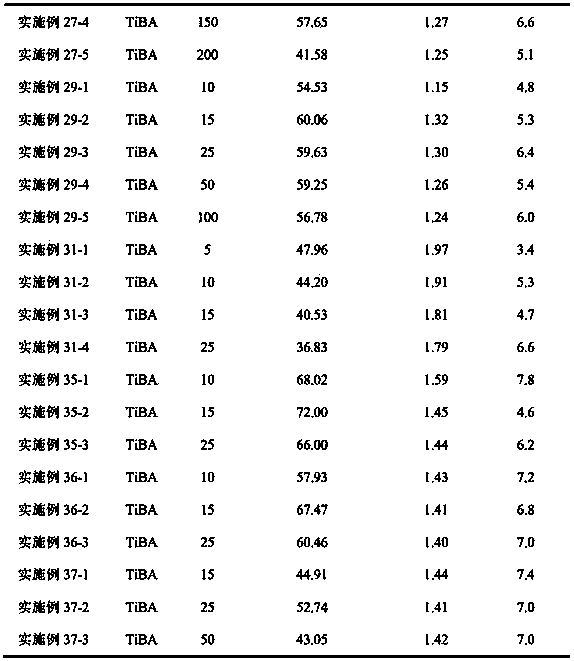

Patents

Literature

155results about How to "Improve polymerization effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicone-containing ocular lens material with high safety and preparing method thereof

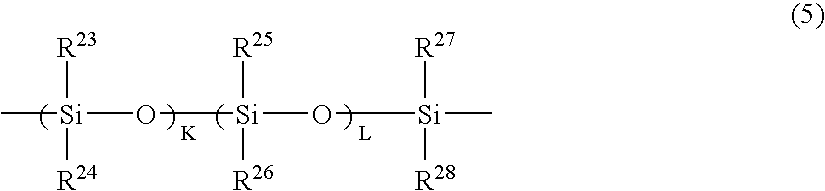

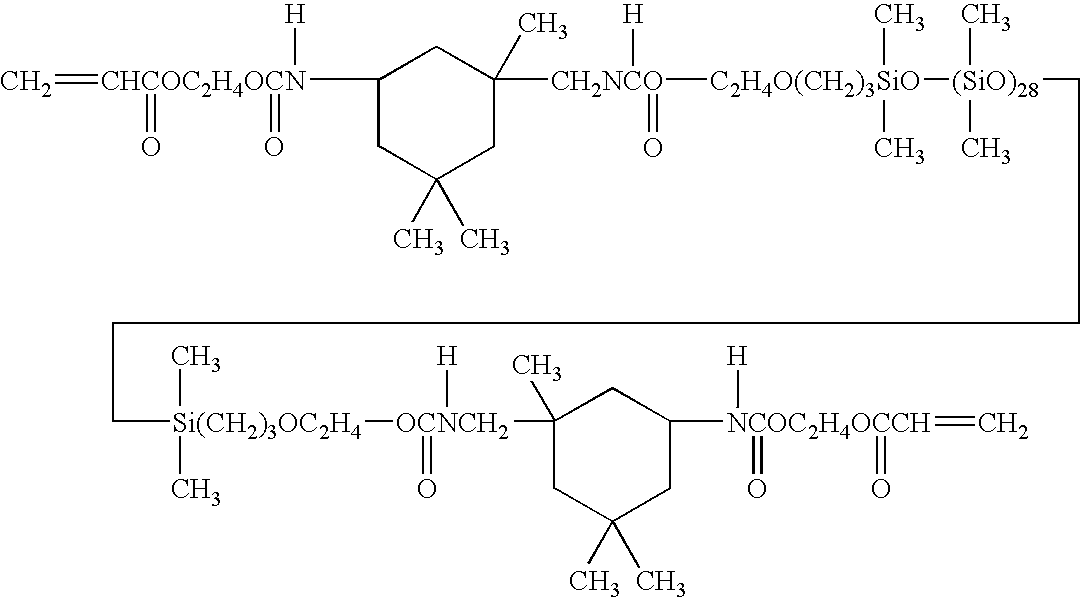

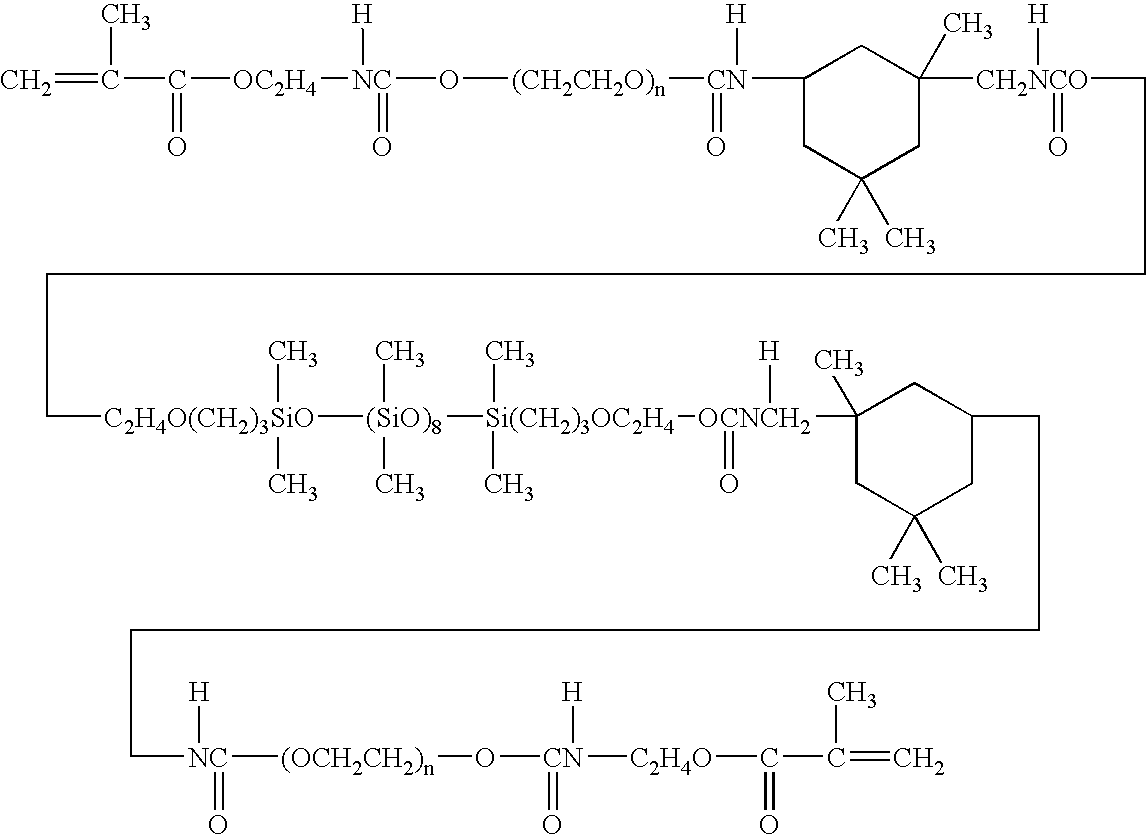

ActiveUS20060142410A1Increase flexibilityImprove the lubrication effectCeramic shaping apparatusEye diagnosticsIntraocular lensPliability

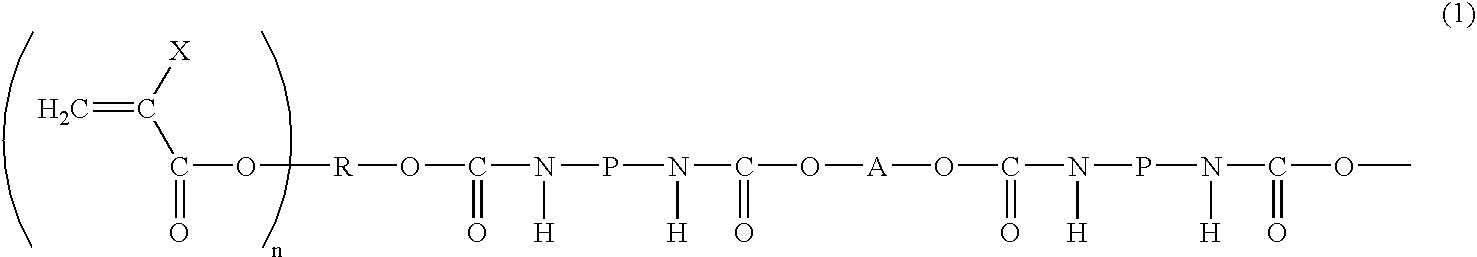

The present invention provides a safe ocular lens material having high oxygen permeability, excellent surface wettability, the excellent lubricity / easy lubricating property of surface, little in surface adhesive and superior flexibility and stress relaxation, in addition, suppressing elution of a monomer from the final product. That is, the present invention relates to an ocular lens material comprising at least one kind of a compound (A) having an ethylenically unsaturated group and polydimethylsiloxane structure through a urethane bond and at least one kind of a pyrrolidone derivative (B) in which a polymerizable group is a methylene group.

Owner:MENICON CO LTD

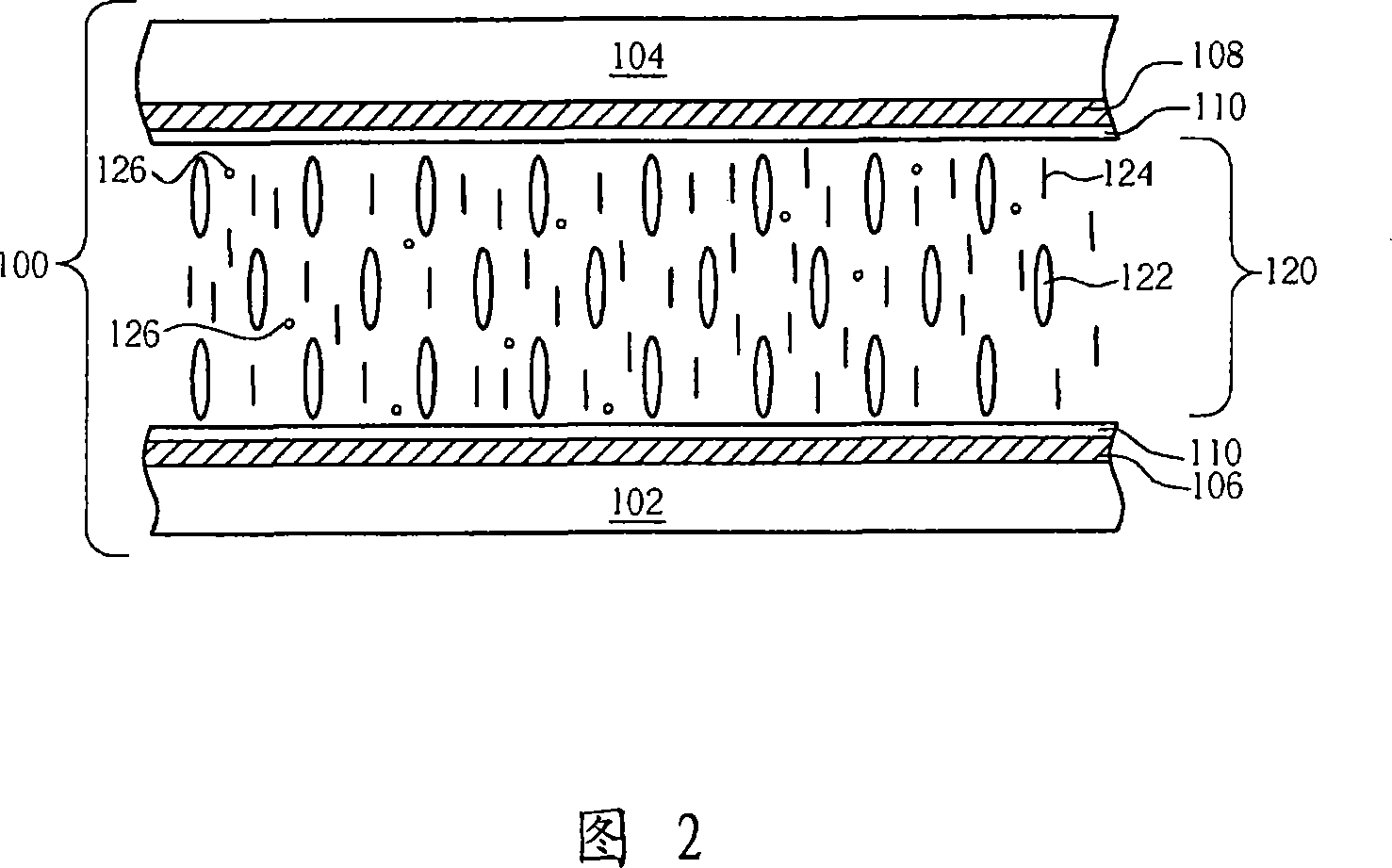

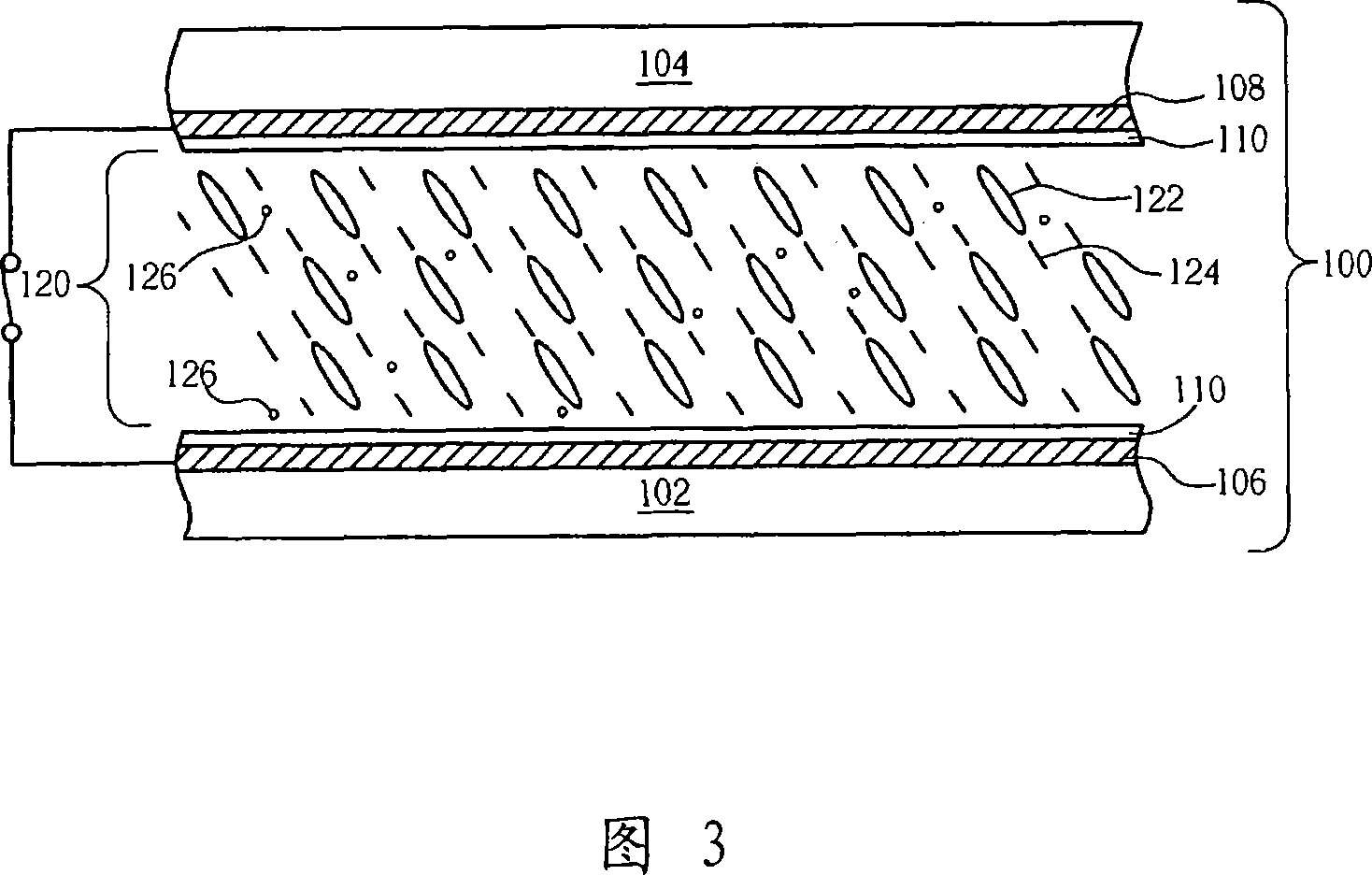

Liquid crystal mixture used for polymerization alignment manufacture process and method for manufacturing liquid crystal display board

ActiveCN101108968AImprove stabilityImprove aggregationLiquid crystal compositionsNon-linear opticsPolymer chemistryMonomer

A liquid core crystal compound for polymerizing the distribution process is provided, which comprises at least a liquid crystal molecule, at least a reactive monomer and an inhibitor with weight concentration range 0.01wt per cent to 1wt per cent of the reactive monomer content. The inhibitor quenches free radicals and polyreaction produced by the reactive monomer due to lighting or heat effect before polymerizing the distribution process, therefore reducing the reaction of the reactive monomer before polymerizing the distribution process and greatly improving the stability of the liquid core crystal compound.

