Patents

Literature

84results about How to "Guaranteed cohesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

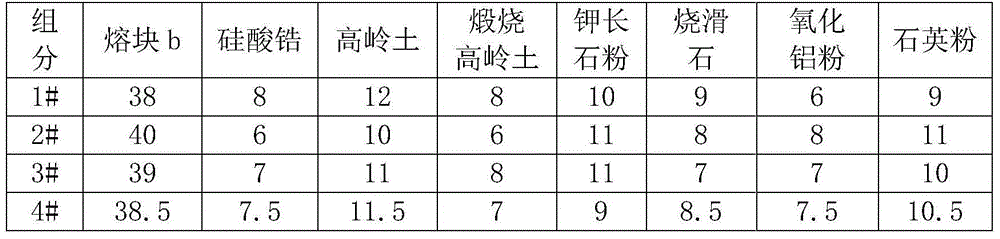

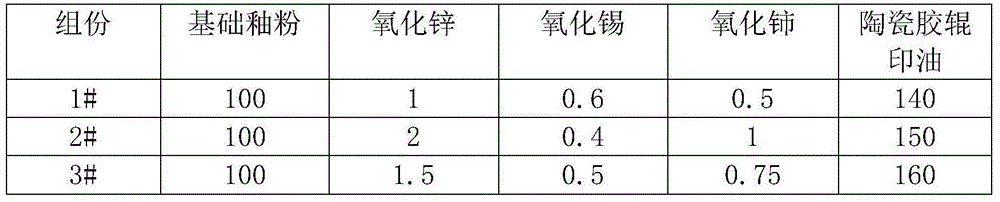

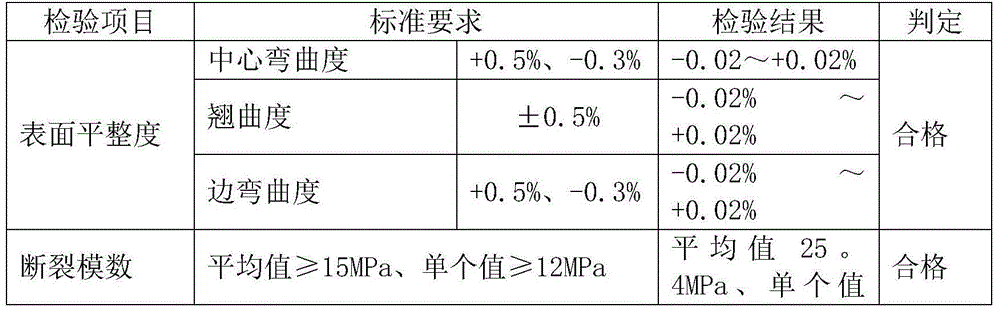

Glaze and preparation of embossment phantom glazed brick

The invention discloses a glaze and preparation of an embossment phantom glazed brick. The glaze comprises a ground glaze, a surface glaze and an embossment phantom printing glaze, wherein the ground glaze is prepared from a frit b, zirconium silicate, kaolin, calcined kaolin, potassium feldspar powder, fired talc, aluminum oxide powder, quartz powder, carboxymethyl cellulose, sodium tripolyphosphate and water; the surface glaze is prepared from a frit, the frit b, a frit c, kaolin, carboxymethyl cellulose, sodium tripolyphosphate and water; the embossment phantom printing glaze is prepared from parent glaze powder, zinc oxide, tin oxide, cerium oxide and ceramic adhesive roll-printing oil; the parent glaze powder is prepared from the frit c, kaolin, carboxymethyl cellulose, sodium tripolyphosphate and water. The preparation method comprises the following steps: sequentially applying the ground glaze and the surface glaze on a green brick, then printing the embossment phantom printing glaze, performing inkjet printing, and finally firing to obtain the embossment phantom glazed brick. The product disclosed by the invention has unique decorative effect and visual aesthetic feeling; moreover, each indicator can reach the standard requirements, so that the product has relatively strong universality, and is easily popularized in the industry.

Owner:GUANGDONG WINTO CERAMICS +3

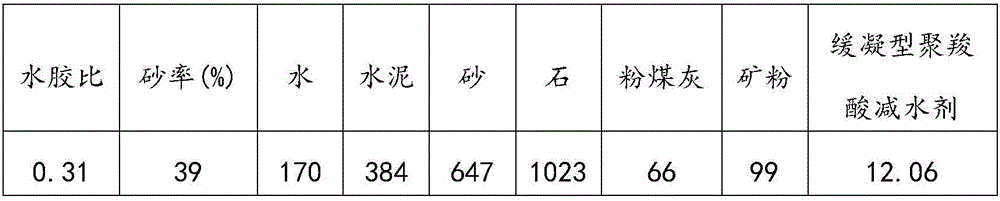

Set-retarding type long-distance pumping type concrete prepared by waste slag of subway project and application

The invention provides a set-retarding type long-distance pumping type concrete prepared by waste slag of subway projects and application, and belongs to the field of concrete. The prepared concrete has the advantages that the density and fluidity are good, the extension and strength are high, the production cost is low, and the concrete is suitable for long-distance pumping. The set-retarding type long-distance pumping type concrete prepared by the waste slag of the subway projects comprises the following components in parts by weight: 260 to 300 parts of cement, 151 parts of water, 990 to 1010 parts of stone, 700 to 720 parts of stone chips, 50 to 80 parts of stone powder, 80 to 105 parts of ore powder, 85 to 100 parts of fly ash, 4.9 to 4.95 parts of set-retarding type polycarboxylate superplasticizer, 0.049 to 0.0495 part of starch ether, and 0.098 to 0.099 part of building glue 1093.

Owner:青岛磊鑫混凝土有限公司

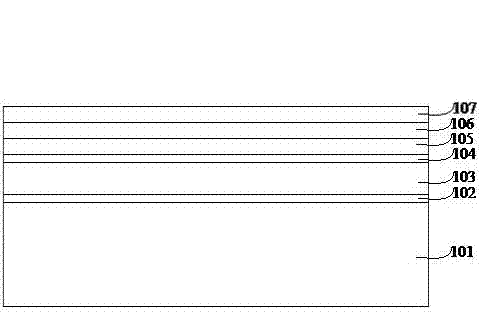

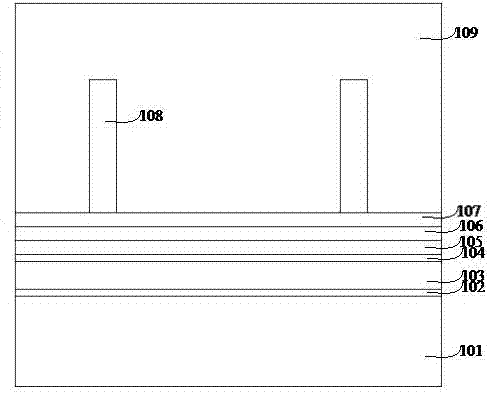

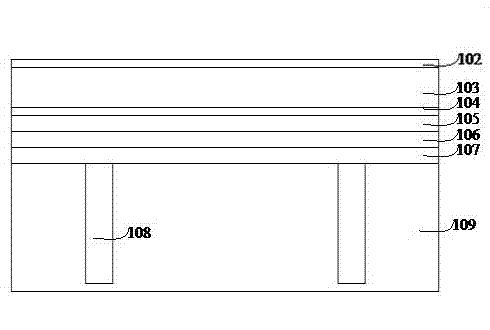

Composite thick film based on diamond-like carbon thin film and coating method of composite thick film

PendingCN107022761AReduce internal stressIncrease internal stressVacuum evaporation coatingSputtering coatingCarbon layerFilm base

The invention discloses a composite thick film based on a diamond-like carbon thin film and a coating method of the composite thick film. The composite thick film comprises a metal base layer, a transition layer and a diamond-like carbon layer which are successively formed from the surface of a substrate to the outside, wherein the transition layer is a mixture layer which is formed by stacking two film layers in a staggered manner by simultaneously using a magnetron sputtering technology and an enhanced type cathode arc technology; and the thickness of the diamond-like carbon layer is between 1 mu m and 10 mu m. The composite thick film is exquisite in design and simple in structure; the transition layer has the structure which is formed by stacking the two film layers in the staggered manner, the advantages of small internal stress of a magnetron sputtering film layer and large hardness of an enhanced type cathode arc film layer are played fully, large hardness and small internal stress of the transition layer are combined effectively, large hardness and small stress facilitate increasing of the thickness of the diamond-like carbon layer, and the thickness of the finally formed composite thick film reaches 20 mu m or above; and moreover, huge stress caused by a thick film function layer can be buffered effectively, therefore, the binding force of the composite thick film and the substrate is guaranteed, and meanwhile, surface defects of the composite thick film can be reduced effectively.

Owner:STARARC COATING TECH SUZHOU

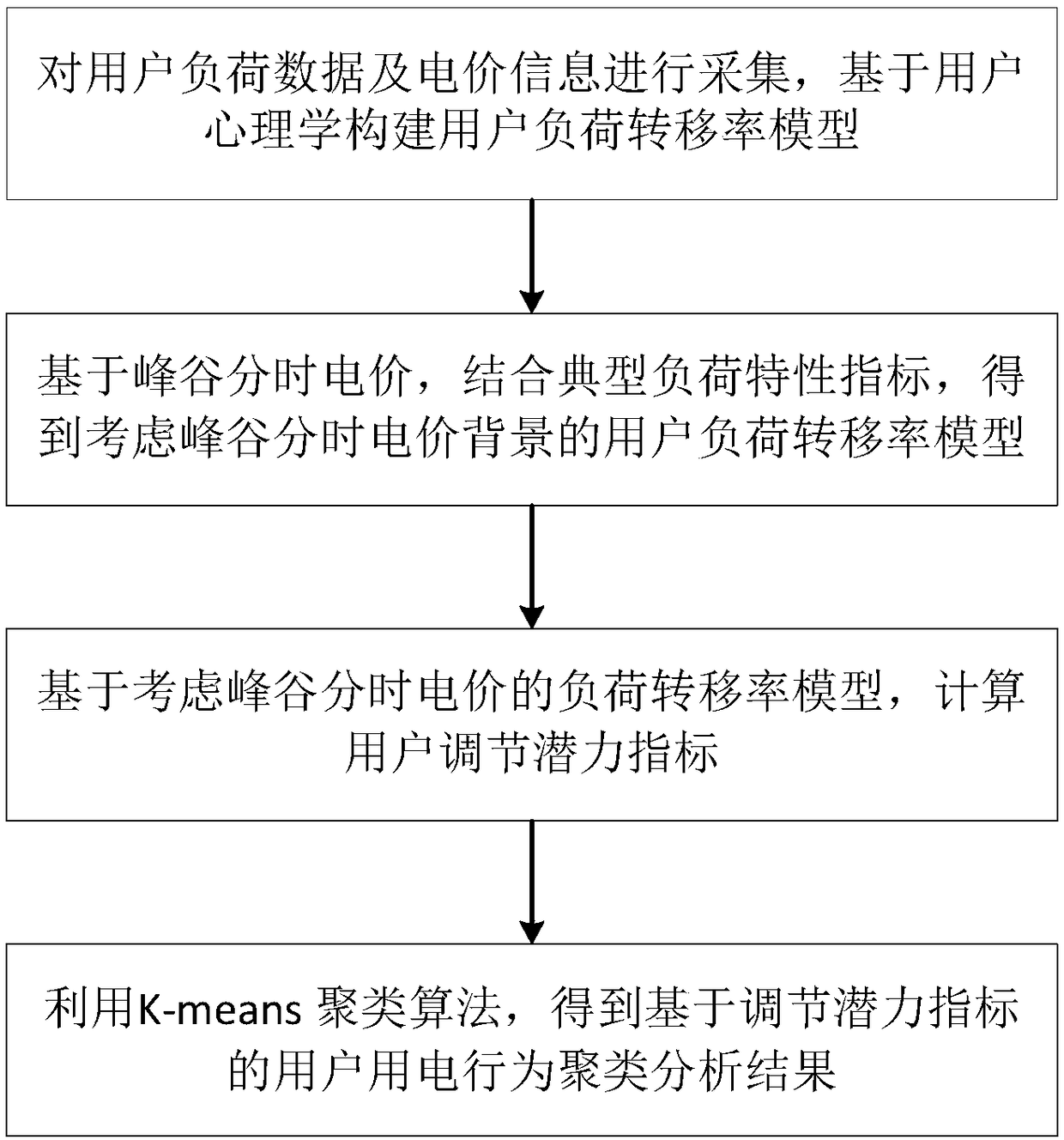

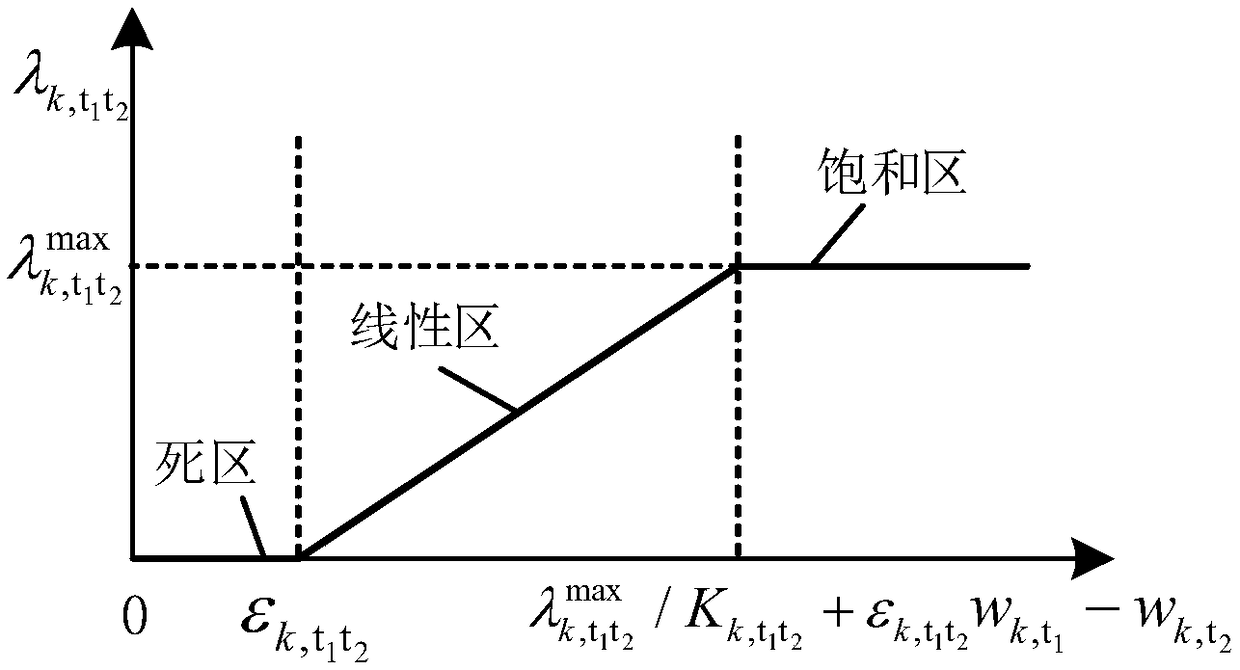

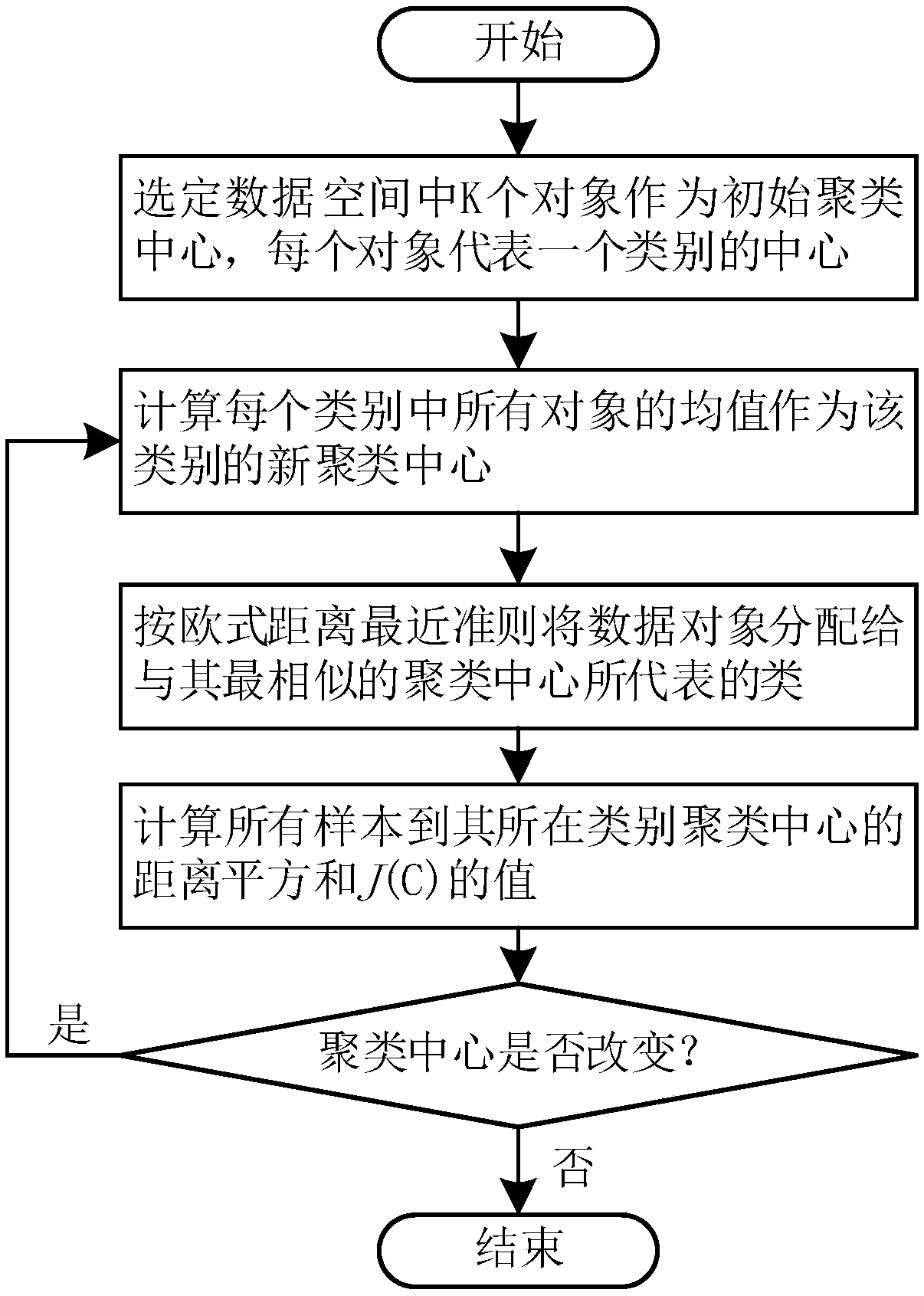

Cluster analysis method and system for consumer power consumption behavior based on regulating potential index

InactiveCN109146252AImprove polymerization effectGuaranteed cohesionCharacter and pattern recognitionTechnology managementCluster algorithmElectricity price

The invention relates to a method and a system for clustering analysis of user power consumption behavior based on an adjustment potential index, characterized by comprising the following steps of: 1)constructing a user load transfer rate model considering the peak-valley time-of-use price according to the user daily load curve information and the peak-valley time-of-use price information obtained in advance, and calculating a user regulation potential index; 2) taking the user regulation potential index as a sample space set, combining with K. Means clustering algorithm, getting the consumerbehavior clustering results based on the adjustment potential index. The invention has good aggregation effect when clustering analysis is carried out on users with obvious peak-valley characteristics, and can ensure clustering effect while improving clustering efficiency when clustering analysis is carried out on large-scale users, and can be widely used in the field of power system data analysis of peak-valley time-of-use electricity price.

