Set-retarding type long-distance pumping type concrete prepared by waste slag of subway project and application

A technology of pumping concrete and retarding setting, applied in the field of concrete, can solve the problems of time-consuming and labor-intensive treatment of slag, inability to guarantee strength, and inability to pump, and achieve the effect of reducing water consumption, maintaining strength, and ensuring water retention rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

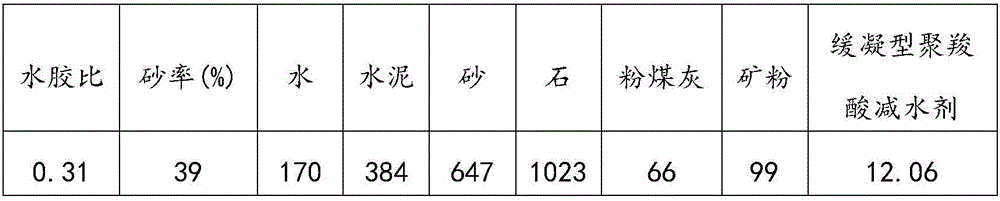

Method used

Image

Examples

Embodiment 1

[0035] The slow-setting long-distance pumping concrete prepared by using the waste residue of the subway project includes the following components according to the weight fraction: 260kg cement, 151kg water, 1010kg gravel, 720kg stone chips, 50kg stone powder, 105kg mineral powder, 100kg fly ash, 4.9kg retarded polycarboxylate superplasticizer, 0.049kg starch ether, 0.098kg1093 construction glue. The total weight is about 2400kg, the water-binder ratio is 0.32, and the cementitious material is 465kg.

[0036] Among them, the cement is P.I52.5 cement, the 28-day strength is 62MP; the mineral powder is S95 grade mineral powder, and the specific surface area is 400m 2 / kg, 28 days activity index is 95%, fluidity ratio is 100%; stone particle size is 5-25mm; retarding polycarboxylate superplasticizer water reducing rate is greater than 30%.

Embodiment 2

[0038] The slow-setting long-distance pumping concrete prepared by using the waste residue of the subway project includes the following components according to the weight fraction: 285kg cement, 151kg water, 1005kg gravel, 710kg stone chips, 65kg stone powder, 95kg mineral powder, 85kg fly ash, 4.92kg retarded polycarboxylate superplasticizer, 0.0492kg starch ether, 0.098kg1093 glue. The total weight is about 2400kg, the water-binder ratio is 0.32, and the cementitious material is 465kg. Wherein the selection of material is with embodiment 1

Embodiment 3

[0040] The slow-setting long-distance pumping concrete prepared by using the waste residue of the subway project includes the following components according to the weight fraction: 300kg cement, 151kg water, 990kg gravel, 700kg stone chips, 80kg stone powder, 80kg mineral powder, 95kg fly ash, 4.95kg retarded polycarboxylate superplasticizer, 0.0495kg starch ether, 0.099kg1093 glue. The total weight is about 2400kg, the water-binder ratio is 0.32, and the cementitious material is 475kg. Wherein the selection of material is with embodiment 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com