Owner:AU OPTRONICS CORP

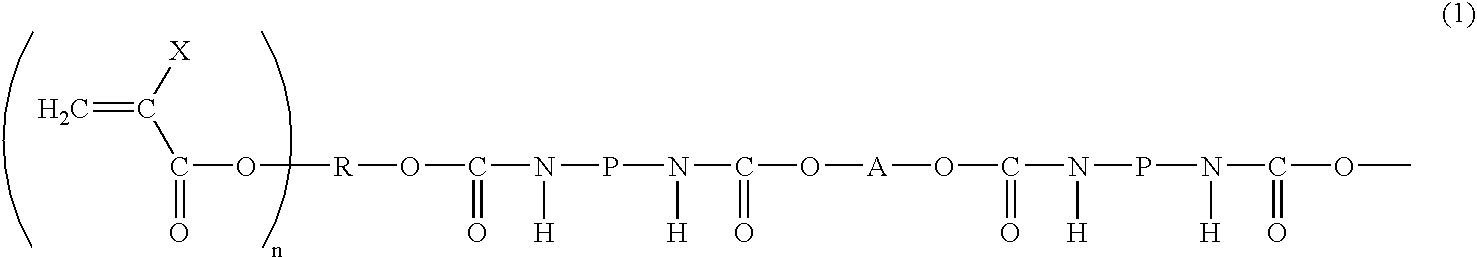

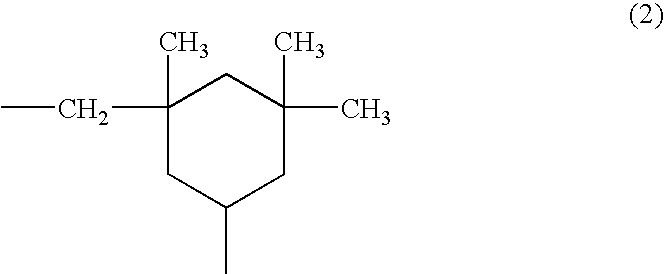

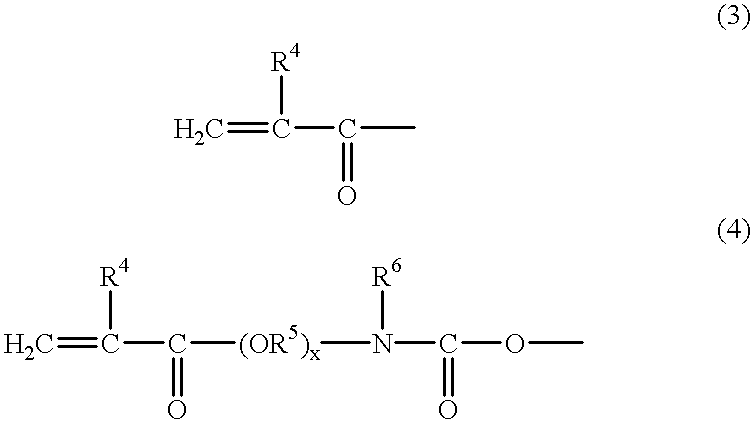

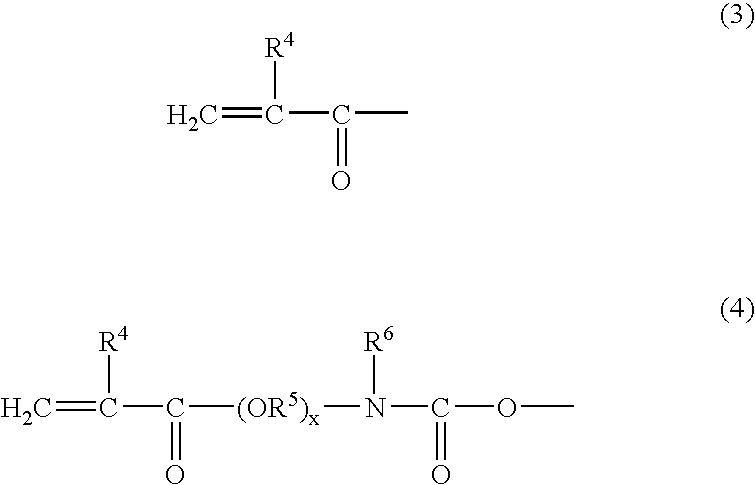

Photosensitive resin composition, image forming material and image forming method using thereof

InactiveUS20070099115A1Improve curing effectSuppressing polymerization inhibitionPhotosensitive materialsRadiation applicationsMeth-Side chain

There is devised a novel acryl resin in which an unsaturated group introduced in an alkali soluble resin is placed at a longer distance from the resin skeleton of the alkali soluble resin, the mobility of the unsaturated group is promoted and the number of the unsaturated double bonds is increased; therefore it allows crosslinking reaction to occur easily and a functional resin portion which imparts a specific function, in particular, function of suppressing polymerization inhibition due to oxygen by introduction of an active methylene group is provided at a resin portion existing between the acryl resin skeleton and the unsaturated double bond, and a photosensitive resin composition containing thereof is to be provided. A photosensitive resin composition comprising an alkali soluble resin, an ethylenically unsaturated compound, a near infrared absorbing dye, a compound containing a halomethyl group and a compound containing an organoboron anion, wherein the alkali soluble resin comprises an acryl resin having one or more of pendant groups in which both terminals of a diol compound have been blocked with isophorone diisocyanates and then (meth)acryloyl has been added, and, an image forming material comprising a substrate, and a photosensitive layer formed by the photosensitive resin composition on the substrate, as well as an image forming method.

Owner:NIPPON PAINT CO LTD

Polymerizable composition and use thereof

InactiveUS20020018938A1Improve ionic conductivityImprove polymerization effectLight-sensitive devicesOrganic chemistryPolymer electrolytesPolymer science

The present invention provides a solid polymer electrolyte; a polymerizable composition having low viscosity and excellent processability for obtaining the solid polymer electrolyte; and a polymerizable compound having low viscosity, and good polymerizability and stability for use in the polymerizable composition. The present invention also provides primary and secondary batteries capable of working with high capacity and current; an electric double-layer capacitor ensuring high output voltage, large takeout current, and good processability; and an electrochromic device favored with high response speed. Each thereof use the solid polymer electrolyte of the present invention and are ensured with long life, excellent safety free of liquid leakage, high reliability and production at a low cost. A solid polymer electrolyte, including a carbonate-based polymer in which a branched chain is introduced and having a high dielectric constant and a wide electrochemical stability range, having excellent processability, good safety and high ionic conductivity, is provided.

Owner:SHOWA DENKO KK

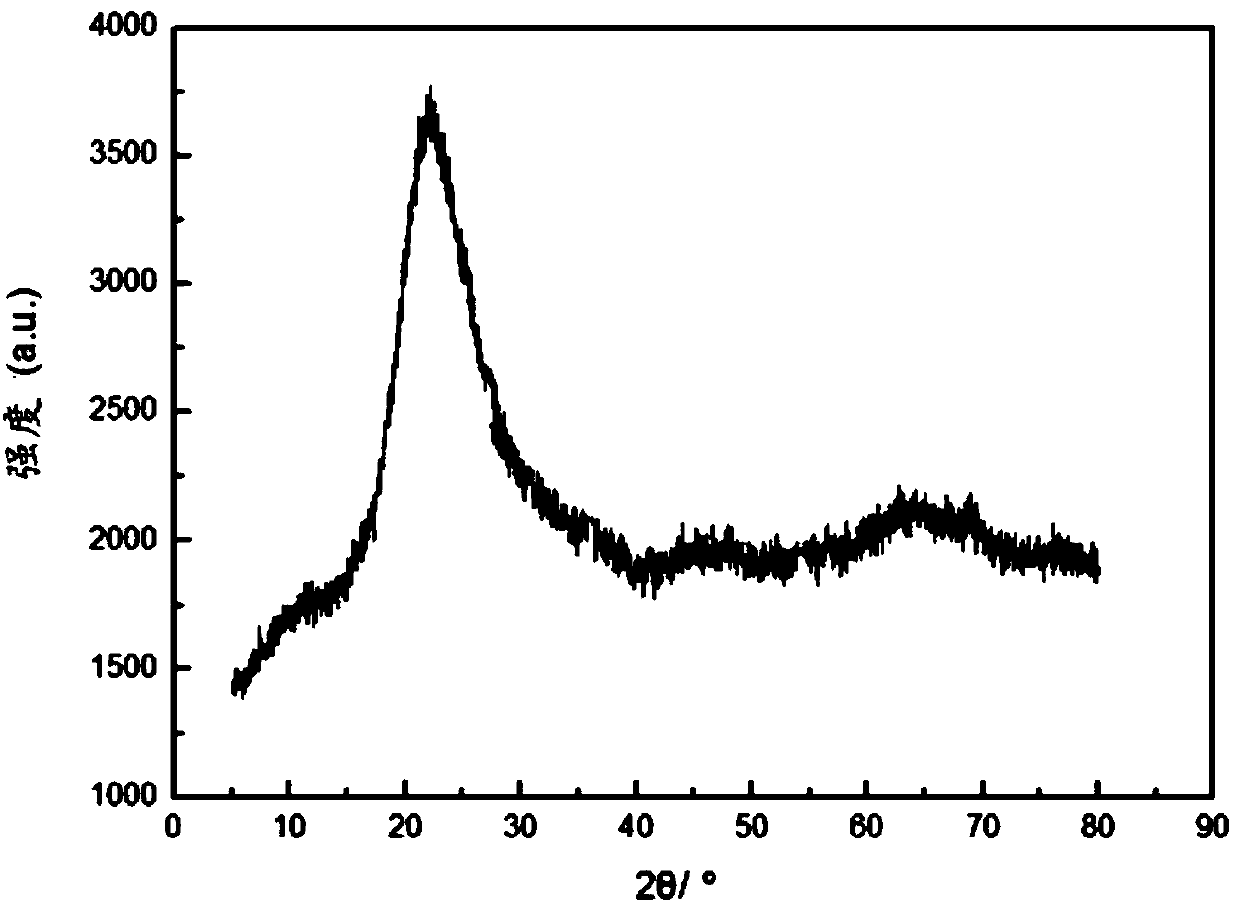

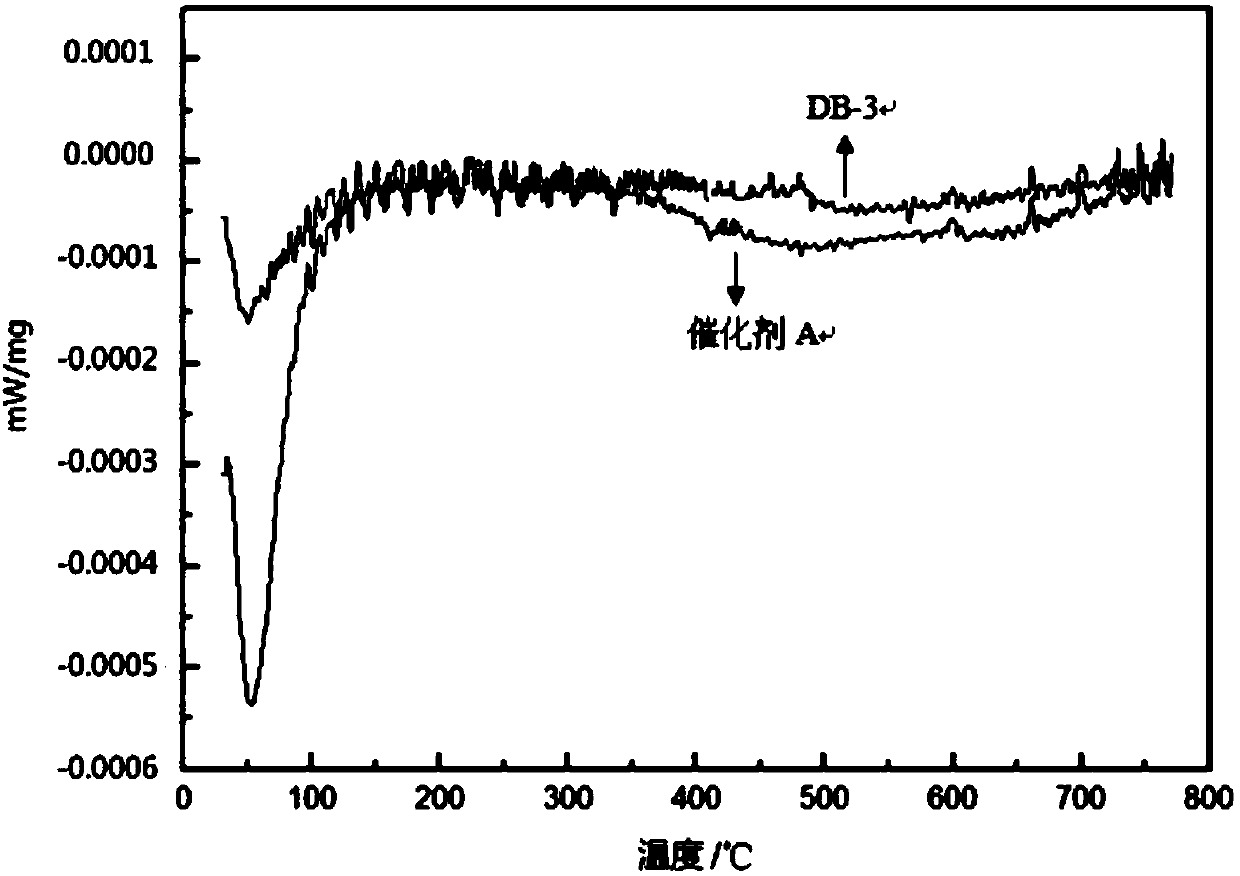

Preparation method of alkene epoxidation catalyst as well as catalyst prepared thereby

ActiveCN107930610AHigh reactivityReduce surface acidityOrganic chemistryMolecular sieve catalystsComposite oxideKinetic diameter

The invention relates to a preparation method of an alkene epoxidation catalyst. The preparation method of the alkene epoxidation catalyst comprises the following steps: (1) preparing titanium silicongel; (2) performing pore-enlarging treatment on the titanium silicon gel by using organic amine or liquid ammonia, drying and roasting to obtain titanium silicon composite oxide; (3) optionally performing alcohol solution treatment on organic alkali metal salt; and (4) optionally performing gas phase silanization treatment. The pore diameter of the catalyst prepared by the method is adjustable, so that the catalyst has higher activity on epoxidation reaction of olefin molecules with different kinetic diameter; and the catalyst is subjected to two-step modification, the surface acidity of thecatalyst is effectively reduced and the catalyst has higher epoxidation product selectivity.

Owner:WANHUA CHEM GRP

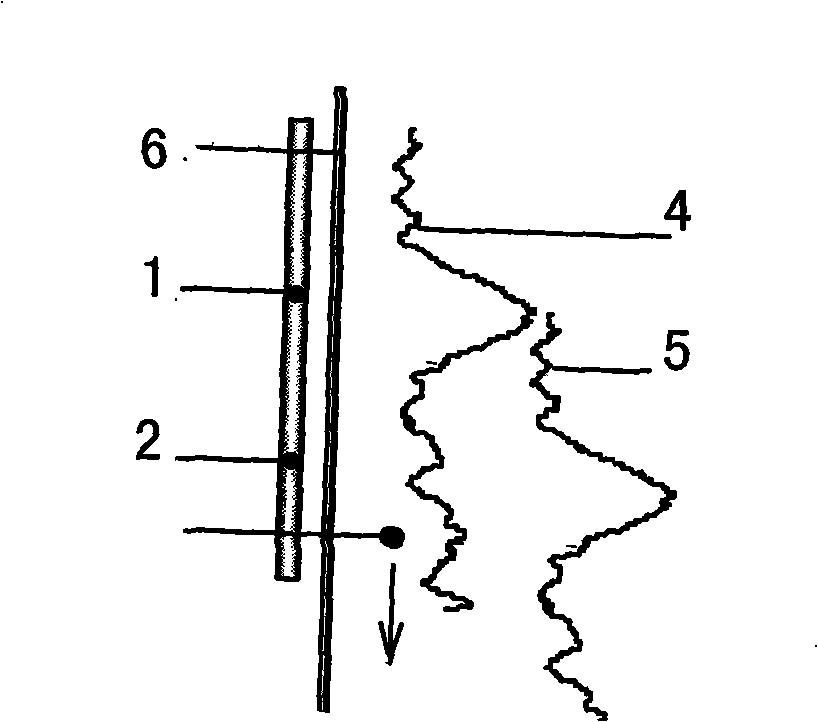

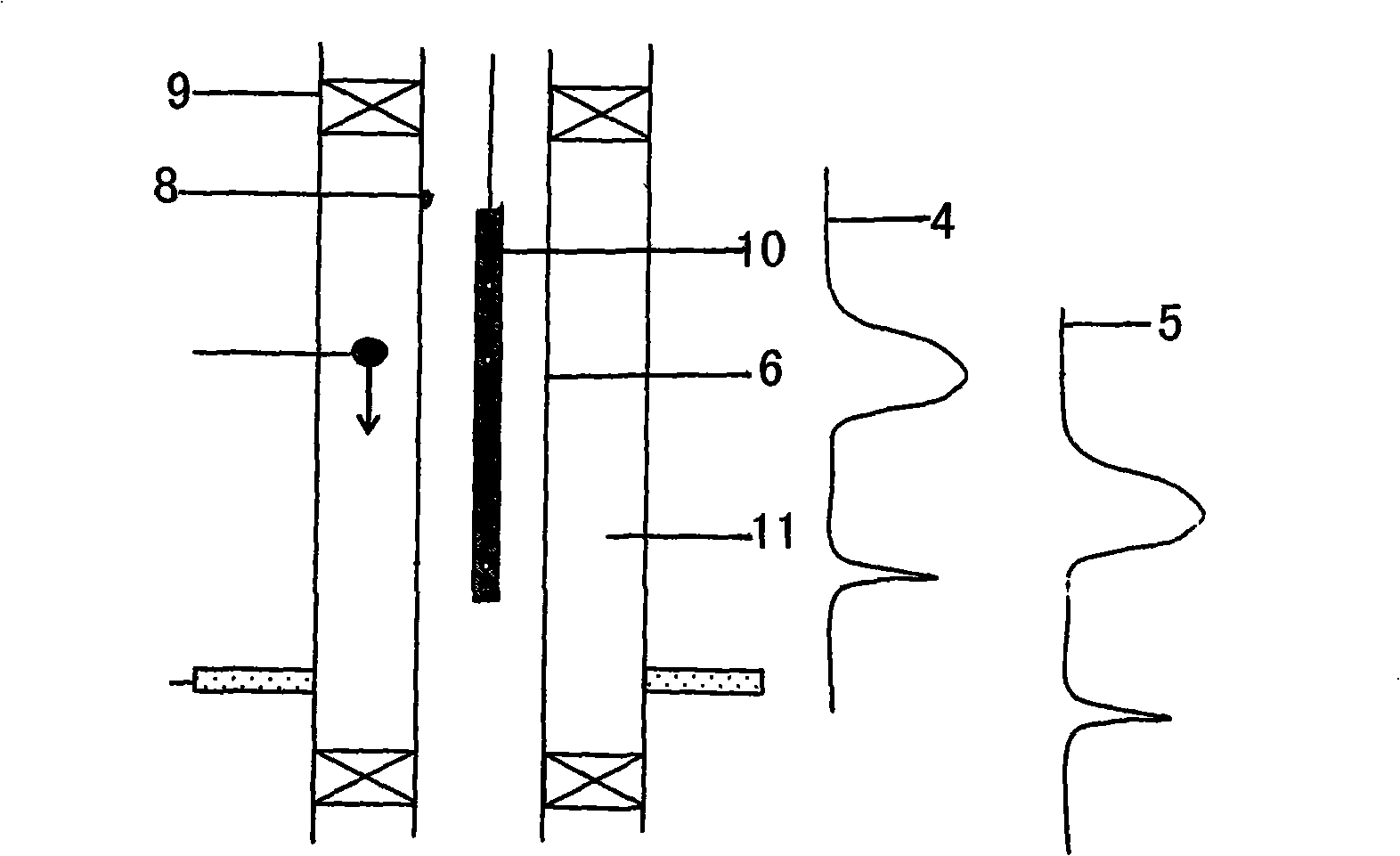

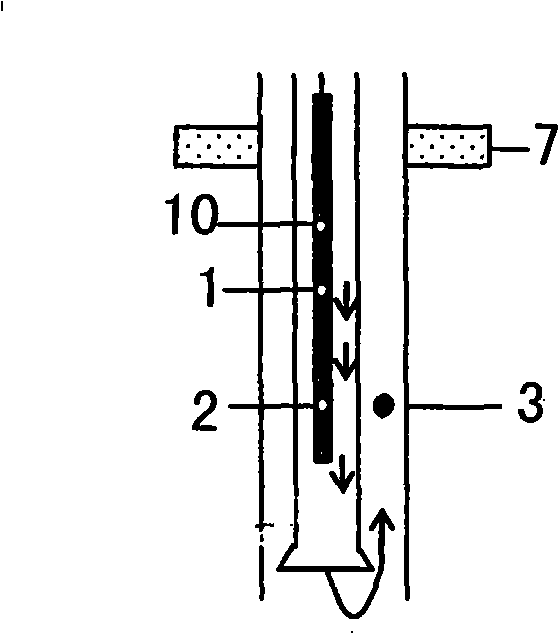

Correlated flux injection section test method and construction technique

A method is used for measuring flow injected into a section. A tracer with polymerization characteristic is released into the oil pipe of a flooding well. A part of the tracer goes through a water faucet, flows into the ring space of an oil sleeve and enters an injection layer when passing by an eccentric distributor. When the tracer is released into the oil sleeve, an instrument with two detectors should be placed at a position through which the tracer flows. When the tracer flows through two detectors in the ring space of the oil sleeve, a reciprocal change signal will be measured by the upper and the lower detectors. The other part of the tracer continues to flow down in the oil tube and the change signal is also measured by the upper and the lower detectors. Two wave crests appear on a well log. Owing to the good polymerization characteristic of the tracer, minor fluid state change combined, the small area of the ring space of the oil tube, short going-through time and the narrow width of the crest, the inner crest value of the oil tube and the crest value of the ring space of the oil sleeve can be determined. As the inner crest value of the oil tube is removed, the time when the tracer goes through the upper and the lower detectors can be worked out. Because the section of flow speed is known, the monolayer injection flow can be worked out according to an arithmetic mode.