Owner:STATE GRID CORP OF CHINA +3

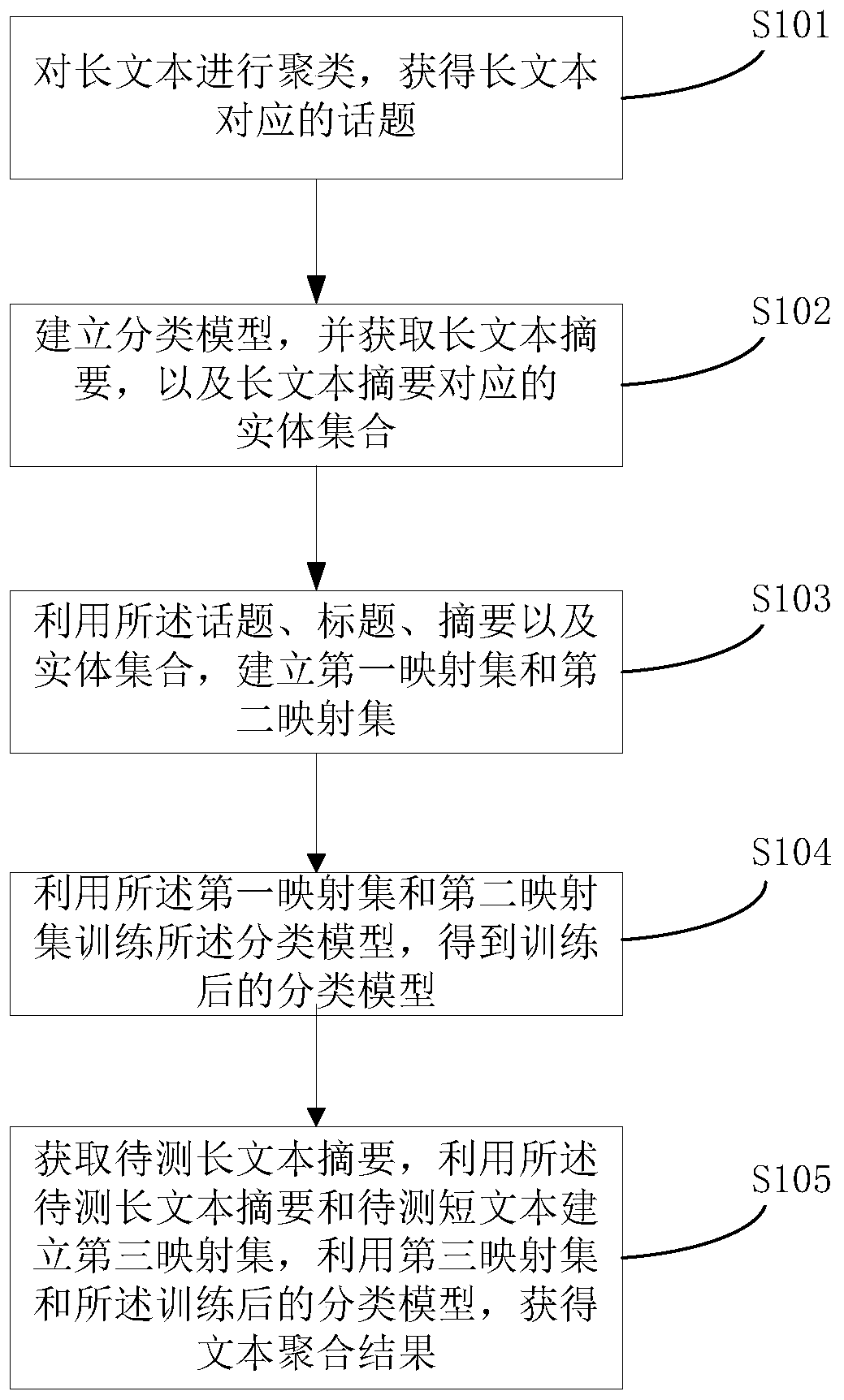

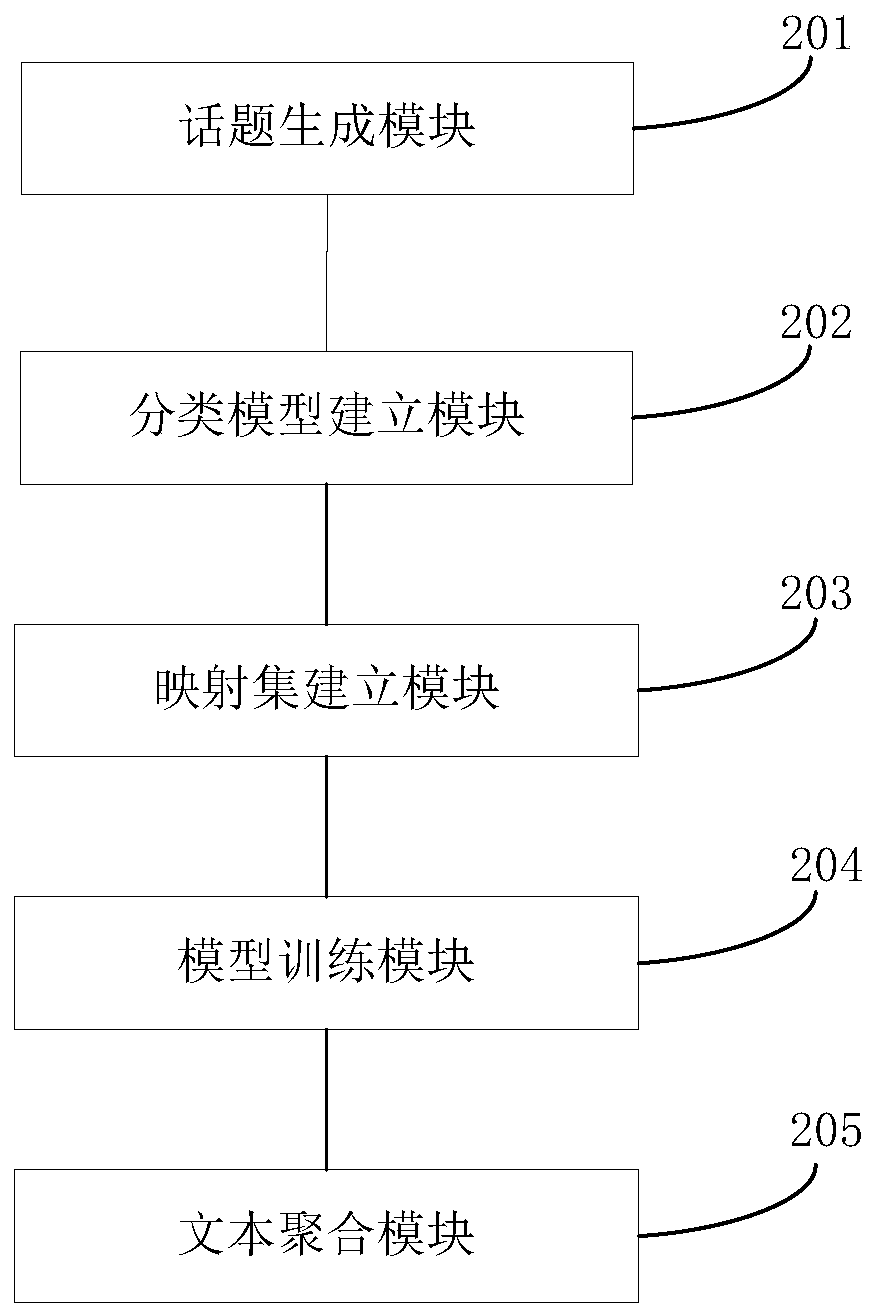

A text aggregation method and system

ActiveCN109815336AGuaranteed polymerization efficiencyGuaranteed cohesionText database browsing/visualisationText database clustering/classificationComputation complexityData mining

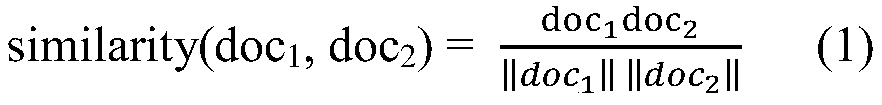

The invention provides a text aggregation method and a text aggregation system, which are used for aggregating long texts and short texts. The method comprises the following steps of clustering the long texts to obtain topics corresponding to the long texts, the long texts comprising titles; establishing a classification model, and obtaining an abstract of the long text and an entity set; establishing a first mapping set and a second mapping set by using the topic, the title, the abstract and the entity set; using the first mapping set and the second mapping set to train the classification model to obtain a trained classification model; obtaining an abstract of a long text to be measured, establishing a third mapping set by using the abstract of the long text to be measured and a short text to be measured, and obtaining a text aggregation result by using the third mapping set and the trained classification model. According to the method and the system, the entity characteristics of thelong text and the short text are utilized to screen out the short text containing the same entity as the long text, so that the calculation complexity is reduced, and the text aggregation efficiencyis ensured.

Owner:无码科技(杭州)有限公司

White-light emitting diode with vertical structure and manufacturing method thereof

InactiveCN102637783AGuaranteed stabilityGuaranteed yieldSemiconductor devicesQuantum wellLight-emitting diode

The invention discloses a white-light emitting diode with a vertical structure and a manufacturing method thereof and relates to the fields of illumination and manufacturing of semiconductor photoelectric devices and semiconductors. The white-light emitting diode disclosed by the invention comprises a metal supporting substrate, a metal seed layer, a reflecting metal layer, a P-type GaN-based semiconductor layer, a quantum well source region, an N-type GaN-based semiconductor layer and a passivation layer which are sequentially superposed form bottom to top, wherein an electrode trough on the top of a device is provided with an N-face electrode. The white-light emitting diode is structurally characterized in that a fluorescent powder layer is arranged on the passivation layer. Compared with the prior art, the white-light emitting diode disclosed by the invention is capable of effectively improving the luminescence power of the device and has the characteristics of simple process and low cost.

Owner:TONGFANG OPTO ELECTRONICS

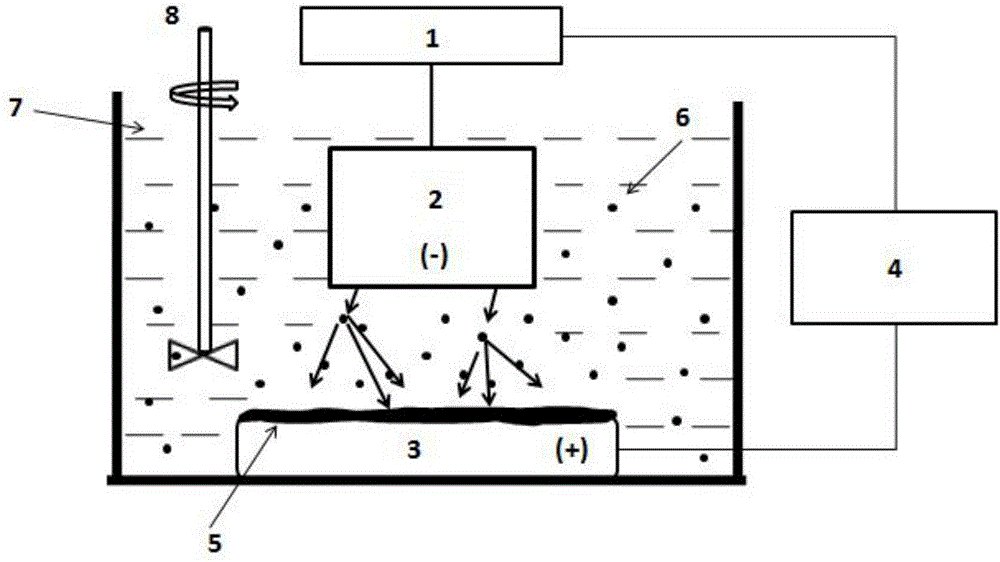

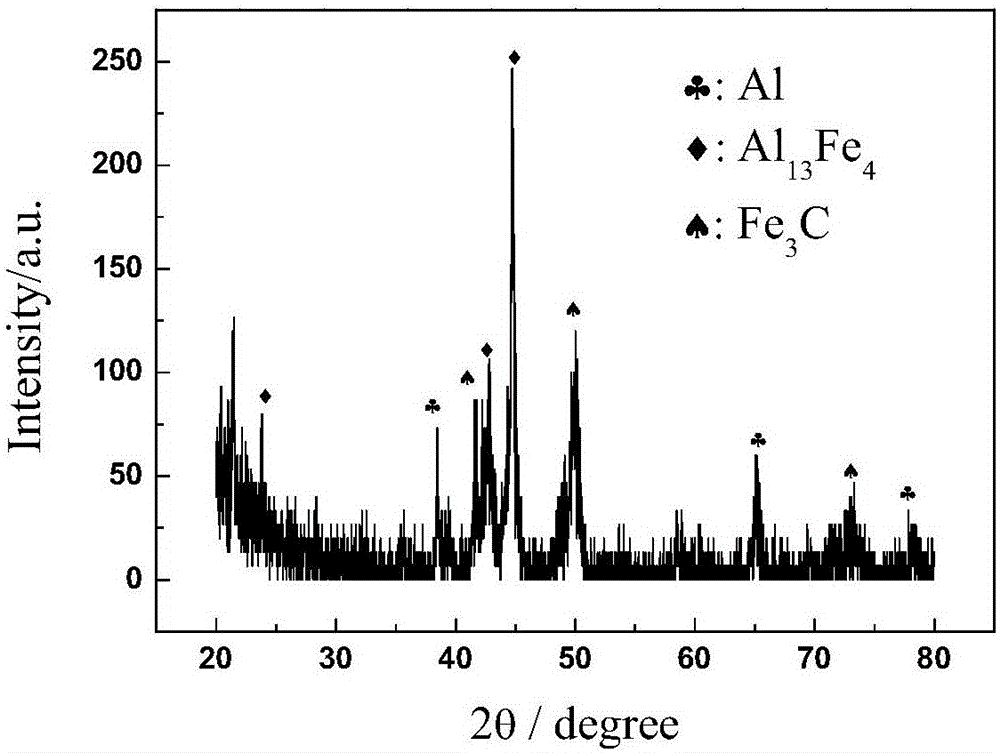

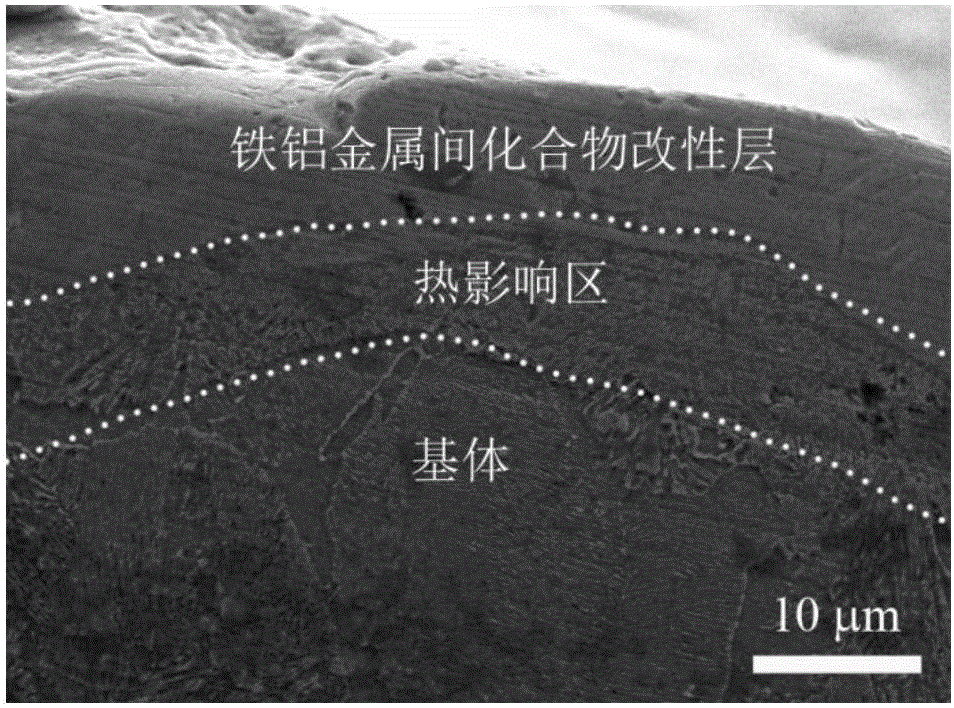

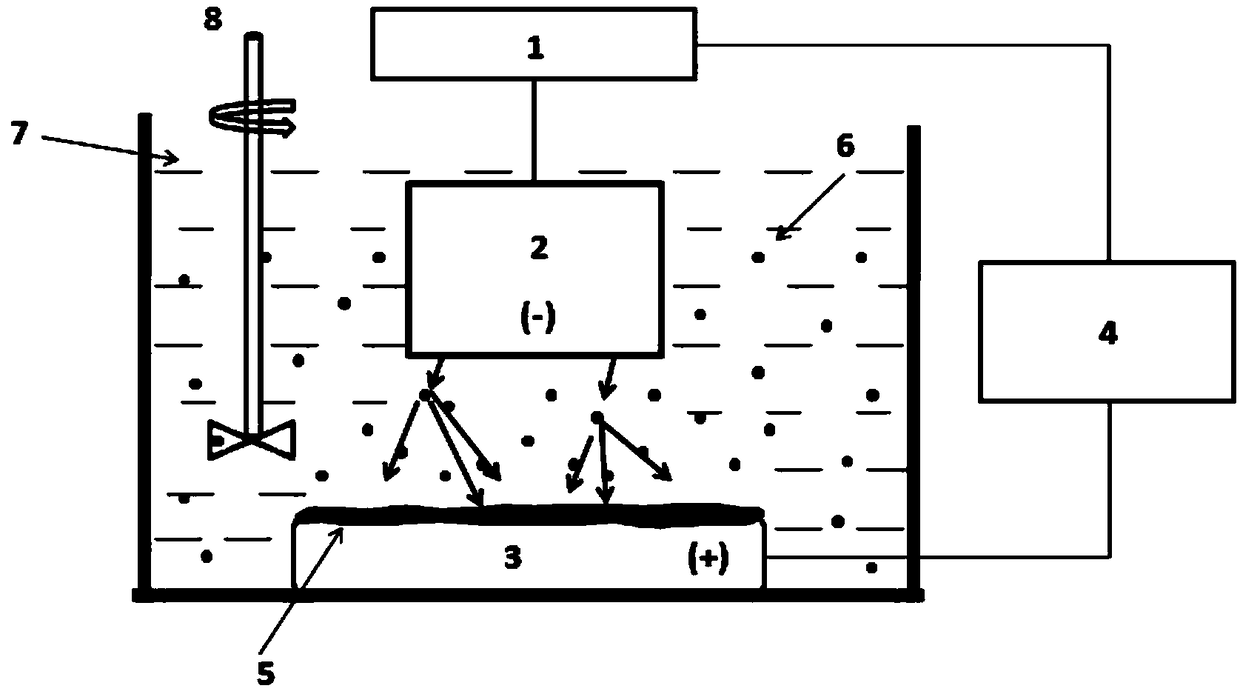

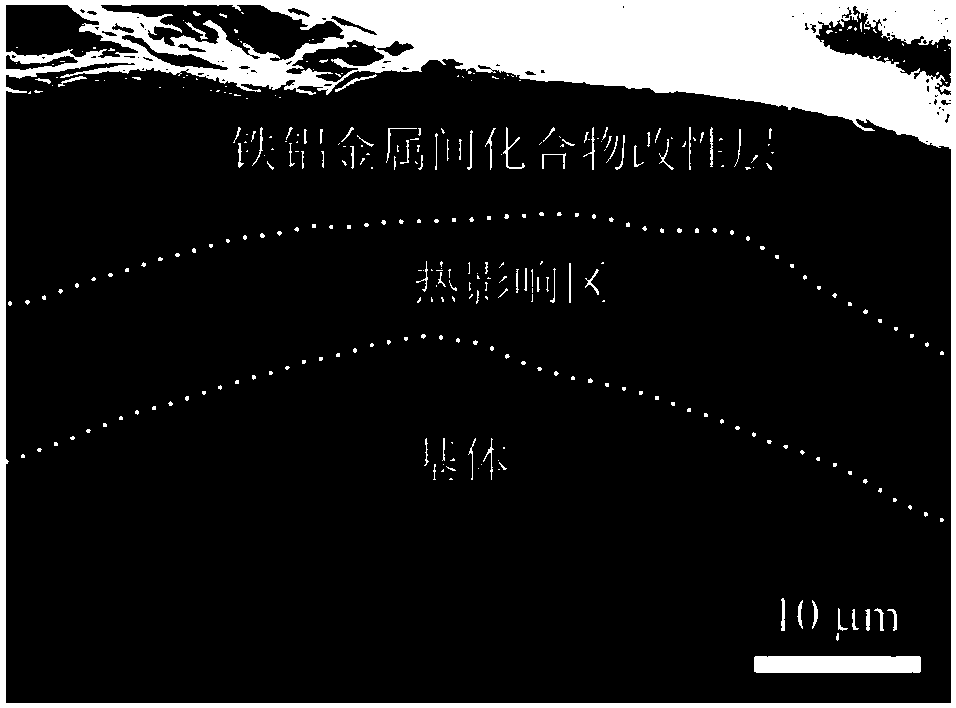

Preparation method of surface modification layer containing iron and aluminum intermetallic compound

