Preparation method of reactive branched polyurethane polymeric dispersant

A polymer dispersant and branched polyurethane technology, which can be used in dyeing, textiles and papermaking, and can solve the problems of poor fiber feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

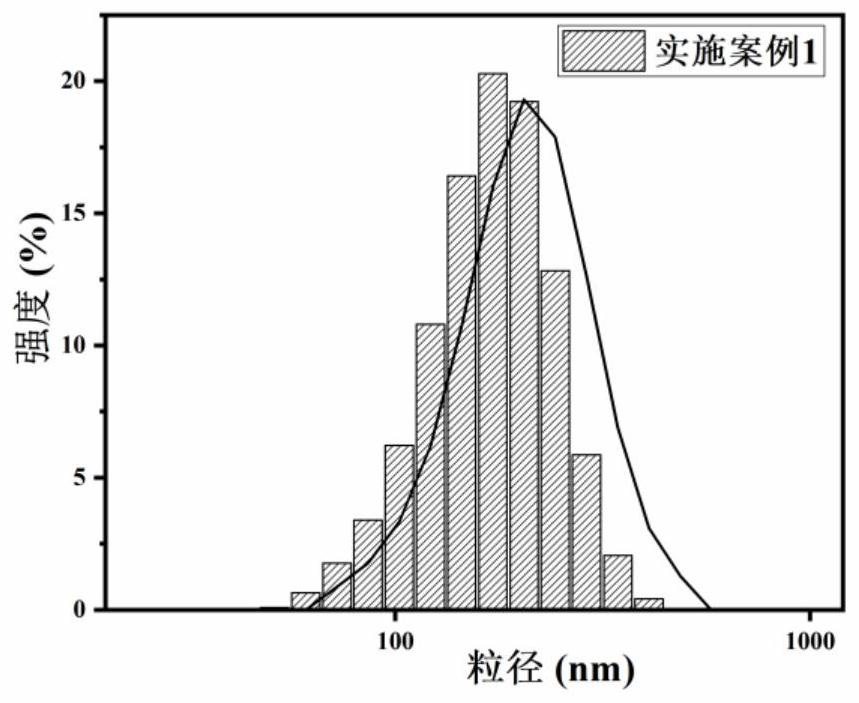

Embodiment 1

[0037](1) 10.5 g of isofluorone diisocyanate 30g solvent tetrahydrofuran was added in three flasks, and the temperature was raised to 70 ° C, and 30 g of polyethylene glycol 1000 was slowly added to prepolymerize 2 h at 70 ° C. Synthetic waterborne polyurethane prepolymer. This process adds 3 to 4 drops of DBTDL as a reaction catalyst.

[0038](2) The temperature was further increased to 80 ° C, and 1.6 g of trimethylolpropane is suck 20 g of tetrahydrofuran, and in the reaction system, the branched reaction is carried out with the polyurethane prepolymer.

[0039](3) The system was then cooled to 60 ° C, weighing 2.5 g of 1- (3-aminopropyl) morpholine as an anchoring group reaction 2 h under 70 ° C for 2 h grafted to the branched urethane end.

[0040](4) Reactive group epoxopropanol 1 g was grafted to a polyurethane end, and the reactive branched polyurethane dispersant is synthesized, and its state is a micro-yellow solution.

[0041]The synthetic polyurethane dispersant vacuum was vacuum, a...