Owner:林建伟

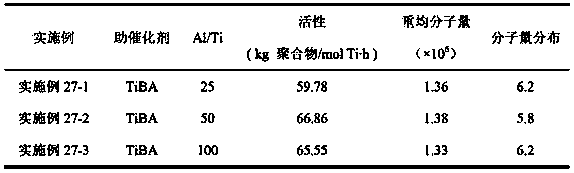

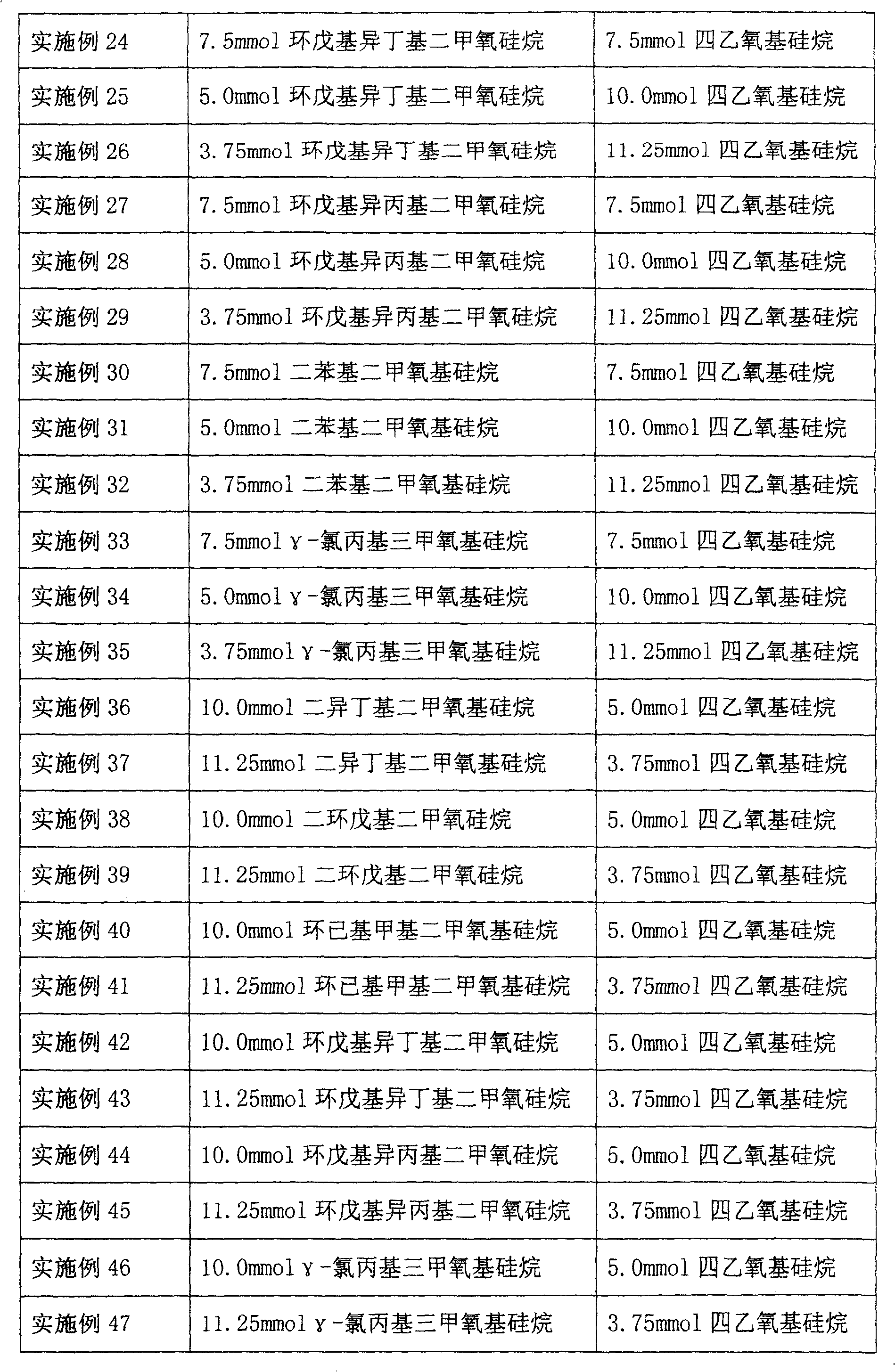

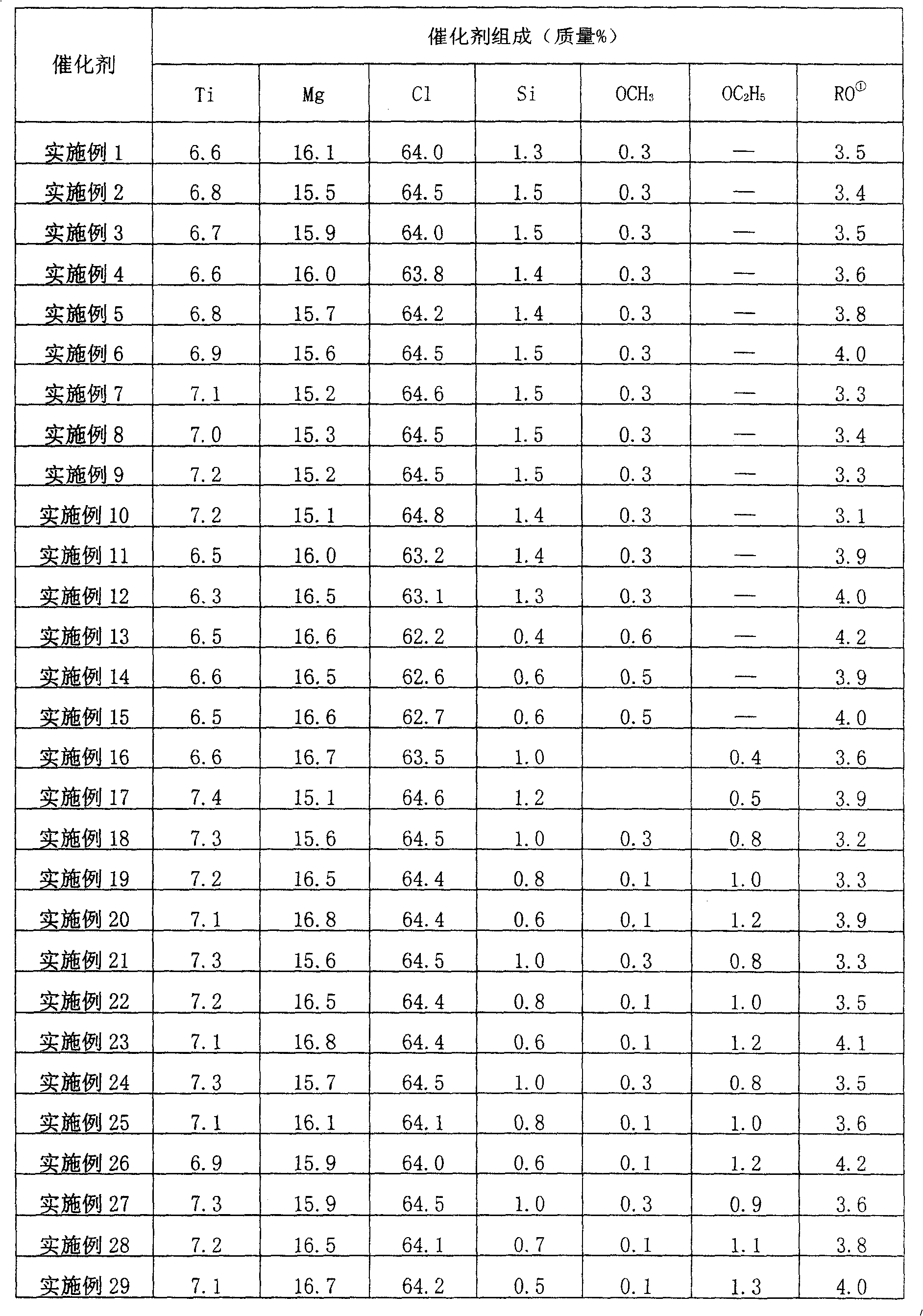

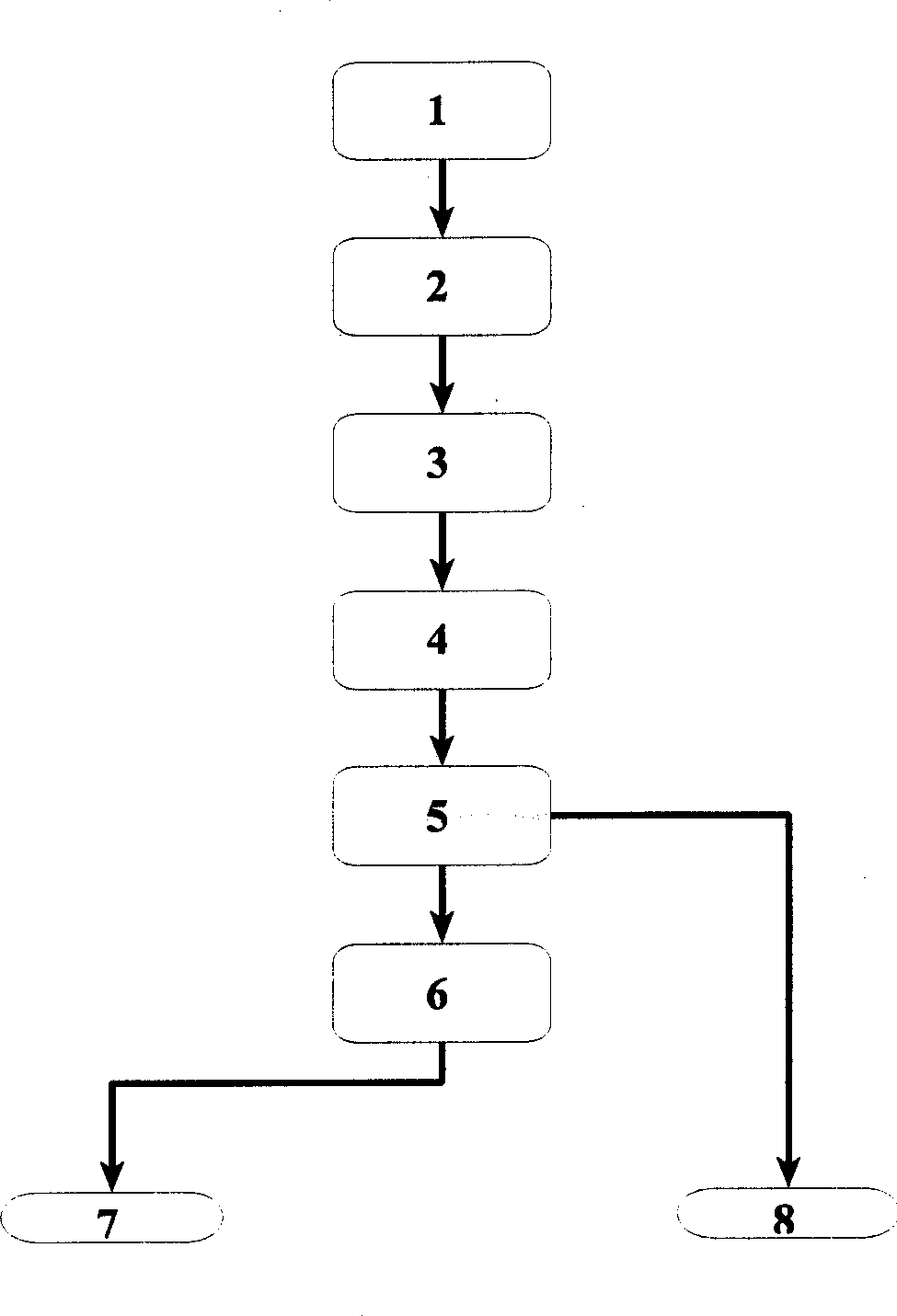

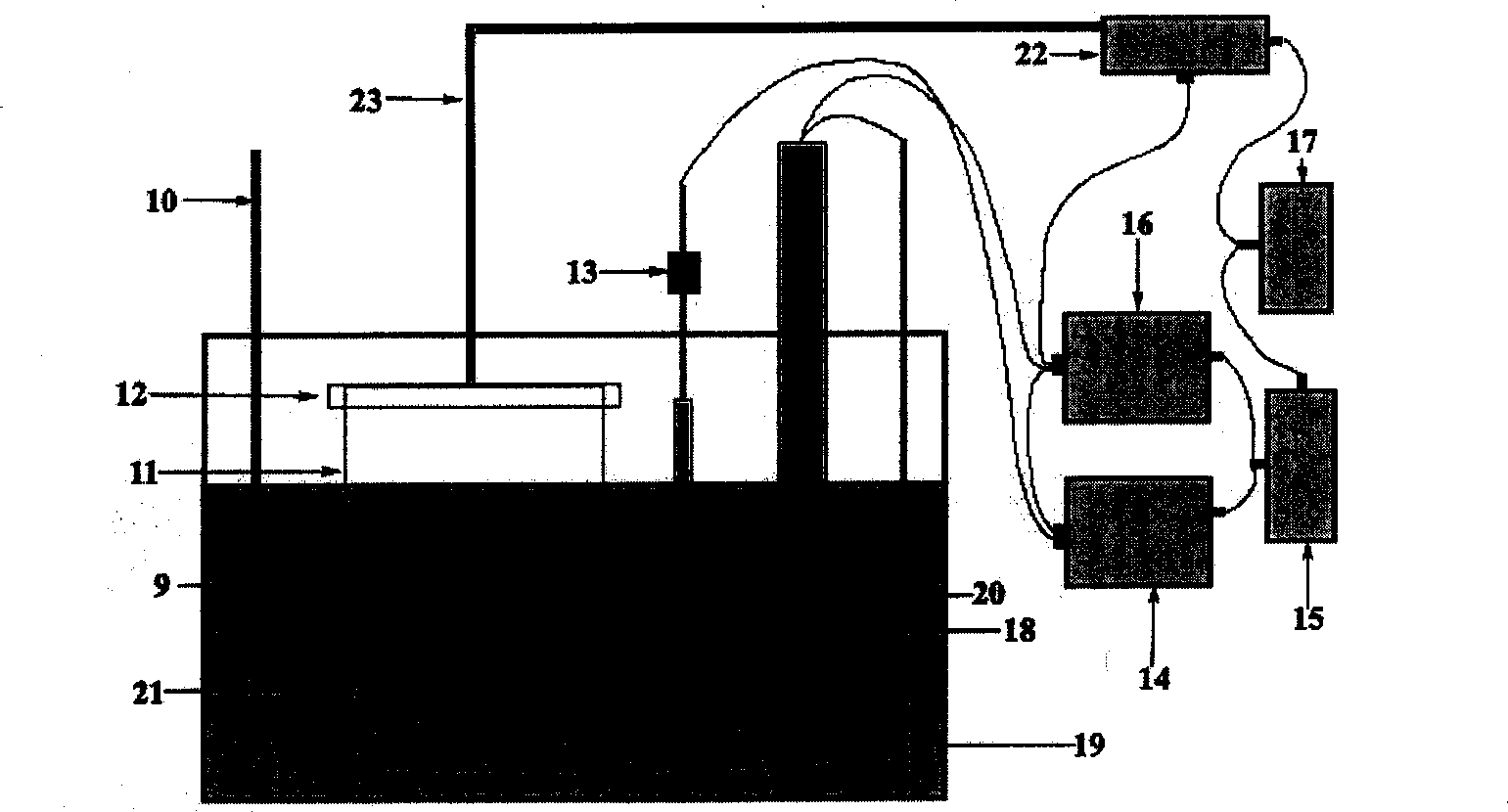

Supported olefin polymerization catalyst, preparation method and application thereof

The invention discloses a supported olefin polymerization catalyst, a preparation method thereof, and an application of the supported olefin polymerization catalyst in production of olefin homopolymer and olefin copolymer. The supported olefin polymerization catalyst mainly comprises a multihole carrier A, a magniferous carrier B, and a supported transition-metallic-titanium-contained active component and is a compound supported efficient Ziegler-Natta titanium catalyst formed by a magnesium compound and a silicon compound. The raw material for the carrier of the magnesium compound is any soluble magnesium salt. The compound carrier supported olefin polymerization catalyst can be used for preparing the olefin homopolymer or olefin copolymer. The catalyst is simple in preparation method, low in cost, easy to control the form, and excellent in polymerization performance. By changing the type and dosage of an organic metal promoter, molecular weight modifier and other factors, the molecular weight and molecular weight distribution of the olefin homopolymer or olefin copolymer, and content and distribution of a comonomer can be conveniently and easily adjusted, therefore, a polymer product with required performance is acquired.

