Flat knitted vamp and manufacturing technology thereof

A manufacturing process and flat knitting technology, applied in the field of sports shoes, can solve the problems of complicated stitching process and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

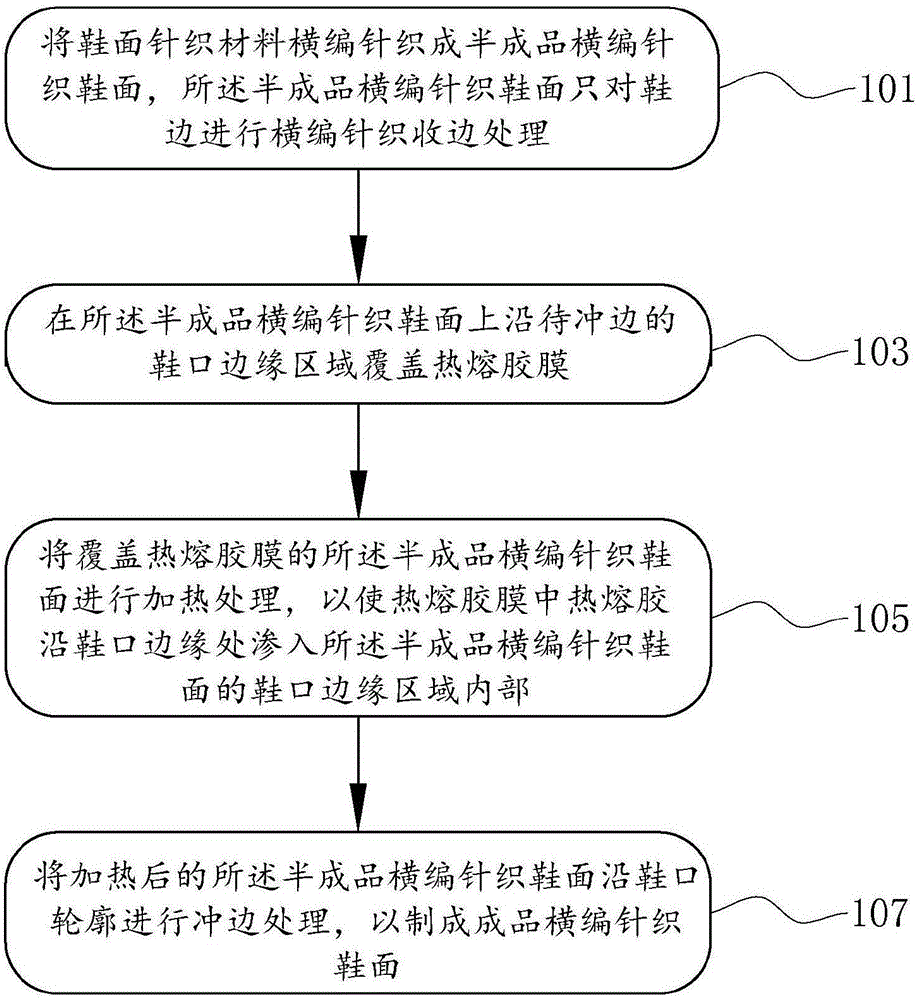

[0034] figure 1 A flow chart of the manufacturing process for flat knitted shoe uppers, such as figure 1 As shown, the manufacturing process of the flat knitted shoe upper is carried out in the following steps:

