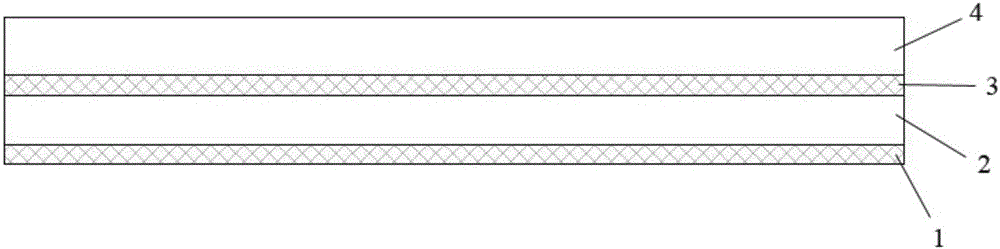

Preparation method for double-layer PET protective film for lithium battery pack

A lithium battery pack and protective film technology, which is applied in the field of preparation of double-layer PET protective films, can solve the problems of flammable and explosive electric vehicle fragility of battery packs, restricting the development of lithium battery enterprises, poor high temperature resistance, etc., and achieves puncture resistance. High strength, easy control, good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

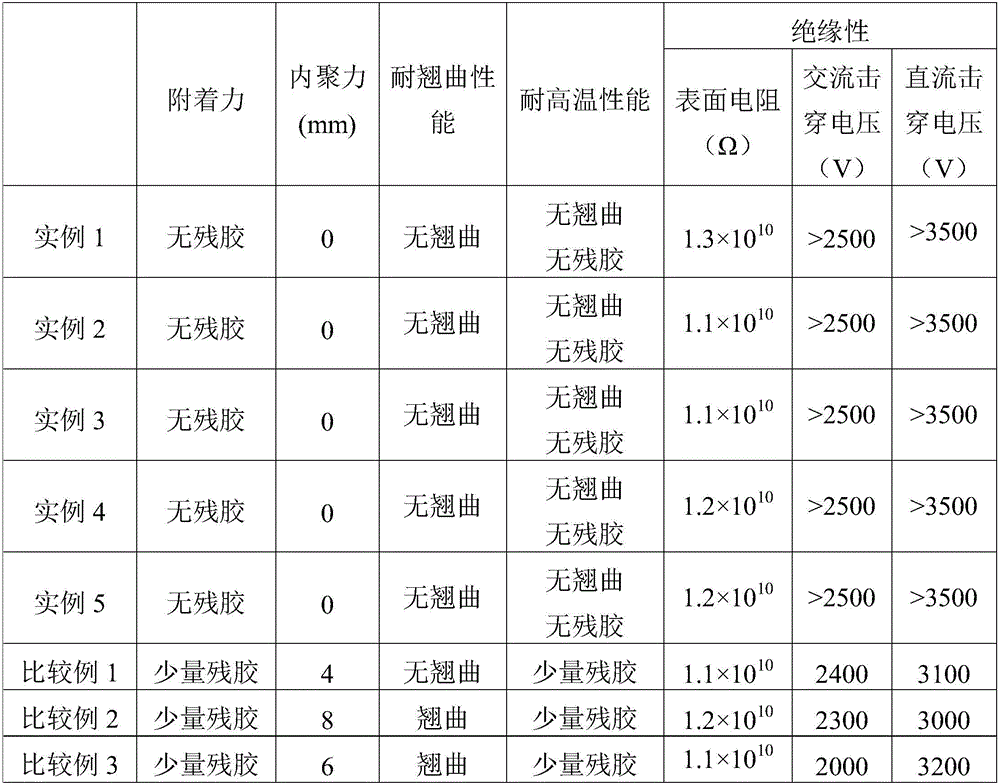

Examples

example 1

[0033] A preparation method for a double-layer PET protective film for a lithium battery pack, comprising the steps of:

[0034] Step 1): Take 80 parts by weight of acrylic pressure-sensitive adhesive, 30 parts by weight of ethyl acetate and 30 parts by weight of methyl ethyl ketone and stir and mix evenly, then add 10 parts by weight of blue color paste, 2 parts by weight of white color paste, 0.5 parts by weight of Yellow color paste, 0.1 parts by weight of tannic acid and 1 part by weight of auxiliary agents, finally add 2 parts by weight of hexamethylene diisocyanate and 0.8 parts by weight of lithium tetrafluoroborate, stir evenly to obtain an adhesive liquid, wherein the auxiliary agent Including 40wt% polyoxyethylene polyoxyacetone amine ether, 15wt% polydimethylsiloxane, 15wt% acetylacetone and 30wt% dibutyltin dilaurate, the blue color paste, white color paste and yellow The viscosity of the color paste is 1500CPS;

[0035] Step 2): After coating the adhesive liquid ...

example 2

[0038] A preparation method for a double-layer PET protective film for a lithium battery pack, comprising the steps of:

[0039]Step 1): Take 120 parts by weight of acrylic pressure-sensitive adhesive, 50 parts by weight of ethyl acetate and 40 parts by weight of methyl ethyl ketone and stir and mix evenly, then add 5 parts by weight of blue color paste, 1 part by weight of white color paste, 0.1 parts by weight of Yellow color paste, 0.5 parts by weight of glyceryl tristearate and 3 parts by weight of additives, finally add 1 part by weight of hexamethylene diisocyanate and 0.2 parts by weight of lithium tetrafluoroborate, stir to obtain the adhesive liquid, wherein, The auxiliary agent includes 50wt% polyoxypropylene glyceryl ether, 20wt% polyester modified organosiloxane, 10wt% ethylenediaminetetraacetic acid and 20wt% dibutyltin maleate, the blue color paste The viscosities of the white color paste and yellow color paste are both 5000CPS;

[0040] Step 2): After coating t...

example 3

[0043] A preparation method for a double-layer PET protective film for a lithium battery pack, comprising the steps of:

[0044] Step 1): Take 100 parts by weight of acrylic pressure-sensitive adhesive, 40 parts by weight of ethyl acetate and 35 parts by weight of methyl ethyl ketone and stir and mix evenly, then add 7 parts by weight of blue color paste, 1.5 parts by weight of white color paste, 0.3 parts by weight of Yellow color paste, 0.3 parts by weight of glyceryl tristearate and 2 parts by weight of additives, finally add 1.5 parts by weight of hexamethylene diisocyanate and 0.5 parts by weight of lithium tetrafluoroborate, stir evenly to obtain the adhesive liquid, wherein, The auxiliary agent includes 43wt% polyoxypropylene polyoxyethylene glyceryl ether, 16wt% polyester modified organosiloxane, 13wt% ethylenediaminetetraacetic acid and 28wt% dibutyltin dilaurate. The viscosity of blue color paste, white color paste and yellow color paste is 3500CPS;

[0045] Step 2)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com