Owner:EAST CHINA UNIV OF SCI & TECH

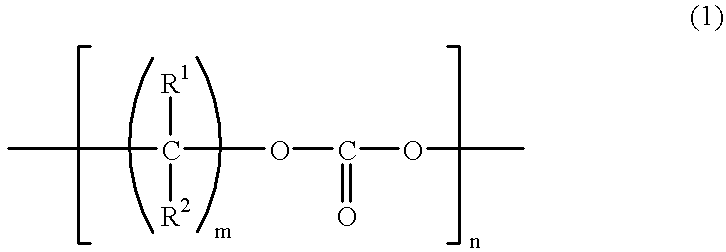

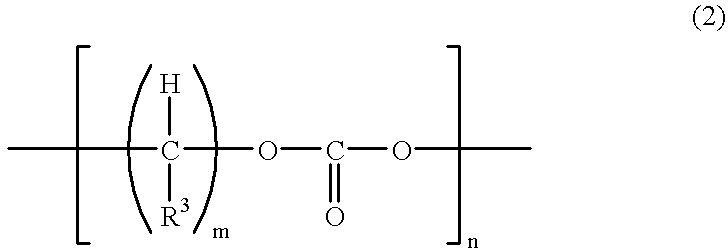

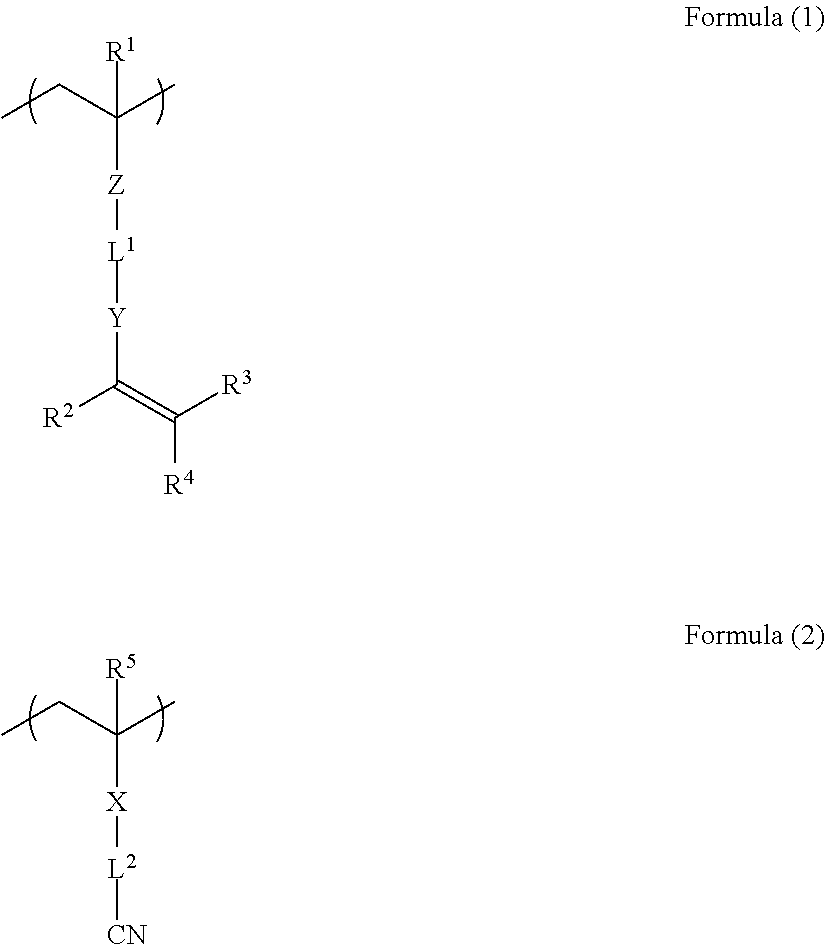

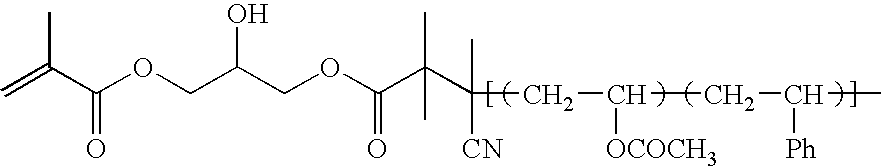

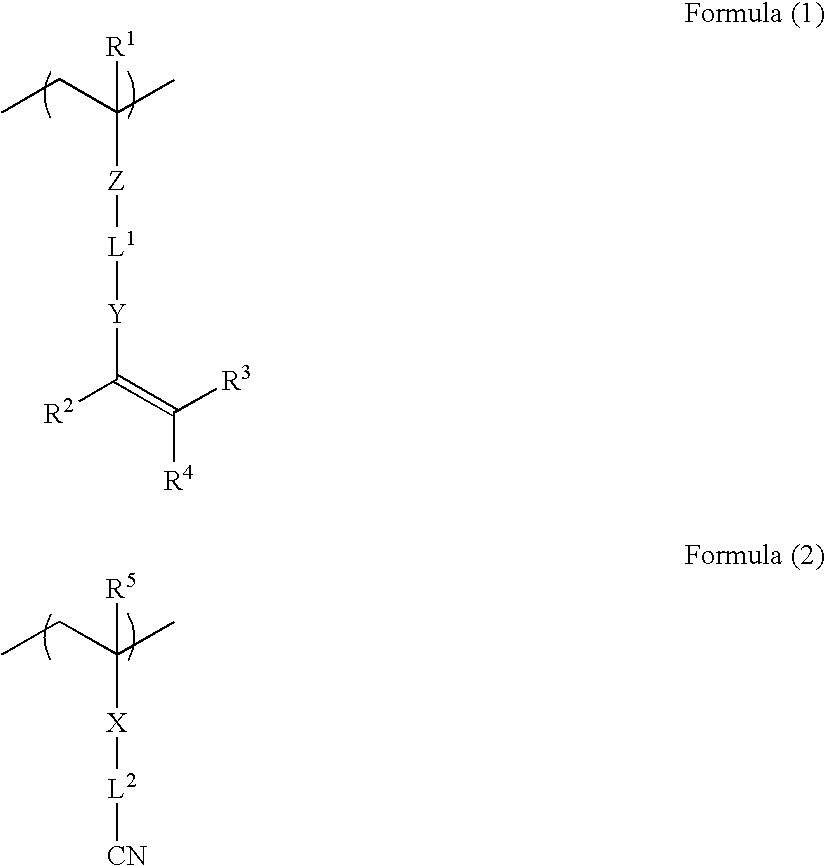

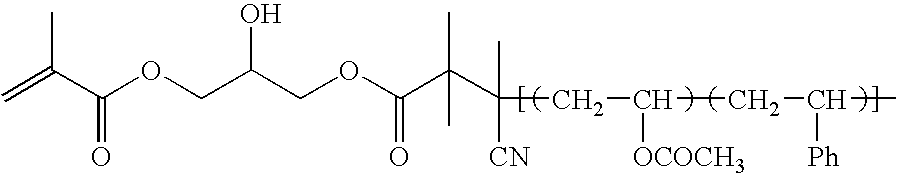

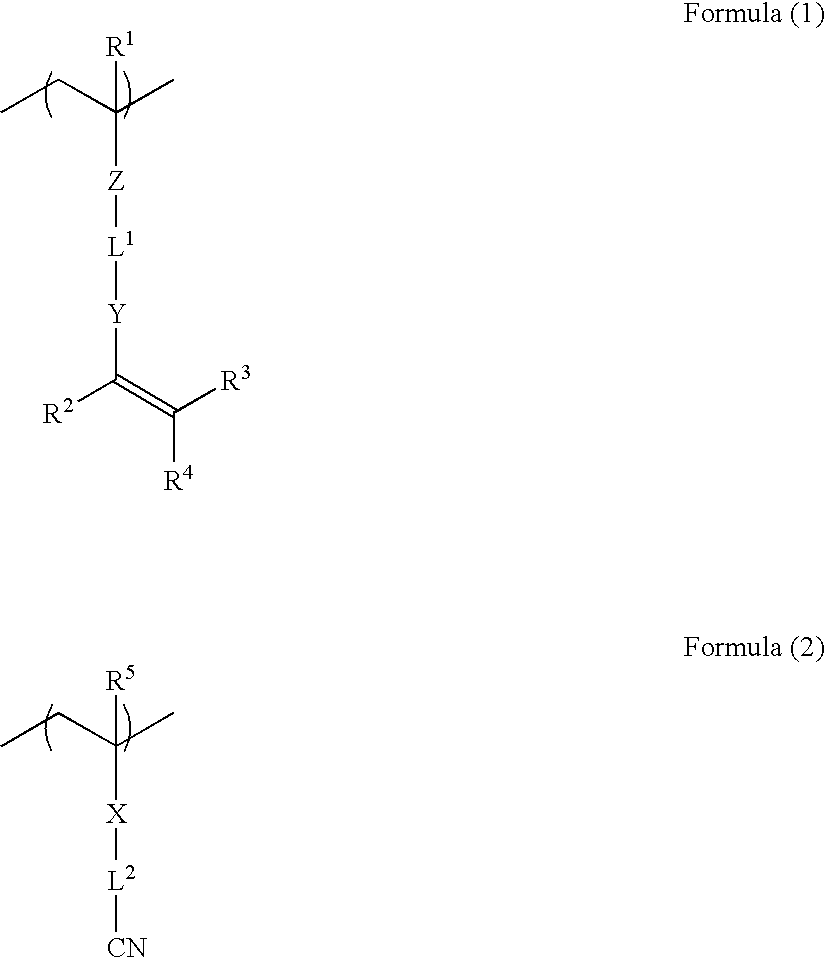

Metal-film-coated material and process for producing the same, metallic-pattern-bearing material and process for producing the same, composition for polymer layer formation, nitrile group-containing polymer and method of synthesizing the same, composition containing nitrile group-containing polymer, and laminate

InactiveUS8084564B2Improve adhesionLess fluctuationSynthetic resin layered productsLiquid/solution decomposition chemical coatingPolymer scienceEther

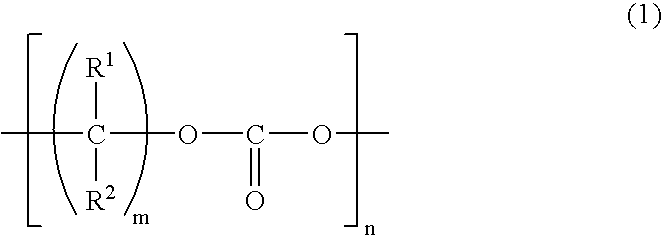

The invention provides a polymer containing at least a unit represented by the following Formula (1) and a unit represented by the following Formula (2). In Formula (1) and Formula (2), R1 to R5 each independently represent a hydrogen atom or a substituted or unsubstituted alkyl group; X, Y and Z each independently represent a single bond, a substituted or unsubstituted divalent organic group, an ester group, an amide group or an ether group; and L1 and L2 each independently represent a substituted or unsubstituted divalent organic group. The invention provides a method of synthesizing embodiments of the polymer, a composition containing the polymer, and a laminate formed by applying the composition on a resin base material.

Owner:FUJIFILM CORP

Catalyst active constituent and catalyst containing same

ActiveCN1814627ACatalyst particles are largeSettling fastOlefin polymerizationPolymerization catalysts

This invention provides an olefin polymerization catalyst active component suitable for ethene polymerization or copolymerization reaction of ethene and alpha-olefin and a catalyst containing said active component, which introduces electronic compound and halohydrocarbon into an active component containing Ti to get a high-active olefin polymerized catalyst. When carrying out olefin polymerrization by the catalyst prepared in such method, one can get the polymer in large density and resin in good size.

Owner:BEIJING JINDINGKE CHEM TECH

Metal-film-coated material and process for producing the same, metallic-pattern-bearing material and process for producing the same, composition for polymer layer formation, nitrile group-containing polymer and method of synthesizing the same, composition containing nitrile group-containing polymer, and laminate

InactiveUS20090214876A1Improve adhesionLess fluctuationSynthetic resin layered productsLiquid/solution decomposition chemical coatingPolymer sciencePtru catalyst

A process for producing a metal film-coated material, the process including: (a1) forming, on a substrate, a polymer layer formed from a polymer which has a functional group capable of interacting with a plating catalyst or a precursor thereof, and is directly chemically bonded to the substrate; (a2) providing a plating catalyst or a precursor thereof to the polymer layer; and (a3) performing plating with respect to the plating catalyst or a precursor thereof. The polymer layer satisfies all of the following requirements (1) to (4): (1) the saturated water absorption coefficient of the polymer layer as measured in an environment of temperature of 25° C. and relative humidity of 50% is 0.01 to 10% by mass; (2) the saturated water absorption coefficient of the polymer layer as measured in an environment of temperature of 25° C. and relative humidity of 95% is 0.05 to 20% by mass; (3) the water absorption coefficient of the polymer layer as measured after 1 hour of immersion in boiling water at 100° C. is 0.1 to 30% by mass; and (4) the surface contact angle of the polymer layer as measured after dropping 5 μL of distilled water thereonto and leaving to stand for 15 seconds in an environment of temperature of 25° C. and relative humidity of 50% is 50 to 150 degrees.

