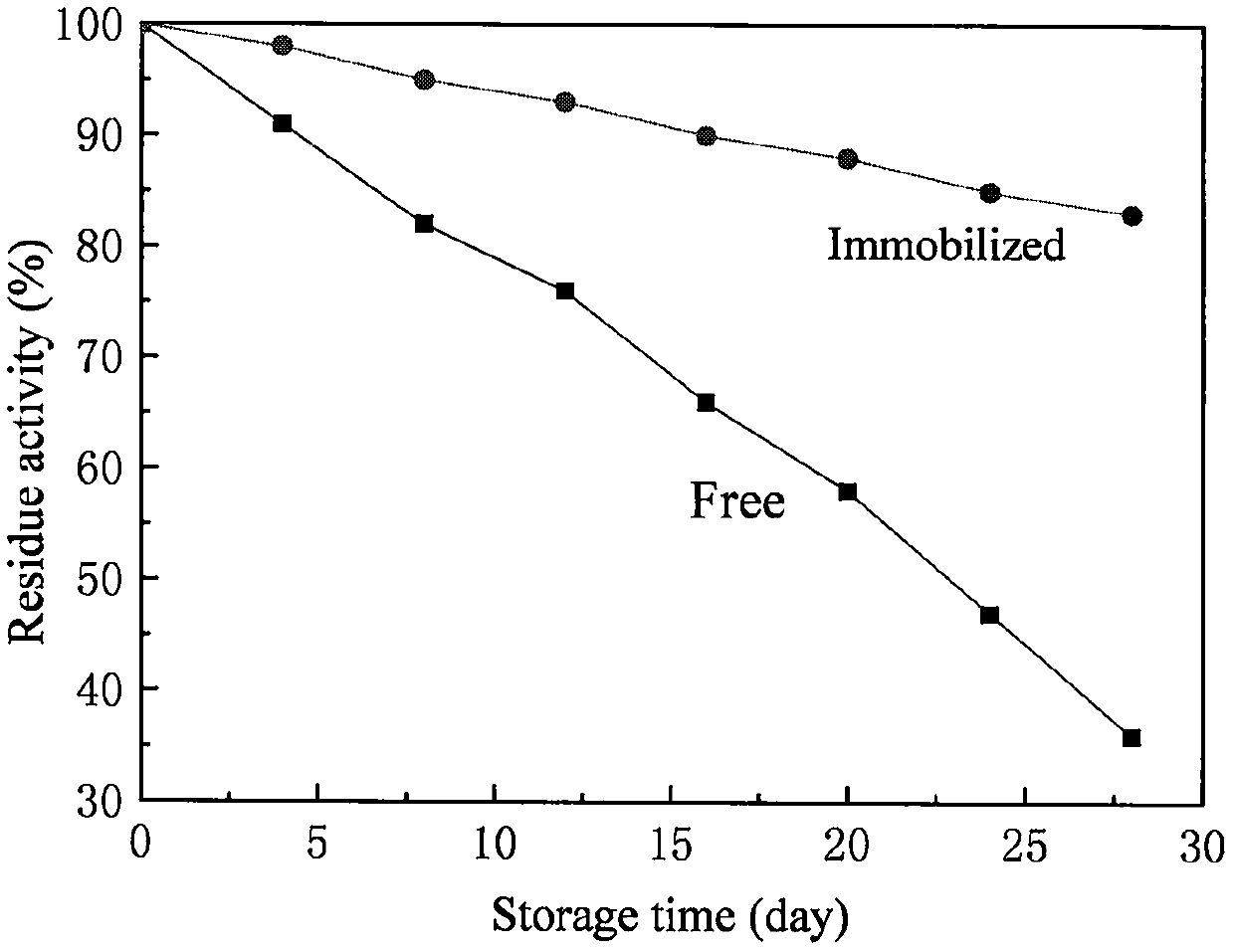

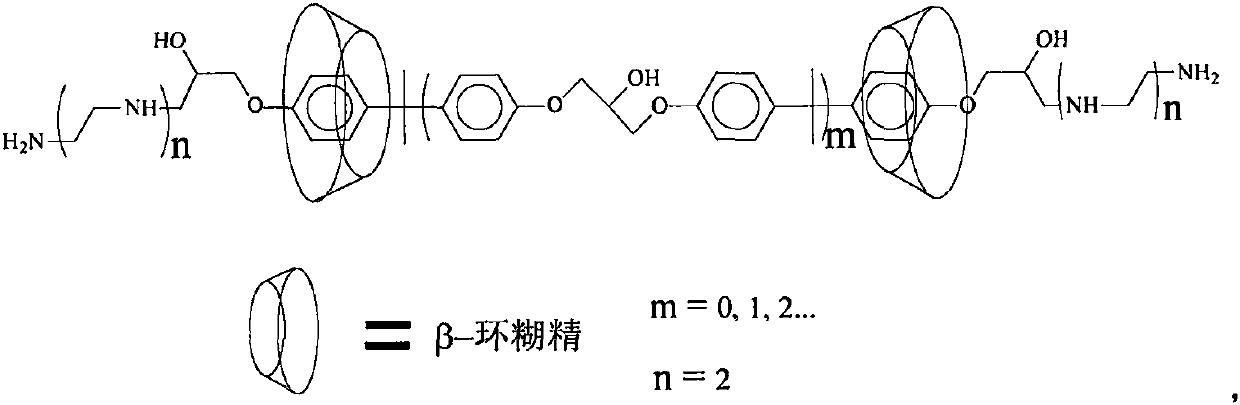

ActiveCN110760496AImprove microenvironmentHigh catalytic activityHydrolasesChemical industryEpoxyPolymer science