ActiveCN106245023AImprove production efficiencyLow costHeat inorganic powder coatingPulse dischargeBinding force

The invention discloses a surface modification layer containing an iron and aluminum intermetallic compound and a preparation method of the surface modification layer. The preparation method comprises the following steps: taking an aluminum powder pressing body as a tool electrode, taking aluminum powder and coal oil mixed liquid as working liquid, and taking common low-carbon steel as a workpiece; enabling pulse discharge to be generated between the electrode and the workpiece in the working liquid by using a common electric spark machine tool; enabling the electrode, aluminum in the working liquid and iron in the workpiece to carry out in-situ alloying reaction with the aid of discharge energy; and finally, forming the surface modification layer containing the iron and aluminum intermetallic compound on the surface of the workpiece. The modification layer prepared by the method has the advantages of compact structure, good basic binding force and the like, and is expected to be widely used in the field of surface modification for improvement of corrosion resistance and wear resistance of structure materials.

Owner:GUANGDONG UNIV OF TECH

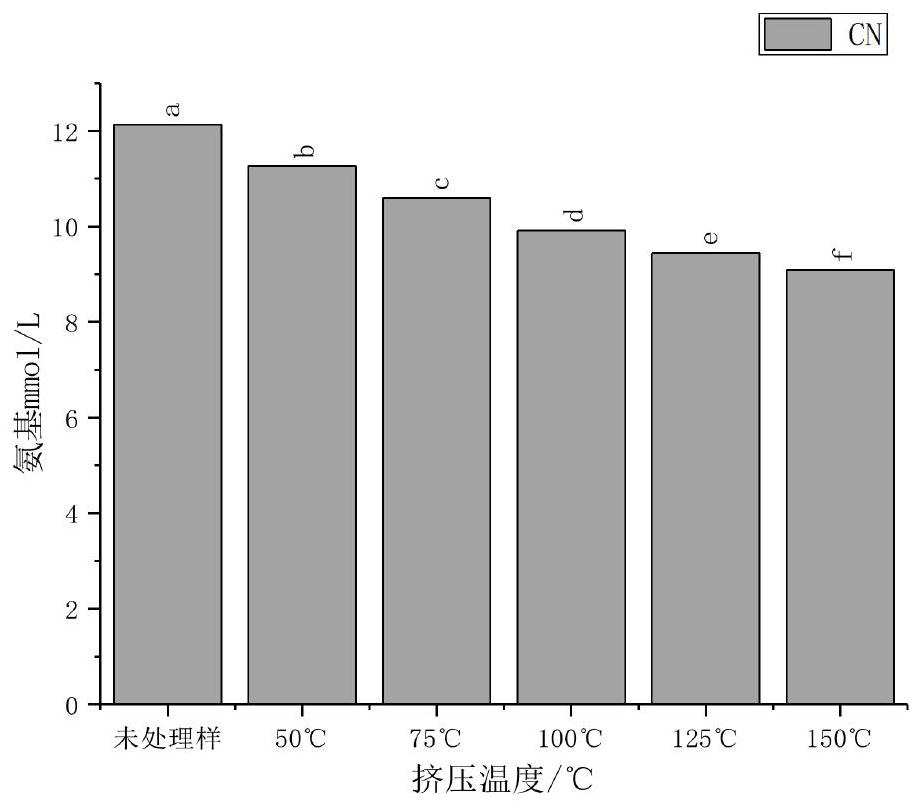

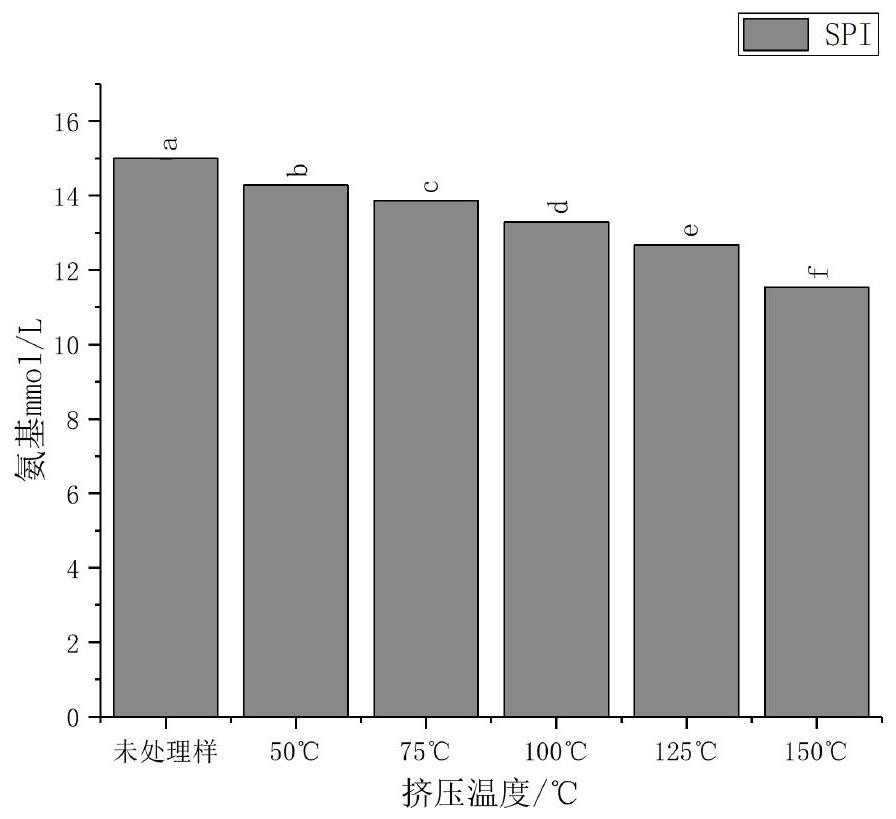

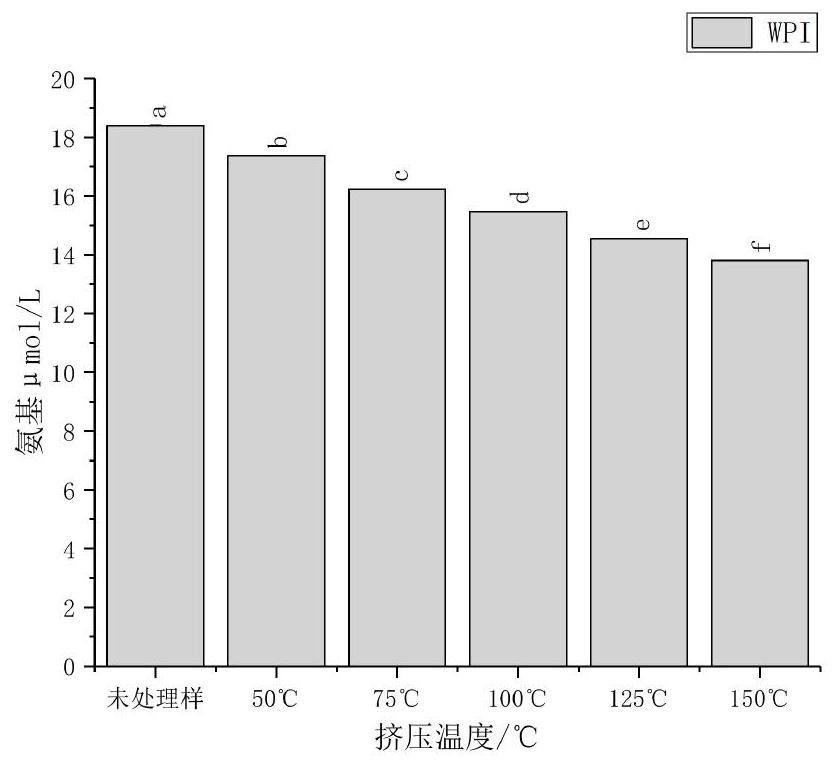

Method for treating protein powder through extrusion and application thereof

InactiveCN112369495APromote linearizationIncrease shear forceSugar food ingredientsProteins working-up by texturisingMaillard reactionPROTEIN S HEERLEN

The invention discloses a method for treating protein powder through extrusion and application thereof, and belongs to the technical field of functional foods. In terms of commercially available high-protein nutritional bar formulas and the problems of texture hardening and the like during the shelf life, the method is provided and comprises the following steps of putting whey isolate protein, soyisolate protein and sodium caseinate into a co-rotating twin-screw extruder, and extruding at the speed of 240 rpm, wherein the extrusion pretreatment parameters are set as follows: the temperature is 75 + / -2 DEG C, and the moisture content is adjusted to 38 + / -1%; and conducting cooling and granulating, grinding into powder after freeze-drying in vacuum, conducting sieving twice to obtain modified protein powder, and hermetically storing the protein powder for later use. According to the invention, sugar alcohol is used for replacing part of syrup, so that the quality deterioration of nutritional bars caused by Maillard reaction is slowed down, and the situation that the protein bars belong to an intermediate moisture food, of which the appearance, color, flavor, texture, nutritional characteristics and other qualities of the protein bars may be greatly changed in the storage process is avoided; and partial sugar alcohol is adopted for replacement, so that a certain adhesion degree is guaranteed, and meanwhile, the softness in the texture is effectively guaranteed.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

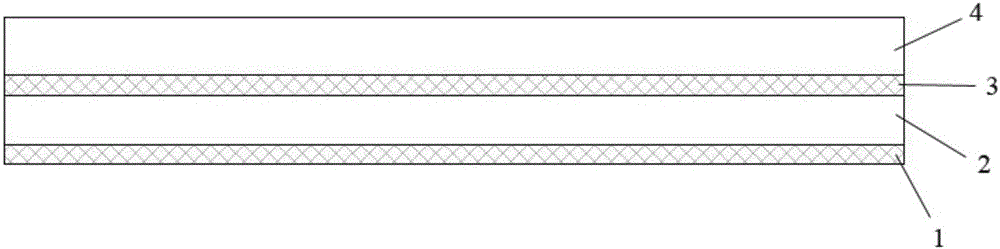

Preparation method for double-layer PET protective film for lithium battery pack

ActiveCN105778804AAvoid filiform cracksHigh compressive strengthNon-macromolecular adhesive additivesLamination ancillary operationsChemistryAluminium

The invention provides a preparation method for a double-layer PET protective film for a lithium battery pack. The preparation method comprises the following steps: firstly, uniformly stirring and mixing acrylic pressure sensitive adhesive, ethyl acetate and butanone, then adding blue paste, white paste, yellow paste, a retarder and an assistant into the mixture in sequence, finally, adding hexamethylene diisocyanate and lithium tetrafluoroborate, and stirring uniformly to obtain an adhesive liquid; secondly, coating a single surface of a PET substrate with the adhesive liquid, performing heating treatment through 6 to 8 sections of baking channels in sequence until the residual solvent amount of the adhesive liquid does not exceed 0.5 parts; adhering the PET substrate which is coated with the adhesive liquid and a PET which is not coated with the adhesive liquid to obtain a double-layer PET composite film; coating the single surface of the PET composite film with the adhesive liquid, heating until the residual solvent amount of the adhesive liquid does not exceed 0.5 parts, discharging bubbles and winding at normal temperature. The PET protective film disclosed by the invention has high toughness, puncture resistance, high insulating property, high temperature resistance, and high adhesivity to an aluminum shell of a lithium battery, and has no residual adhesive after the PET protective film is peeled; the protection on the lithium battery pack when a new energy vehicle is driven is effectively realized.

