Preparation method of high-impact-resistant waterproof type epoxy resin toughening agent

An epoxy resin and high impact resistance technology, which is applied in the field of toughening agent preparation, can solve the problems of insufficient internal structure, poor impact strength and water resistance of epoxy resin, achieve good polymerization effect and improve impact strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

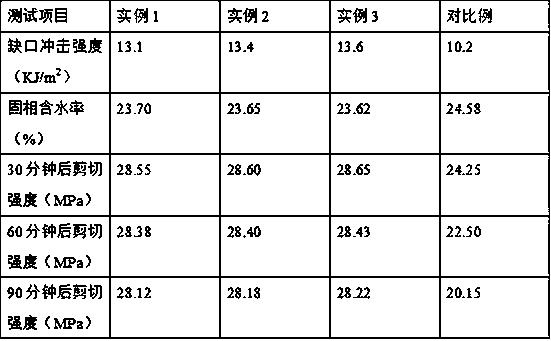

Examples

example 1

[0024] Weigh 20g of nano-silica with a particle size of 10nm and 5g of silane coupling agent KH-560 and mix and stir for 6 minutes. After stirring, add 24mL of deionized water and 10mL of absolute ethanol and mix them in an ultrasonic stirrer. After continuing to stir for 20min, Adjust the pH to 3 with 0.1 mol / L hydrochloric acid, pour it into a four-neck flask equipped with a stirrer, an addition funnel, a condenser tube and a thermometer after adjustment, and place it in a water bath. After stirring for 12 minutes under the protection of r / min and nitrogen, filter to obtain the filter residue, wash the filter residue with absolute ethanol, put it in an oven at 60°C and dry it for 1 hour to obtain modified nano-silica, and set aside, the volume ratio is 10 : 1:1 Mix butyl acrylate, 1,4-butanediol diacrylate and allyl methacrylate and stir for 10 minutes to obtain a mixed solution. Take 20 mL of the mixed solution and add it to a In the reactor of sodium phenylsulfonate and 0....

example 2

[0026] Weigh 25g of nano-silica with a particle size of 15nm and 6g of silane coupling agent KH-560 and mix and stir for 7 minutes. After stirring, add 27mL of deionized water and 11mL of absolute ethanol and mix them in an ultrasonic stirrer. After continuing to stir for 25min, Adjust the pH to 3 with 0.1 mol / L hydrochloric acid, pour it into a four-necked flask equipped with a stirrer, an addition funnel, a condenser tube and a thermometer after adjustment, and place it in a water bath. After stirring for 14 minutes under the protection of r / min and nitrogen, filter to obtain the filter residue, wash the filter residue with absolute ethanol, put it in an oven at 70°C and dry it for 1.5h to obtain modified nano-silica, which is set aside, and the volume ratio is Mix and stir butyl acrylate, 1,4-butanediol diacrylate and allyl methacrylate at 10:1:1 for 11 minutes to obtain a mixed solution. Take 30 mL of the mixed solution and add it to a mixture with 160 mL of distilled water...

example 3

[0028]Weigh 30g of nano-silica with a particle size of 20nm and 7g of silane coupling agent KH-560, mix and stir for 8 minutes, add 30mL of deionized water and 12mL of absolute ethanol after stirring, mix them in an ultrasonic stirrer, and continue stirring for 30 minutes , adjust the pH to 4 with 0.1mol / L hydrochloric acid, pour it into a four-neck flask equipped with a stirrer, an addition funnel, a condenser tube and a thermometer after adjustment, and place it in a water bath. After stirring at 400 r / min and under the protection of nitrogen for 16 minutes, filter to obtain the filter residue. After cleaning the filter residue with absolute ethanol, put it in an oven at 80°C and dry it for 2 hours to obtain modified nano-silica. Mix butyl acrylate, 1,4-butanediol diacrylate and allyl methacrylate at 10:1:1 and stir for 12 minutes to obtain a mixed solution. Take 40 mL of the mixed solution and add it to a mixture with 180 mL of distilled water and 0.7 g of In the reactor of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com