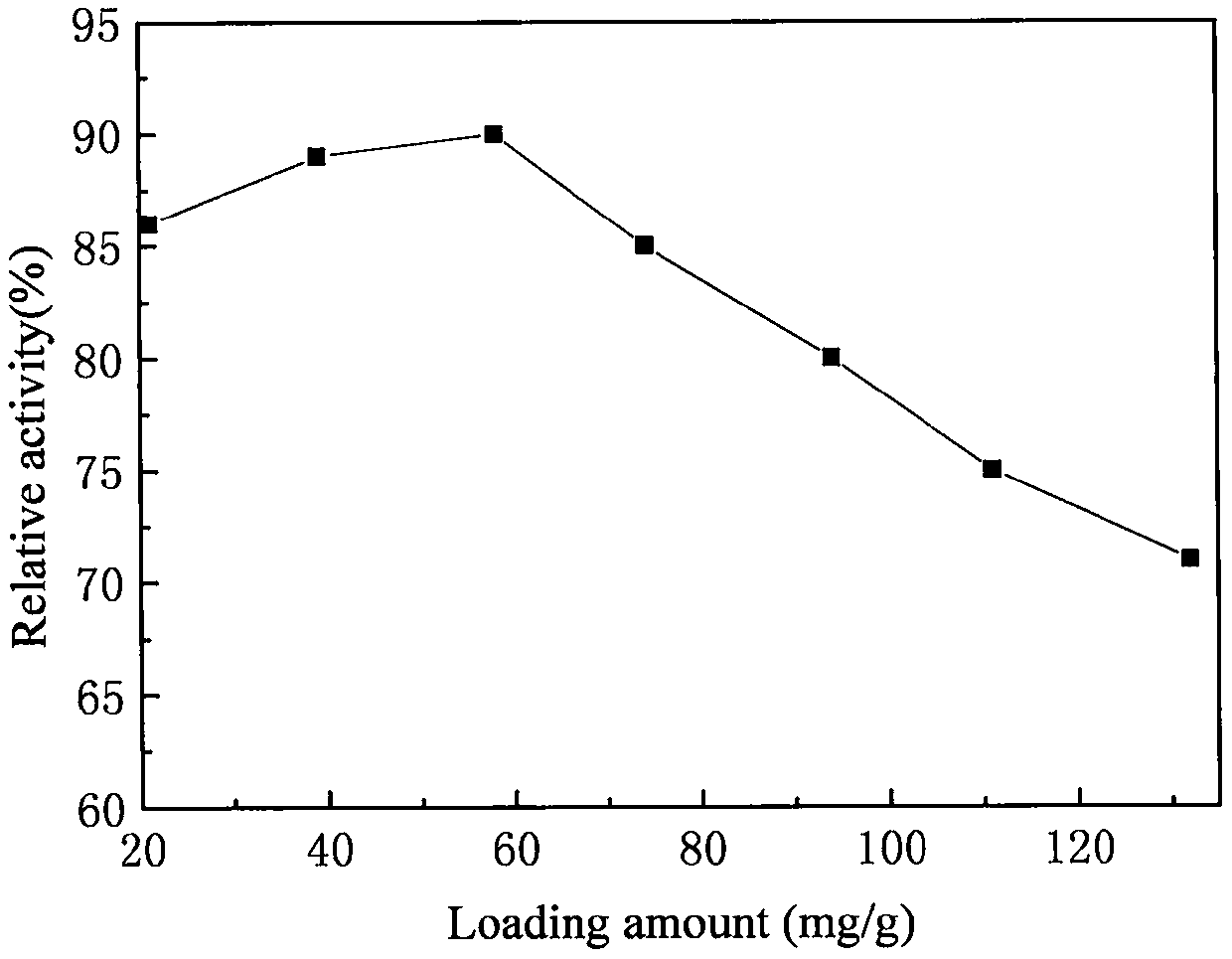

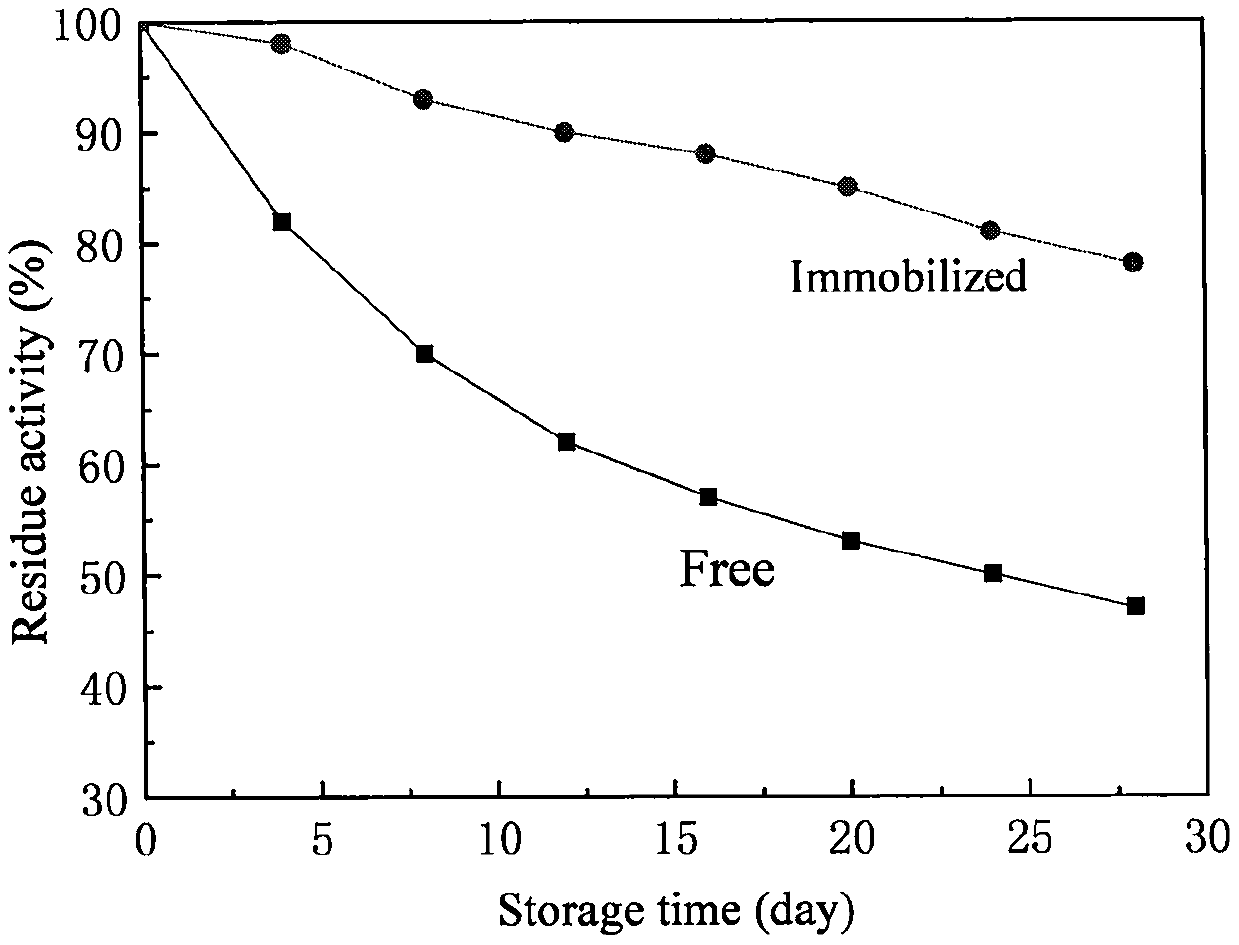

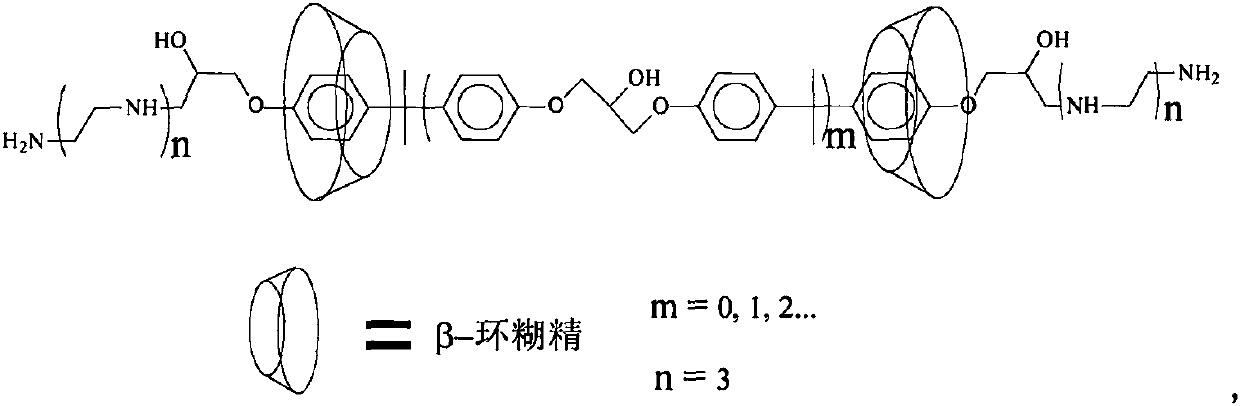

The invention discloses a co-crosslinking immobilization method of penicillin G acylase. According to the co-crosslinking immobilization method of the penicillin G acylase, oil-soluble butanediol diacrylate is used as a crosslinking agent; penicillin G acylase containing amino groups, as well as a supramolecular complex formed by aminated epoxy resin and beta-cyclodextrin are used as reactants inan aqueous phase; and then, through a Michael addition reaction of the amino groups with double bonds, co-crosslinking polymerization is conducted at a relatively low temperature so as to prepare immobilized penicillin G acylase with different loading capacity. With crosslinking degree controlled, dispersivity enhanced and internal mass transfer microenvironment improved, the immobilized penicillin G acylase has relatively high catalytic activity that relative activity of the immobilized penicillin G acylase can be up to 91% of that of free enzyme when the loading capacity is 37 milligrams ofthe immobilized penicillin G acylase per gram of carrier.