Owner:FUJIFILM CORP

Catalyst active component, its preparation and catalyst containing it

Owner:BEIJING JINDINGKE CHEM TECH

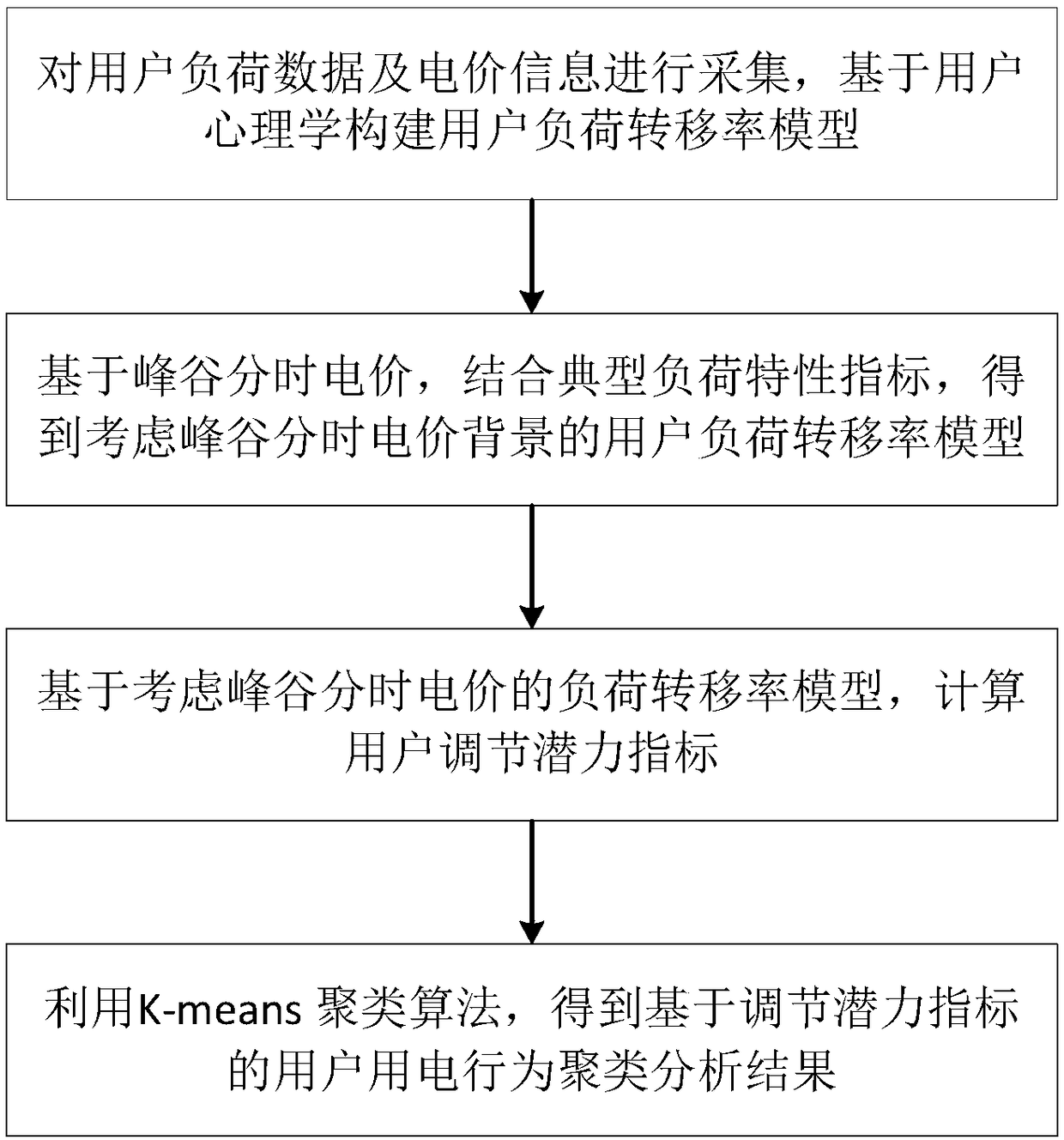

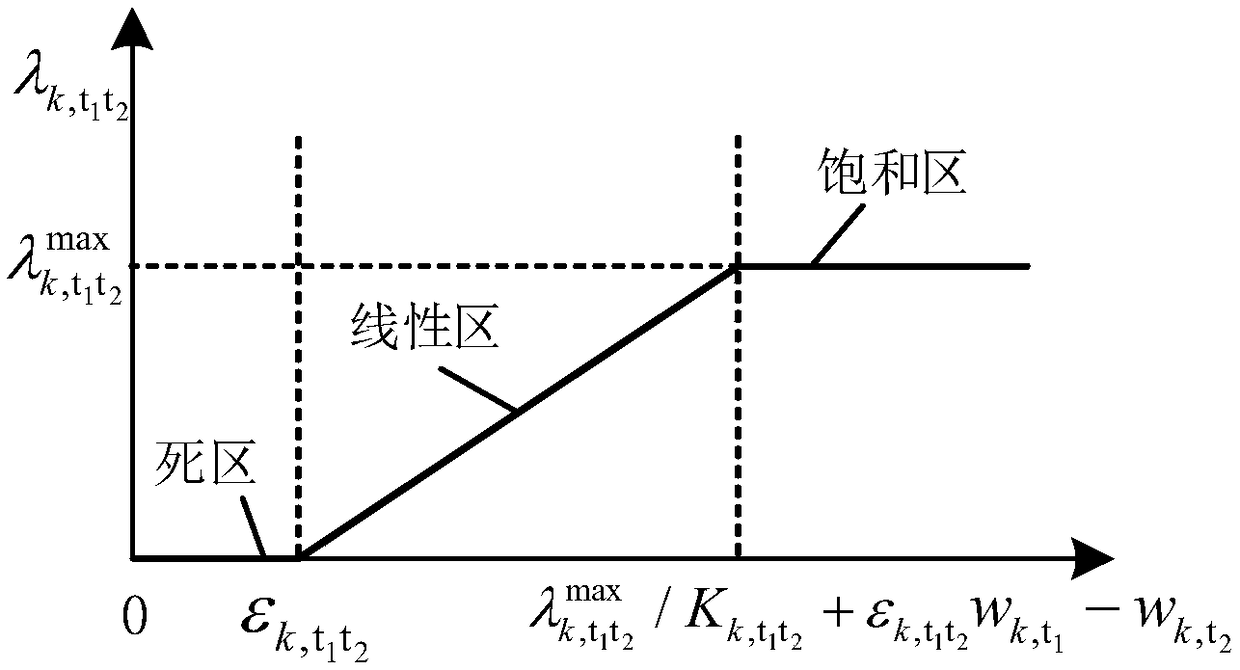

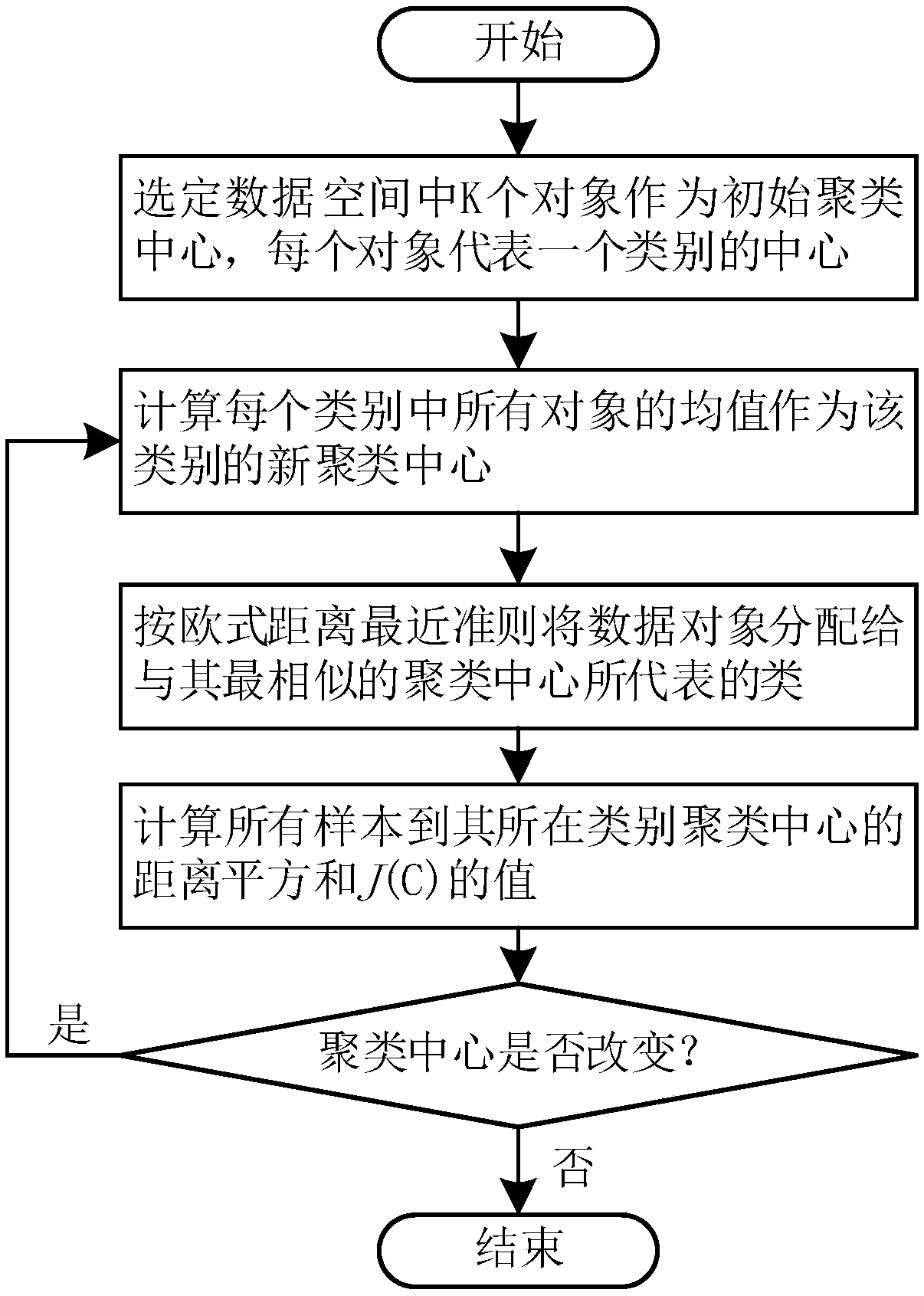

Cluster analysis method and system for consumer power consumption behavior based on regulating potential index

InactiveCN109146252AImprove polymerization effectGuaranteed cohesionCharacter and pattern recognitionTechnology managementCluster algorithmElectricity price

The invention relates to a method and a system for clustering analysis of user power consumption behavior based on an adjustment potential index, characterized by comprising the following steps of: 1)constructing a user load transfer rate model considering the peak-valley time-of-use price according to the user daily load curve information and the peak-valley time-of-use price information obtained in advance, and calculating a user regulation potential index; 2) taking the user regulation potential index as a sample space set, combining with K. Means clustering algorithm, getting the consumerbehavior clustering results based on the adjustment potential index. The invention has good aggregation effect when clustering analysis is carried out on users with obvious peak-valley characteristics, and can ensure clustering effect while improving clustering efficiency when clustering analysis is carried out on large-scale users, and can be widely used in the field of power system data analysis of peak-valley time-of-use electricity price.

Owner:STATE GRID CORP OF CHINA +3

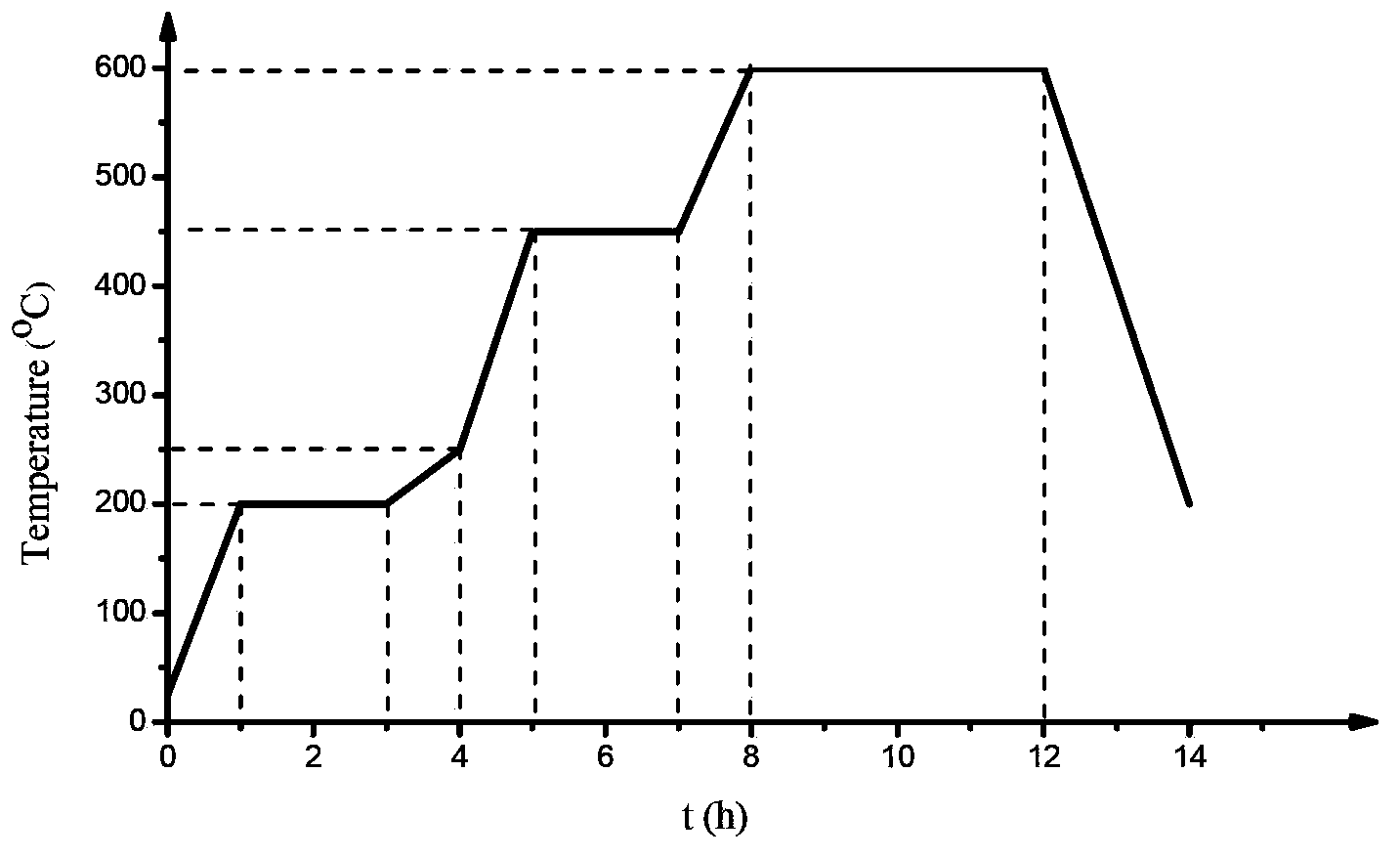

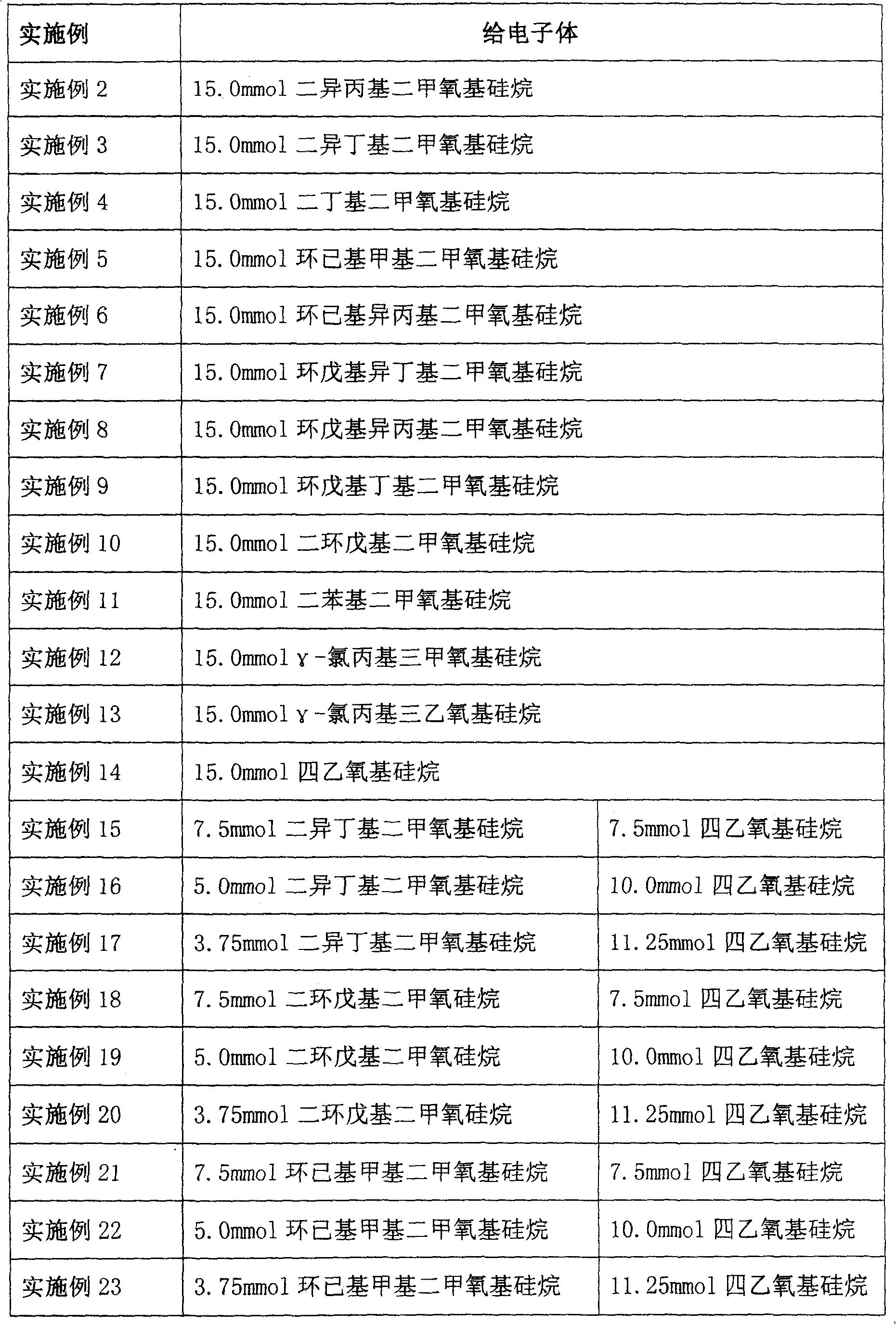

Catalytic system for producing ultrahigh molecular weight polyethylene

The invention provides a catalyst system used for preparing ultra-high molecular weight polyethylene. According to the invention, the catalyst system comprises active ingredients, outer electron donors and catalyst promoters; wherein, the total weight of active ingredients of the catalyst based on 100 parts by weight comprises 12.0 to 18.0 parts by weight of magnesium, 4.0 to 8.0 parts by weight of titanium, 1.1 to 11.0 parts by weight of alkoxy group and 55.0 to 75.0 parts by weight of halogens by weight. The method for preparing the active ingredients comprises the steps that: serous fluid of magnesium-alcohol complex is prepared, the serous fluid reacts with the electron donor of (R)nSi, pre-loading titanium reacts with loading titanium. The ultra-high molecular weight polyethylene is prepared by adopting the synergistic effect of the active ingredients, R <1> R <11> Si (OR <111>) <2> and the organoaluminium compound R 3-n ALX n of the invention. The catalyst system of the invention has the advantages of high bulk density, excellent dynamic stability, and the ultra-high molecular weight polyethylene prepared has the advantages of good product form, mean particle distribution and high bulk density; the molecular weight can be adjusted between 2 million and 7 million.

Owner:BEIJING JINDINGKE CHEM TECH

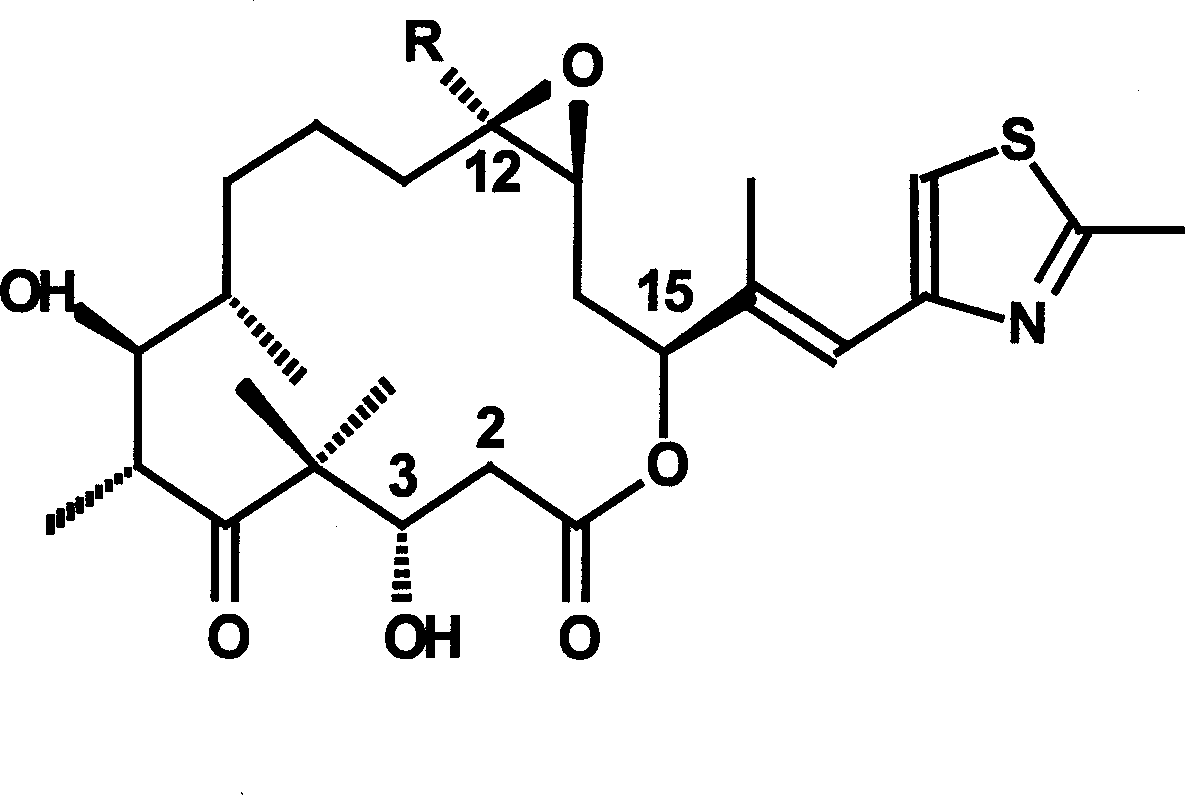

Process for separating and purifying ebormycine from fermented myxobacterium liquid

A process for extracting Epophilone from fermented liquid of myxobacterium includes mixed resin adsorption, solid and liquid extractions, molecular sieve chromatography, crystallizing and effiicent liquid-phase separation. Its advantages are high purity and extraction rate (more than 80%). The said Epophilone is an antineoplastic compound.

Owner:SHANDONG UNIV

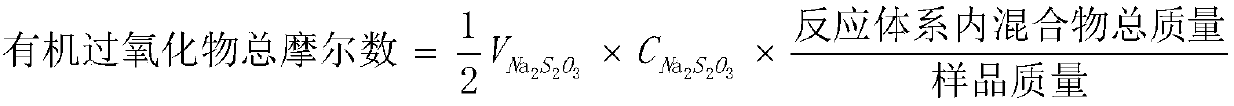

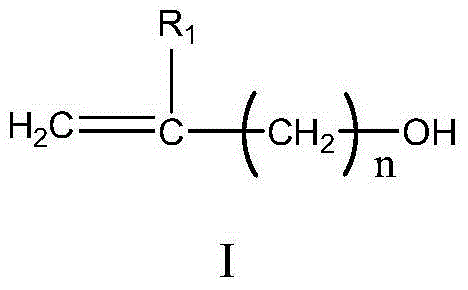

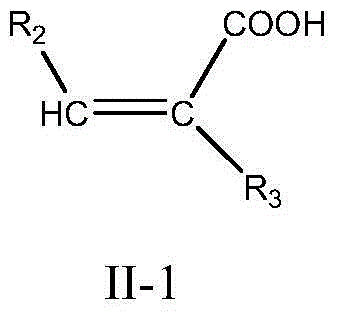

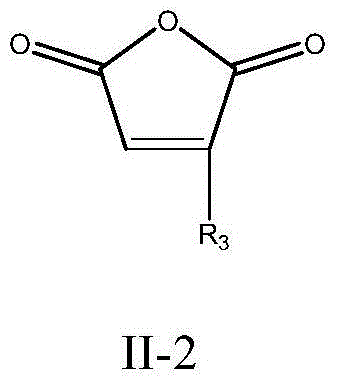

Preparation method of polycarboxylate water reducer containing polyether side chains

The invention provides a preparation method of a polycarboxylate water reducer containing polyether side chains. The preparation method comprises the following steps: firstly, carrying out copolymerization on terminal alkenyl-containing alcohol and unsaturated carboxylic acid or anhydride to prepare a copolymer; and then carrying out oxyalkylation reaction on the obtained copolymer and epoxyalkane to obtain the polycarboxylate water reducer. The preparation method provided by the invention firstly prepares a main chain structure of the polycarboxylate water reducer through copolymerization and then forms the polyether side chains through oxyalkylation reaction. As the double bonds of a polymer monomer forming the main chain structure are not damaged, the double bond retention rate of the monomer is high, the polymerization effect is relatively good, and the viscosity of the obtained polycarboxylate water reducer is relatively high. The polycarboxylate water reducer prepared by the preparation method is obviously superior to that of a product prepared by the existing preparation method in concrete application performance. The preparation method provided by the invention is simple and convenient in process, mild in condition and strong in operability.

