Catalytic system for producing ultrahigh molecular weight polyethylene

An ultra-high molecular weight, catalytic system technology, applied in the field of catalytic systems, can solve the problems of cumbersome catalyst preparation, failure to provide the average particle size of polymer particles, and no practical value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

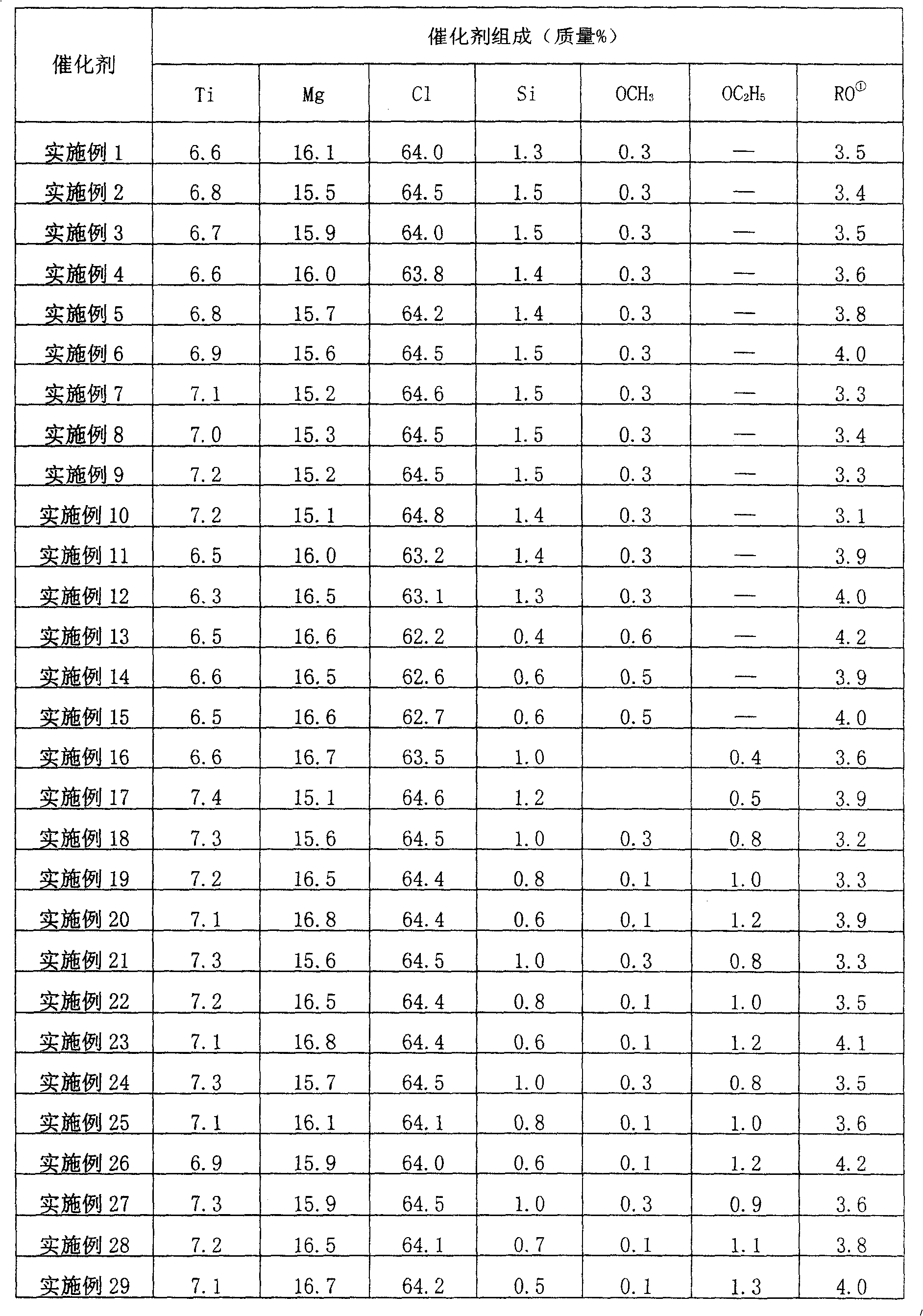

[0054] Embodiment 1 prepares catalyst active component

[0055] Put 4.76 grams (0.05mol) of MgCl 2 , 100 mL of decane and 26 mL of isooctyl alcohol (0.167 mol), heated to 130 ° C for 180 minutes, cooled to 65 ° C, added 15 mmol of dipropyldimethoxysilane electron donor at this temperature, and continued to react for 60 minutes. After cooling to room temperature. Slowly add 50 mL of TiCl dropwise over 90 minutes at 0°C 4 In the mixed solution, keep the temperature at 0°C for 60 minutes after the dropwise addition, then add 25mL chlorocyclohexane and slowly raise the temperature to 110°C over 120 minutes, add 2.5mmol of the same silane electron donor at this temperature, continue After reacting for 120 minutes, a solid catalyst was obtained. After the stirring was stopped, it was found that the solid catalyst particles settled very fast. After the reaction was finished, the solid catalyst was filtered out with heat. Wash with hexane, 40 mL each time, until the filtrate is ba...

