Modified lithium-based concrete sealing curing agent and preparation method thereof

A sealing and curing agent, concrete technology, applied in the direction of alkali metal silicate paint, coating, etc., can solve the problems of concrete surface strength, general waterproof performance, easy to be corroded, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

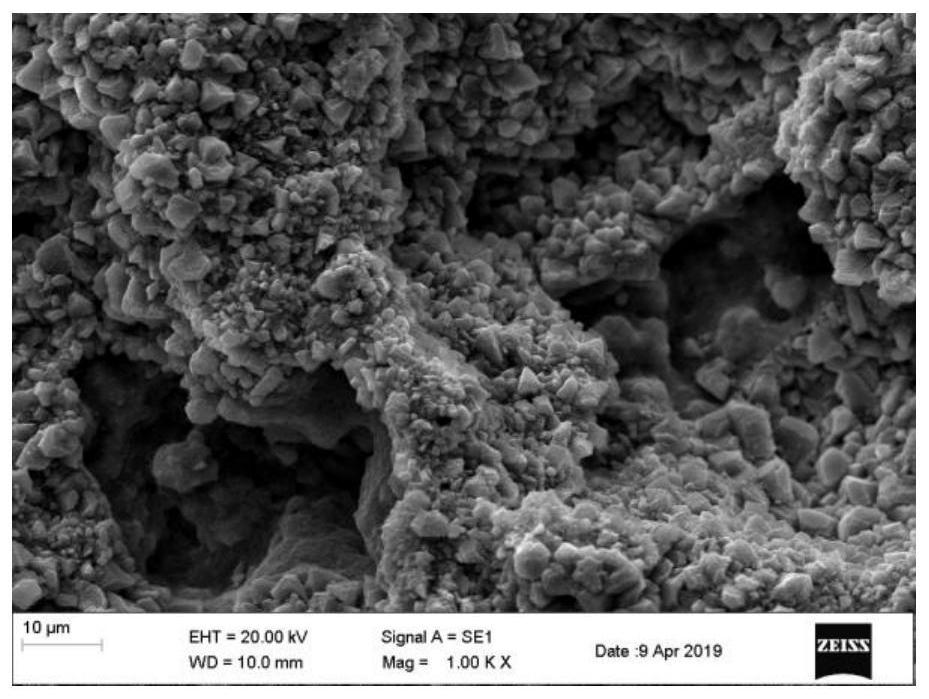

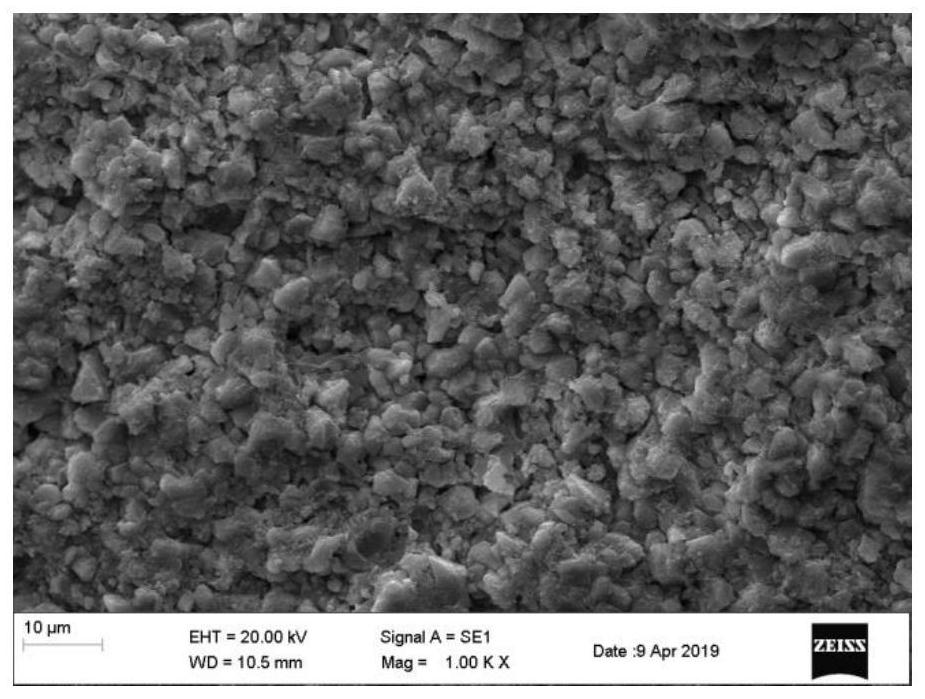

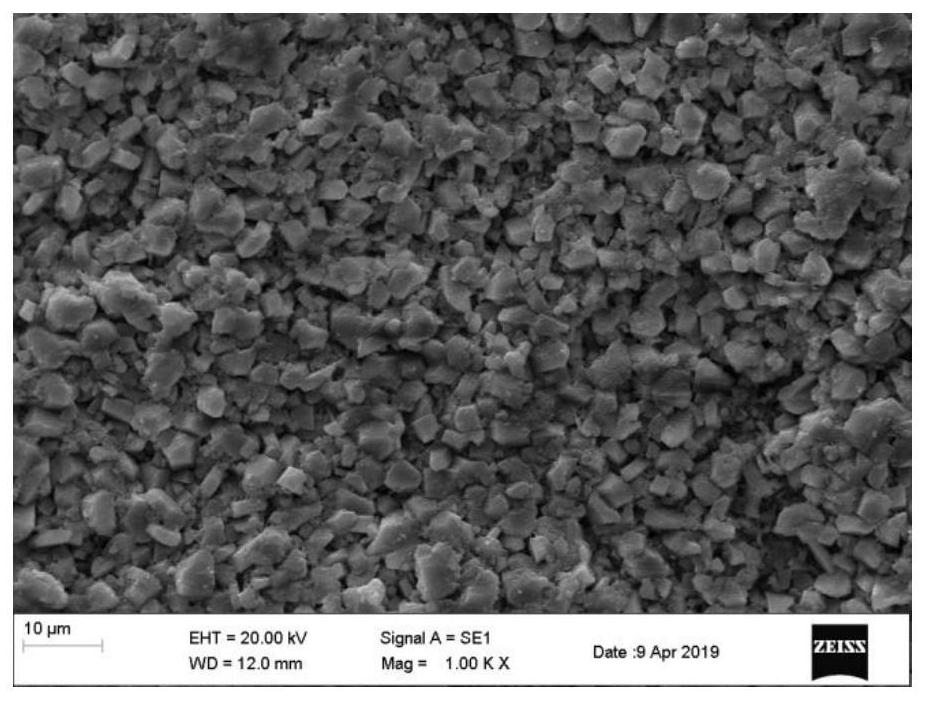

Image

Examples

Embodiment 1

[0043] A modified lithium-based concrete sealing and curing agent, according to the mass percentage, is made of the following raw materials: liquid lithium silicate 30wt%, sodium silicate 1wt%, neutral silica sol (average particle diameter 15nm) surfactant 0.5wt %, dispersant 0.5wt%, defoamer 0.5wt%, fluorosilicate 5wt%, graphene oxide 0.05wt%, the balance is deionized water; Surfactant is sodium stearate in the present embodiment, dispersing The agent is polyethylene glycol PEG200, the defoamer is food-grade silicone defoamer, and the fluorosilicate is MgSiF 6 , the thickness of the graphene oxide sheet is 0.5nm, and the sheet diameter is 7μm.

[0044] The preparation method of the present embodiment modified lithium-based concrete sealing and curing agent, the preparation steps are as follows:

[0045] (1) Accurately weigh each raw material;

[0046] (2) Mix liquid lithium silicate, sodium silicate, fluorosilicate and graphene oxide, stir at 60°C for 60 minutes, cool to ro...

Embodiment 2

