Phase change microcapsule based on ultrasound wave irradiation technology and preparing method

A technology of phase change microcapsules and irradiation technology, which is applied in the field of phase change material preparation, can solve the problems of large volume change during the phase change process, slow response speed of temperature change, and non-compliance with environmental protection requirements, and achieve high latent heat of phase change, high temperature The effect of fast change response speed and large latent heat of melting phase change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

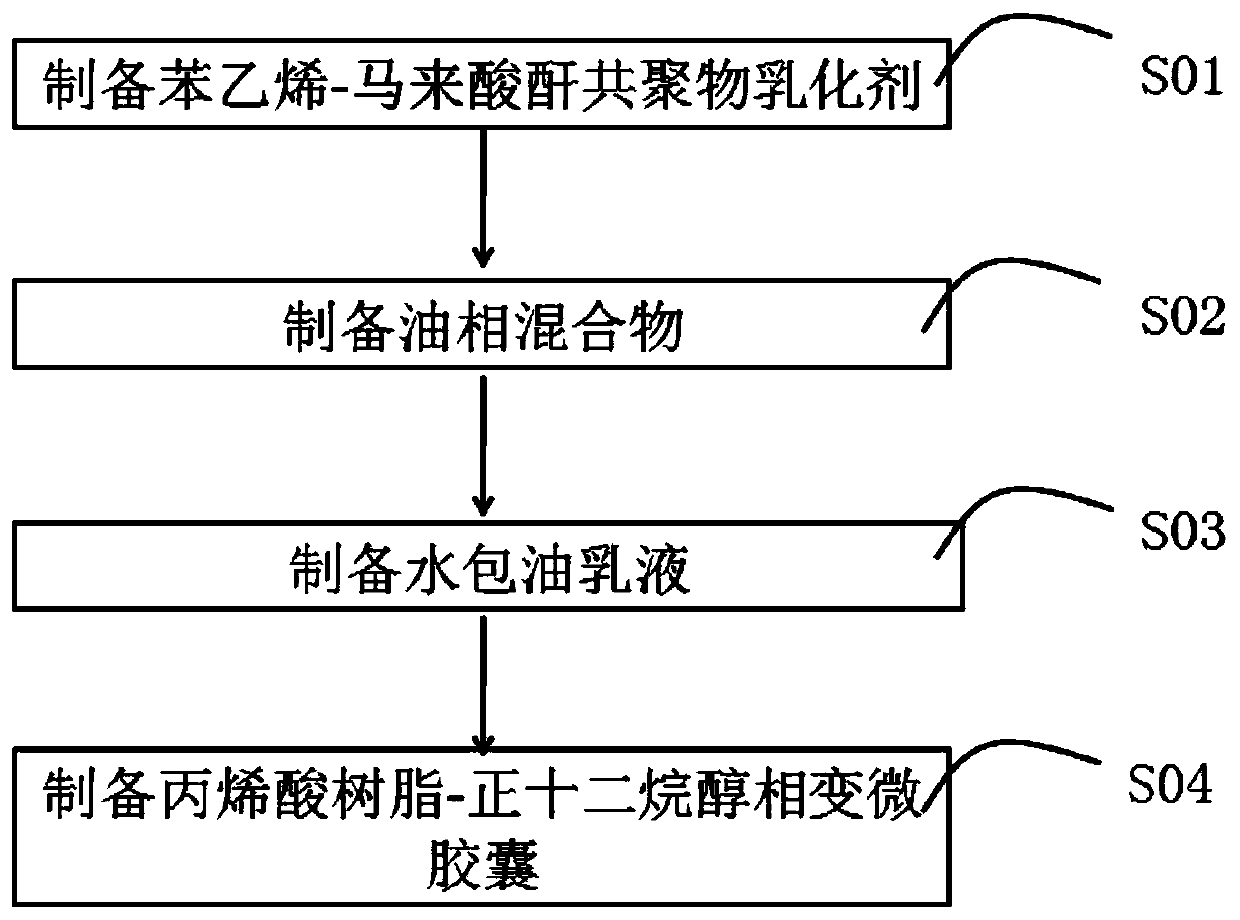

[0038] Correspondingly, the embodiment of the present invention also provides a preparation method of the phase-change microcapsules of the above-mentioned embodiments. Embodiments of the present invention phase change microcapsules preparation method process such as figure 1 shown, including the following steps:

[0039] Step S01, preparing styrene-maleic anhydride copolymer emulsifier: adding styrene-maleic anhydride copolymer powder, NaOH and deionized water to the container in sequence, stirring magnetically at 80-90°C for 1-3 hours, when the solution When it is light yellow and transparent, use citric acid to adjust the pH value of the solution to 4-6 to obtain a styrene-maleic anhydride copolymer emulsifier;

[0040] Step S02, preparing the oil phase mixture: adding urethane acrylate, 1,4-butanediol diacrylate, acrylic acid, azobisisobutyronitrile and n-dodecanol to the container in sequence, and ultrasonic irradiation at 25-45°C Stir at a constant temperature for 30-4...

Embodiment 1

[0048] Styrene-maleic anhydride copolymer 1.8g

[0050] Urethane acrylate 9.0g

[0051] 1,4-Butanediol diacrylate 3.0g

[0052] Acrylic acid 2.0g

[0053] Azobisisobutyronitrile 0.15g

[0054] n-dodecyl alcohol 11.5g

[0055] Deionized water 120.0g

[0056] Preparation of styrene-maleic anhydride copolymer emulsifier: Add styrene-maleic anhydride copolymer powder, NaOH, and deionized water into a three-necked flask, stir magnetically and heat up to 85°C in a water bath, and keep it for 1 hour. When the solution is light yellow and transparent, adjust the pH value of the solution to 5 with citric acid;

[0057] The concentration of styrene-maleic anhydride copolymer emulsifier is 4mg·mL ~1 ;

[0058] Prepare the oil phase mixture: Add polyurethane acrylate, 1,4-butanediol diacrylate, acrylic acid, azobisisobutyronitrile, n-dodecanol to the container in sequence, and stir for 30 minutes under ultrasonic irradiation at 30°C ;

[0059] Prep...

Embodiment 2

[0064] Styrene-maleic anhydride copolymer 1.8g

[0066] Urethane acrylate 9.0g

[0067] 1,4-Butanediol diacrylate 3.0g

[0068] Acrylic acid 2.0g

[0069] Azobisisobutyronitrile 0.15g

[0070] n-dodecyl alcohol 11.5g

[0071] Deionized water 120.0g

[0072] Preparation of styrene-maleic anhydride copolymer emulsifier: Add styrene-maleic anhydride copolymer powder, NaOH, and deionized water into a three-necked flask, stir magnetically and heat up to 90°C in a water bath, and keep it for 2 hours. When the solution is light yellow and transparent, adjust the pH value of the solution to 5 with citric acid;

[0073] The concentration of styrene-maleic anhydride copolymer emulsifier is 8mg·mL ~1 ;

[0074] Prepare the oil phase mixture: add polyurethane acrylate, 1,4-butanediol diacrylate, acrylic acid, azobisisobutyronitrile, n-dodecanol to the container in sequence, and stir for 20 minute;

[0075] Preparation of oil-in-water emulsion: Afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com