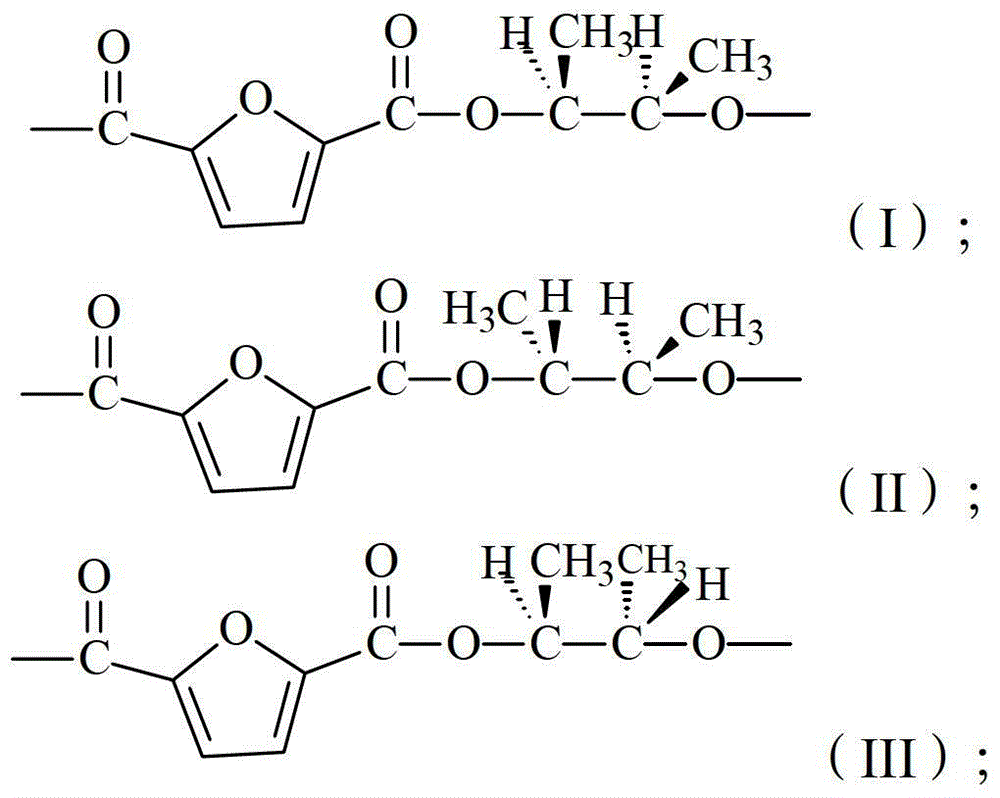

Poly furan-2,5-dicarboxylic acid-2,3-butanediol diacrylate and preparation method thereof

A technology of furandicarboxylic acid and butanediol ester, which is applied in the field of polyester, can solve the problems that are not completely based on renewable resources, environmental friendliness needs to be improved, and achieve the effect of simple operation and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention also provides a preparation method of poly-2,5-furandicarboxylate-2,3-butylene glycol, comprising the following steps:

[0037] a) reacting 2,5-furandicarboxylic acid and 2,3-butanediol under the action of a tetravalent titanium compound catalyst to obtain an intermediate product;

[0038] b) polycondensing the intermediate product under the condition of a pressure of 10Pa to 70Pa to obtain poly-2,5-furandicarboxylate-2,3-butylene glycol;

[0039] Described tetravalent titanium compound catalyst comprises:

[0040] Mesoporous silica modified by an organic modifier, the organic modifier is a titanate coupling agent or a silane coupling agent;

[0041] A tetravalent titanium compound supported on the mesoporous silica.

[0042] In the embodiment of the present invention, 2,5-furandicarboxylic acid, 2,3-butanediol and a tetravalent titanium compound catalyst are firstly mixed, and then reacted to obtain an intermediate product.

[0043] The inventi...

Embodiment 1

[0064] In the reactor, add 0.6g specific surface area is 850m 2 / g of dry SBA-15, 0.06g of isopropyl tris (dioctyl pyrophosphoryl) titanate organic modifier and 300mL of toluene, nitrogen with a flow rate of 0.5L / min as protective gas, dispersed by ultrasonic After 30 minutes, continue to stir and heat to 90°C for reaction. After 5 hours of reaction, the obtained reaction product dispersion liquid is rotary evaporated, and the solid obtained after rotary evaporation is washed and filtered to obtain organic modifier-modified SBA- 15;

[0065] In the loader, add 0.4g of SBA-15 modified by the organic modifier, 0.2g of tetrapropyl titanate and 200mL of toluene, pass through nitrogen as a protective gas, and after ultrasonic vibration for 30min, magnetically stir at 25°C After 48 hours, stop stirring and heating. After the reaction, excess tetrapropyl titanate was removed by suction filtration and washing, repeated several times, and then dried to obtain tetrapropyl titanate / SBA...

Embodiment 2

[0068] In the reactor, add 0.6g specific surface area is 1000m 2 / g dry MCM-41, 0.03g gamma aminopropyltrimethoxysilane organic modifier and 300mL toluene, nitrogen gas with a flow rate of 0.5L / min as protective gas, after ultrasonic dispersion for 30min, continue stirring and heating to The reaction was carried out at 90°C, and after 5 hours of reaction, the obtained reaction product dispersion liquid was rotated to evaporate, and the solid obtained after the rotary evaporation was washed and filtered to obtain MCM-41 modified by an organic modifier;

[0069] In the loader, add 0.4g of MCM-41 modified by the organic modifier, 0.4g of tetrabutyl titanate and 200mL of toluene, pass through nitrogen as a protective gas, and after ultrasonic vibration for 30min, magnetically stir at 25°C After 48 hours, stop stirring and heating. After the reaction, excess tetrabutyl titanate was removed by suction filtration and washing, repeated several times, and then dried to obtain tetrabut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com