Owner:NINGBO UNIV

Temporary plugging agent capable of realizing well zone seepage and preparation method thereof

ActiveCN114044851AUnblocking time is adjustableAutomatic adjustment of unblocking timeProductsReagentsMeth-Neopentylglycol diacrylate

The invention provides a temporary plugging agent capable of realizing well zone seepage and a preparation method thereof. The temporary plugging agent is prepared by the following steps: dissolving an acrylamide monomer and a glyceryl allyl ether monomer in a solvent, adding N,N-methylene acrylamide, an acrylate compound, and an initiator, continuously reacting for 5-12 hours, and after reaction, drying to obtain thetemporary plugging agent, wherein the acrylate compound is one of butanediol diacrylate, dipropylene glycol acrylate and neopentyl glycol diacrylate, the mass ratio of N,N-methylene acrylamide to the acrylate compound is 1: (5-12), and the mass of N,N-methylene acrylamide accounts for 0.08%-0.15% of the total mass of the monomer. According to the temporary plugging agent, the plugging rate is high and can reach 95% or above, the plug removal rate is high and can reach 82% or above, residual gel obtained after plug removal is conducted finally is little, the influence on the stratum is small, and the temporary plugging agent can be used for well zone seepage volume fracturing.

Owner:西安维克特睿油气技术有限公司

Method for preparing 4-hydroxybutyl acrylate by means of extraction and separation

InactiveCN109053450ASimple processLow costOrganic compound preparationPreparation by ester-hydroxy reactionSolventAqueous solution

The invention relates to a method for preparing 4-hydroxybutyl acrylate by means of extraction and separation. The method is characterized by comprising the following steps: (1) putting 1, 4-butanediol, a catalyst, a polymerization inhibitor and a solvent into a reactor to form mixed liquid; (2) slowly heating and controlling the temperature to be 40-60 DEG C, and dropwise adding acrylic acid containing a certain amount of the polymerization inhibitor for 30-50min at the temperature; (3) continuously and slowly heating and controlling the temperature to be 100-120 DEG C, carrying out a refluxreaction for 2-5h reaction and then finishing the reaction; (4) adding aqueous solution into the mixed liquid and then adding a certain amount of extractant for firstly extracting 1, 4-butanediol diacrylate from an aqueous phase; (5) extracting the 4-hydroxybutyl acrylate from the aqueous phase by using an extractant; (6) distilling under reduced pressure to obtain a finished product. The productof the method is colorless and does not need to be faded, so that the aftertreatment process is simpler, and the quality and yield of the final product are increased.

Owner:QINGDAO UNIV OF SCI & TECH

Active energy beam-curable ink

InactiveUS20100234523A1Increase flexibilityDuplicating/marking methodsInksDiacrylate esterUrethane acrylate

An active energy beam-curable ink, comprising a polytetramethylene glycol diacrylate, a bifunctional to tetrafunctional urethane acrylate and a colorant, wherein an amount of the polytetramethylene glycol diacrylate relative to a total mass of the ink is not less than 35% by mass, and an amount of the bifunctional to tetrafunctional urethane acrylate relative to a total mass of the ink is within a range from 5 to 35% by mass.

Owner:RISO KAGAKU CORP

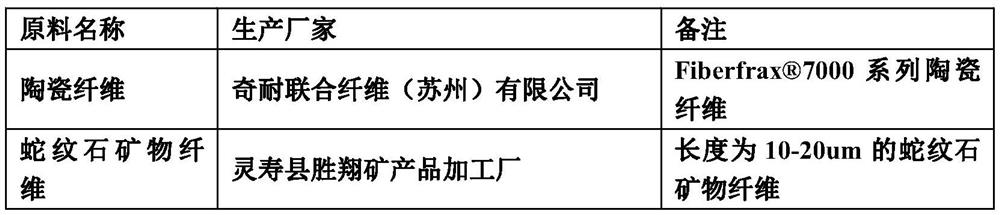

High-temperature-resistant adhesive tape and preparation method thereof

PendingCN113072893AImprove high temperature resistanceImprove stabilityNon-macromolecular adhesive additivesFilm/foil adhesivesMeth-Adhesive belt