Embodiment 2~50

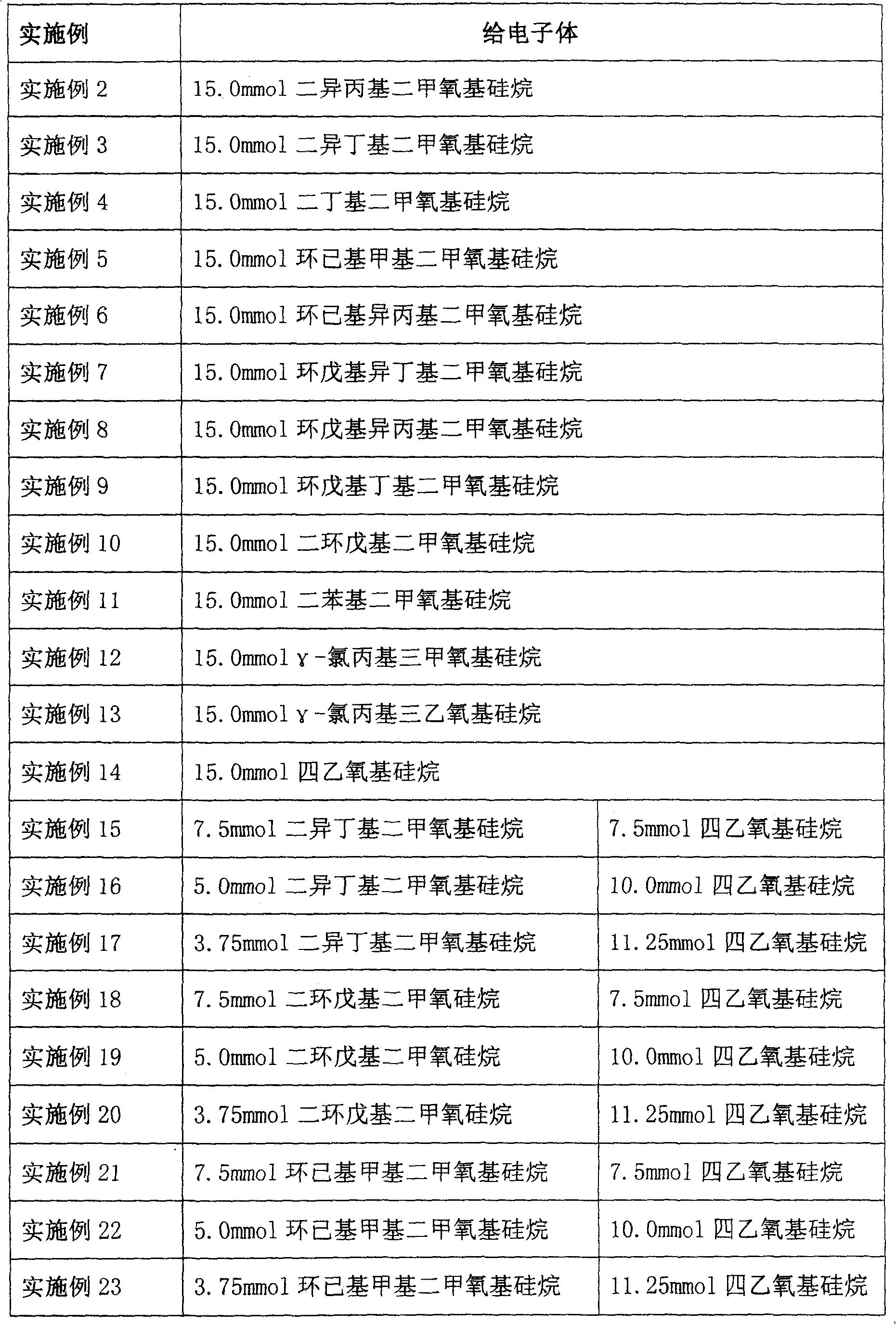

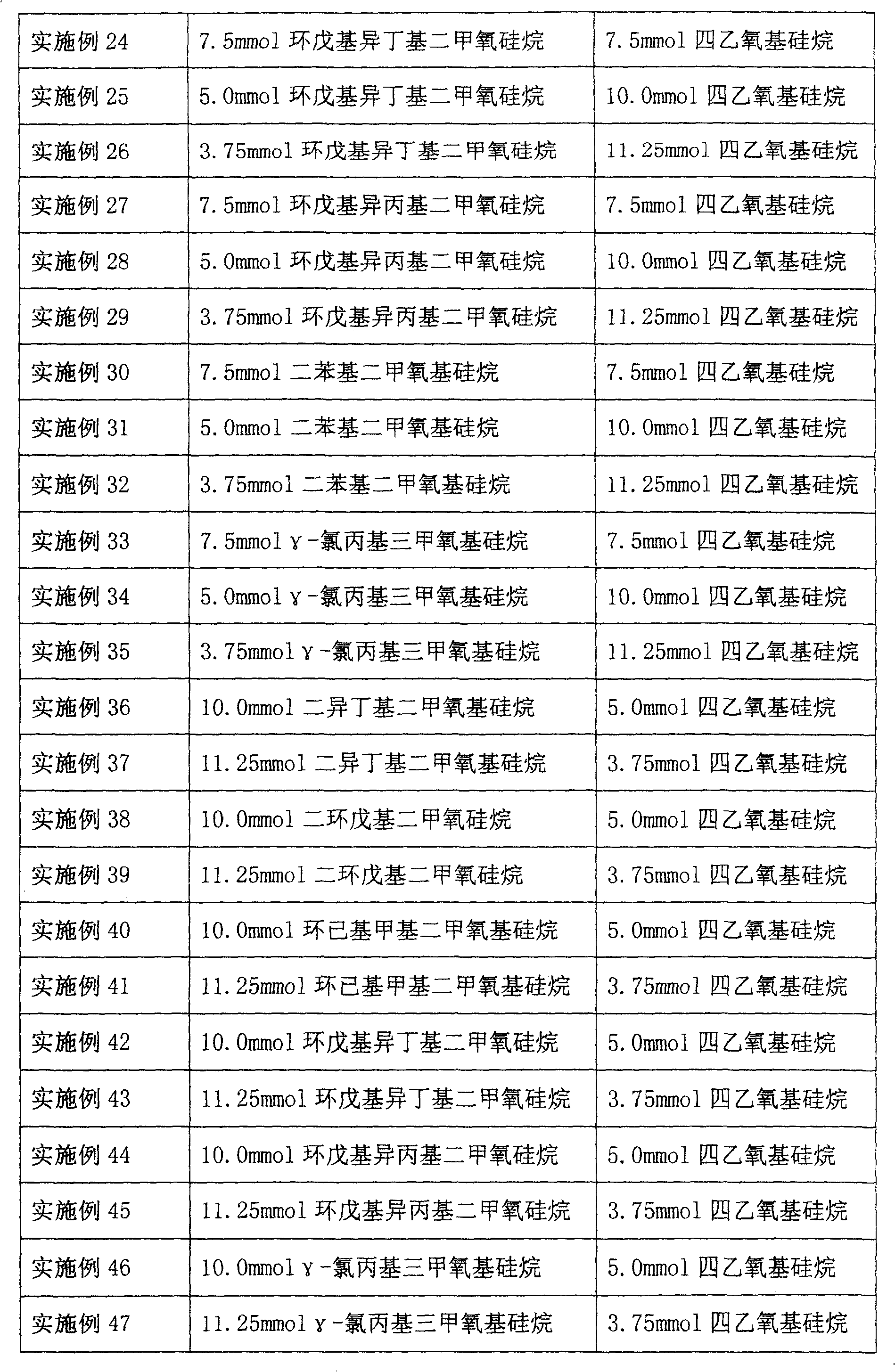

[0057] The solid catalyst component was prepared in the same manner as in Example 1 except that the amount and composition of the electron donor used were shown in Table 1.

[0058] Table 1

[0059]

[0060]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com