Nanometer metal-organic carboxylic acid complex colloid collector and production and application as metallic mineral flotation collector thereof

A technology of organic carboxylic acid and nano-metal, which is applied in flotation, solid separation, etc., can solve the problems of low resource utilization rate, difficult to improve selectivity, poor selectivity, etc., and achieve strong harvesting capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

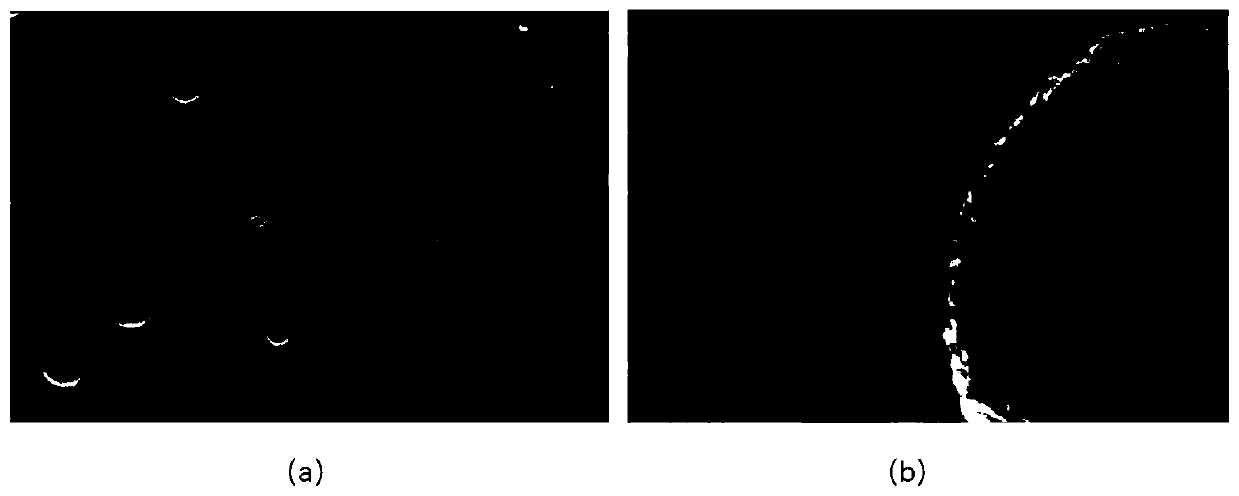

Image

Examples

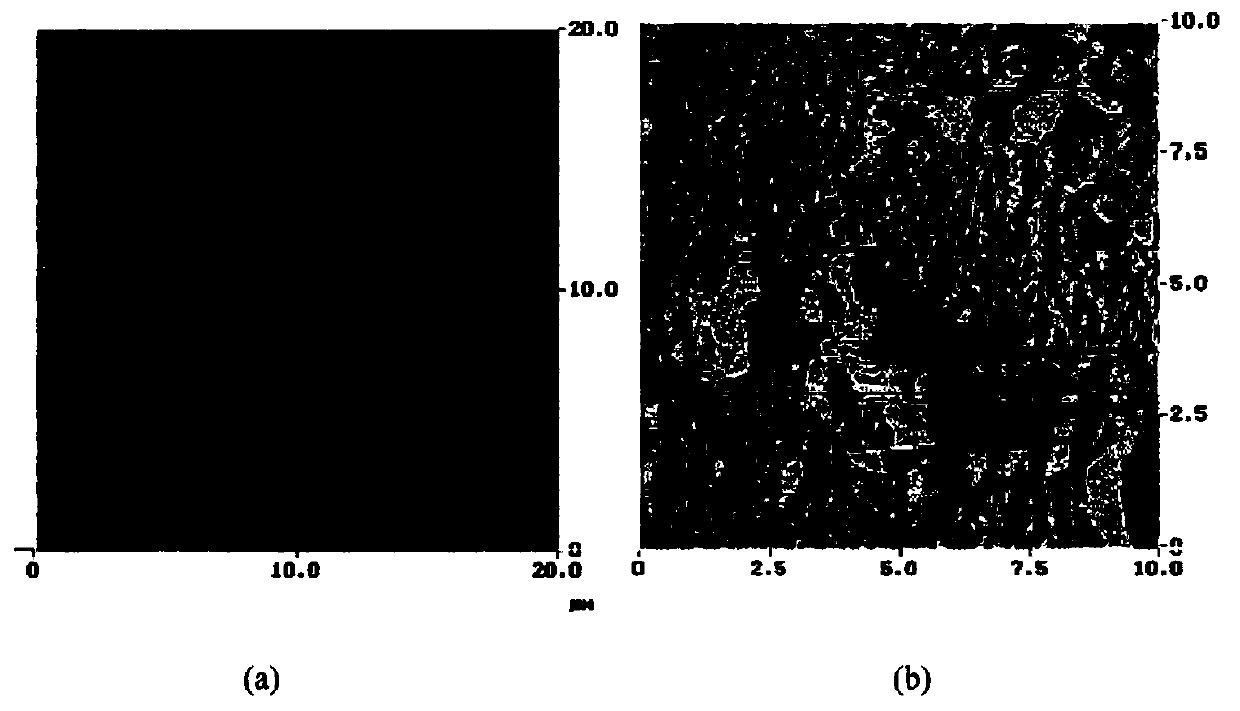

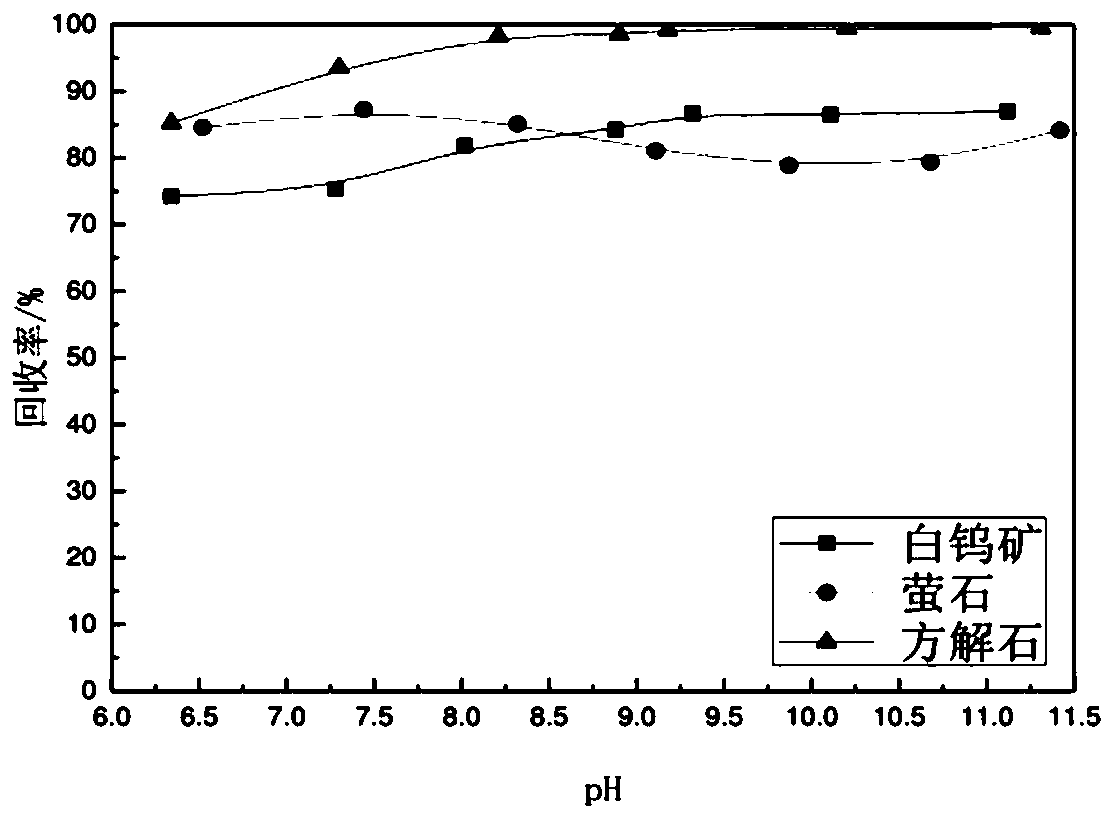

Embodiment 1

[0063] Prepare 8mL of 0.5mol / L calcium chloride solution and 100mL of 0.1mol / L oleic acid ethanol solution respectively, add sodium hydroxide to the oleic acid solution to adjust the pH to 9, heat it to about 60°C, and slowly add to the oleic acid solution Add calcium chloride solution, and the reaction time is 1.5h; transfer the obtained oleic acid-calcium complex solution into a stirring tank, add 30g of magnetite powder with a particle size range of 10-37μm, mix and stir for 15min, and then use the magnetic strength as The 1000GS dry-type permanent magnet magnetic separator is magnetically separated, and the magnetic products are collected and filtered; the magnetite powder is transferred into an ethanol solution, and is shaken and washed by an ultrasonic scrubber, so that the oleic acid adsorbed on the surface of the magnetite - Desorption of the calcium complex to obtain the oleic acid-calcium complex-ethanol mixture. The mixture was dried at room temperature to obtain ol...

Embodiment 2

[0066] The experimental conditions were the same as in Example 1, except that the ratios of 20 mL of 0.5 mol / L calcium chloride solution and 100 mL of 0.1 mol / L oleic acid ethanol solution to oleic acid were different:

[0067] The example is C Ca / C 油酸 =Nano oleic acid-calcium complex colloidal collector prepared under the condition of 1:1.

Embodiment 3

[0069] The experimental conditions were the same as in Example 1, except that the ratio of calcium chloride to oleic acid was different: 40 mL of 0.5 mol / L calcium chloride solution and 100 mL of 0.1 mol / L oleic acid ethanol solution.

[0070] The example is C Ca / C 油酸 =Nano oleic acid-calcium complex colloidal collector prepared under the condition of 2:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Magnetic field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com