Owner:LIAONING OXIRANCHEM INC

Method for preparing modified poly-ferric chloride coagulant

The invention relates to a method for preparing modified poly-ferric chloride coagulant, which comprises the following steps of: adding sufficient waste iron scraps and carbon powder into the hydrochloric acid steel acid-washing waste liquid of a mechanical processing industry; after reaction is finished, filtering, wherein the filter liquid is the purified hydrochloric acid steel acid-washing waste liquid; adding the purified hydrochloric acid steel acid-washing waste liquid into a reactor, starting a stirrer, slowly adding the mixed liquid of industrial sodium silicate and sodium chlorate at constant speed and ageing at room temperature to obtain the modified poly-ferric chloride coagulant. The industrial sodium silicate and the sodium chlorate are mixed into the mixed liquid, the mixed liquid is added into the purified hydrochloric acid steel acid-washing waste liquid under the condition of stirring, the ferric iron generated after ferrous oxidation and silicon carry out interpenetrating network type polymerization immediately, and an inorganic macromolecule with favorable polymerization performance is obtained.

Owner:3R ENVIRONMENTAL TECH CO LTD

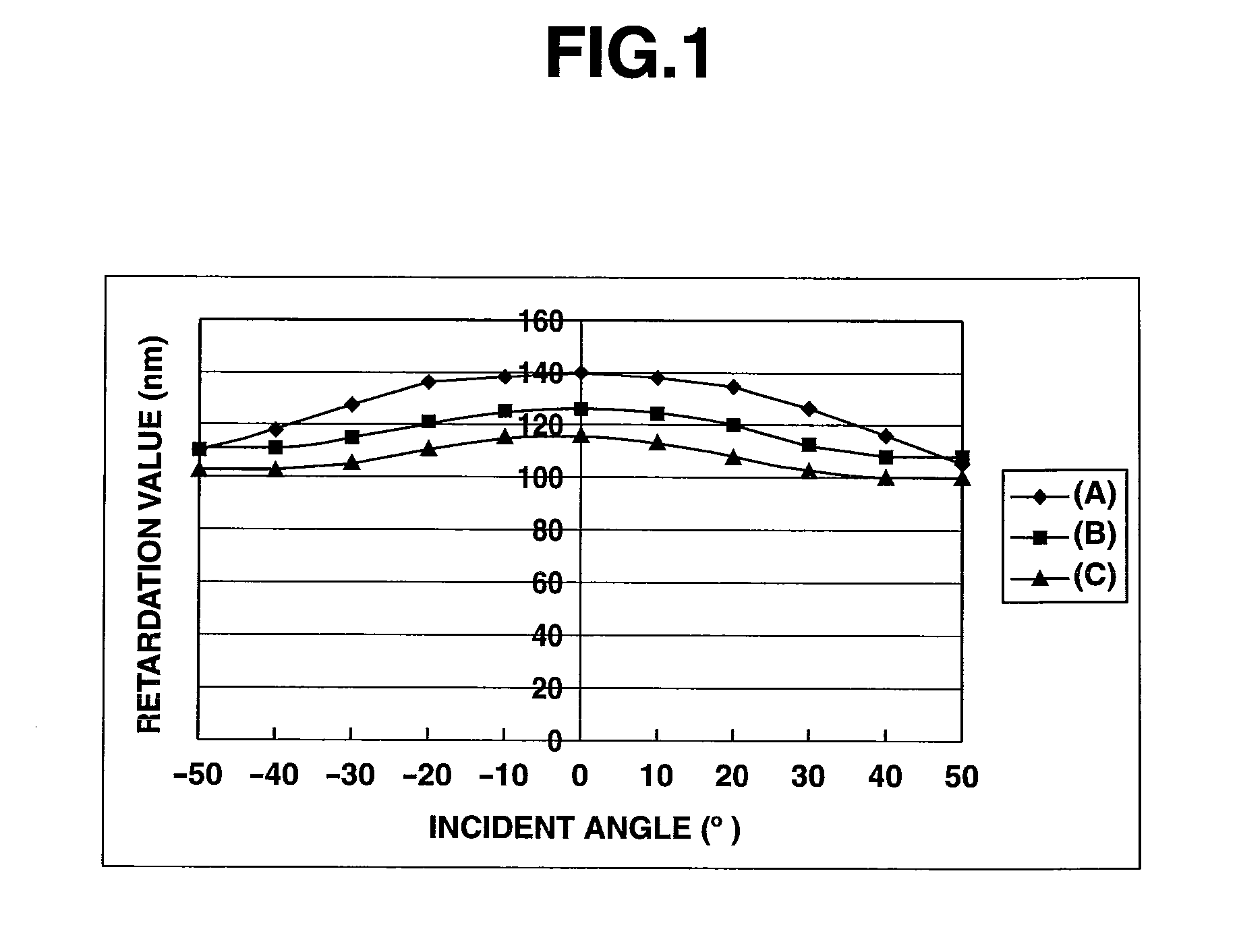

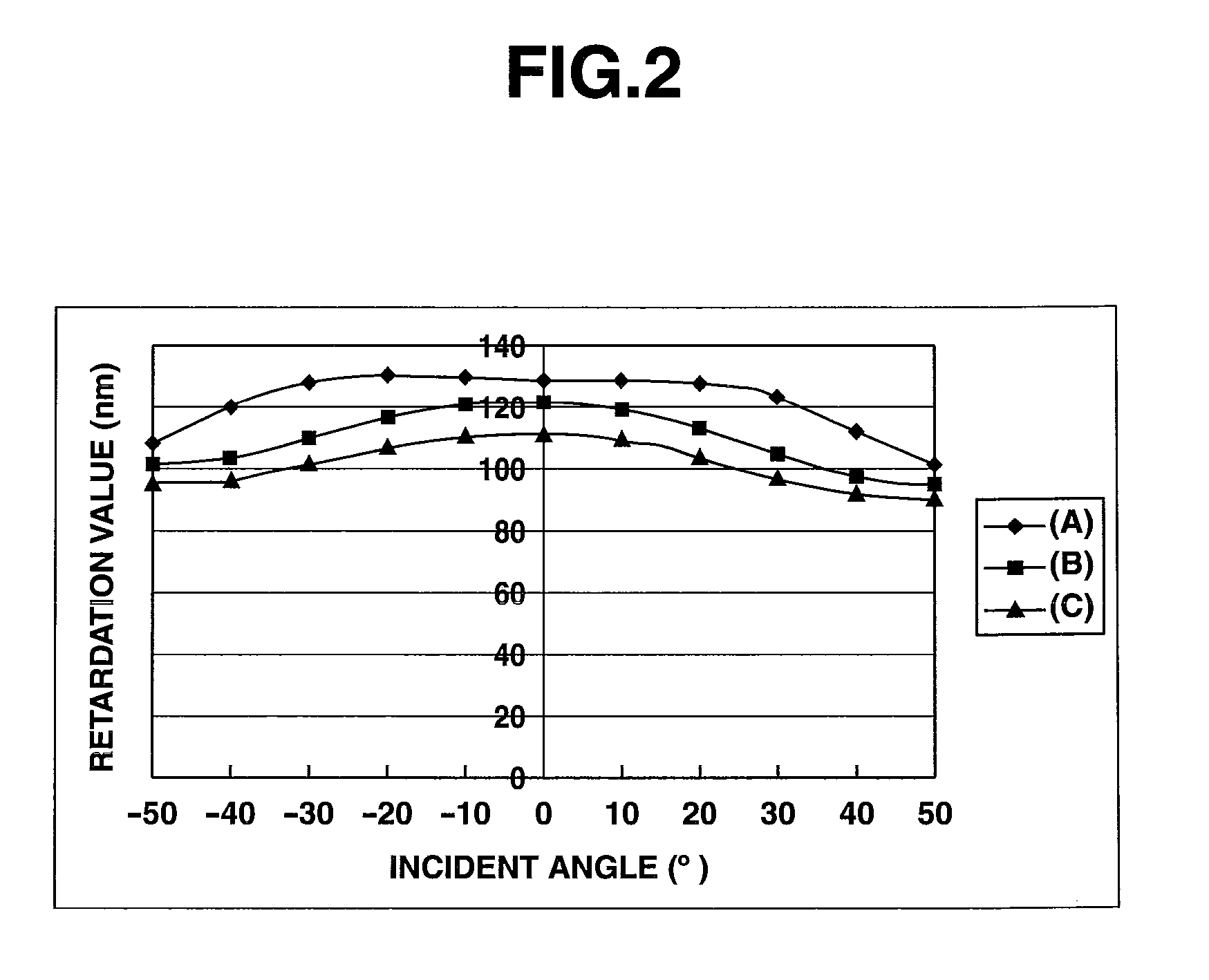

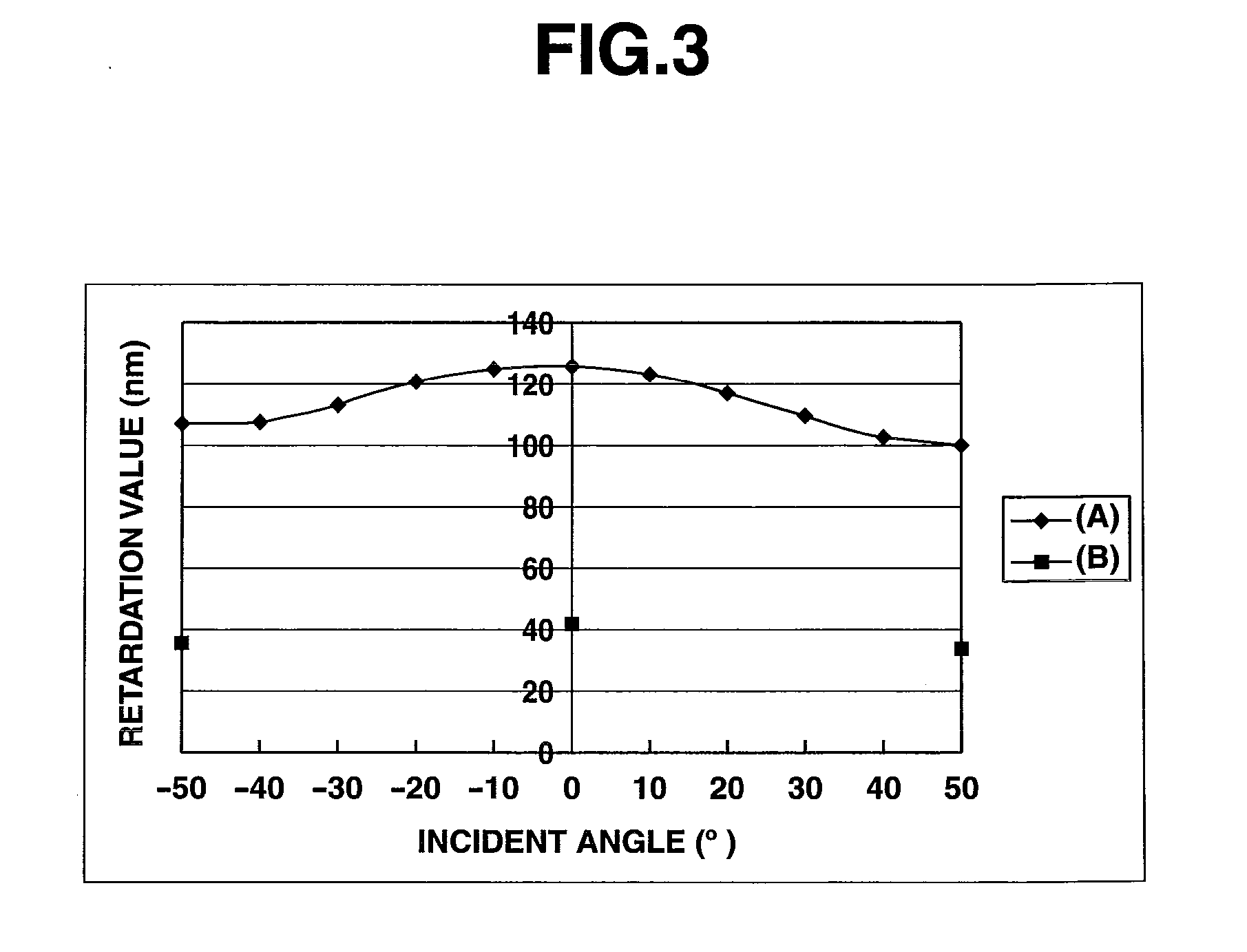

Bifunctional polymerizable compound, polymerizable liquid crystal composition, and oriented film

ActiveUS20100044632A1Improve compatibilityStable optical anisotropyLiquid crystal compositionsOrganic chemistryCrystallization temperatureCrystallinity

Disclosed is a bifunctional polymerizable compound represented by the formula [1]. Also disclosed is a polymerizable liquid crystal composition comprising at least one bifunctional polymerizable compound represented by the formula [1] and a polymerizable liquid crystal compound. The bifunctional polymerizable compound has a high polymerizability. When added to a polymerizable liquid crystal compound to prepare a polymerizable liquid crystal composition, the bifunctional polymerizable compound enables to remarkably improve the thermal stability of a polymer produced from the composition. The polymerizable liquid crystal composition containing the bifunctional polymerizable compound has a low crystallization temperature and shows a stable liquid-crystallinity under ordinary environment.wherein X1, X2 and X3 independently represent a single bond or a benzene ring; Y represents —O— or a single bond; M represents a lactone ring or an acrylate group; and n represents an integer of 4 to 10.

Owner:NISSAN CHEM IND LTD

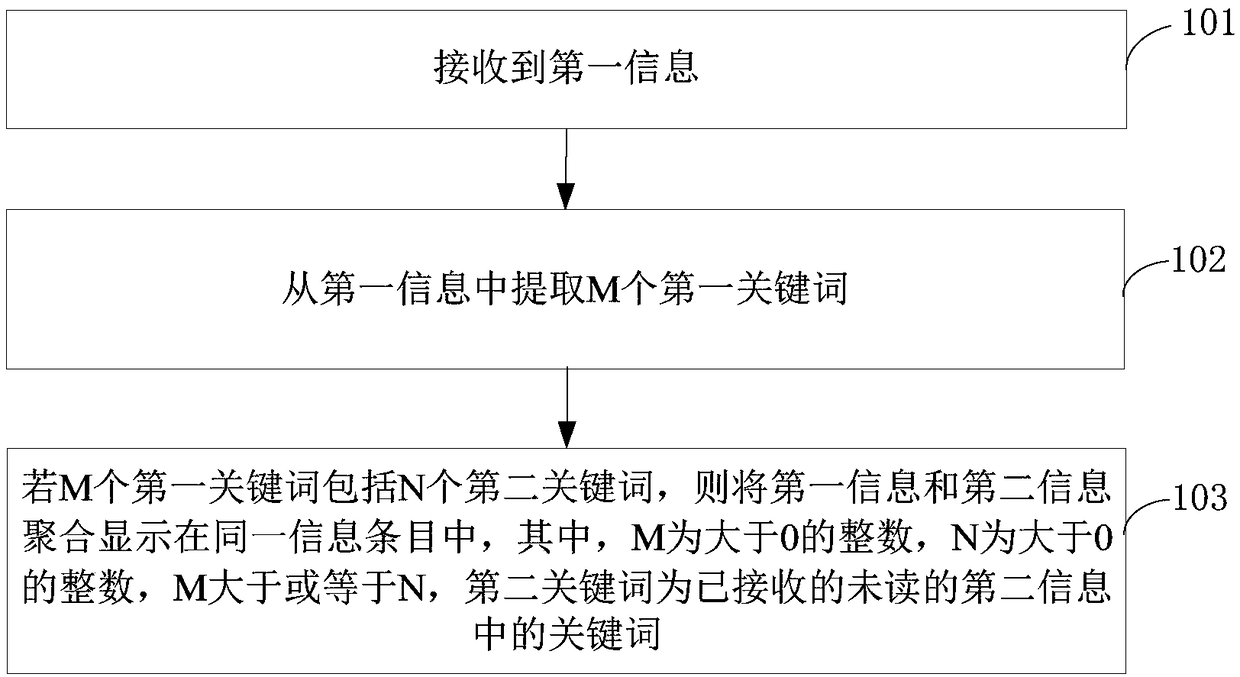

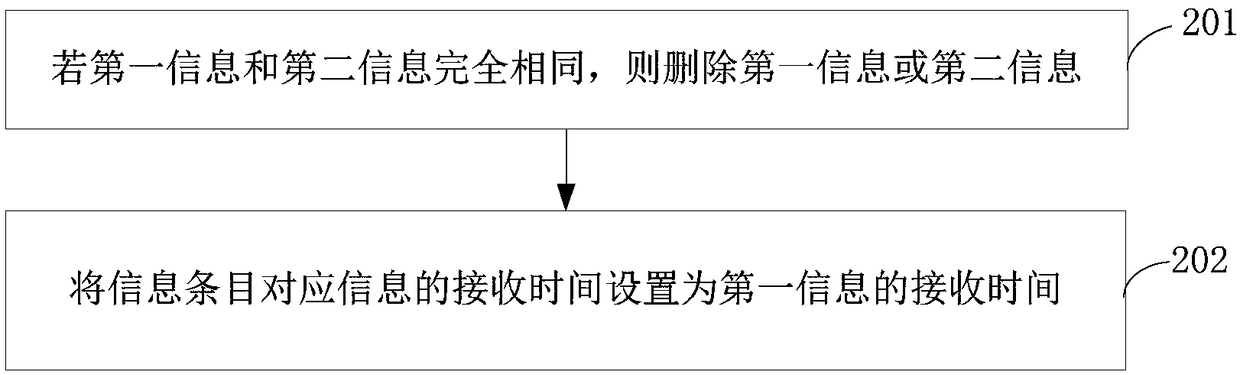

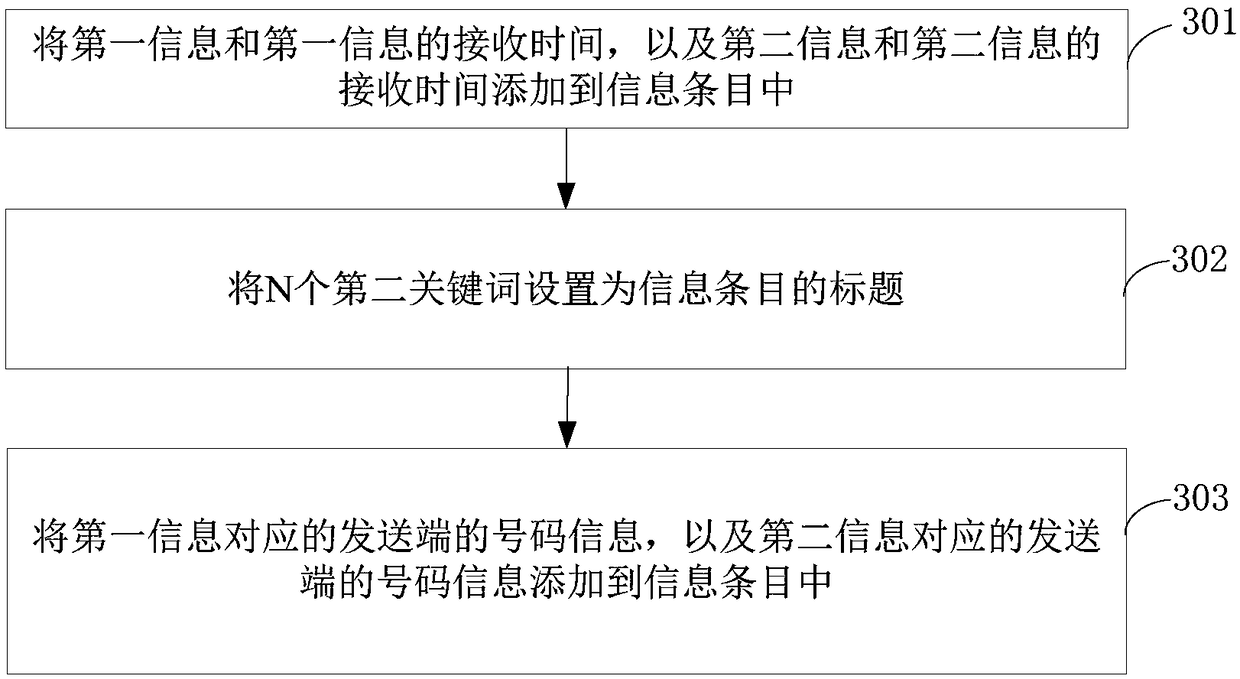

A method, apparatus and device for information aggregation

PendingCN109446323AGood polymerization effectConvenient one-time viewingNatural language data processingSubstation equipmentInformation aggregationComputer science

A method, apparatus and device for information aggregation is provided. The method includes extracting M first keyword from first information upon receipt of that first information, if the M first keywords comprise N second keywords, aggregating and displaying the first information and the second information in the same information entry, wherein M is an integer greater than 0, N is an integer greater than 0, M is greater than or equal to N, and the second keyword is a keyword in the received unread second information. The technical solution provided by the present disclosure can be used to implement information aggregation based on information content.