[0050] A modified lithium-based concrete sealing and curing agent, according to the mass percentage, is made of the following raw materials: 40wt% of liquid lithium silicate, 5wt% of sodium silicate, 30wt% of alkaline silica sol (average particle size 15nm), surface active Agent 1.25wt%, dispersant 0.75wt%, defoamer 1.25wt%, fluorosilicate 3wt%, graphene oxide 0.02wt%, deionized water surplus; Present embodiment surfactant is dodecylsulfuric acid Sodium, dispersant is polyethylene glycol PEG200, defoamer is food grade silicone defoamer, fluorosilicate is MgSiF 6 , the thickness of the graphene oxide sheet is 2 nm, and the sheet diameter is 8 μm.

[0051] The preparation method of the modified lithium-based concrete sealing and curing agent in this example is the same as that in Example 1.

Embodiment 3

[0053] A modified lithium-based concrete sealing and curing agent is made of the following raw materials in terms of mass percentage: 50wt% of liquid lithium silicate, 8wt% of sodium silicate, 20wt% of alkaline silica sol (average particle size 15nm), surface active Agent 2wt%, dispersant 1wt%, defoamer 2wt%, fluorosilicate 10wt%, graphene oxide 0.02wt%, deionized water surplus; Present embodiment surfactant is sodium dodecylbenzenesulfonate , the dispersant is polyethylene glycol PEG200, the defoamer is food-grade silicone defoamer, and the fluorosilicate is CaSiF 6 , the thickness of the graphene oxide sheet is 0.8nm, and the sheet diameter is 6μm.

[0054] The preparation method of the modified lithium-based concrete sealing and curing agent in this example is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Film diameter | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com