Owner:SUZHOU SIDIKE NEW MATERIALS SCI & TECH

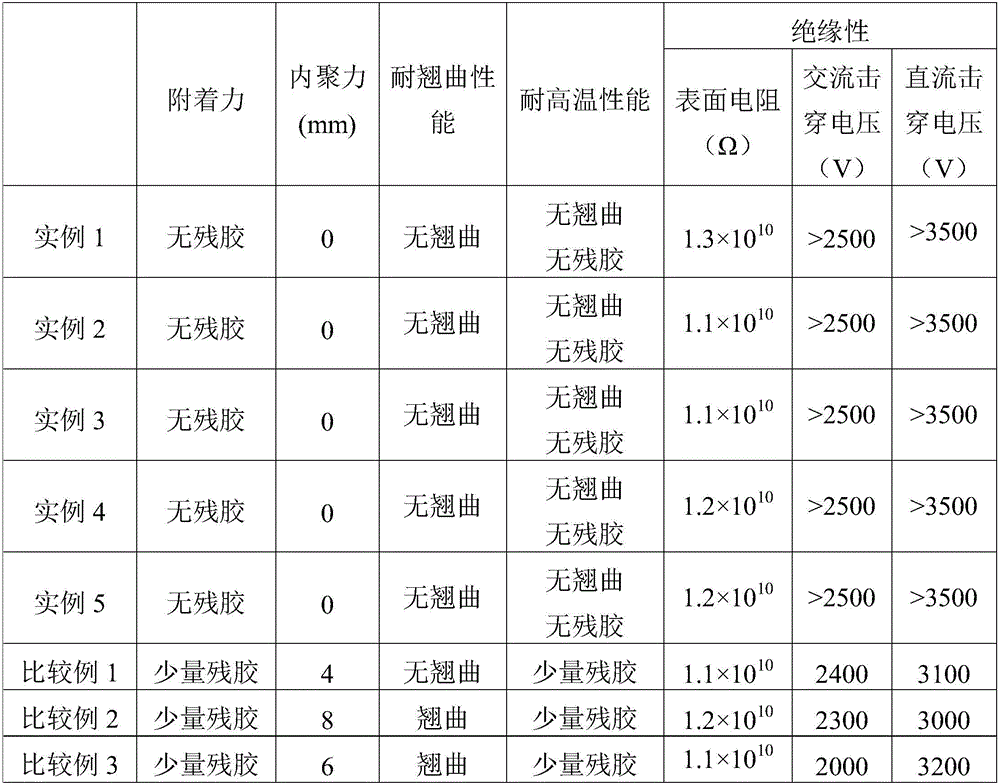

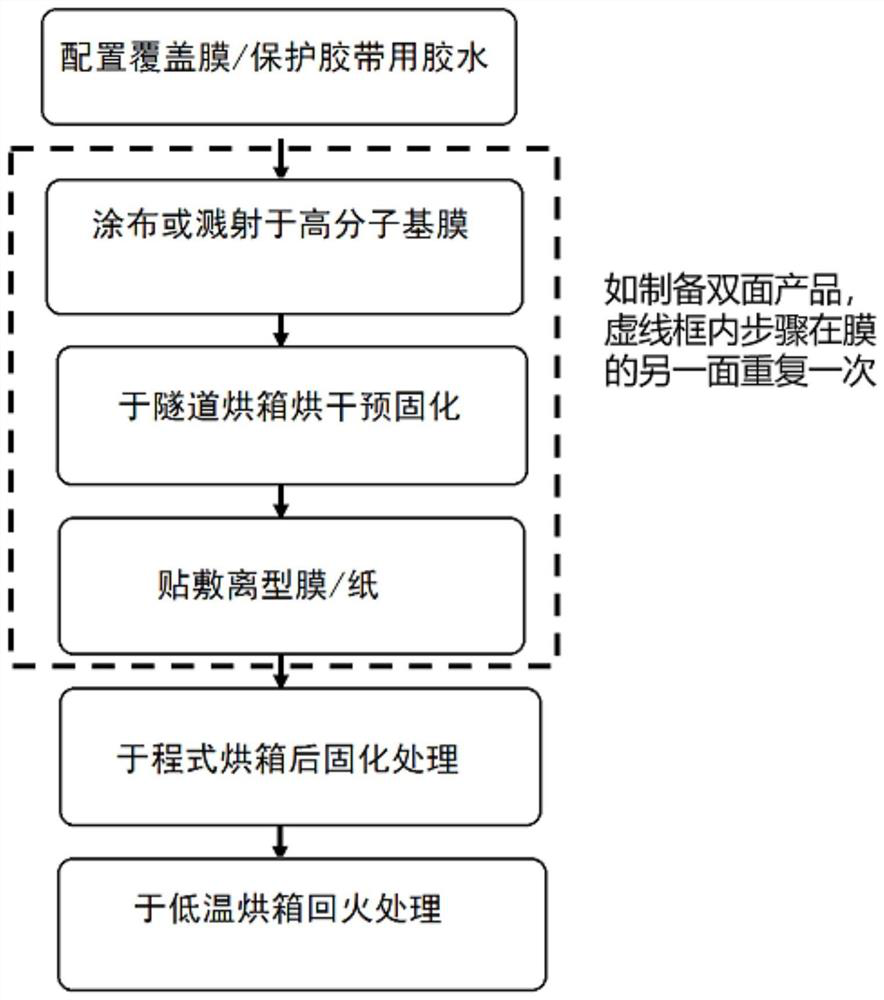

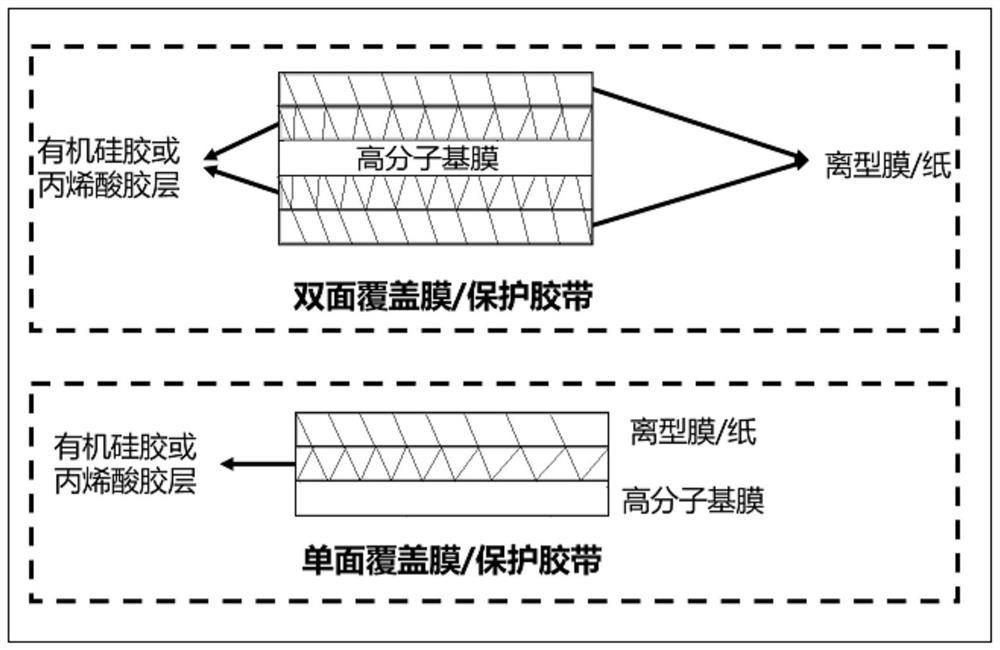

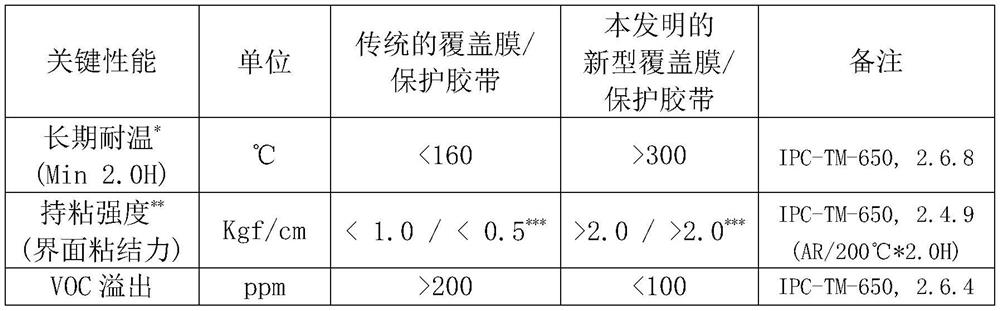

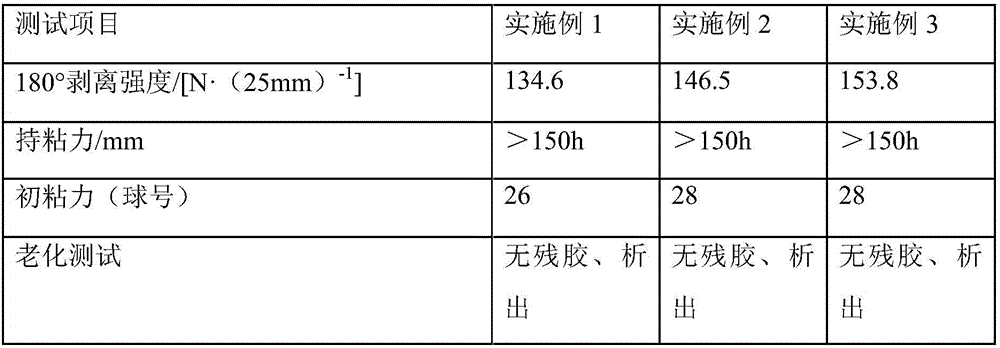

Preparation method of high-temperature-resistant high-persistent-adhesivity cover film or protective adhesive tape

InactiveCN111892881AReduce contentIncrease stickinessNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceAdhesive glue

The invention belongs to the field of electronic materials and new materials, and particularly relates to a preparation method of a high-temperature-resistant high-persistent-adhesivity cover film orprotective adhesive tape. The method comprises the following steps: step 1, adding gum and a performance enhancing component into a solvent to prepare glue; step 2, subjecting a layer of a polymer base film to coating or sputtering with the glue, conducting drying and pre-curing by using a tunnel drying oven, and pasting a release film / paper on the glue layer to obtain a pre-cured cover film / protective adhesive tape; step 3, putting the pre-cured cover film / protective adhesive tape into a programmable oven for post-curing to obtain a cured cover film / protective adhesive tape; and step 4, putting the cured cover film / protective adhesive tape into a medium-and-low-temperature oven for tempering treatment to obtain a product. According to the invention, the proper gum, the proper reinforcingcomponent and a proper solvent are adopted, so the low VOC content and high persistent viscosity of a cured glue layer are ensured; process steps are reasonable, the adhesive layer can be gradually and completely cured to form a high-quality three-dimensional cross-linked network, and cohesion, high persistent adhesivity, high temperature resistance and stability of the comprehensive performance of the adhesive layer are guaranteed.

Owner:四川铂利明德科技有限公司

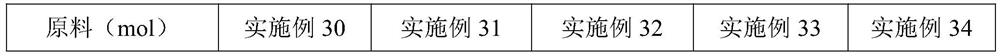

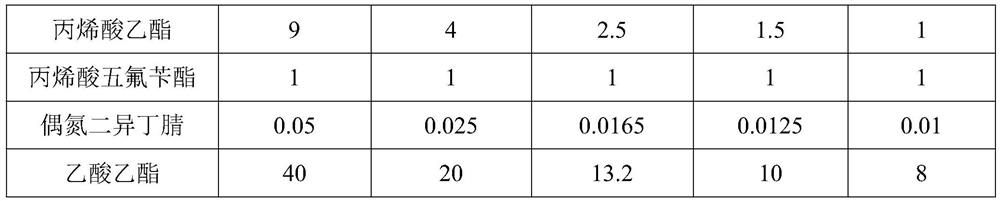

Ultraviolet curing pressure-sensitive adhesive and preparation method thereof

ActiveCN106752987AReduce wasteNo dischargeNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveSolventFumed silica

The invention relates to an ultraviolet curing pressure-sensitive adhesive and a preparation method thereof. The ultraviolet curing pressure-sensitive adhesive comprises the following raw material components in parts by weight: 20-60 parts of an acrylic compound, 35-80 parts of a hydroxyl-containing oligomer, 1-5 parts of fumed silica, 0.1-3 parts of a photoinitiator and 0.2-1 part of a coupling agent. The preparation method comprises the following steps: mixing the raw materials, coating a film substrate, and curing, thereby obtaining the ultraviolet curing pressure-sensitive adhesive. The ultraviolet curing pressure-sensitive adhesive provided by the invention is free of solvent, and cross-linking curing can be resulted under radiation of ultraviolet rays, so that the cohesion, the solvent resistance, the thermal resistance, the adhesion property and the like of the adhesive can be all ensured, the cross-linking velocity is rapid, a great deal of energy can be saved when being compared with that of thermal curing, and meanwhile no organic solvent can be discharged.

Owner:宁波卓胜新材料有限公司

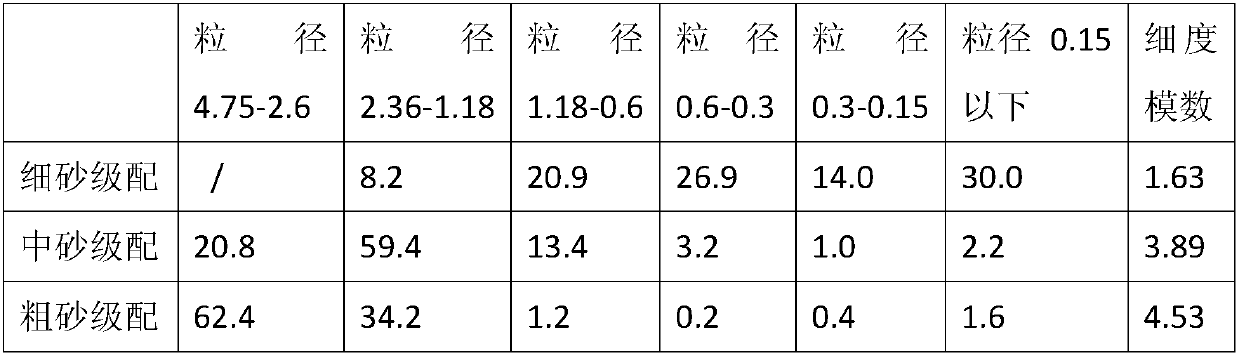

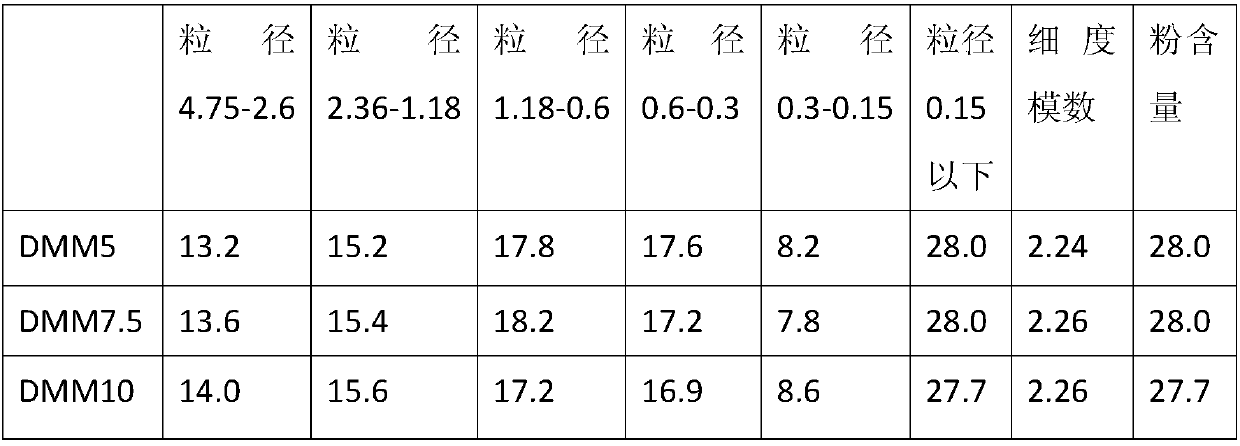

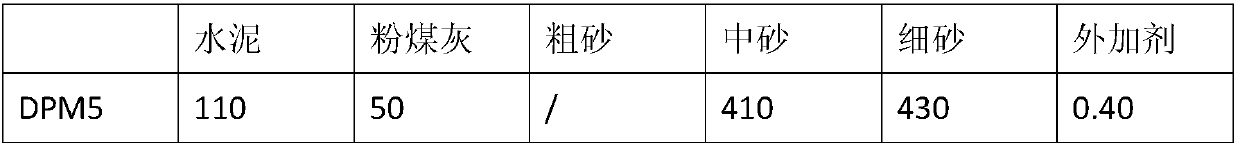

Grading method of mechanism sand used for dry-mixed mortar, and prepared dry mixed mortar

The invention relates to a grading method of mechanism sand used for dry-mixed mortar, and the prepared dry-mixed mortar. The grading method of the mechanism sand used for the dry-mixed mortar comprises the step of sieving the mechanism sand part, which has the particle size of 4.75mm or less and the fineness modulus of 2.3-3.0, into three types of sand, i.e., coarse sand, medium sand and fine sand, wherein the fineness modulus of the coarse sand is 4.3-4.6, the fineness modulus of the medium sand is 3.7-4.0, and the fineness modulus of the fine sand is 1.4-1.7. Furthermore, the dry-mixed mortar is prepared according to a grading formula of the mechanism sand; the ratio of the two or three types of sand in the dry-mixed mortar is adjusted according to the variety of the mortar. The contentof powder with the particle size of less than 0.15 is controlled, so that the powder content of dry-mixed plastering mortar (DPM) can be further effectively controlled; the fineness modulus of dry-mixed masonry mortar (DMM) is 2.3-2.6; the powder content of the DPM is controlled to be within a range of 26-30%, and the fineness modulus of the finished product mortar is controlled to be within a range of 2.1-2.3. The quality of the mortar is guaranteed. By combining the use of a composite additive, the construction performance of the mortar is greatly improved, and the quality of the mortar isguaranteed.

Owner:章丘华明水泥新型建材有限公司

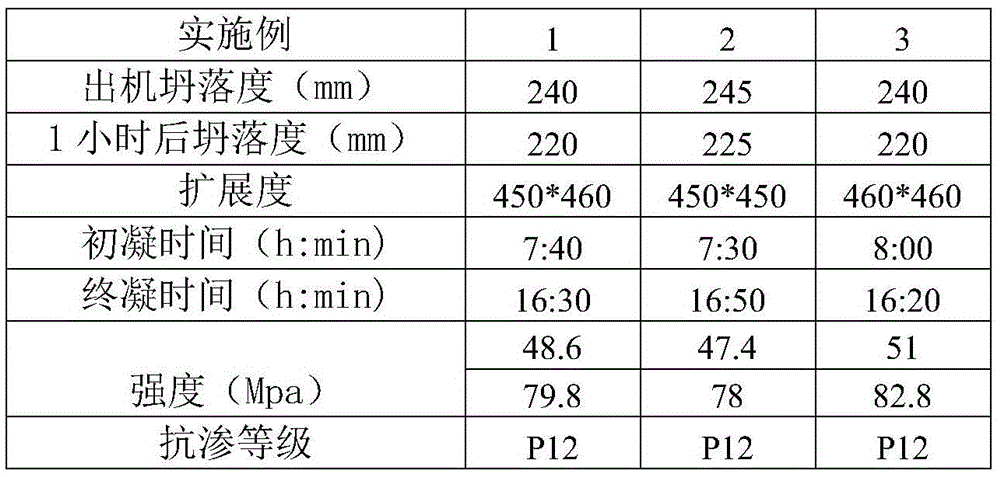

High grade concrete prepared from stone chips, iron mine tailings and polycarboxylate superplasticizer

InactiveCN105565742AEasy to get materialsLow priceSolid waste managementFineness modulusSuperplasticizer

The invention relates to a building raw material, and relates to a high grade concrete prepared from stone chips, iron mine tailings and a polycarboxylate superplasticizer. The high grade concrete comprises 400-420 parts of cement, 50-55 parts of fly ash, 50-65 parts of mineral powder, 160-190 parts of tailing sand, 720-780 parts of stone chips, 870-900 parts of cobblestones, 150-155 parts of water and 6.5-6.7 parts of the polycarboxylate superplasticizer, wherein the sand percentage is 0.50-0.52; the fineness modulus of the stone chips is 3.1, and the fineness modulus of the tailing sand is 1.7; and the particle size of the cobblestones is 5-31.5mm continuous grading. Commonly produced stone chips and iron mine tailings are used to substitute machine-produced sand and river sand produced through grading of cobblestones to be ground, so the production cost is reduced, and the adaptability of fine aggregates and the polycarboxylate superplasticizer is improved; and the high water reduction of the polycarboxylate superplasticizer is used, so the water consumption is reduced, the water-binder ratio is reduced, the viscosity of concrete is reduced, the concrete can be pumped, and the quality of the concrete is guaranteed.

Owner:青岛磊鑫混凝土有限公司

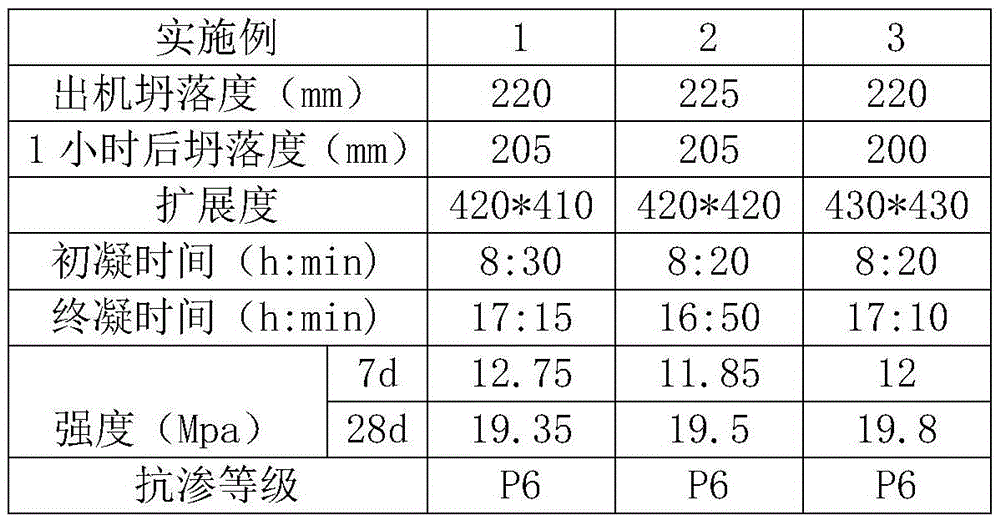

Lean cemented concrete prepared from aggregate chip iron tailings sand and polycarboxylate water reducer

InactiveCN105481320ARealize rational utilizationReduce pollutionSolid waste managementWater useFineness modulus

The invention relates to lean cemented concrete prepared from aggregate chip iron tailings sand and polycarboxylate water reducer. The concrete is prepared from 100-130 parts of cement, 50-75 parts of fly ash, 115-120 parts of mineral powder, 250-280 parts of tailings sand, 830-850 parts of aggregate chips, 780-800 parts of pebbles, 175-185 parts of water and 3.8-3.9 parts of the polycarboxylate water reducer, wherein the sand ratio ranges from 0.58 to 0.59, the fineness modulus of the aggregate chips is 3.1, the fineness modulus of the tailings sand is 1.7, and the particle size of the pebbles is 5-31.5 mm continuous grading. Commonly-produced aggregate chips and the iron tailings sand are used for replacing machine-made sand and river sand which need to be produced by grinding the pebbles according to grading, production cost is reduced, adaptability of fine aggregate and the polycarboxylate water reducer is improved, and water use amount is reduced. Meanwhile, viscosity of the concrete is improved, good flowability and cohesiveness of the concrete are guaranteed, and adverse influences caused by small amount of cement are reduced.