The invention relates to the field of adhesive tapes, in particular to a high-temperature-resistant adhesive tape and a preparation method thereof. The high-temperature-resistant adhesive tape comprises a base material and a high-temperature-resistant adhesive layer, and the high-temperature-resistant adhesive layer is prepared from butyl acrylate, acrylic acid, methacrylamide, ceramic fibers, ammonium persulfate and modified serpentine mineral fibers. The modified serpentine mineral fibers are prepared by the following steps of: uniformly stirring serpentine mineral fibers, polytetrafluoroethylene fibers, 1, 4-butanediol diacrylate, a dispersing agent and deionized water, heating, performing ultrasonic treatment, filtering, drying, adding nano aluminum oxide, uniformly mixing, roasting, and cooling to room temperature, thereby obtaining the modified serpentine mineral fibers. According to the high-temperature-resistant adhesive tape, the modified serpentine mineral fibers cooperate with the ceramic fibers, so that the high-temperature-resistant effect of the high-temperature-resistant layer is improved, and the prepared high-temperature-resistant adhesive tape has relatively good stability and adhesion at 200-250 DEG C and a relatively good high-temperature-resistant effect.

Owner:东莞市美鑫工业胶带有限公司

Ammonium dinitramide with moisture-absorption-preventing coating layer and preparation method of ammonium dinitramide

ActiveCN113072415AGood compatibilityImprove securityNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsMoisture absorptionButanediol

The invention discloses a preparation method of ammonium dinitramide with a moisture-absorption-preventing coating layer. The preparation method comprises the following steps: mixing an energetic macromolecular prepolymer, 1,4-butanediol diacrylate and ammonium dinitramide particles in dichloromethane, conducting uniform stirring, performing standing for 25-45 minutes, and then conducting mixing with n-hexane heated to 55-65 DEG C to obtain a mixture; and subjecting the mixture to a reflux reaction for 5-6 h at a temperature of 65-68 DEG C so as to obtain cross-linked, cured and coated ammonium dinitramide particles, wherein a mass ratio of ammonium dinitramide to dichloromethane to the energetic macromolecular prepolymer to 1,4-butanediol diacrylate to n-hexane is 1: 30: 0.02: (0.01-0.0055): 40. The compatibility between the coating layer and ADN is good, the safety of an ADN coating process can be greatly improved, and the saturation moisture absorption rate of the ADN with the moisture-absorption-preventing coating layer is only 0.65% under the conditions that relative humidity is 50% and temperature is 35 DEG C.

Owner:XIAN MODERN CHEM RES INST

Special plastic gravure printing ink with high stability

A special plastic gravure printing ink with high stability is prepared from the following raw materials in parts by weight: 2.5-4.6 parts of MP resin liquid, 0.15-0.3 part of fumed silica, 3-6 parts of propylene glycol methyl ether, 2-4 parts of urea, 12-16 parts of epoxy resin, 8-12 parts of a wetting dispersant BYK-19, 7-13 parts of methyl silicone oil, 5-15 parts of isopropyl alcohol, 6-15 parts of a yellow printing ink, 4-7 parts of 1,4-butylene glycol diacrylate, 8-14 parts of hydroxyl fluorine silicon resin, 5-10 parts of silver powder, 8-14 parts of vegetable oil, 1-4 parts of silicon carbide, 5-7 parts of dimethyl phthalate, 1-3 parts of dibutyl phthalate and 1.5-3.2 parts of ethanolamine. The special plastic gravure printing ink has the benefits of high hardness, high high-temperature resistance, high water resistance, high drying speed, good stability and excellent adhesion.

Owner:王丽萍

Co-crosslinking immobilization method for acid urease

ActiveCN110777141AHigh catalytic activityImprove microenvironmentHydrolasesChemical industryEpoxyPolymer science

The invention relates to a co-crosslinking immobilization method for acid urease. Oil-soluble butanediol diacrylate is used as a cross-linking agent; reactant in an aqueous phase is amino-containing acid urease and a supramolecular complex formed by aminated epoxy resin and beta-cyclodextrin; and through the utilization of the Michael addition reaction of double bonds and amino groups, co-crosslinking polymerization can occur under a low temperature, and immobilized acid urease with different loading amount can be prepared. Through the controlling of the degree of cross-linking, dispersibilitycan be enhanced, internal mass transfer microenvironment can be improved; and the immobilized enzyme can have high catalytic activity when the loading amount is in the range of 21-58 mg enzyme / g carrier, and the highest relative activity can reach 90% of free enzymes.

