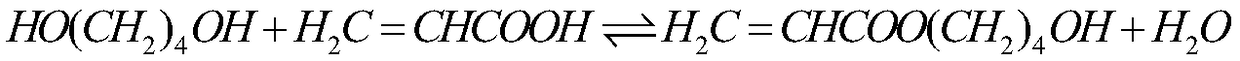

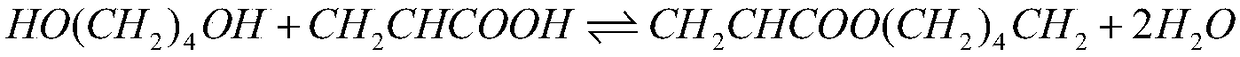

Method for preparing 4-hydroxybutyl acrylate by means of extraction and separation

A technology of hydroxybutyl acrylate and acrylic acid, which is applied in the preparation of carboxylic acid esters, organic compounds, and the reaction between ester groups and hydroxyl groups. It can solve the problems of deepening product color, difficulty in separation and purification, and easy polymerization. And the effect of good flexibility, simple process and simple post-processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

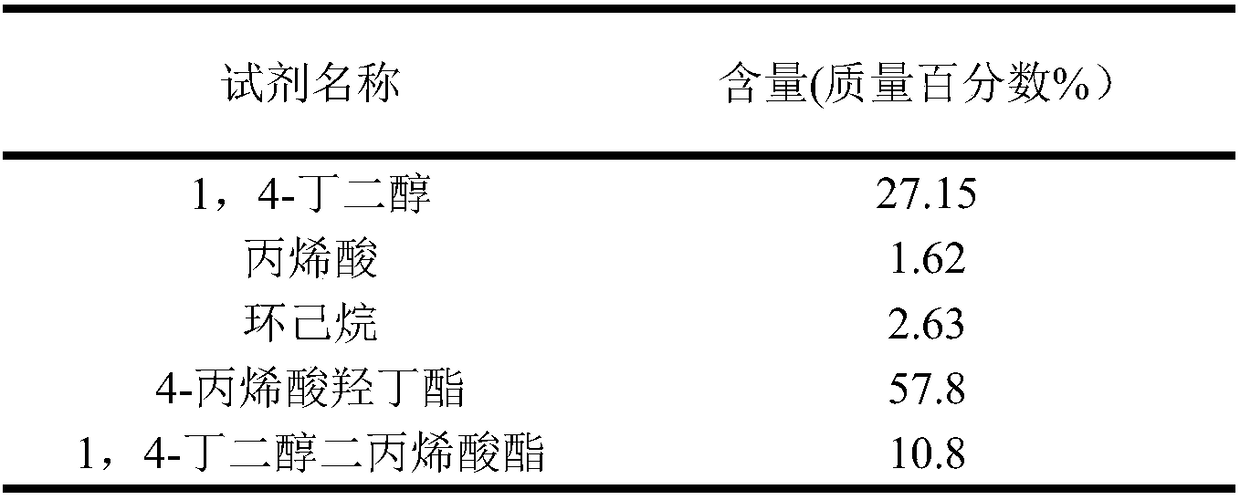

Embodiment 1

[0034] A preparation method of 4-hydroxybutyl acrylate separated by extraction, the steps of the preparation method are:

[0035] (1) Put 200g of 1,4-butanediol, 5g of p-toluenesulfonic acid, 0.05g of hydroquinone, 0.05g of p-hydroxyanisole and 115g of cyclohexane into the reactor to form a mixed solution;

[0036] (2) Slowly heat to control the temperature to 40°C and add dropwise 75g of acrylic acid with 0.05g of hydroquinone for 30-50min at this temperature;

[0037] (3) Continue to slowly heat the mixed solution to control the temperature at 100°C, and then reflux at 100°C for 3h to complete the reaction;

[0038] (4) Add aqueous solution to the mixed solution obtained from the reaction, then add cyclohexane and ultrasonically vibrate for 15 minutes at 20°C, V (raw material solution): V (water): V (solvent) = 1:1:1, first Extracting 1,4-butanediol diacrylate from the water phase, the upper layer is an organic phase, and the lower layer is an aqueous phase;

[0039] (5) A...

Embodiment 2

[0045] A preparation method of 4-hydroxybutyl acrylate separated by extraction, the steps of the preparation method are:

[0046] (1) Put 250g of 1,4-butanediol, 7g of p-toluenesulfonic acid, 0.03g of hydroquinone, 0.03g of p-hydroxyanisole and 120g of cyclohexane into the reactor to form a mixed solution;

[0047] (2) Slowly heat to control the temperature to 60°C and add dropwise 80g of acrylic acid with 0.03g of hydroquinone for 30-50min at this temperature;

[0048] (3) Continue to slowly heat the mixed solution to control the temperature at 120° C., and then reflux at 120° C. for 4 hours to complete the reaction;

[0049] (4) Add aqueous solution to the mixed solution obtained from the reaction, then add cyclohexane and ultrasonically vibrate for 20 minutes at 25°C, V (raw material solution): V (water): V (solvent) = 1:1:1, first Extract 1,4-butanediol diacrylate from the water phase, the upper layer is the organic phase, and the lower layer is the water phase;

[0050]...

Embodiment 3

[0056] A preparation method of 4-hydroxybutyl acrylate separated by extraction, the steps of the preparation method are:

[0057] (1) Put 250g of 1,4-butanediol, 7g of p-toluenesulfonic acid, 0.035g of hydroquinone, 0.035g of p-hydroxyanisole and 120g of cyclohexane into the reactor to form a mixed solution;

[0058] (2) Slowly heat to control the temperature at 60°C and add dropwise 80g of acrylic acid with 0.035g of hydroquinone for 30-50min at this temperature;

[0059] (3) Continue to slowly heat the mixed solution to control the temperature at 120° C., and then reflux at 120° C. for 4 hours to complete the reaction;

[0060] (4) Add aqueous solution to the mixed solution obtained from the reaction, then add cyclohexane and ultrasonically vibrate for 20 minutes at 25°C, V (raw material solution): V (water): V (solvent) = 1:1:1, first Extract 1,4-butanediol diacrylate from the water phase, the upper layer is an organic phase, and the lower layer is an aqueous phase;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com