Owner:青岛磊鑫混凝土有限公司

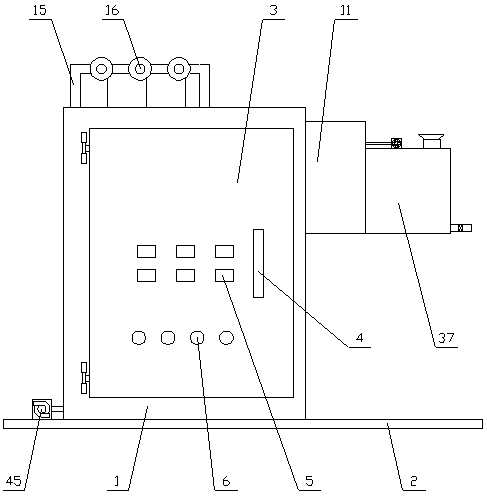

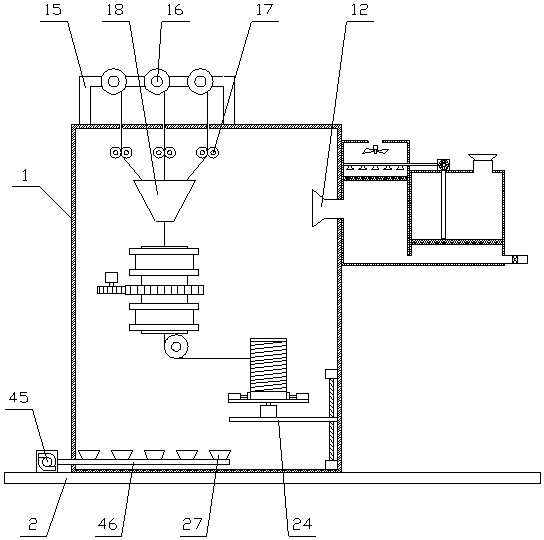

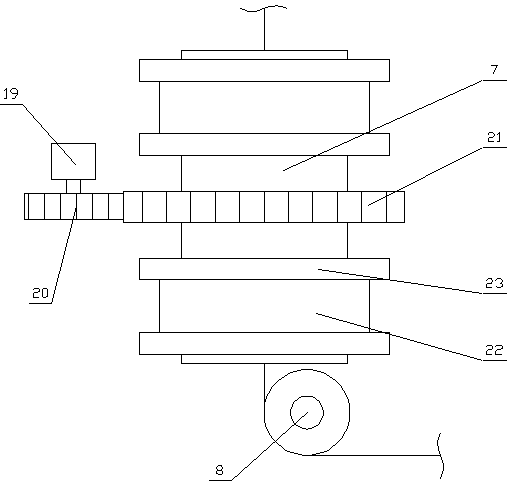

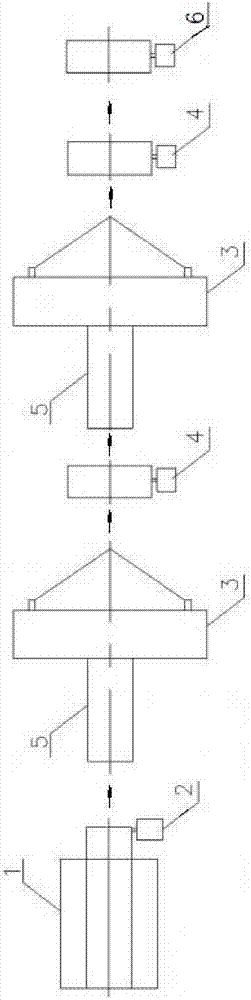

Drawing device with air pollution preventing capacity and high aggregation power

The invention relates to a drawing device with air pollution preventing capacity and high aggregation power. The drawing device comprises a thread supply mechanism, a case, a base, a dust collection mechanism and a case door, wherein a handle, a plurality of keys and a plurality of indicator lamps are arranged on the case door; an aggregation mechanism comprises a rotating assembly, an aggregationpipe and a guiding wheel, fixing assemblies are arranged in the two ends of the aggregation pipe, each fixing assembly comprises two fixing units and two guiding rods, and each fixing unit comprisesa translation unit and a clamp plate; the dust collection mechanism comprises a dust collection box, a spraying assembly and a suction hood, and a first fan and a first filter screen are arranged in the dust collection box. According to the drawing device with air pollution preventing capacity and high aggregation power, multiple strands of cotton bundles are aggregated together by the aggregationmechanism and rotated so as to be wound together, aggregation force between the cotton bundles is guaranteed, cotton threads are prevented from being fluffy, besides, the dust collecting mechanism adsorbs cotton batting during drawing, air pollution is prevented, respiratory health of surrounding workers is guaranteed, and therefore, practicability of equipment is improved.

Owner:JIAXING UNIV

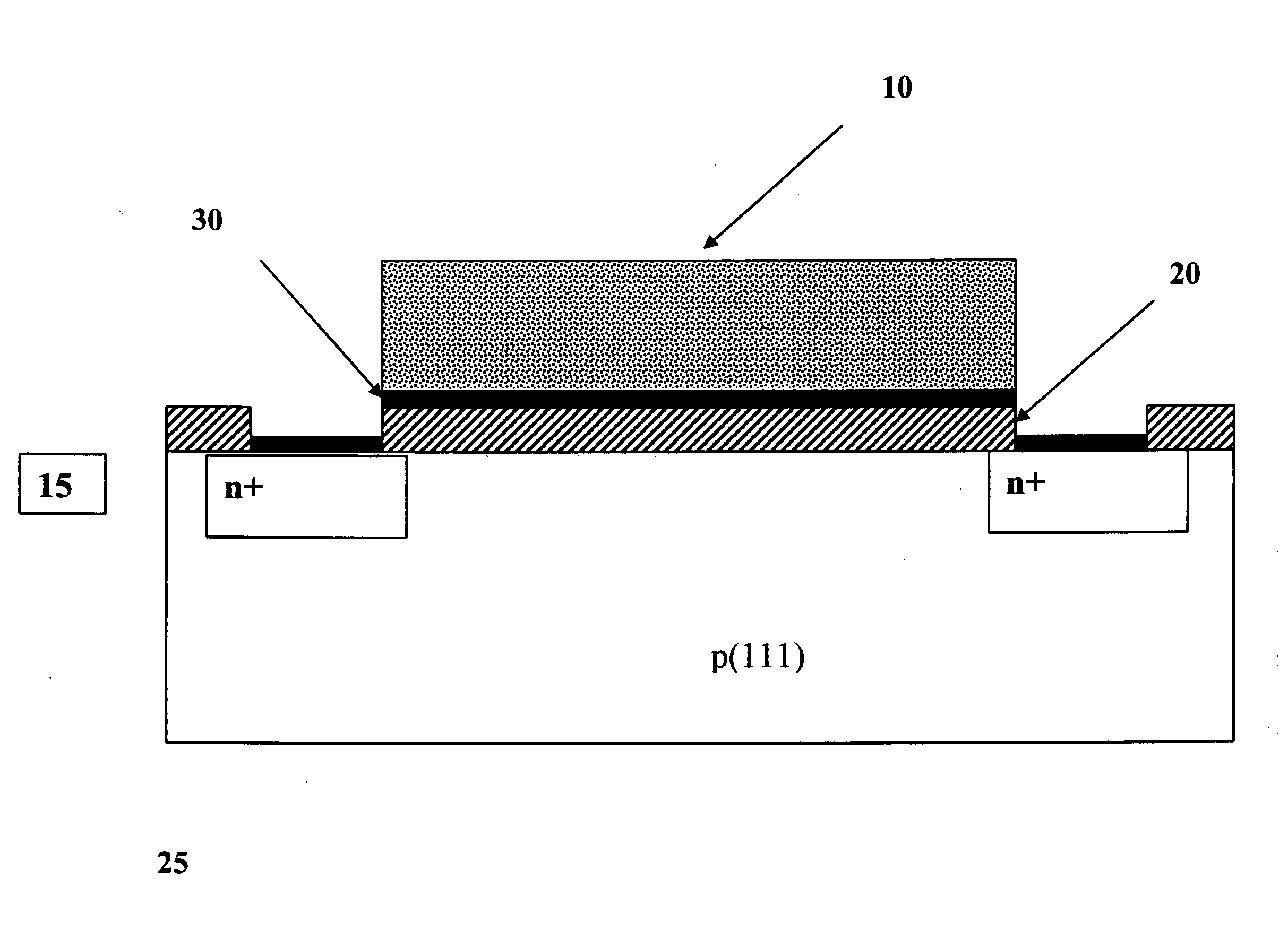

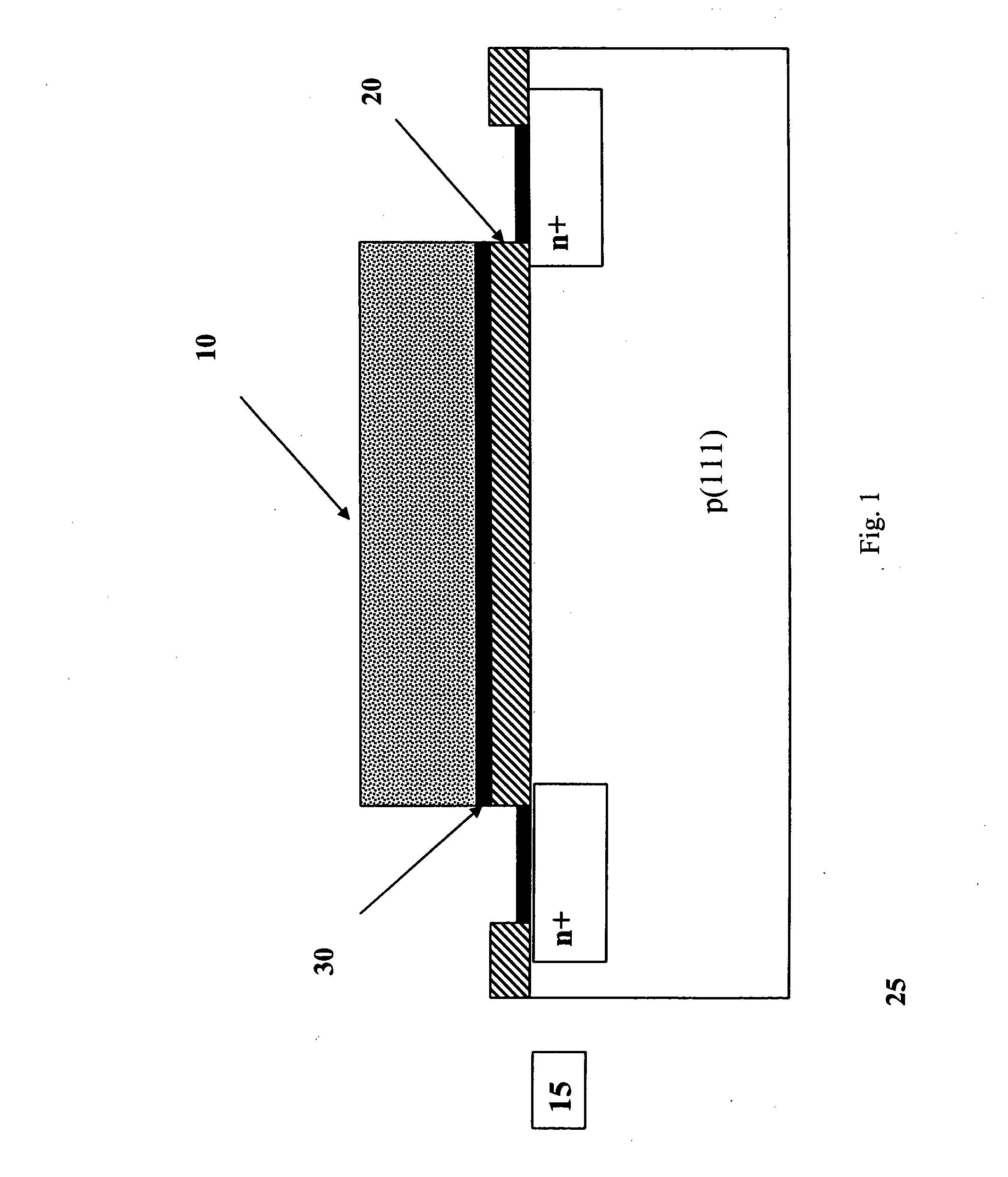

Deposition of layers of porous materials, layers thus obtained and devices containing them

InactiveUS20100117165A1Reducing and modifying absorptionReducing and modifying and capacityLayered productsSolid-state devicesBipolar junction transistorDeposition process

The present invention describes a process for the deposition of one or more layers of zeolites on rigid supports of various natures and geometry, particularly on silicon wafers. The coating containing zeolites is characterised by pore sizes ranging from 1 Angstrom to a few nanometer units. The deposition process does not interfere with and / or alter the correct functioning of the electronic devices (diodes, bipolar junction transistors, field effect transistors and electronic amplifiers in general) already integrated on the support to be coated on which said deposition is effected. The process according to the invention can be applied to electronic devices and permits their unaltered correct functioning.

Owner:UNIV DEGLI STUDI MAGNA GRAECIA DI CATANZARO

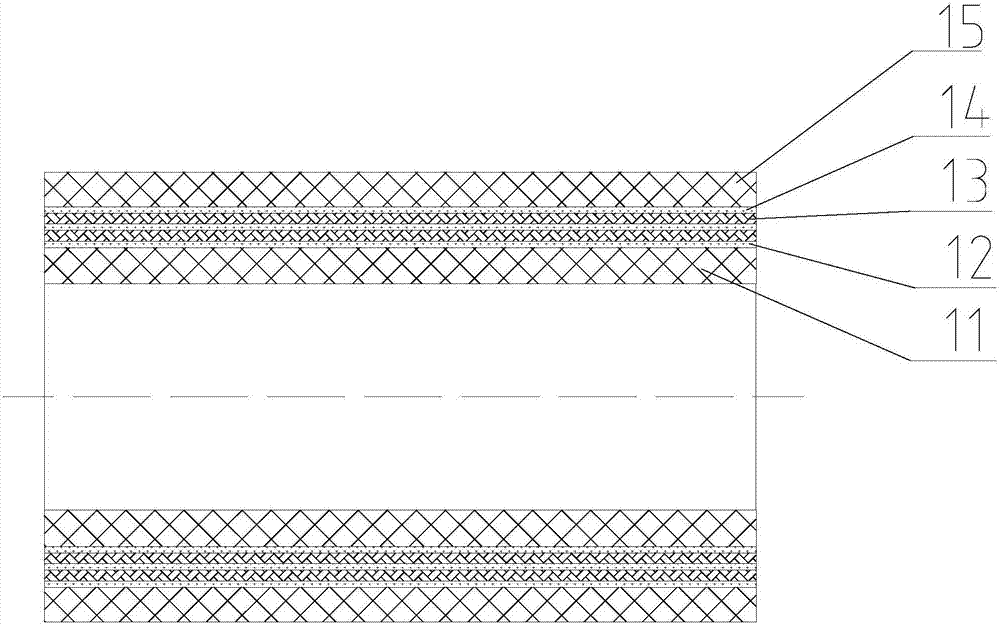

Thick film substrate having low void content and high reliability and manufacturing method thereof

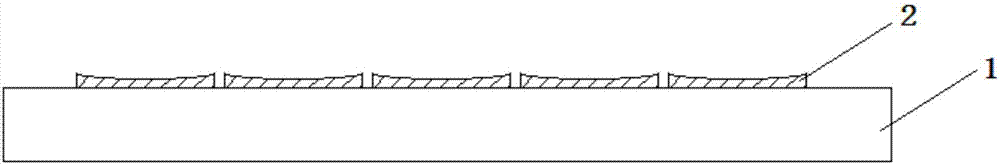

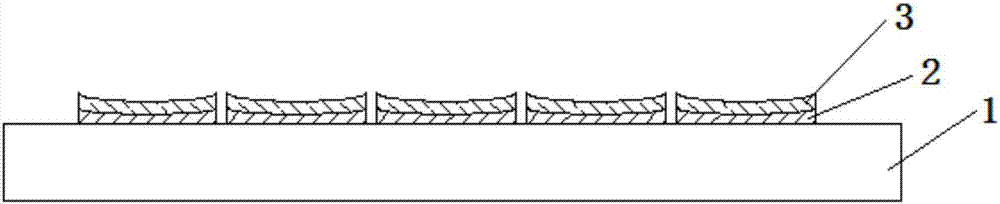

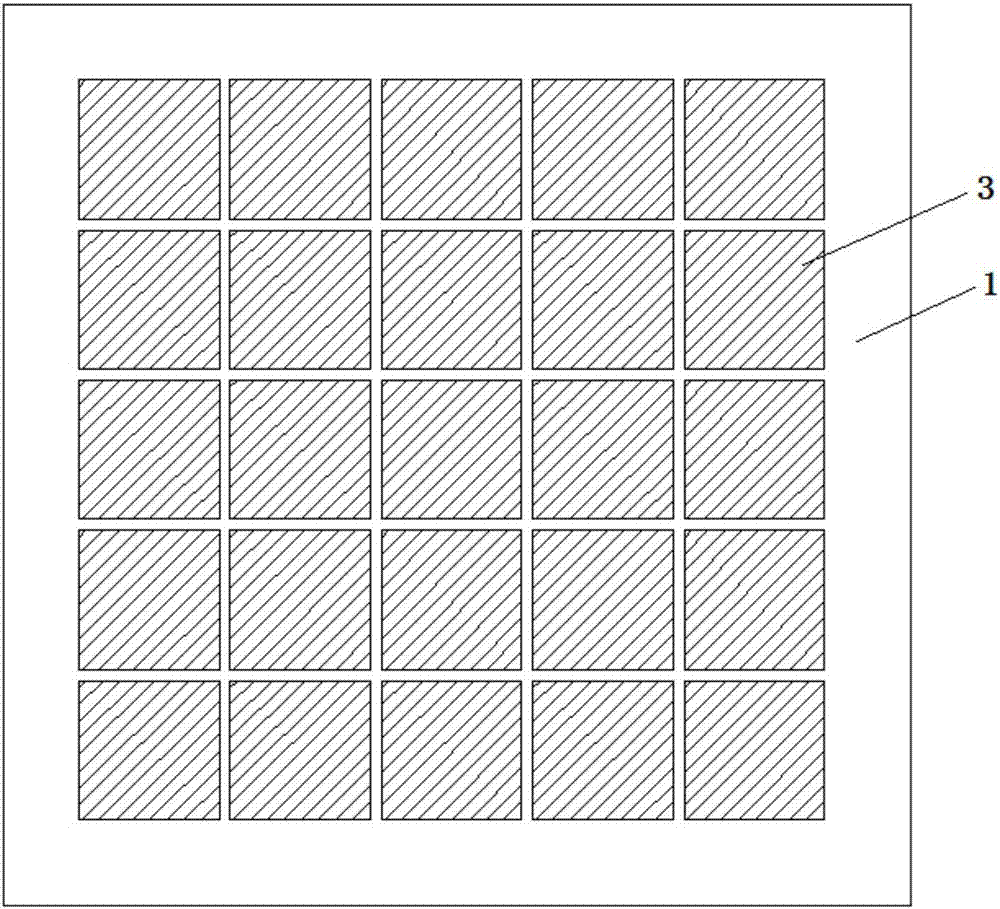

ActiveCN107039358AGuaranteed mechanical reliabilityImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesMechanical reliabilityProcess manufacturing

The invention relates to a thick film substrate having low void content and high reliability and a manufacturing method thereof. The thick film substrate comprises a ceramic substrate, a first grid layer arranged on the ceramic substrate, a second grid layer arranged on the first grid layer and an emboss layer arranged on the second grid layer, wherein each emboss in the emboss layer is located in the center of each grid of the second grid layer. The emboss layer can effectively reduce the void content of a circuit and improve the heat dissipation of the substrate; meanwhile, the structure can be manufactured by adopting high-palladium silver-palladium paste, so that the binding force between the substrate and a tube shell is guaranteed while the low void content is guaranteed, and the mechanical reliability of the substrate is ensured. The method for manufacturing the thick film substrate is simple and effective, does not have special control requirement in the process manufacturing link, can realize manufacturing by three times of printing and burning, and can be used for large-scale production.