Owner:BEIJING XIAOMI INTELLIGENT TECH CO LTD

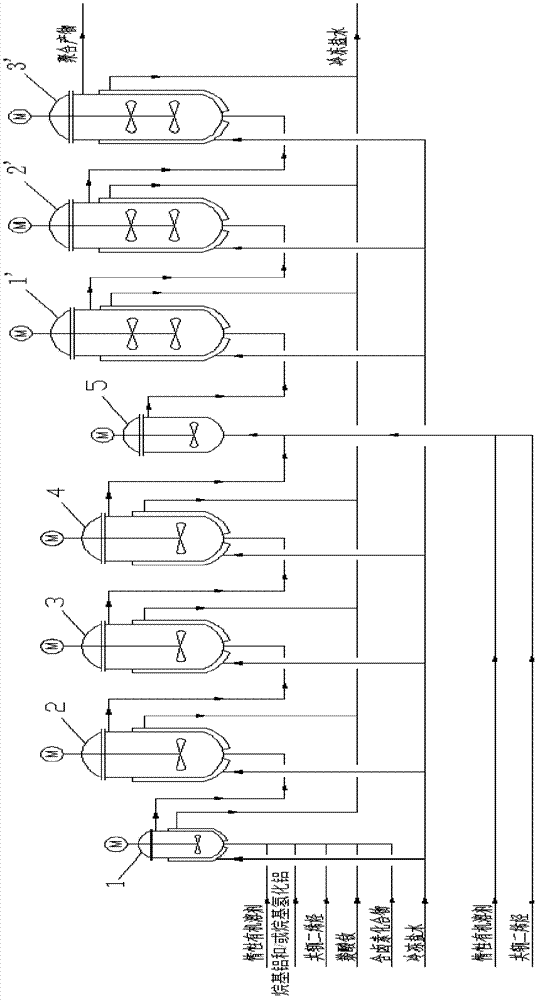

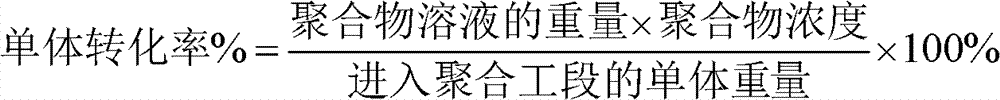

Polymerization method

InactiveCN103360525AImprove polymerization effectIncrease productivityAutomatic controlContinuous integration

The invention provides a polymerization method. The method comprises the steps of: in the presence of an inertia organic solvent, continuously feeding aluminum alkyl and / or alkyl aluminium hydride, conjugated diene, neodymium carboxylate and a halogen-containing compound into a catalyst preparing unit to contact to obtain a neodymium homogeneous rare earth catalyst; and continuously feeding the conjugated diene, the inertia organic solvent and the neodymium homogeneous rare earth catalyst into a polymerization unit to contact under the conditions of a polymerization reaction. By adopting the polymerization method provided by the invention, a good polymerization effect can be obtained when the catalyst is prepared under normal conditions (for example, the feeding sequence in the catalyst preparing process is not strictly controlled and the operating condition in the catalyst preparing process is not strictly controlled). Furthermore, through carrying out continuous integration on the preparation process and the polymerization process, the polymerization method provided by the invention has the advantages that the production efficiency is improved; the labor intensity is reduced; the operating cost is reduced; the automatic control is easily realized; and the obtained product is stable and uniform in quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

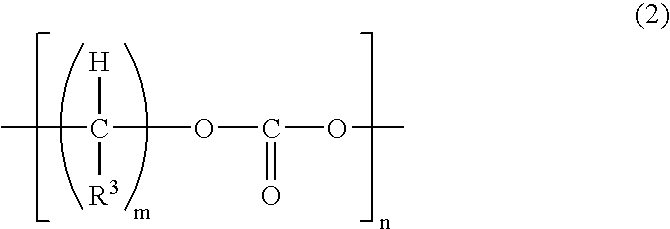

Polymerizable composition and use thereof

InactiveUS20040218346A1Improve ionic conductivityImprove polymerization effectHybrid capacitor electrolytesLight-sensitive devicesPolymer electrolytesPolymer science

The present invention provides a solid polymer electrolyte; a polymerizable composition having low viscosity and excellent processability for obtaining the solid polymer electrolyte; and a polymerizable compound having low viscosity, and good polymerizability and stability for use in the polymerizable composition. The present invention also provides primary and secondary batteries capable of working with high capacity and current; an electric double-layer capacitor ensuring high output voltage, large takeout current, and good processability; and an electrochromic device favored with high response speed. Each thereof use the solid polymer electrolyte of the present invention and are ensured with long life, excellent safety free of liquid leakage, high reliability and production at a low cost. A solid polymer electrolyte, including a carbonate-based polymer in which a branched chain is introduced and having a high dielectric constant and a wide electrochemical stability range, having excellent processability, good safety and high ionic conductivity, is provided.

Owner:SHOWA DENKO KK

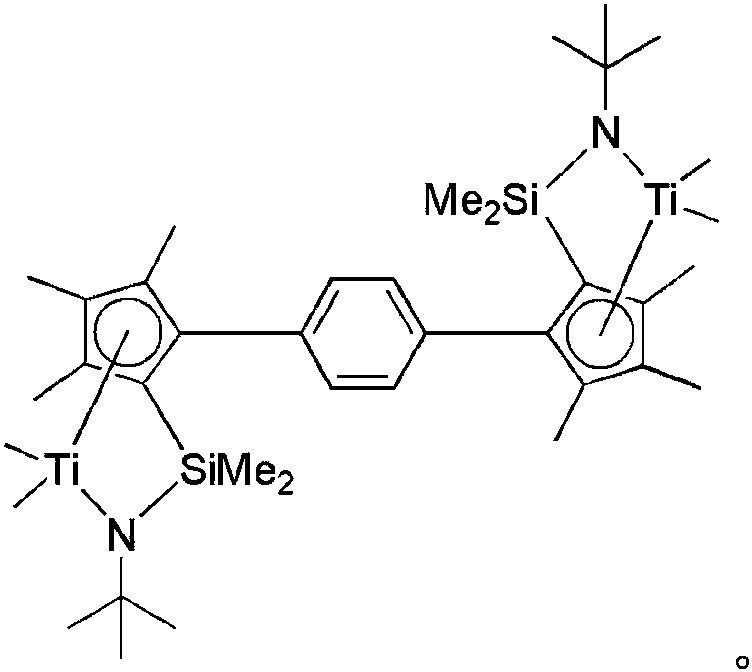

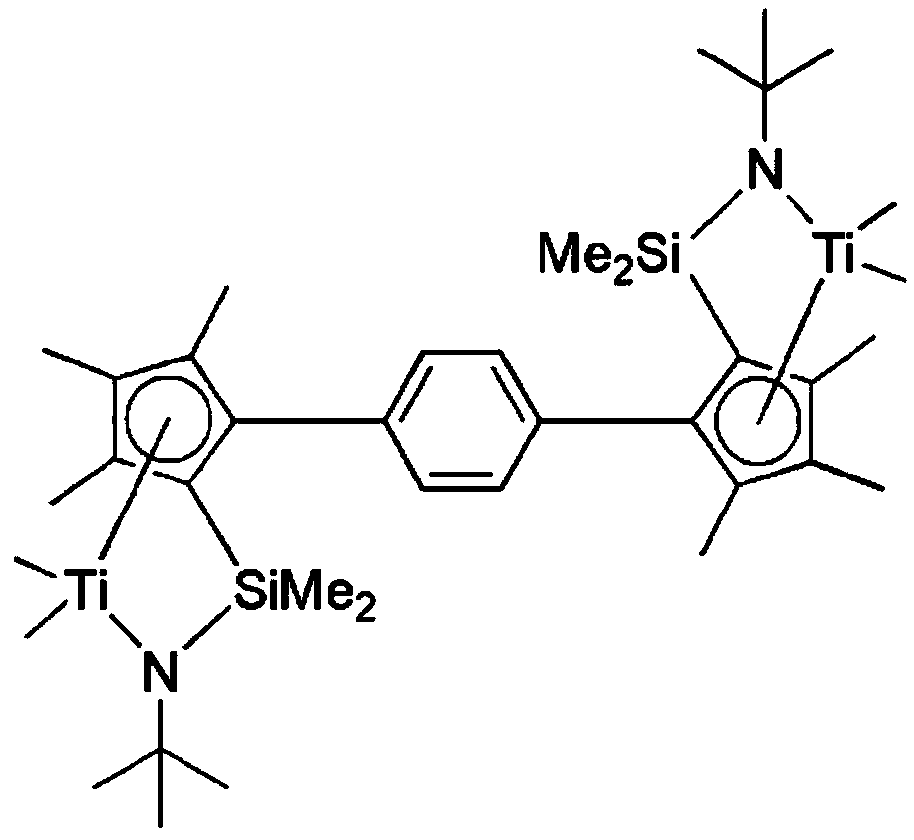

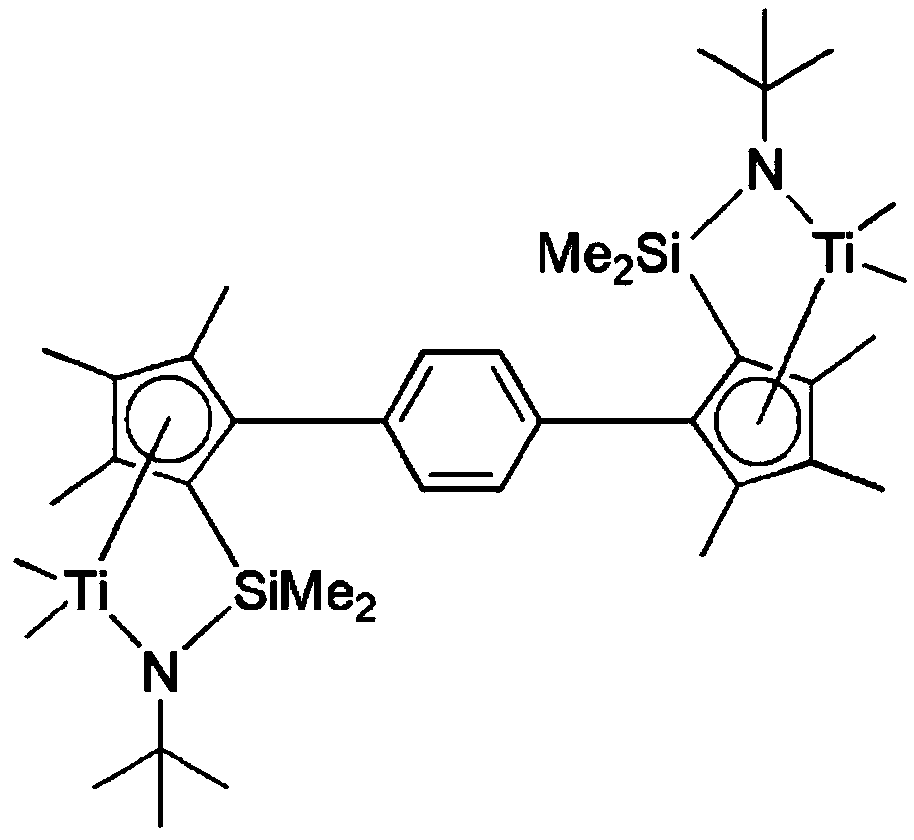

CATALYST COMPOSITION FOR PREPARING ELASTIC COPOLYMER, AND METHOD FOR PREPARING ELASTIC COPOLYMER, WHICH COMPRISES ETHYLENE AND alpha-OLEFIN OR ETHYLENE, alpha-OLEFIN AND UNCONJUGATED DIENE, BY USING SAME

The present invention relates to a method for preparing an ethylene-based elastic copolymer and, more specifically, to a method for preparing an ethylene-based elastic copolymer by using a catalyst composition for preparing an ethylene-based elastic copolymer, the composition using, as a main catalyst, a binuclear constrained geometry transition metal compound having a structural advantage in theobtainment of a high-molecular-weight ethylene-based elastic copolymer due to a high polymerization activity and comonomer reactivity since the binuclear constrained geometry transition metal compoundhas a structure in which two cyclopentadiene ligands of a constrained geometry catalyst are linked by a 1,4-phenylene, and comprising one or more cocatalyst compounds selected from the group consisting an organoaluminum compound, an organoaluminoxane compound and a boron compound.

Owner:KUMHO POLYCHEM

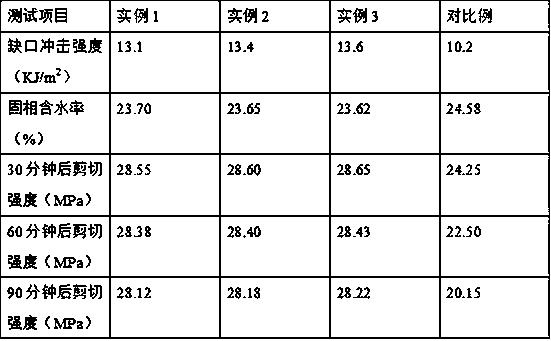

Preparation method of high-impact-resistant waterproof type epoxy resin toughening agent

The invention discloses a preparation method of a high-impact-resistant waterproof type epoxy resin toughening agent, and belongs to the technical field of preparation of toughening agents. The methoddisclosed by the invention is characterized in that butyl acrylate, 1,4-butanediol diacrylate, allyl methacrylate, distilled water, sodium dodecyl benzene sulfonate and potassium persulfate are subjected to heating reaction to prepare a home-made seed emulsion, and the home-made seed emulsion is mixed with butyl acrylate, methyl methacrylate, a cross-linking agent, an emulsifying agent, an initiating agent and a grafting agent together to prepare a core layer emulsion and a shell layer emulsion; divinyl benzene is an oil-soluble initiating agent and mainly swells in emulsion particles, and only a small amount of divinyl benzene is dissolved in a water phase, thereby improving the impact-resistance strength of the toughening agent; and nano silicon dioxide is added to a polyacrylate emulsion with better water resistance and physical and mechanical properties to enable the polymer to have high water absorbing capacity, and resin can be cured in a humid environment or even underwater andcan keep good water resistance, thereby improving the water resistance of the toughening agent.

Owner:常州市万昌化工有限公司

Suspending solid phase polymerization method for preparing polymer

The invention discloses a suspension solid-phase polymerization method for producing polymers, comprising the steps of suspending monomer or prepolymer powder or particle in liquid inert medium or gaseous inert medium to solid-phase polymerize. The polymerization temperature is between the glass transition temperature of monomer or prepolymer and the melting point. The invention solves the problems that the common solid-phase polymerization is easy to cause polymerization heat, the crystalization heat is hard to spread and particle or powder is easy to agglomerate. The suspension solid-phase polymerization method of the invention is suitable for (but not limited to) condensation polymerization and is also suitable for (but not limited to) preparing and manufacturing aromatic polyester, aliphatic polyester, polycarbonate, polyamide, polyimide, polysulfone, polyether and the like.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Metal-film-coated material and process for producing the same, metallic-pattern-bearing material and process for producing the same, composition for polymer layer formation, nitrile group-containing polymer and method of synthesizing the same, composition containing nitrile group-containing polymer, and laminate

InactiveUS20100003533A1Improve adhesionLess fluctuationSynthetic resin layered productsPretreated surfacesWater absorption coefficientPolymer chemistry

Owner:FUJIFILM CORP

PVC foam processing aid, method for preparing the same and polyvinyl chloride resin composition comprising the same

ActiveUS20160333176A1Improve polymerization effectReinforces aggregation propertyCoatingsPolyvinyl chloridePolymer chemistry

Disclosed are a PVC foam processing aid, a method for preparing the same, and a polyvinyl chloride resin composition comprising the same. More specifically, provided are a PVC foam processing aid and a polyvinyl chloride resin composition exhibiting superior aggregation property and improving foam moldability of polyvinyl chloride (PVC) resins, prepared therefrom.

Owner:LG CHEM LTD

Enclosed type overlapped garden residence

The present invention discloses a planning building unit, wherein the building structure is composed of an external wall, an inner wall and a floor. The building structure is provided with a traffic roadway leading to the outside. The floor divides the planning building unit to a plurality of using units. The planning building unit is provided with a direction focusing point. The using units are arranged around the direction focusing point. The building structure surrounds centripetally and the planning building unit is provided with at least one recessing platform to the direction of the using unit from the base layer to the top layer. The space of the surrounding middle floor satisfies the requirement of sunshine and light collecting with a form of longitudinal recessing platform of the floor body by stage, and the length of the distance between the surrounding opposite floor body is reduced. The storey is overlapped to the stage recessing platform outwards and longitudinally from the surrounding center. The outdoor walking channel and private garden are formed through the recessing platform. The target that a courtyard and a door are in each household is realized. The invention can be used for planning the planning building unit which is formed by arranging a plurality of planning building units.

