High-hardness easily-scrubbed interior wall coating for kitchen and preparation method

An interior wall coating, high hardness technology, applied in anti-corrosion coatings, anti-fouling/underwater coatings, coatings, etc., can solve problems such as high cost, peeling, powder loss or paint film damage, and improve anti-contamination. , to achieve the effect of durability and improved adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

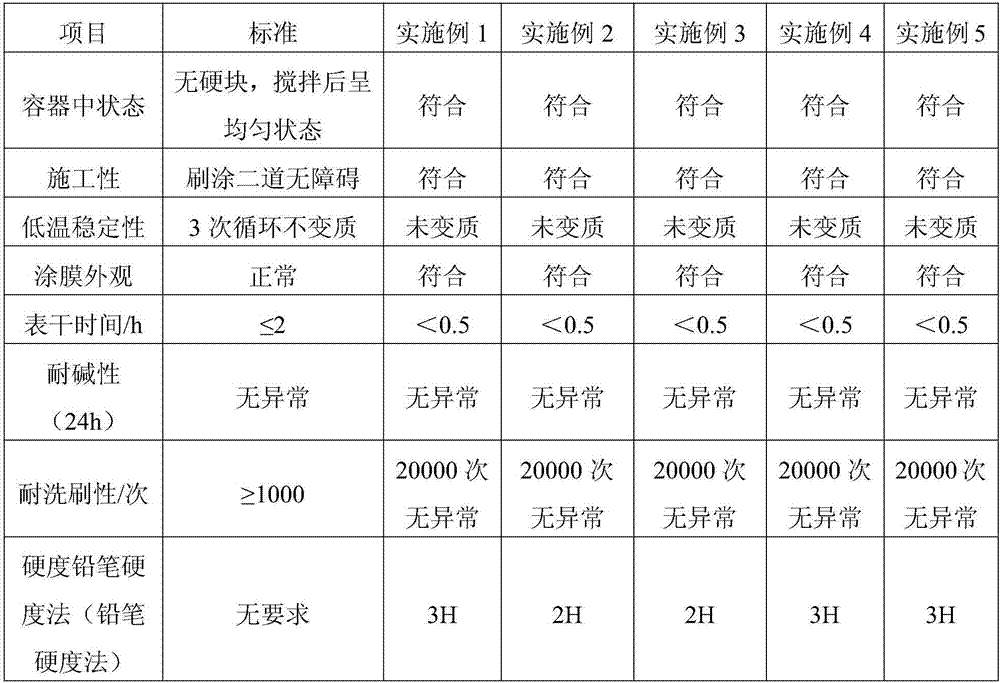

Examples

preparation example Construction

[0040] The present invention also provides a preparation method of high-hardness and easy-to-clean interior wall paint for kitchens, comprising:

[0041] Step 1. According to the ratio of raw materials, first add water to the container, add wetting and dispersing agent at a speed of 300r / min; slowly add cellulose, stir for 2min; add defoamer and antifreeze, and adjust the speed to 500r / min, stir for 5min; add anti-scratch agent, titanium dioxide, calcite powder, adjust the speed to 1500r / min, add pH regulator, stir for 30min;

[0042] Step 2. According to the ratio of raw materials, slowly add silane-siloxane emulsion, film-forming agent, anti-mold agent, bactericide, hydrophobic agent and anti-graffiti agent at a speed of 800r / min to prepare a kitchen with high hardness and easy to scrub Interior paint.

Embodiment 1

[0044] The invention provides a high-hardness and easy-to-clean interior wall coating for kitchens, which comprises the following components by weight percentage:

[0045] 14.5% water, 0.4% wetting and dispersing agent, 0.2% cellulose, 0.1% defoamer, 0.8% antifreeze, 0.3% anti-scratch agent, 0% titanium dioxide, 30% calcite powder, 0.1% pH regulator, Silane-siloxane emulsion 50%, film-forming aid 2.5%, antifungal agent 0.5%, bactericide 0.1%, hydrophobic agent 0.2%, anti-graffiti agent 0.3%.

Embodiment 2

[0047] The invention provides a high-hardness and easy-to-clean interior wall coating for kitchens, which comprises the following components by weight percentage:

[0048] 18.72% water, 0.5% wetting and dispersing agent, 0.23% cellulose, 0.15% defoamer, 1% antifreeze, 0.45% anti-scratch agent, 5% titanium dioxide, 25% calcite powder, 0.15% pH regulator, Silane-siloxane emulsion 45%, film-forming aid 2.3%, antifungal agent 0.75%, bactericide 0.2%, hydrophobic agent 0.3%, anti-graffiti agent 0.25%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com