Long-chain alkyl polyester polyol, waterborne polyurethane emulsion and preparation methods thereof

A technology of long-chain alkyl diols and polyester polyols, applied in the direction of polyurea/polyurethane adhesives, adhesive types, adhesives, etc., can solve the problems of decreased strength, easy to open glue, difficult to glue film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

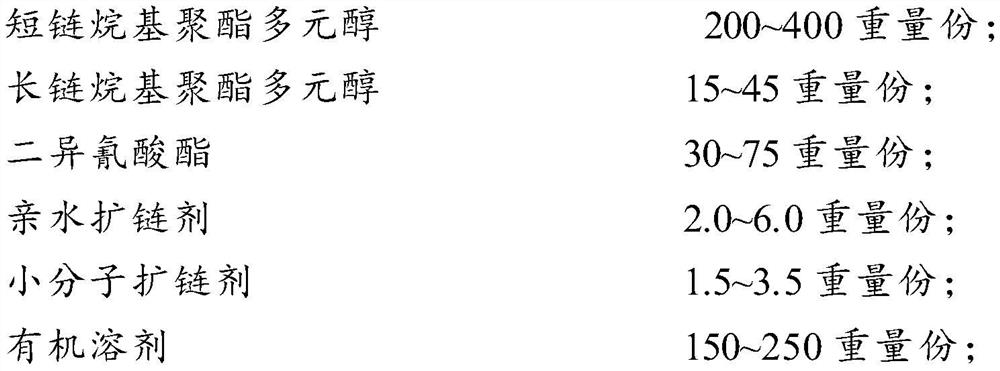

Method used

Image

Examples

preparation example Construction

[0027] In order to solve the problem of poor film-forming and mechanical properties of water-based polyurethane, the application provides a preparation method of long-chain alkyl polyester polyol, which can be introduced into water-based polyurethane to improve the film-forming of water-based polyurethane sex and mechanical properties. Concrete, the application first provides a kind of preparation method of long-chain alkyl polyester polyol, comprising the following steps:

[0028] A) Castor oil, hydroxy-terminated nitrile rubber, long-chain alkyl glycol and long-chain alkyl dibasic acid are mixed, and reacted after heating to obtain a small molecule prepolymer;

[0029] B) mixing the small molecule prepolymer and isopropyl titanate, and reacting at elevated temperature to obtain a long-chain alkyl polyester polyol.

[0030] In the above-mentioned process of preparing long-chain alkyl polyester polyols, the applicant first mixes the raw materials castor oil, hydroxyl-terminat...

Embodiment 1

[0051] Embodiment 1 long-chain alkyl polyester polyol is synthesized

[0052] 1) 950g of castor oil, 4.5g of hydroxy-terminated nitrile rubber (Mn=2300Da), 85g of 1,10-decanediol, and 70g of 1,11-undecane dibasic acid are added to the reactor, Under nitrogen protection, raise the temperature to 130°C, react for 2 hours, then raise the temperature to 180°C, and continue the reaction for 3h;

[0053] 2) The temperature of the reaction kettle was raised to 240°C, 0.65g of isopropyl titanate was added, and the reaction was continued for 3h; the acid value of the reactant was 3mgKOH / g, cooled to 80°C, and discharged to obtain a long-chain alkyl polyester polyol, GPC analysis, Mn=5200Da, Mw=7400Da.

Embodiment 2

[0054] Embodiment 2 long-chain alkyl polyester polyols are synthesized

[0055] 1) The castor oil of 1400g, the hydroxy-terminated nitrile rubber (Mn=4200Da) of 8g, the 1,12-dodecanediol of 95g, the 1,12-dodecanedioic acid of 82g are added to the reactor , under nitrogen protection, raise the temperature to 150°C, react for 0.5 hours, then raise the temperature to 210°C, and continue the reaction for 1h;

[0056] 2) The reaction kettle was heated to 260°C, 1.5g of isopropyl titanate was added, and the reaction was continued for 2h; the acid value of the reactant was 5mgKOH / g, cooled to 80°C, and discharged to obtain a long-chain alkyl polyester polyol, GPC analysis, Mn = 8150 Da, Mw = 13507 Da.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com