Owner:马力

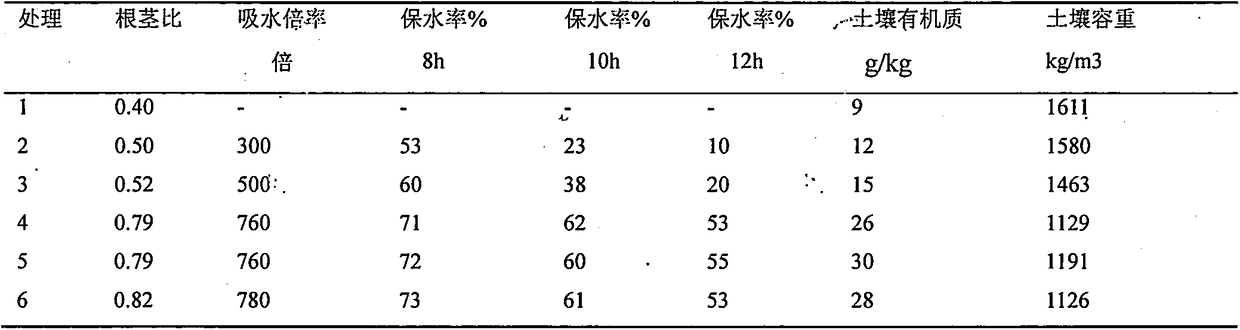

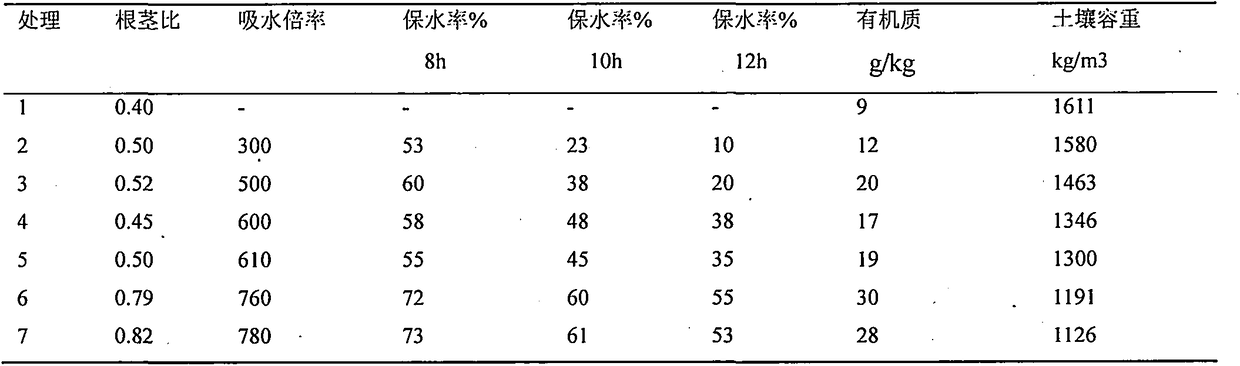

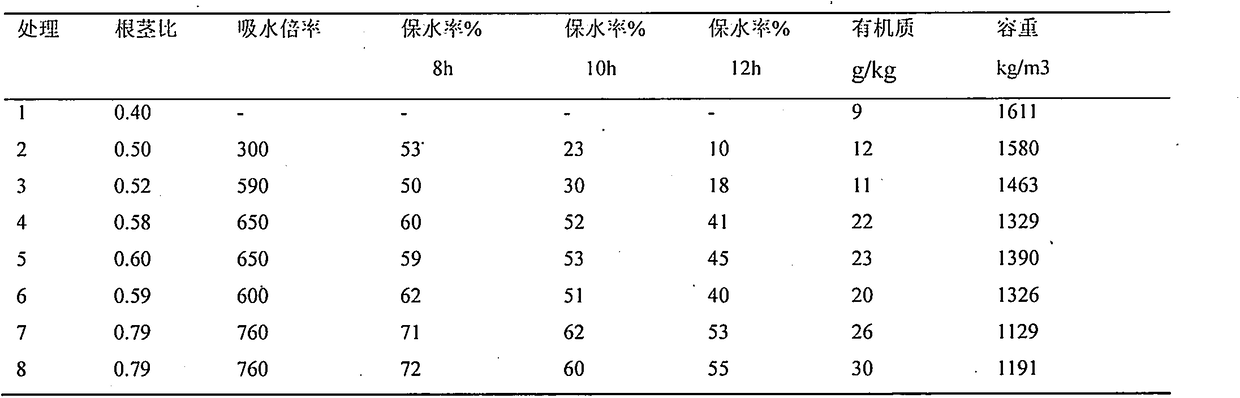

Preparation method of multi-functional soil organic water-retaining agent

InactiveCN108516887AStrong repair functionImprove repair functionAgriculture tools and machinesAnimal corpse fertilisersAbsorption capacityAdditive ingredient

The invention relates to a preparation method of a multi-functional soil organic water-retaining agent. Animal bone blocks and a vinegar humic acid liquid organic matter rich in source are reutilized,straw biochar is combined, and a specially made cross-linking fluid is utilized for preparing an organic water-retaining agent. Bones are semi-carbonized preprocessed so as to have adsorptivity and be increased in specific surface area without being completely carbonized, and the bones can fully adsorb organic matters and nutrient substances in a soak solution during a vinegar humic acid liquid soaking process. According to the water-retaining agent prepared by the invention, the water absorption capacity reaches up to 900, the water retaining rate reaches to 50 percent after 12h at 55 DEG C,the organic content is 28 percent, the gel strength is high, and the water retaining rate is larger than 90 percent after the water-retaining agent is centrifuged in a centrifugal machine for 30 minat 3000r / min; the nutrient releasing rate of the nutrient ingredients does not exceed 75 percent within 30 days; the multi-functional soil organic water-retaining agent is good for loosening soil, reproducing microorganisms, effectively improving a soil structure, and improving the permeability and the drought resistance of soil, non-toxic, harmless, green and environmental-friendly, so that a benign cycle is formed.

Owner:上海金禾天地信息科技有限公司

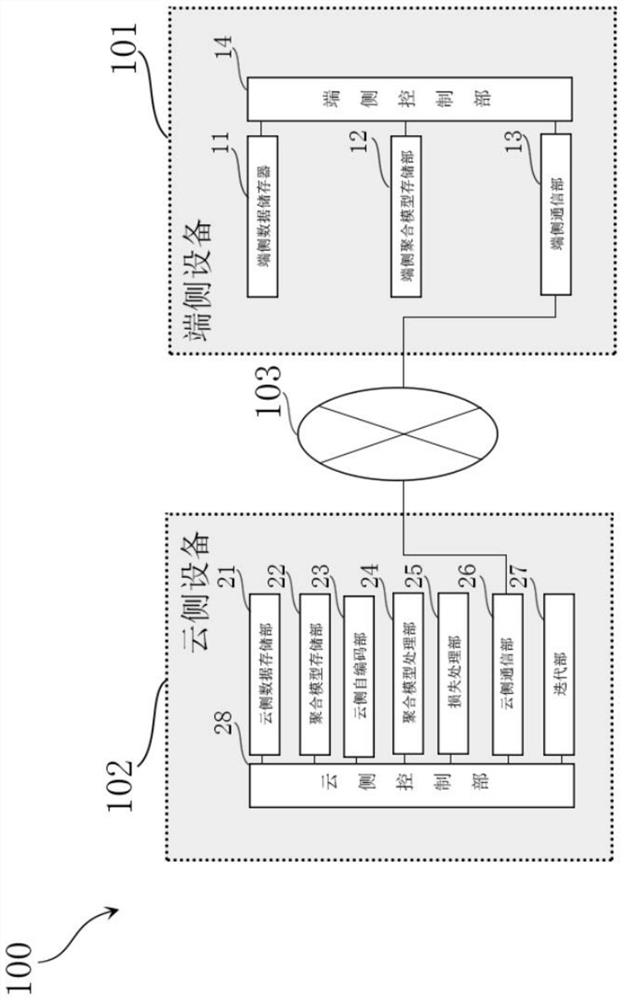

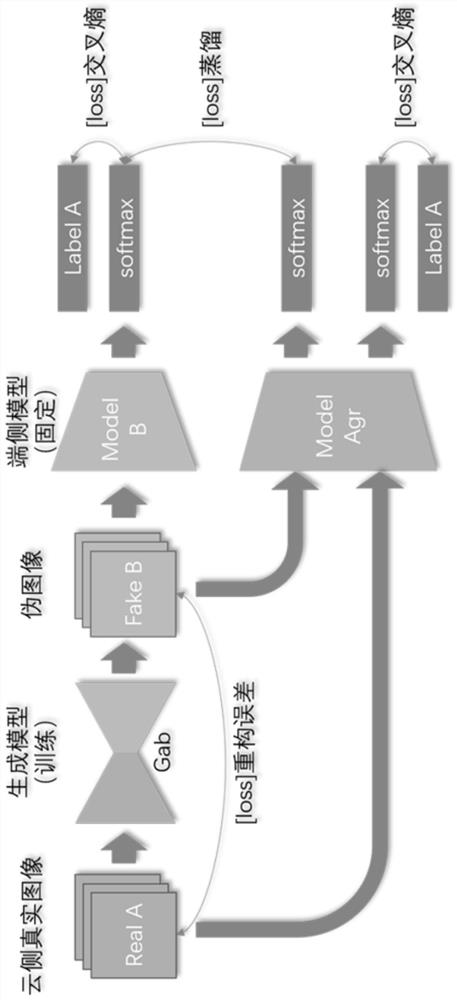

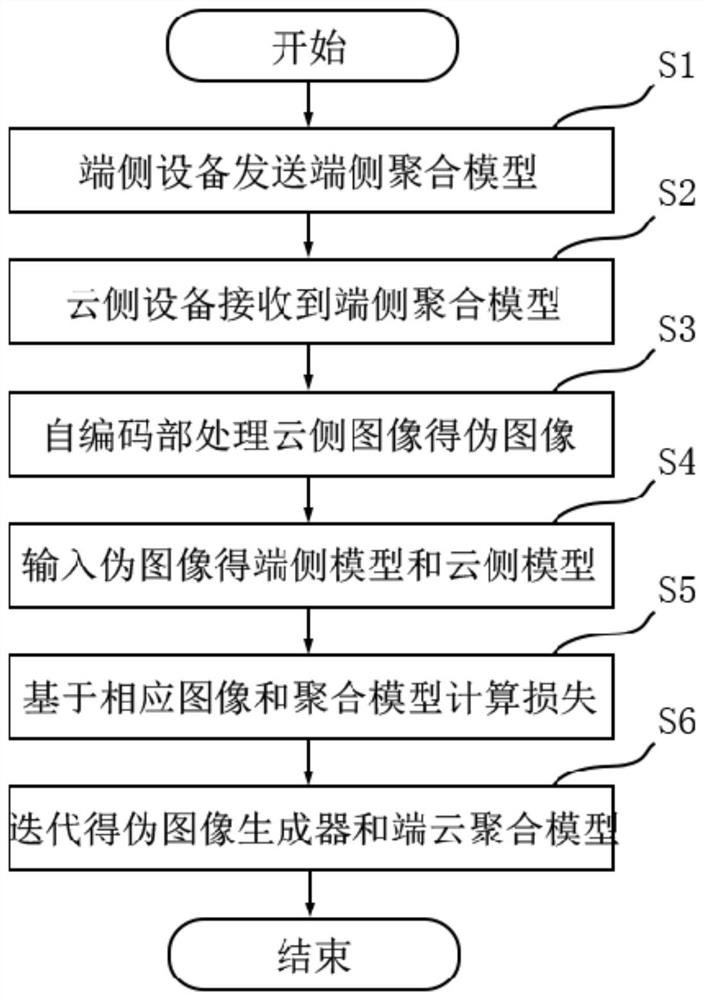

End-cloud cooperative training system for protecting end-side privacy

ActiveCN111985562AProtect user privacyGood polymerization effectCharacter and pattern recognitionDigital data protectionModel aggregationReal-time computing

The invention provides an end-cloud cooperative training system for protecting end-side privacy. An aggregation model storage part stores at least a pre-trained cloud side aggregation model, an end-side communication part sends an end-side aggregation model to cloud-side equipment, a cloud-side communication part receives the end-side aggregation model, a cloud-side self-encoding part processes acloud-side image to obtain a pseudo image, an aggregation model processing part is used for respectively inputting the pseudo image into the end-side aggregation model and the cloud-side aggregation model for processing to obtain an output end-side aggregation model and an output cloud-side aggregation model, and according to a plurality of loss iteration parts processed by the loss processing part, model parameters are updated through back propagation and repeated iteration to obtain a cloud side training pseudo image generator and an end cloud aggregation model. Therefore, the system can still efficiently and stably aggregate the model under the condition of protecting the privacy of the user, has the advantages of protecting the privacy of the user, being good in aggregation effect, good in robustness, good in generalization ability and the like, and is suitable for practical application such as model aggregation between user equipment and end-cloud collaborative training.

Owner:FUDAN UNIV

Technology for preparing itaconic acid-propenoic acid copolymer from fermented liquid

InactiveCN1458177ASolve the characteristics of difficult homopolymerizationLow costItaconic acidIon exchange

The present invention provides technology of preparing itaconic acid-propenoic acid copolymer from fermented liquid. With the fermented liquid for producing itaconic acid via biological fermentationas material, and through ionic exchange, concentration, copolymerization with propenoic acid in the presence of initiator, itaconic acid-propenoic acid copolymer solution is prepared. Using the fermented liquid as initial material can lower the cost greatly, and the free radical polymerization process solves the demerit of hard homopolymerization of itaconic acid. The process has less residual monomer and high conversion rate. The copolymer may be used as scale inhibitor, scale remover, dispersant, detergent assistant, etc.

Owner:ZIBO MINING GRP

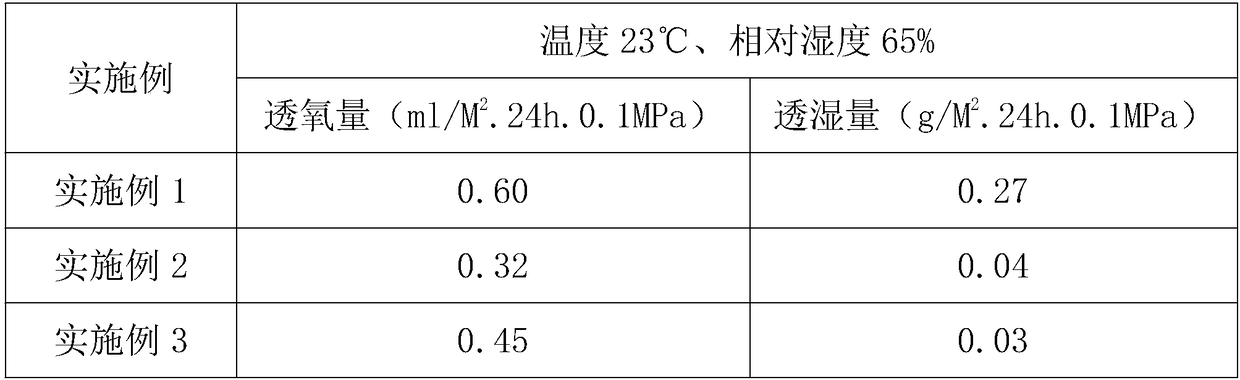

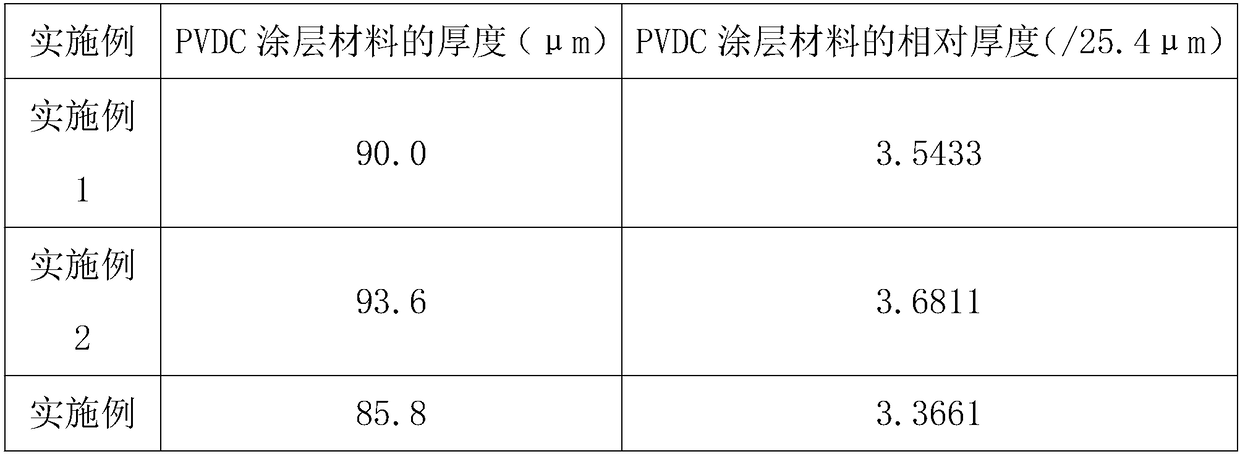

PVDC coating material with high barrier performance and preparation method thereof

InactiveCN108250475AImprove barrier propertiesStrong oxidation abilityAntifouling/underwater paintsPaints with biocidesPolymer scienceDouble bond

The invention discloses a PVDC coating material with high barrier performance. The PVDC coating material comprises a modified PA membrane, wherein the outer side surface of the modified PA membrane iscoated with modified PVDC rubber latex, the inner side surface of the modified PA membrane is coated with modified PVDC nano rubber, the modified PVDC nano rubber is prepared from the following raw materials: ultrapure water, a PH value buffering adjusting agent, vinylidene chloride monomers, methyl acrylate monomers, an initiator, and a dispersion agent, the thickness of the modified PA membraneis 81 to 89 micrometers, the thickness of the modified PVDC rubber latex smeared on the outer side surface of the modified PA membrane is 1.5 to 1.8 micrometers, the oxygen permeation amount of the PVDC coating material at the standard conditions that the temperature is 23 DEG C, the relative humidity is 65 percent and the thickness is 25.4 micrometers is 1.18 to 2.12 ml / M<2>.24h.0.1MPa, and thehumidity permeation amount is 0.1 to 0.96 g / M<2>.24h.0.1MPa. By adopting the PVDC coating material with the high barrier performance, the technical problems that the PVDC rubber latex is poor in heatstability, the dual-bond conjugation easily occurs when the PVDC rubber latex is heated or stored for a long term at a normal temperature, hydrogen chloride is leaked, holes are formed among molecules and the barrier performance is in failure can be solved.

Owner:CHANGDE JINDE NEW MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com