Owner:NINGBO UNIV

High-adhesion pearized silver printing ink and preparation method thereof

The invention relates to high-adhesion pearized silver printing ink which comprises the following components in parts by weight: 50 parts of pearl powder, 35 parts of silver powder, 52 parts of hydroxy fluorosilicone resin, 20 parts of 1,4-butanediol diacrylate, 6 parts of diammonium citrate, 6 parts of butyl glycidyl ethe, 0.8 parts of octaphenyl polyoxyethyiene, 0.5 parts of antioxidant 1010 and 80 parts of mixed solvent. The environment-friendly printing ink adopts the mixed solvent of dimethyl carbonate and trimethylolpropane polyether with the molecular weight of 400-1000, is basically free of toxic chemicals such as benzene and methylbenzene, is very excellent in environment-friendly property, and has excellent dissolving and dispersing properties for resin and a pigment; good durability is endowed for the printing ink; very good printing quality is represented; the environment-friendly printing ink is suitable for silk-screen printing of the surfaces of glass and a PMMA (polymethyl methacrylate) substrate; and after the printing ink is dried, the printing ink is bright in color, stable in adhesivity, and good in oil resistance and alcohol resistance.

Owner:SUZHOU ANJIE TECH

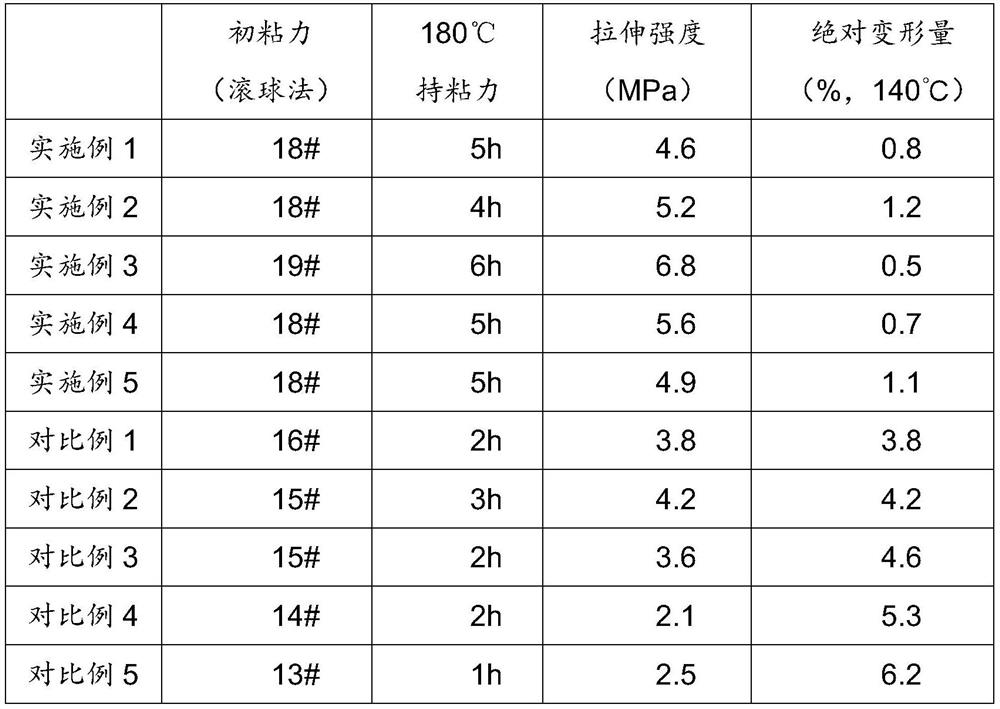

High-tensile-resilience heat-resistant pressure-sensitive adhesive and preparation method thereof

InactiveCN112592682AIncrease elasticityGood initial adhesionGraft polymer adhesivesPolymer scienceMeth-

Owner:张家港保税区汇英聚福材料科技合伙企业(有限合伙)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com