Owner:NO 24 RES INST OF CETC

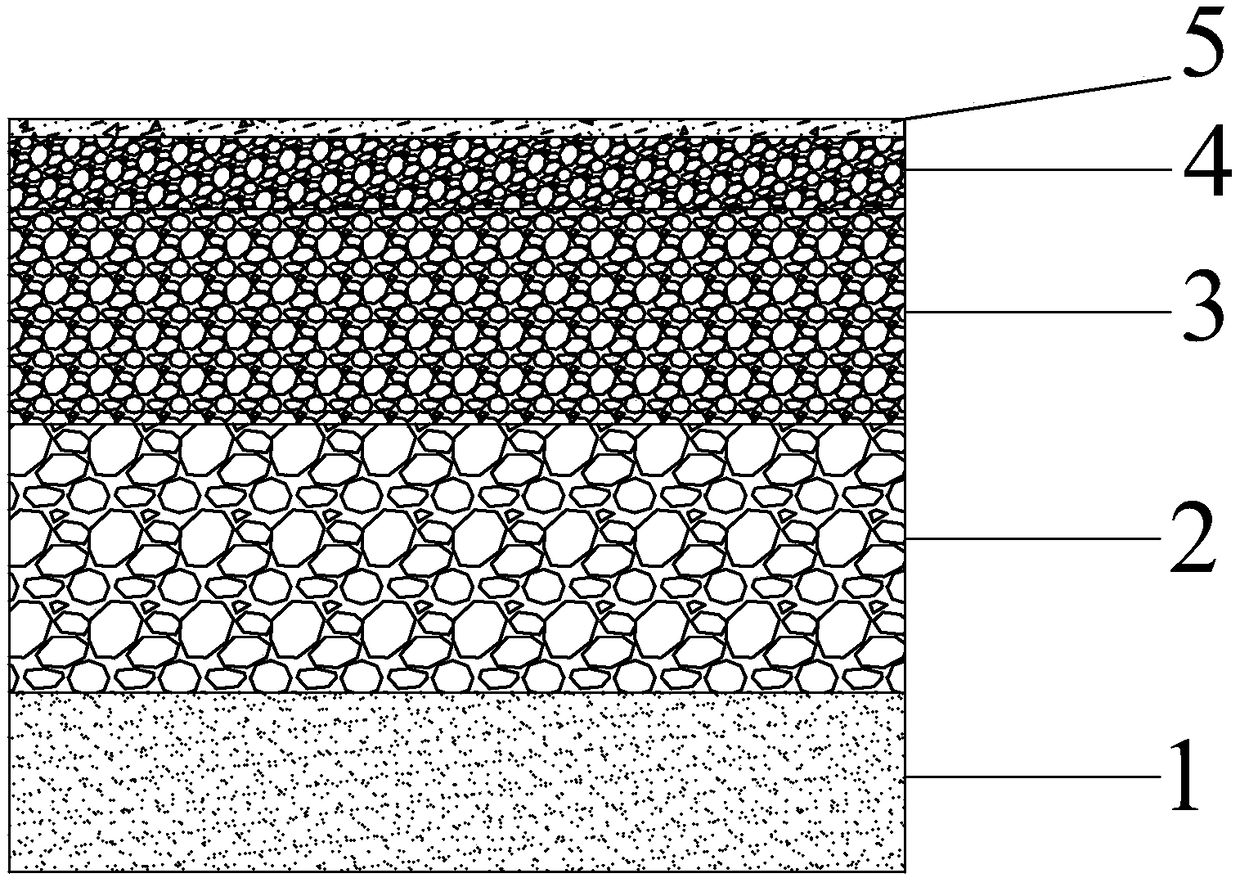

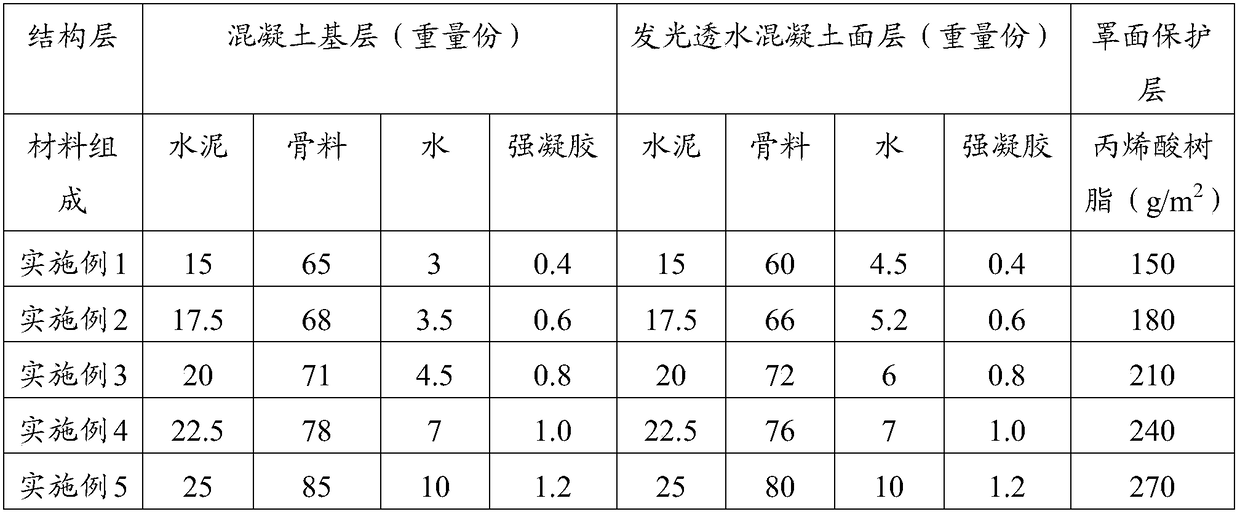

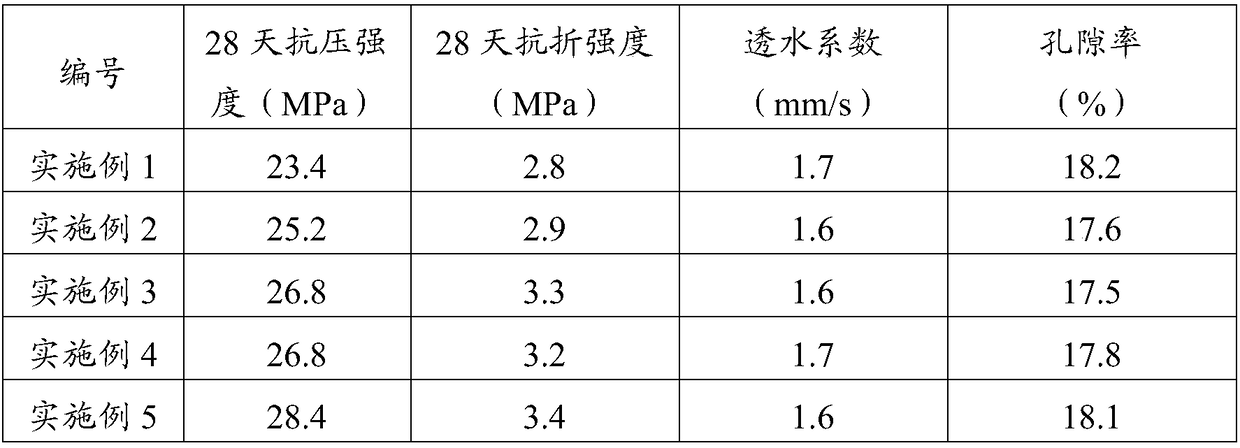

Light-emitting pervious concrete pavement

The invention provides a light-emitting pervious concrete pavement. The light-emitting pervious concrete pavement comprises a soil foundation, a macadam foundation layer, a pervious concrete foundation layer, a light-emitting pervious concrete surface layer and a top facing protection layer, wherein the soil foundation, the macadam foundation layer, the pervious concrete foundation layer, the light-emitting pervious concrete surface layer and the top facing protection layer are sequentially arranged from bottom to top. Light-emitting pervious concrete of the light-emitting pervious concrete pavement can form a great number of gentle light spots on a road in dark light or at night under illumination of weak lamplight, and vehicles and passengers can be safer; a glass waste residue mixture is scattered on the light-emitting pervious concrete surface layer; then, a finishing compacting process is adopted, the bonding degree of light-emitting particles and the light-emitting pervious concrete surface layer can be guaranteed, and the light-emitting particles are prevented from falling; and glass waste residues are adopted as a light-emitting material, the glass waste residues are fullyand effectively utilized, and environmental protection pollution caused by soil burying of the glass waste residues is reduced.

Owner:厦门固泽环保科技有限公司

A kind of preparation method of surface modification layer of iron-containing aluminum intermetallic compound

ActiveCN106245023BImprove production efficiencyLow costHeat inorganic powder coatingPulse dischargeBinding force

The invention discloses a surface modification layer containing an iron and aluminum intermetallic compound and a preparation method of the surface modification layer. The preparation method comprises the following steps: taking an aluminum powder pressing body as a tool electrode, taking aluminum powder and coal oil mixed liquid as working liquid, and taking common low-carbon steel as a workpiece; enabling pulse discharge to be generated between the electrode and the workpiece in the working liquid by using a common electric spark machine tool; enabling the electrode, aluminum in the working liquid and iron in the workpiece to carry out in-situ alloying reaction with the aid of discharge energy; and finally, forming the surface modification layer containing the iron and aluminum intermetallic compound on the surface of the workpiece. The modification layer prepared by the method has the advantages of compact structure, good basic binding force and the like, and is expected to be widely used in the field of surface modification for improvement of corrosion resistance and wear resistance of structure materials.

Owner:GUANGDONG UNIV OF TECH

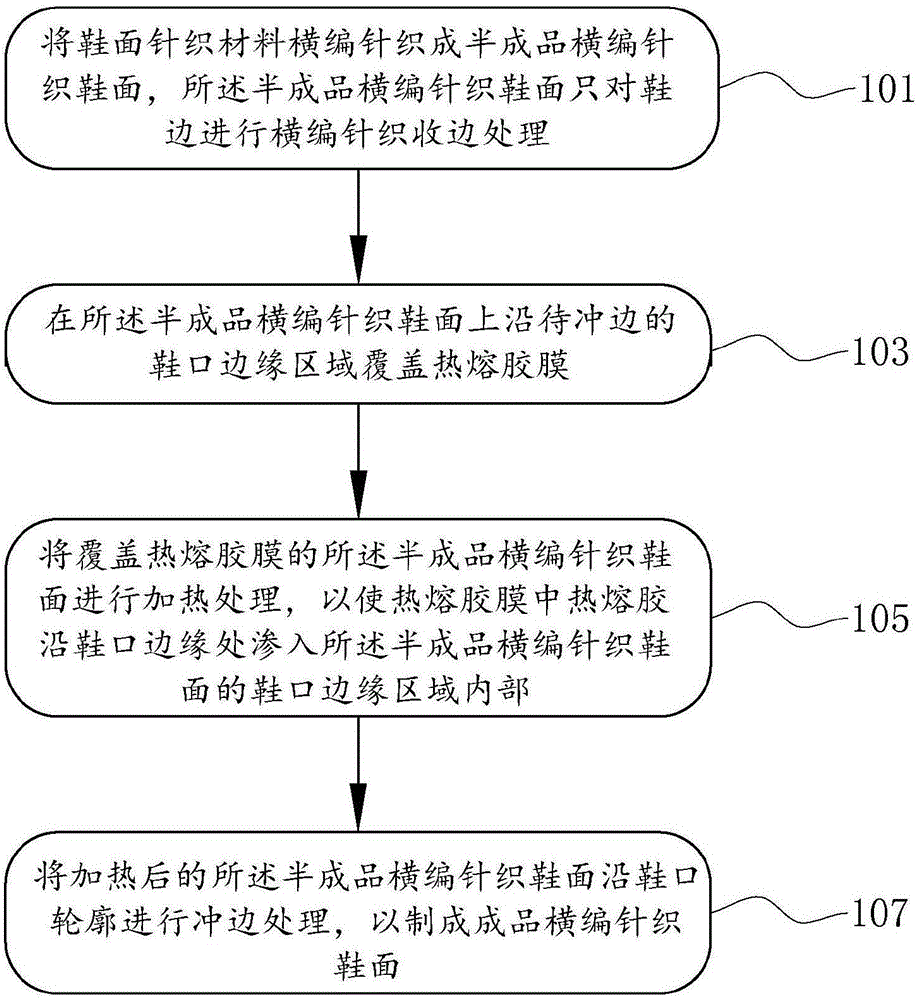

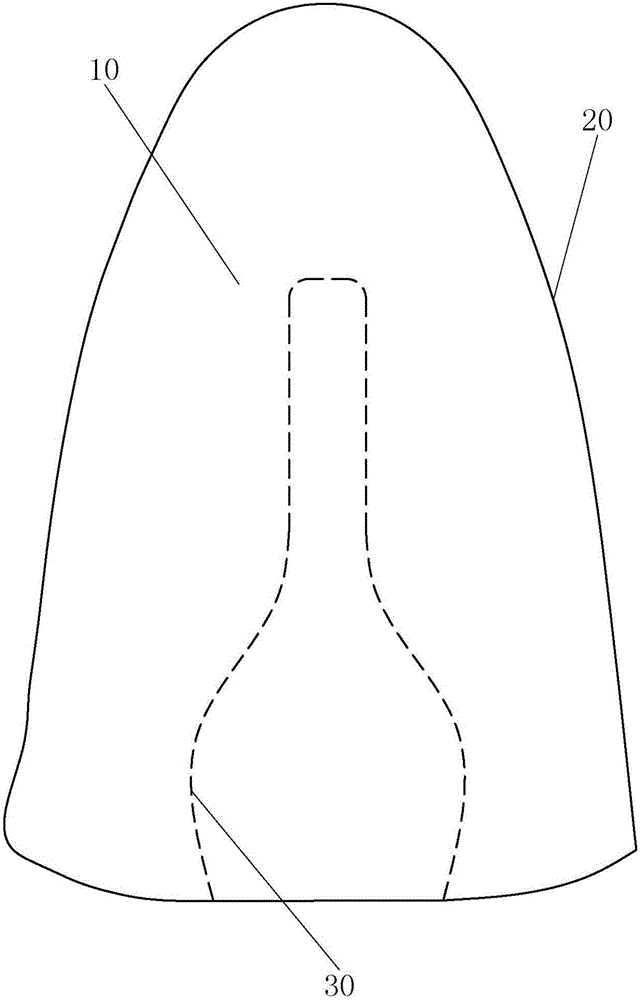

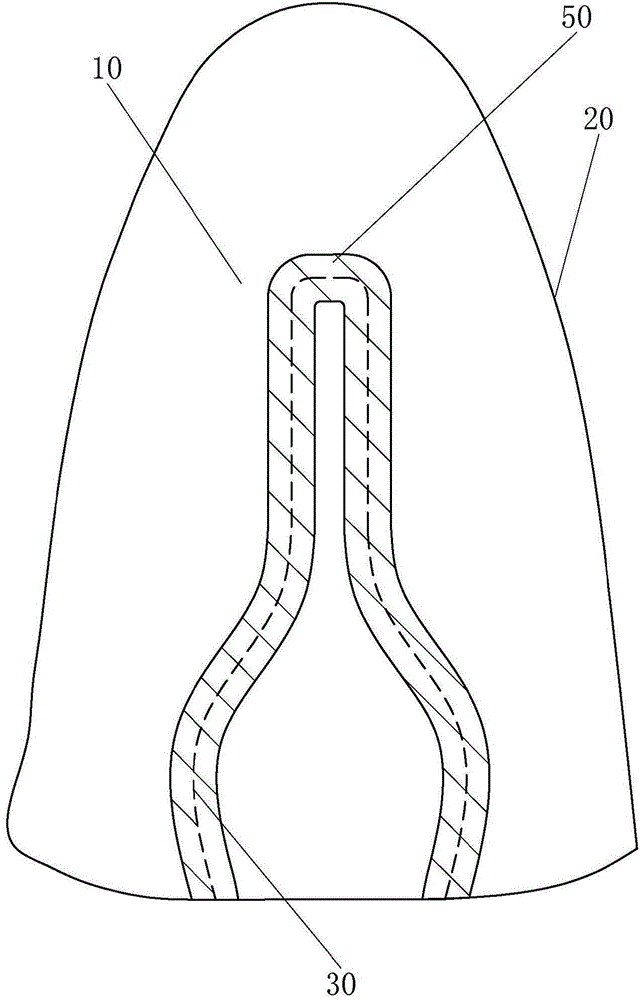

Flat knitted vamp and manufacturing technology thereof

InactiveCN104146440AGuaranteed cohesionEliminate the stitching processShoemaking devicesUpperState of artManufacturing technology

The invention discloses a flat knitted vamp and a manufacturing technology of the flat knitted vamp. The manufacturing technology of the flat knitted vamp includes the steps that vamp knitting material is flat knitted to a semi-finished flat knitted vamp, and according to the semi-finished flat knitted vamp, flat knitting edge closing is only performed on shoe edges; the part, along the shoe mouth edge region to be trimmed, of the semi-finished flat knitted vamp is covered with a hot molten adhesive film; the semi-finished flat knitted vamp covered with the hot molten adhesive film is heated; the heated semi-finished flat knitted vamp is trimmed along the shoe mouth outline to manufacture the flat knitted vamp. The finished flat knitted vamp is obtained through trimming the shoe mouth outline of the semi-finished flat knitted vamp. Compared with the prior art, the stitching process of the flat knitted vamp in the process of edge closing at the shoe mouth position is omitted, and the purposes of simplifying the manufacturing process and improving production efficiency can be achieved.