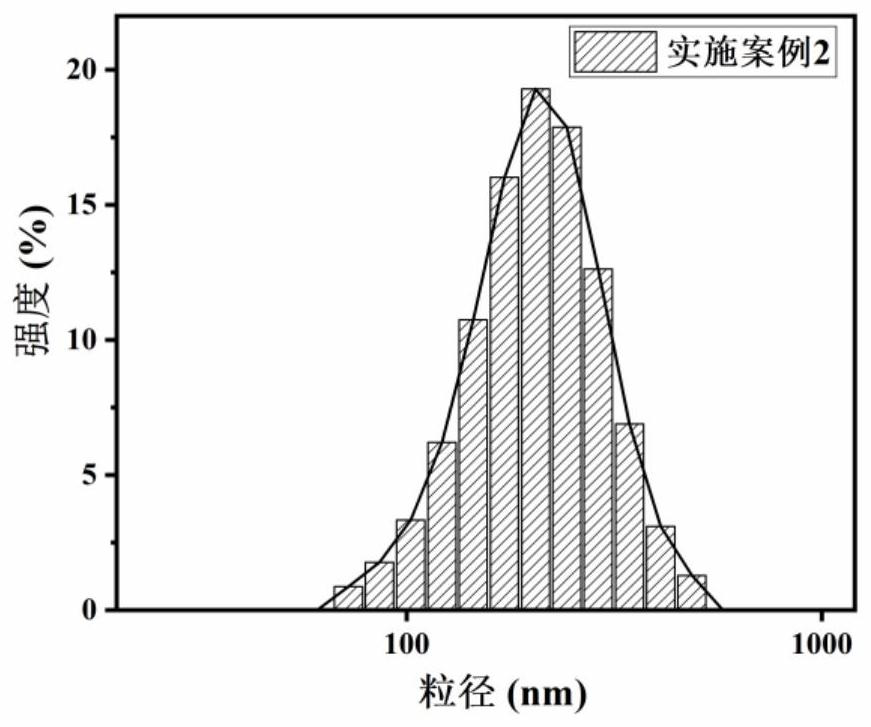

Embodiment 2

[0043](1) In the three flask, 13.3 g of isofluorone diisocyanate was added to 30 g of solvent tetrahydrofuran, and the temperature was raised to 70 ° C, and 2 g of polyethylene glycol 400 was slowly added to prepolymers at 70 ° C for 2 h. .

[0044](2) After the reaction was completed, the hydrophilic chain extender 2,2-dihydroxymethyl propacionic acid was added to the chain-chain reaction, the synthesis of aqueous polyurethane prepolymer, which was added 3 to 4 drops DBTDL as the reaction catalyst.

[0045](3) The temperature was further increased to 80 ° C, and 1.2 g of trihydroxymethane is weighed in 20 g of tetrahydrofuran, and in the reaction system, the reaction was branched with a polyurethane concentration.

[0046](4) The system was then cooled to 50 ° C, and 2.5 g of 1- (3-aminopropyl) morpholine was weighed as an anchoring group to react 2 h under 70 ° C for 2 h into the end of the branched urethane.

[0047](5) Finally, the reactive pentaerythritol trisatyl acrylate 4.0 g was grafte...

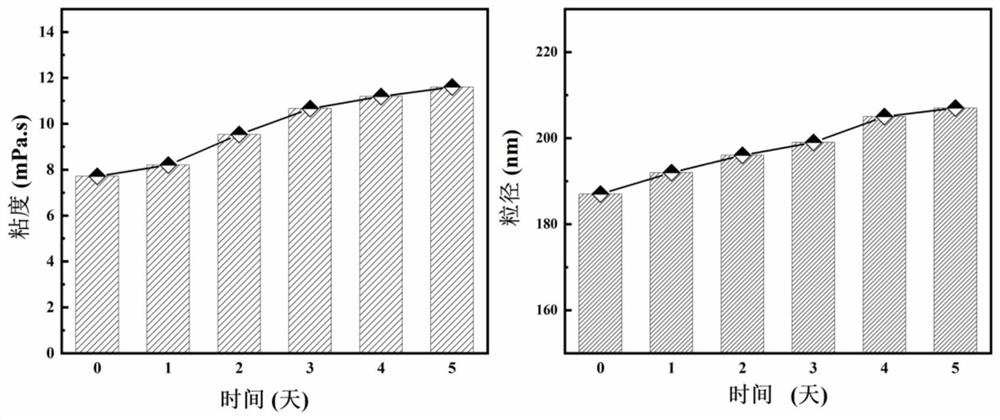

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com