RTP pipeline and manufacturing method thereof

A manufacturing method and technology for pipelines, which are applied in pipeline protection, chemical instruments and methods, and pipeline damage/wear prevention, etc., can solve serious constraints on the compressive strength and shear resistance of pipeline joints, and insufficient shear resistance of RTP pipelines. and other problems, to achieve the effect of improving pressure bearing capacity and corrosion resistance, enhancing shear resistance, and increasing adhesive friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

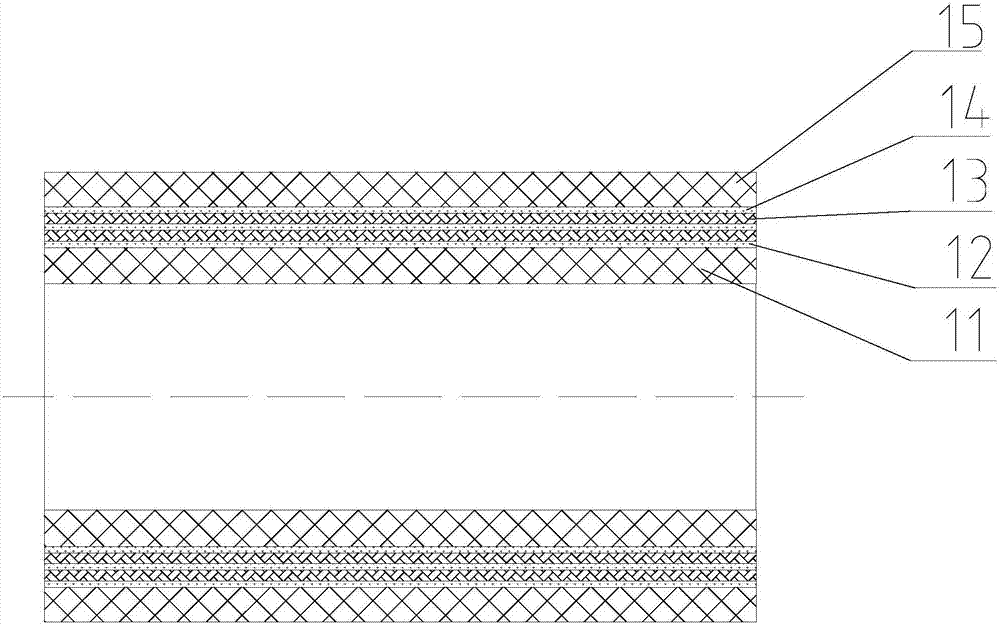

[0036] Such as figure 1As shown, the present invention is a kind of RTP pipeline, comprises HDPE resin inner pipe 11 and PE resin outer pipe 15 coaxially sleeved on the outside of HDPE resin inner pipe 11, and two layers of fibers spirally wound on the outer wall of HDPE resin inner pipe 11 Yarn layer 13, the inner side of the fiber yarn layer 13 adjacent to the HDPE resin inner tube 11 is bonded with the HDPE resin inner tube 11 through the thermoplastic resin layer 12 coated on the outer wall of the HDPE resin inner tube 11, the two layers of fiber yarn layers 13 The outer surface is coated with a thermoplastic resin layer 14, the inner fiber yarn layer 13 is bonded with the outermost fiber yarn layer 13 through the thermoplastic resin layer 14, and the outermost fiber yarn layer 13 is covered by the outermost fiber yarn layer 13. The thermoplastic resin layer 14 is bonded to the inner wall of the PE resin outer tube 15 .

[0037] The fiber yarn among the present invention ...

Embodiment 2

[0049] This embodiment also provides a kind of RTP pipeline, and its only difference with the RTP pipeline of embodiment 1 is that this embodiment has only one layer of fiber yarn, and the inner side of the fiber yarn layer is bonded to the outer wall of the HDPE resin inner tube through a thermoplastic resin layer , The outside of the fiber yarn layer is bonded to the PE resin outer tube through a thermoplastic resin layer.

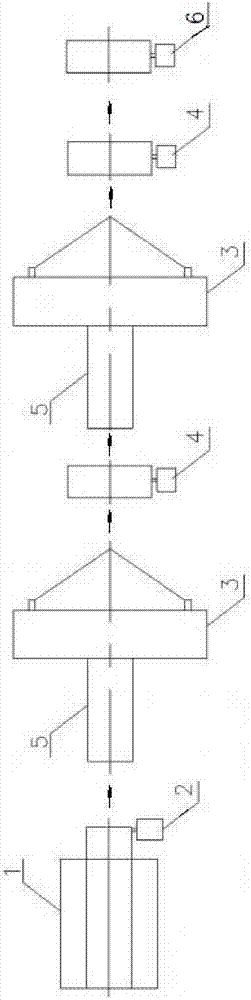

[0050] A manufacturing method of RTP pipeline in embodiment 2, comprises the following steps:

[0051] 1) Coating a 0.15-0.25 mm thick thermoplastic resin layer on the outer wall of the HDPE resin inner pipe by a thermoplastic resin layer coating machine while the plastic extruder 1 extrudes the HDPE resin inner pipe;

[0052] 2) Pass the HDPE resin inner tube treated in step 1) through the pipeline heater at a heating temperature of 180±5°C. After the thermoplastic resin layer on the outer layer of the HDPE resin inner tube is melted, pass the fiber yar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com