Owner:XINSHANGLING FUJIAN GARMENTS

Special fluorine-containing pressure-sensitive adhesive and preparation method thereof

ActiveCN112778916AGood adhesionLower surface energyEster polymer adhesivesPressure sensitive film/foil adhesivesAdhesive cementPolymer science

The invention discloses a special fluorine-containing pressure-sensitive adhesive which is characterized by comprising an adhesive and a base material, wherein the adhesive is coated on the surface of one side of the base material; the adhesive comprises a component A and a component B, the component A comprises the following components in percentage by mole: 5%-50% of a pentafluorobenzene-containing functional monomer, 0.1%-0.5% of an initiator, 50%-95% of a soft monomer, 0%-50% of a hard monomer, and 0%-50% of a cross-linking agent; and the component B is a solvent, and the mole number of the component B is 3-8 times of the total mole number of the component A. The special pressure-sensitive adhesive disclosed by the invention has the advantages that the cohesion, solvent resistance, adhesive force and the like for fluorine-containing polymer materials during bonding are well guaranteed, the crosslinking speed is high, and no solvent is discharged at the same time. The invention further provides a preparation method of the special fluorine-containing pressure-sensitive adhesive, and a new thought and a development direction are provided for development of the pressure-sensitive adhesive.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

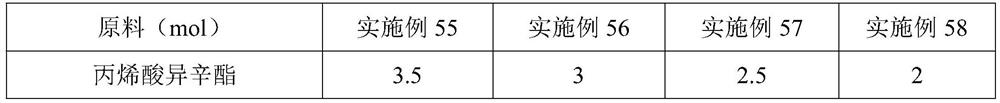

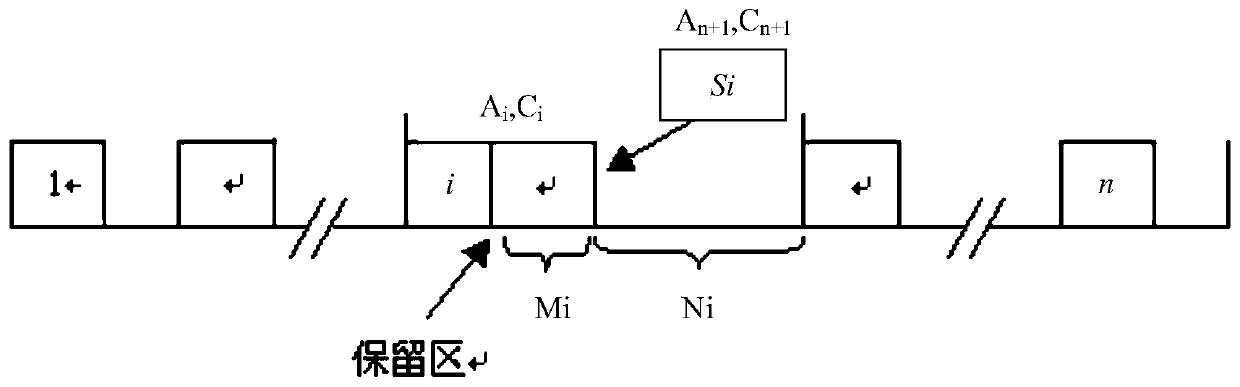

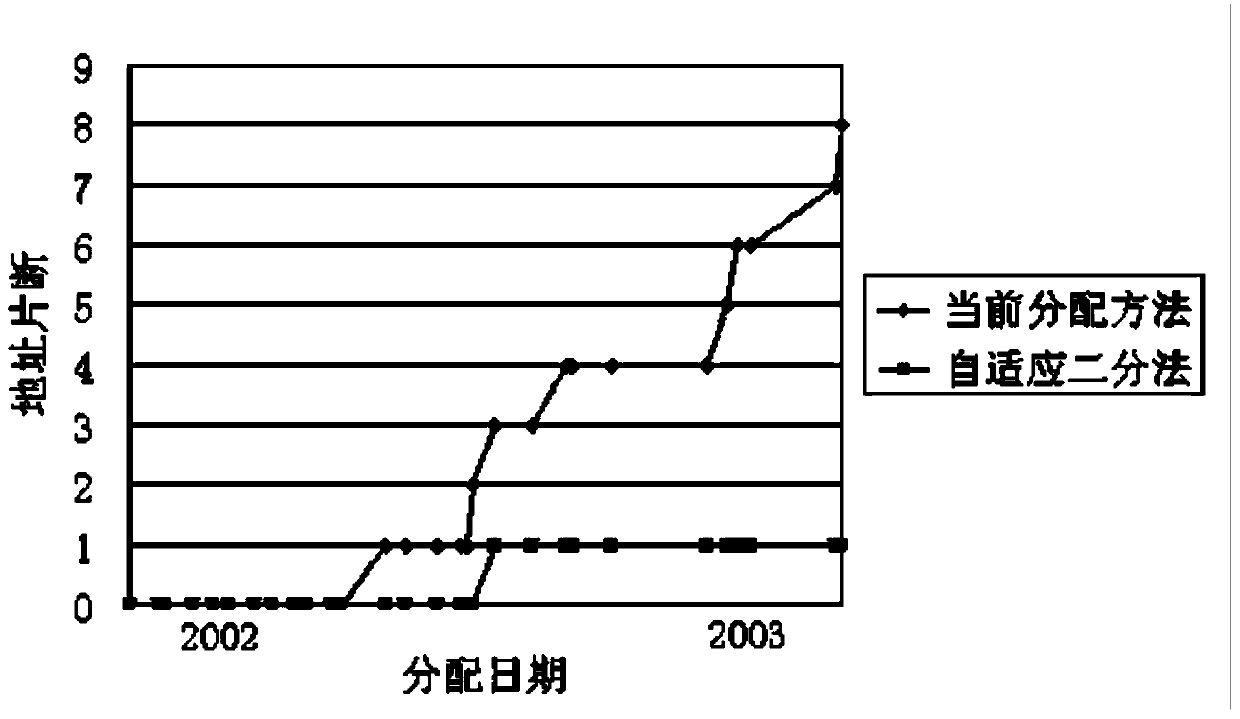

Self-adaptive IPv6 address allocation method for industrial Internet identifier analysis

The invention discloses a self-adaptive IPv6 address allocation method for industrial Internet identifier analysis. The method comprises the following steps: 1) dividing an industrial Internet IP address into a plurality of layers, and each layer corresponding to a section of address space; 2) for each layer of L, when the total amount of the address space applied to be allocated exceeds the capacity of each idle address field in the L address space of the layer, and when the available address space of the layer L is greater than the total amount of the address space allocated by the current application and the HD ratio of the address space of the layer L does not reach the set threshold, decomposing the address application of the user, and allocating an idle address to each decomposed address field. According to the method, excessive address fragments can be avoided, and the overall allocation effect is improved.

Owner:COMP NETWORK INFORMATION CENT CHINESE ACADEMY OF SCI

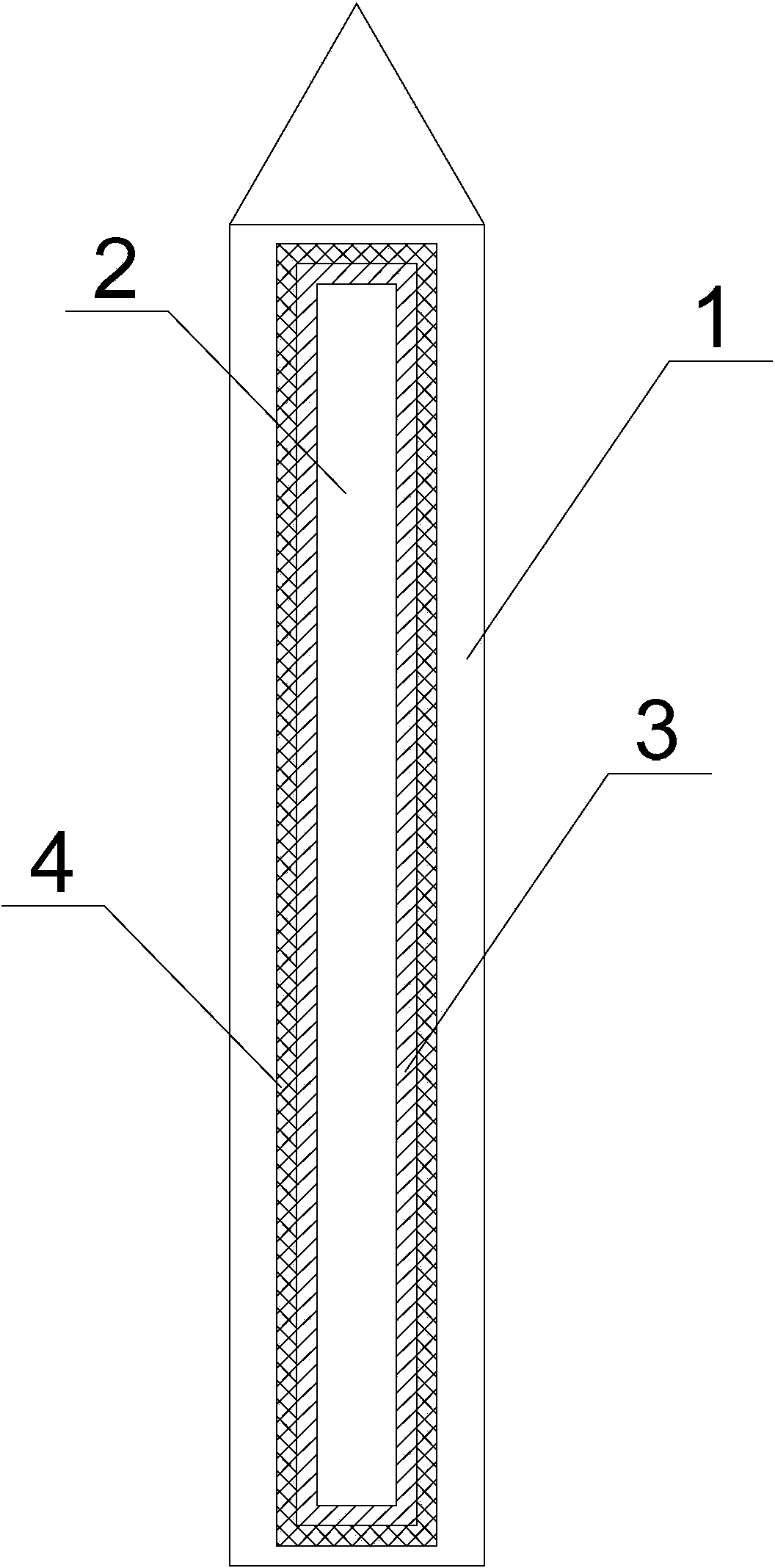

Carbon pen and manufacturing method thereof

ActiveCN103587283AImprove product qualityGuaranteed cohesionNon-propelling pencilsProtection layerBinding force

The invention discloses a carbon pen. The carbon pen comprises a wood penholder and a carbon cartridge inside the wood penholder, wherein a glue layer is arranged between the wood penholder and the carbon cartridge, and a resin protection layer is further arranged between the outer surface of the carbon cartridge and the glue layer. The invention further discloses a manufacturing method of the carbon pen, wherein a coating step is added before the core gluing method is conducted. Before the carbon pen is manufactured, the resin protection layer is formed on the surface of the carbon cartridge so that the cartridge can be well isolated from glue, meanwhile, the PVAC glue is adopted in the core gluing step, the binding force between the carbon cartridge and wood panels is reduced on the premise that the binding force between the wood panels is ensured, and therefore the cartridge can be effectively prevented from being broken in the peeling process, and product quality of the carbon pen is improved.

Owner:AXUS STATIONERY (SHANGHAI) CO LTD

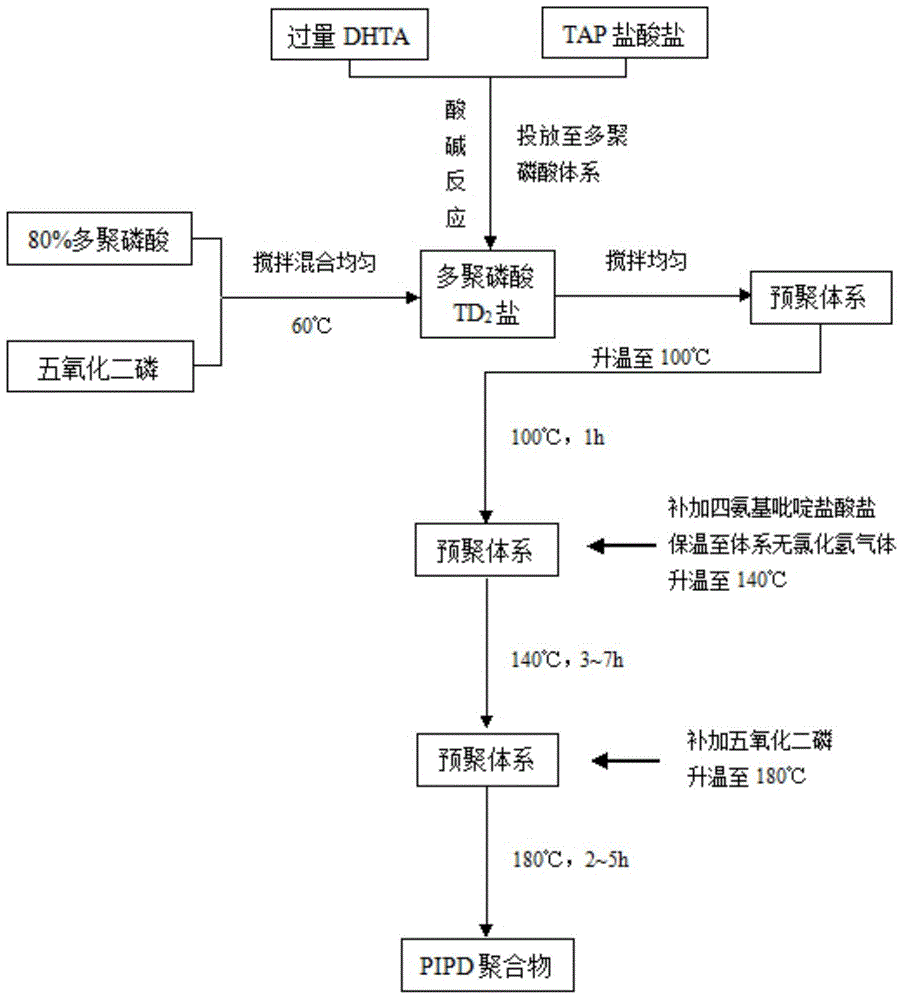

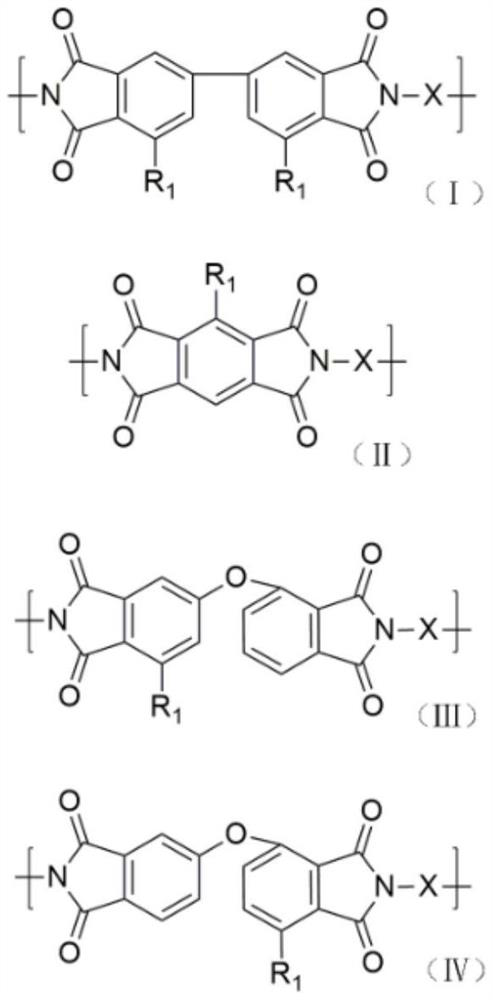

Complex salt and method for preparing high-molecular-weight poly-p-phenylenepyridino-bisiminazole (PIPD) from same

ActiveCN104059017AIncrease profitHigh molecular weightCarboxylic acid salt preparationBenzenePyridine

The invention discloses a complex salt and a method for preparing high-molecular-weight poly-p-phenylenepyridino-bisiminazole (PIPD) from the same. The method solves the problems of low molecular weight, wide molecular weight distribution and low raw material utilization ratio in the PIPD prepared by the existing polymerization method. The method comprises the following steps: reacting raw materials 2,3,5,6-tetraaminopyridine (TAP) hydrochloride and excessive 2,5-dihydroxyterephthalic acid (DHTA) to obtain a stable complex salt (TD2 salt for short), and polymerizing in a polyphosphoric acid (PPA) system to obtain the PIPD polymer. The method solves the problem of high oxidation tendency of the obtained TD salt prepared from equal mole ratio of monomers by changing the raw material proportioning of the complex salt; and the method avoids waste of the raw materials due to the nonuniform stirring in the early reaction stage by changing the phosphorus pentoxide addition mode.

Owner:NANJING UNIV OF SCI & TECH

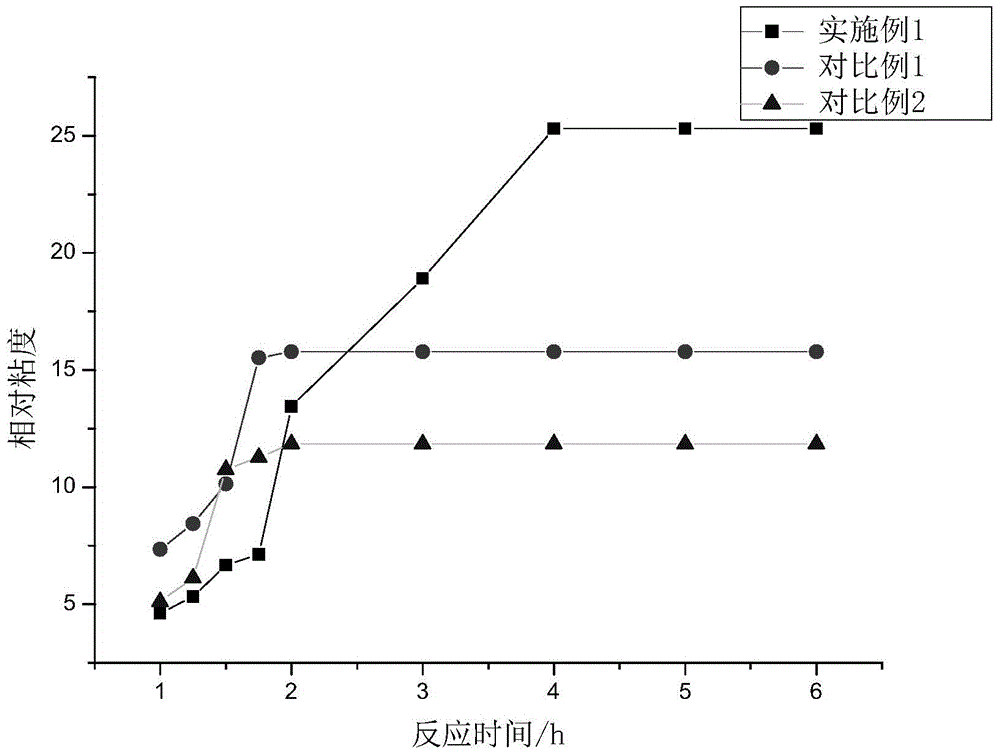

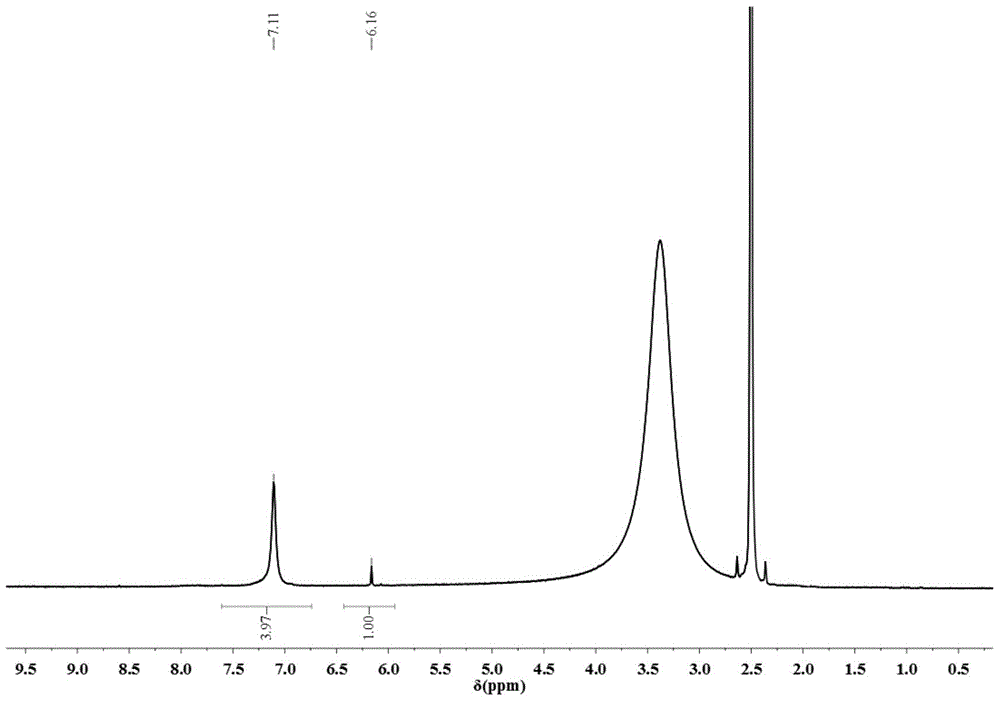

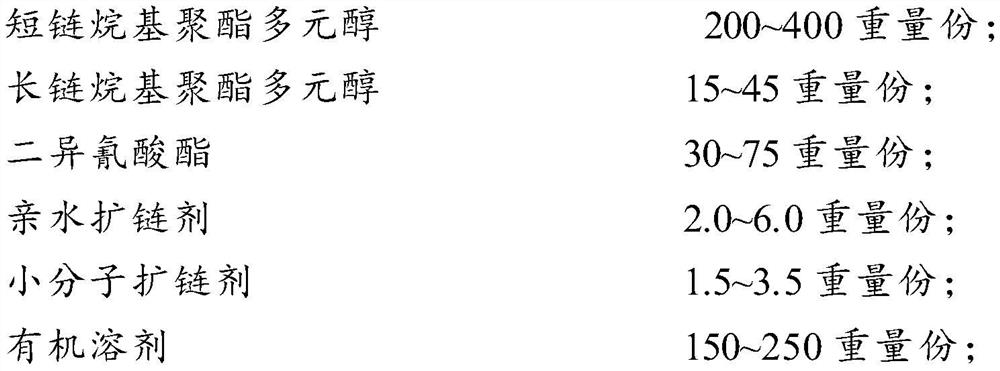

Long-chain alkyl polyester polyol, waterborne polyurethane emulsion and preparation methods thereof

InactiveCN113004501AGood film formingImprove mechanical propertiesPolyureas/polyurethane adhesivesPolymer scienceNitrile rubber

The invention provides a preparation method of long-chain alkyl polyester polyol, which comprises the following steps: A) mixing castor oil, hydroxyl-terminated nitrile rubber, long-chain alkyl dihydric alcohol and long-chain alkyl dibasic acid, and conducting heating and reacting to obtain a small-molecule prepolymer; and B) mixing the micromolecular prepolymer with titanium isopropoxide, and carrying out heating reaction to obtain the long-chain alkyl polyester polyol. The invention further provides waterborne polyurethane. The waterborne polyurethane is prepared from short-chain alkyl polyester polyol, long-chain alkyl polyester polyol, diisocyanate, a hydrophilic chain extender, a small-molecule chain extender, an organic solvent, a catalyst, a neutralizer and water. According to the long-chain alkyl polyester polyol, due to the introduction of nitrile rubber groups, the film forming effect of waterborne polyurethane is greatly improved, a complete self-supporting film can be formed, the obtained waterborne polyurethane is very good in toughness, the tensile strength can be 13.5-25.6 Mpa, and the elongation at break is 475-850%.