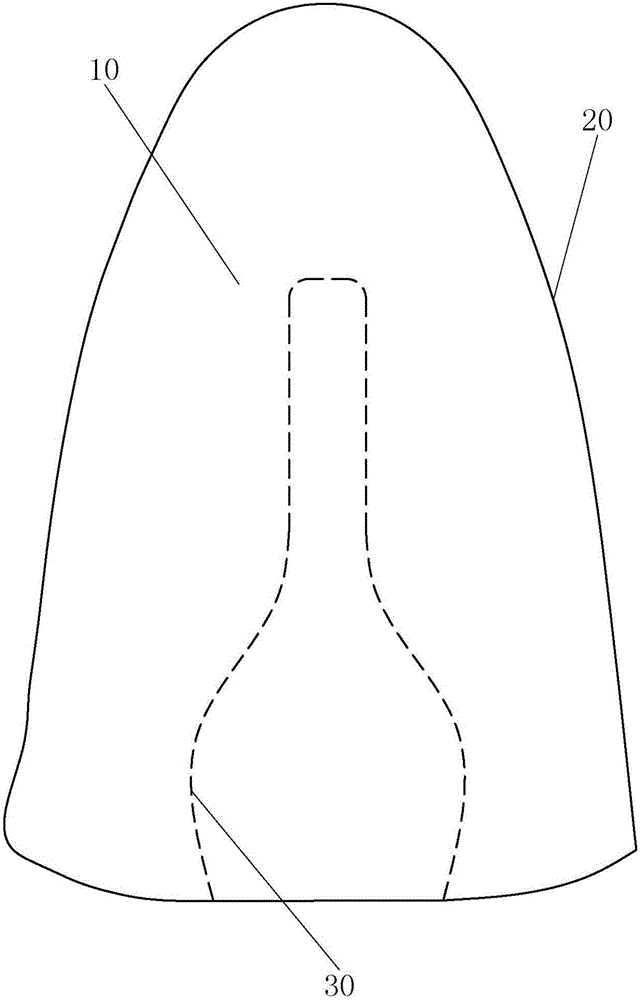

[0035] In step 101, combine figure 2 As shown, the upper knitted material is flat-knitted into a semi-finished flat-knitted upper 10 . During specific implementation, the shoe upper knitting material can be sent into a computerized flat knitting machine to be knitted into a semi-finished flat knitted upper 10, and the semi-finished flat knitted upper 10 only performs flat knitting edge processing on the shoe edge 20, The outline of the shoe opening 30 is not trimmed, that is, the shoe opening area (the area that is trimmed along the shoe opening outline in step 107) is directly knitted and connected, and the entire semi-finished flat knitting upper is integrally formed. It should be noted that the knitting in the area of the shoe mouth 30 can adopt a different k...

Embodiment 2

[0055] Figure 5 It is the flow chart of embodiment two flat knitting shoe upper manufacturing process, as Figure 5 As shown, on the basis of the first embodiment, the covering position of the hot melt adhesive film in the step 103 of the first embodiment is further defined in step 203, and the steps 201, 205 and 207 are respectively the same as the steps 101, 207 in the first embodiment 105 and 107 correspond to the same. Embodiment two specific steps are as follows:

[0056] In step 201, combine figure 2 As shown, the upper knitting material is flat knitted into a semi-finished flat knitting upper 10, specifically, the upper knitting material can be sent into a computerized flat knitting machine to be knitted into a semi-finished flat knitting upper 10, and the semi-finished The flat-knitted upper 10 only performs flat-knitting trimming on the shoe edge 20, and does not trim the outline of the shoe opening 30;

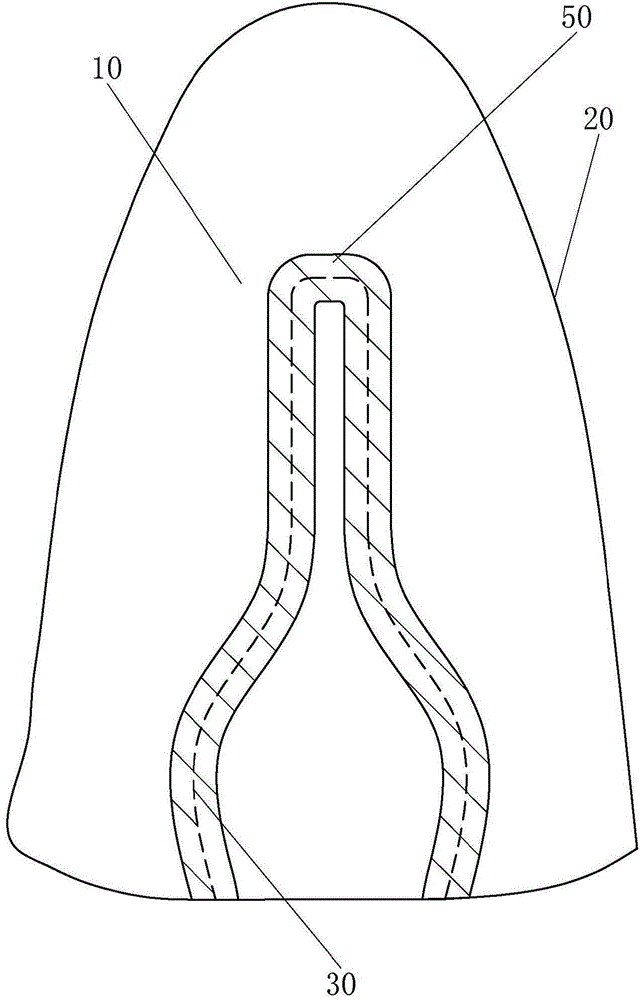

[0057] In step 203, combine image 3 As shown, the hot m...

Embodiment 3

[0062] Figure 6 It is the flow chart of embodiment three flat knitting shoe upper manufacturing techniques, as Figure 6 As shown, on the basis of Embodiment 1, a calendering setting processing step 306 is added, wherein Steps 301, 303, 305 and 307 are respectively the same as Steps 101, 103, 105 and 107 in Embodiment 1. The concrete steps of this embodiment are as follows:

[0063] In step 301, combine figure 2 As shown, the upper knitting material is flat knitted into a semi-finished flat knitting upper 10, specifically, the upper knitting material can be sent into a computerized flat knitting machine to be knitted into a semi-finished flat knitting upper 10, and the semi-finished 10 horizontal knitting vamps only carry out horizontal knitting edge processing on the shoe edge 20;

[0064] In step 303, combine image 3 As shown, the semi-finished flat knitted shoe upper 10 described in step 203 is covered with a hot melt adhesive film 50 along the edge area of the sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com