Polymerization method

A technology of polymerization unit and polymerization reactor, which is applied in the field of polymerization, can solve the problems of large volume of aging kettle, and achieve the effects of reducing labor intensity, realizing self-control and easy self-control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

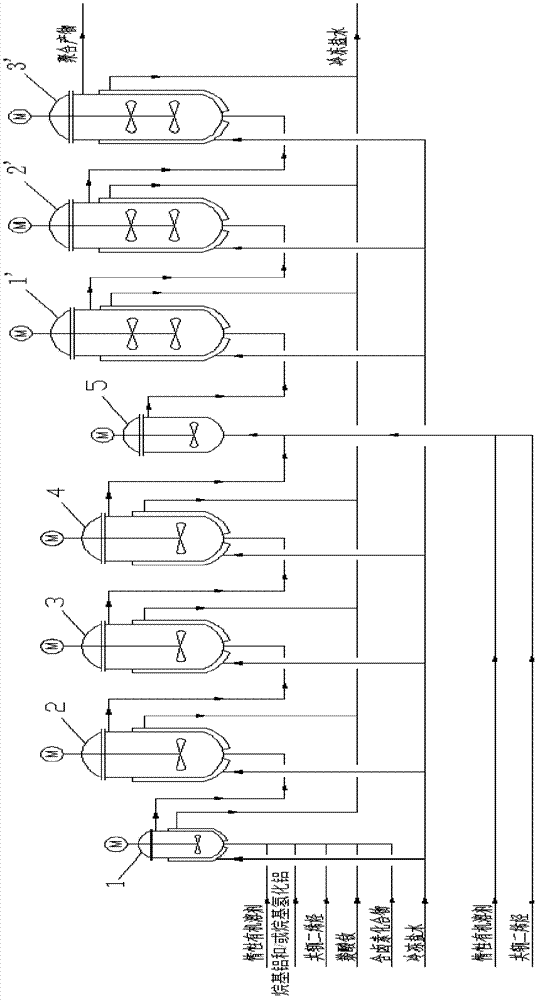

[0053] according to figure 1 The flow shown is aggregated:

[0054] (1) Catalyst preparation section: mix isoprene, neodymium naphthenate / cyclohexane solution, diethylaluminum chloride / cyclohexane solution, triisobutylaluminum / cyclohexane solution and solvent cyclohexane Continuously sent to the first fully mixed aging kettle 1 for contact to obtain the first solution, the flow rates were 270g / h, 320ml / h, 120ml / h, 700ml / h, 4650ml / h; The residence time of the material is 50min, and the low-temperature frozen brine is passed through the jacket of the kettle, and the temperature of the kettle is controlled at 10°C;

[0055] The first solution is introduced from the first fully mixed aging tank 1 into the second fully mixed aging tank 2 for the second contact to obtain the second solution; the second solution is introduced from the second fully mixed aging tank 2 Introduce the third fully mixed aging tank 3 for the third contact to obtain the third solution; introduce the third ...

Embodiment 2

[0059] Carry out polymerization according to the method for embodiment 1, difference is, in the step (1), the material feed amount that enters each full-mixing type aging kettle is reduced to original 5 / 6, but the ratio between each material feed flow rate Keep the same as in Example 1, and the residence time of the materials in the first fully mixed aging tank is 60min, and the residence time of the materials in the second, third and fourth fully mixed aging tanks is 6h;

[0060] Simultaneously in step (2), the feed amount of the isoprene that enters the polymerization section premix tank, solvent is also reduced to original 5 / 6, but the ratio between the two remains the same as in Example 1, and The residence time of the materials in the three polymerization reactors was 48 minutes.

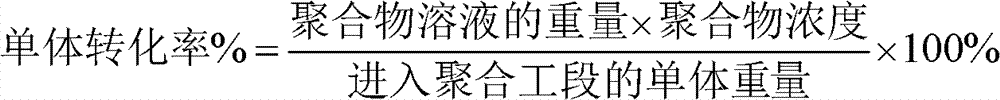

[0061] According to this example, the final conversion of isoprene monomer was 93%, the cis 1,4-structure content of the polymer was 98%, and the Mooney viscosity was 80.

Embodiment 3

[0063] Carry out polymerization according to the method for embodiment 1, difference is, in the step (1), the material feed amount that enters each fully mixed type aging tank is reduced to original 5 / 7, but the ratio between each material feed flow rate Keep the same as in Example 1, and the residence time of the materials in the first fully mixed aging tank is 70min, and the residence time of the materials in the second, third and fourth fully mixed aging tanks is 7h;

[0064] Simultaneously in step (2), the feed amount of the isoprene and solvent entering the polymerization section premixing tank is also reduced to the original 5 / 7, but the ratio between the two remains the same as in Example 1, and The residence time of the materials in the three polymerization reactors was 56 minutes.

[0065] According to this example, the final conversion of isoprene monomer was 94%, the cis 1,4-structure content of the polymer was 98.2%, and the Mooney viscosity was 82.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com