Owner:吉林天泽二氧化碳科技有限公司

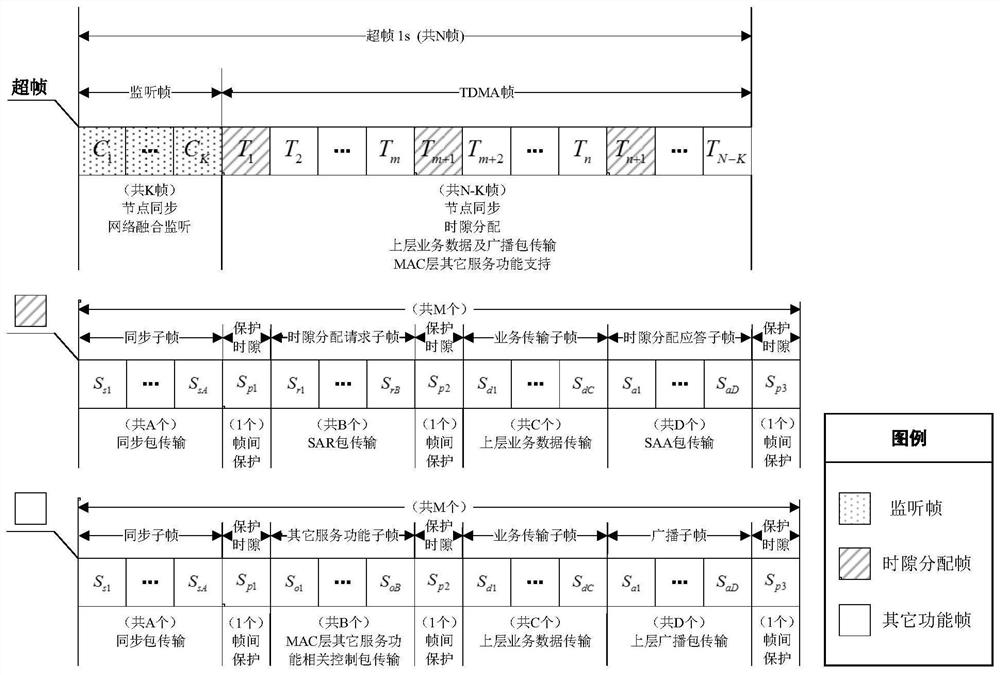

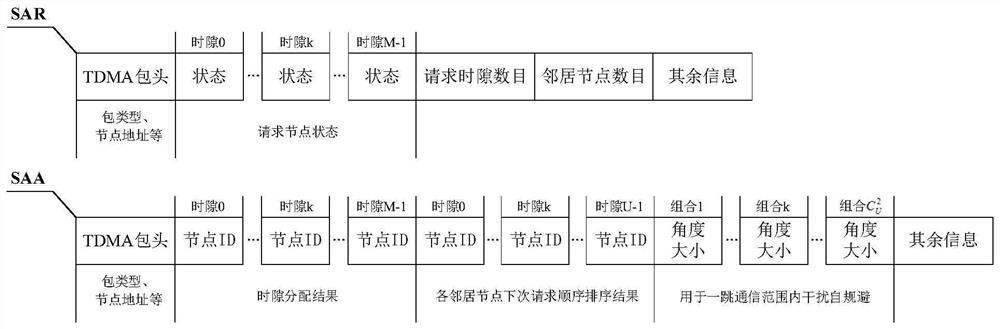

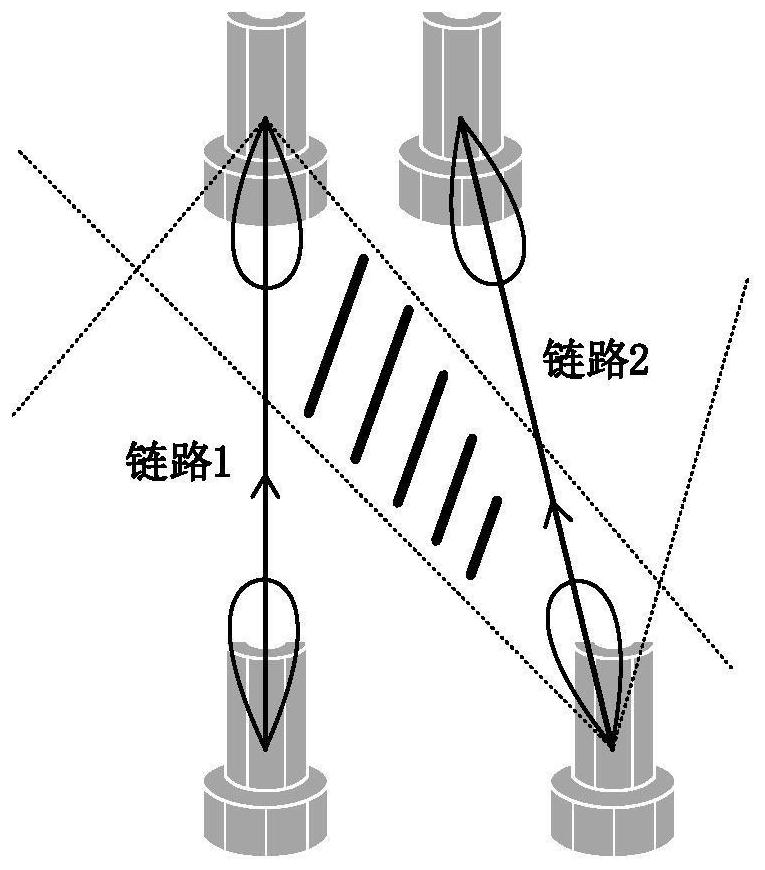

A distributed dynamic time slot allocation method in long-distance tdma mobile ad hoc network

ActiveCN110248416BReduce utilizationFlexible structure adjustmentWireless communicationMultiplexingSmart antenna

Owner:XI AN JIAOTONG UNIV

RTP pipeline and manufacturing method thereof

PendingCN107355599AImprove pressure bearing capacityAccelerated corrosionSynthetic resin layered productsLaminationFiberYarn

The invention provides an RTP pipeline and a manufacturing method thereof. The RTP pipeline comprises an HDPE resin inner pipe, a PE resin outer pipe coaxially sleeving the HDPE resin inner pipe and at least one layer of fiber yarn layers spirally wound on the outer wall of the HDPE resin inner pipe; the inner side of the fiber yarn layer adjacent to the HDPE resin inner pipe is bonded with the HDPE resin inner pipe through a thermoplastic resin layer coated on the outer wall of the HDPE resin inner tube, each outer surface of the fiber yarn layer is coated with one thermoplastic resin layer, and is bonded with the fiber yarn layer adjacent to the outer surface or the PE resin outer pipe inner wall through the thermoplastic resin layer. According t the RTP pipeline, under the action of high temperature and pressure, the fiber yarn layers is fully bonded with the HDPE resin inner pipe and the PE resin outer pipe through the thermoplastic resin layers, and all the layers are bonded together to form a whole, so that the anti-shearing capacity of the RTP pipeline is greatly enhanced, and great contribution is made to improve the compression resistance of the whole pipeline.

Owner:曹如锋

Pervious concrete water-based covering protective agent

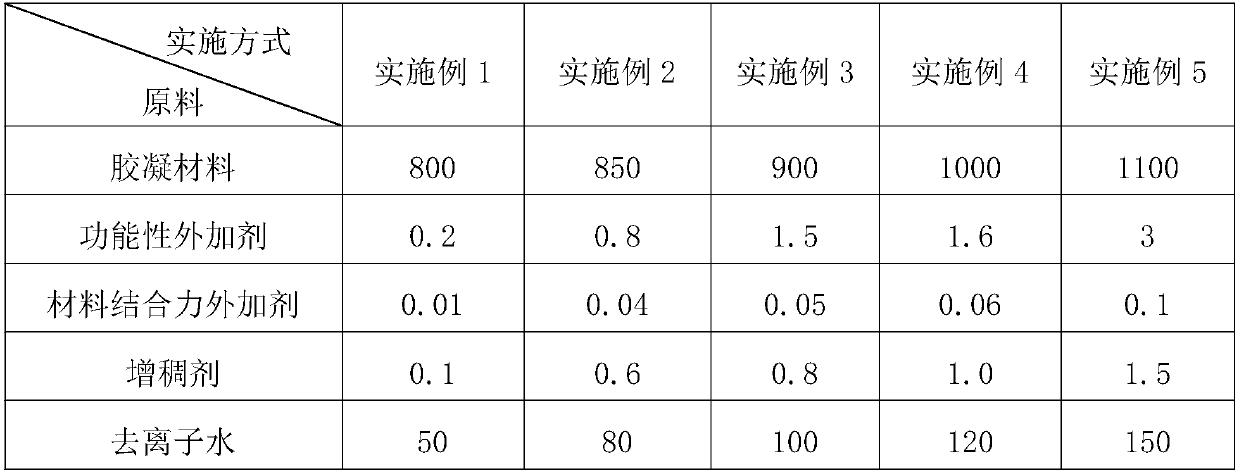

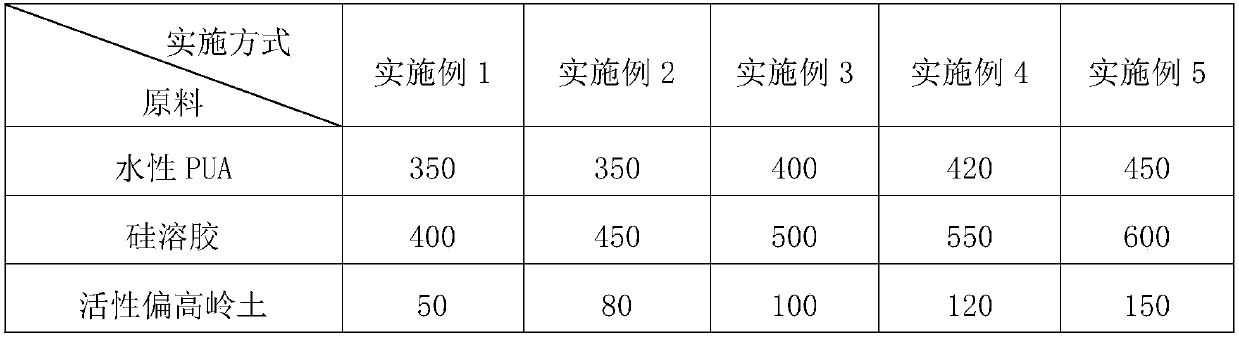

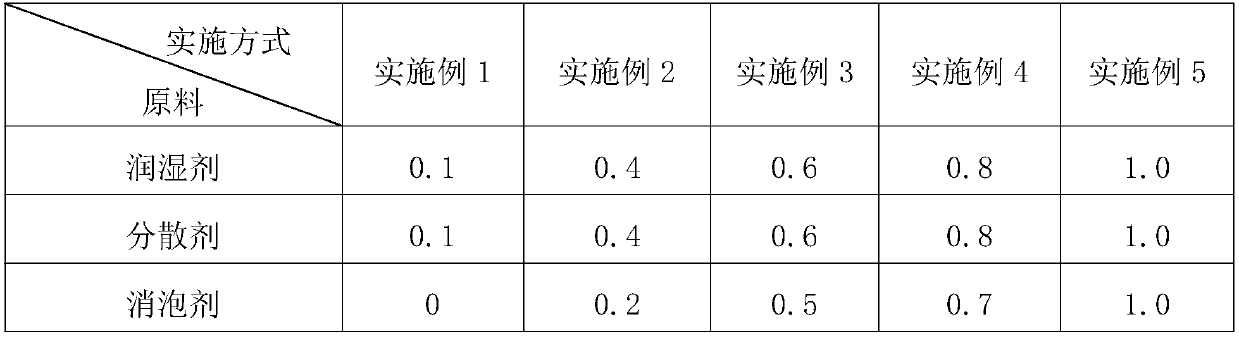

The invention discloses a pervious concrete water-based covering protective agent. The pervious concrete water-based covering protective agent is prepared from the following components in parts by mass: 800 to 1100 parts of cementing material, 0.2 to 3 parts of functional admixture, 0.01 to 0.1 part of material adhesive admixture, 0.1 to 1.5 part of thickening agent and 50 to 150 parts of deionized water. According to the pervious concrete water-based covering protective material disclosed by the invention, an inorganic active material and an organic bonding material are organically combined by a double charge protection and coupling scheme; organic resin is modified by the inorganic material, and the surface of the inorganic material is protected by using double charge through the functional admixture, so that the stability of the inorganic material in an organic system is improved, and thereby the strength and friction resistance of a system are improved.

Owner:SHENZHEN WEITENAI NEW MATERIAL CO LTD

Preparation method of high-performance modified polyimide (MPI) flexible substrate

ActiveCN111716773AHigh dielectric strengthImprove yieldFilm/foil adhesivesFlat articlesMetal foilMoisture absorption

The invention discloses a preparation method of a high-performance modified polyimide (MPI) flexible substrate. An MPI adhesive and performance strengthening components are added into an organic medium solvent, MPI glue is prepared by grinding after pretreatment, then metal foil is coated with the MPI glue or the MPI glue is sputtered on the metal foil, then precuring, postcuring and tempering treatment processes are carried out, and thus the high-performance MPI flexible substrate is obtained. A composite film prepared by the preparation method has the low dielectric constant, dielectric lossand moisture absorption rate, and can meet the high-frequency and high-speed requirements in 5G application; good high-voltage insulation resistance, mechanical strength and toughness are realized; and the preparation process is simple, the yield is up to 92% or above, and the demands of various process windows and low-cost production are met.

Owner:四川铂利明德科技有限公司

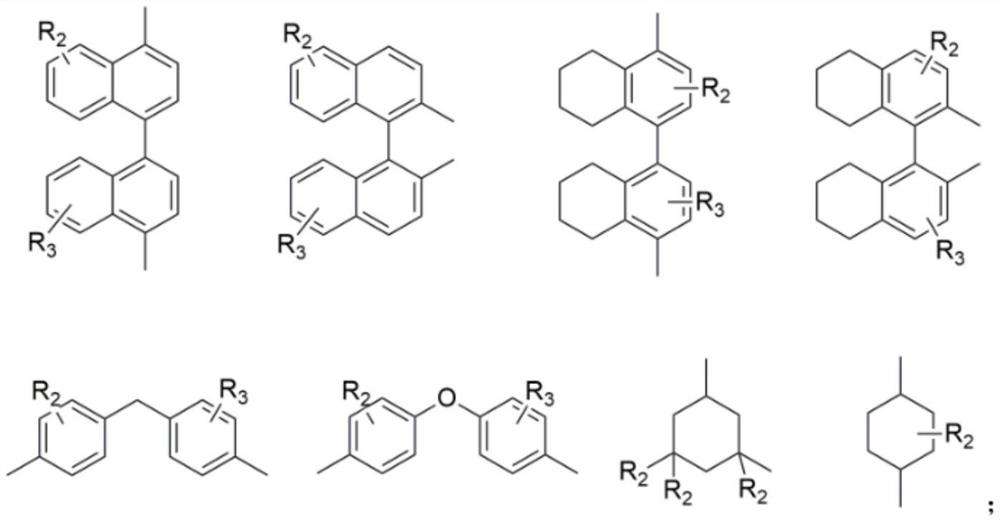

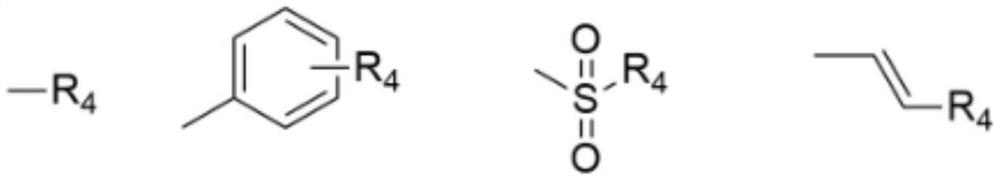

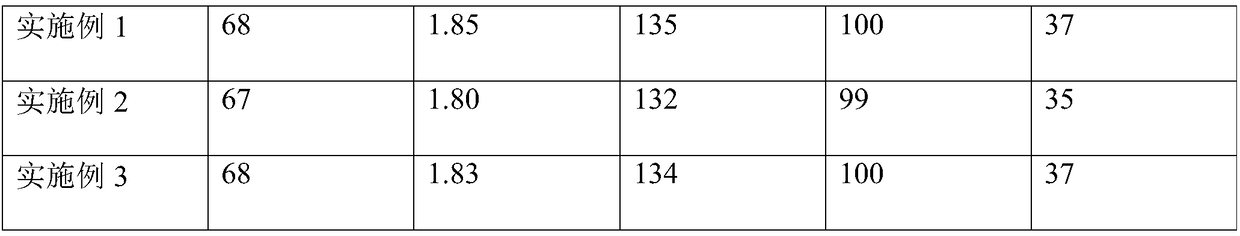

Environment-friendly playground ground floor material and application method

InactiveCN109265638AImprove mechanical propertiesImprove heat resistanceNational standardEngineering

The invention discloses an environment-friendly playground ground floor material, which relates to the technical field. The environment-friendly playground floor material is prepared from a componentA, a component B and a composite catalyst. The invention designs a liquefied MDI and a composite catalyst system, and cancels the use of poisonous substances such as TDI, MOCA, lead, and mercury, so that the performance of the prepared two-component environment-friendly playground ground floor material can meet the national standard requirements.

Owner:江苏叙然智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com