Preparation method of surface modification layer containing iron and aluminum intermetallic compound

A surface modification layer and compound technology, which is applied in metal material coating process, coating, heating inorganic powder coating, etc., can solve the requirements of poor bonding force of modified layer/base, narrow coating thickness range, and preparation environment Advanced problems, to achieve the effect of high preparation efficiency, high efficiency and cost, and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 Preparation of surface modification layer of iron-containing aluminum intermetallic compound

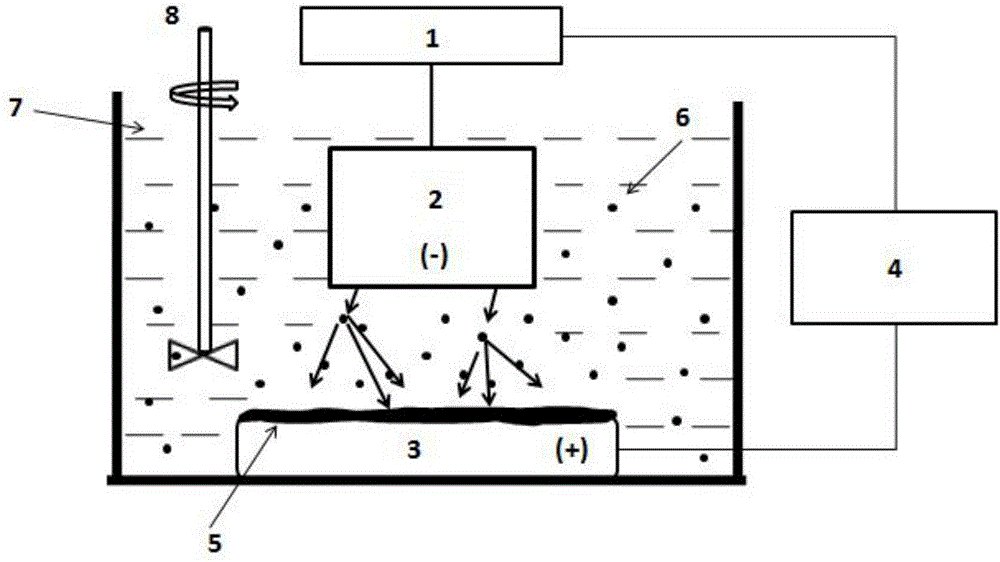

[0028] S1. Add 6gL to kerosene 7 -1 The aluminum powder 6 is continuously stirred for 30 minutes by a small propeller 8, and the aluminum powder is fully dispersed in kerosene to form an aluminum powder / kerosene mixed working fluid;

[0029] S2. Adopt the servo control system 1 of the electric discharge machining machine tool, control the gap between the aluminum powder tool electrode 2 and the ordinary low carbon steel workpiece 3 with a molding pressure of 10MPa to about 200 μm, and start the electric discharge machining pulse power supply 4 at ordinary low Pulse discharge is carried out between the carbon steel and the tool electrode; the pulse discharge parameters are set as follows: pulse width 100μs, peak current 6A, pulse-to-pulse 200μs, discharge time 5min.

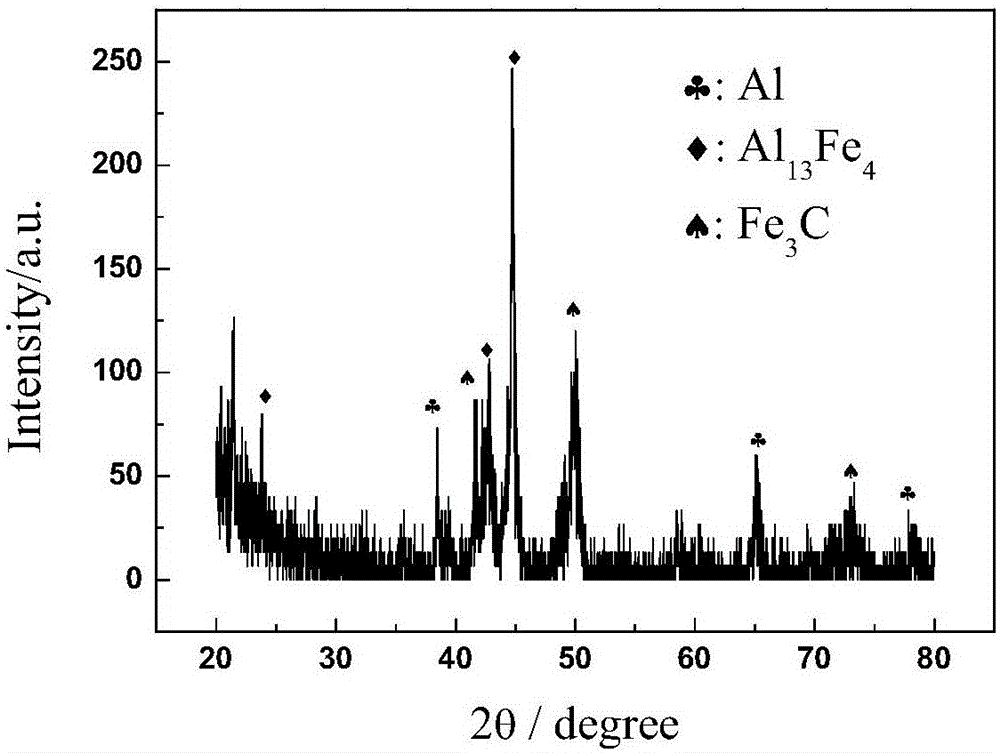

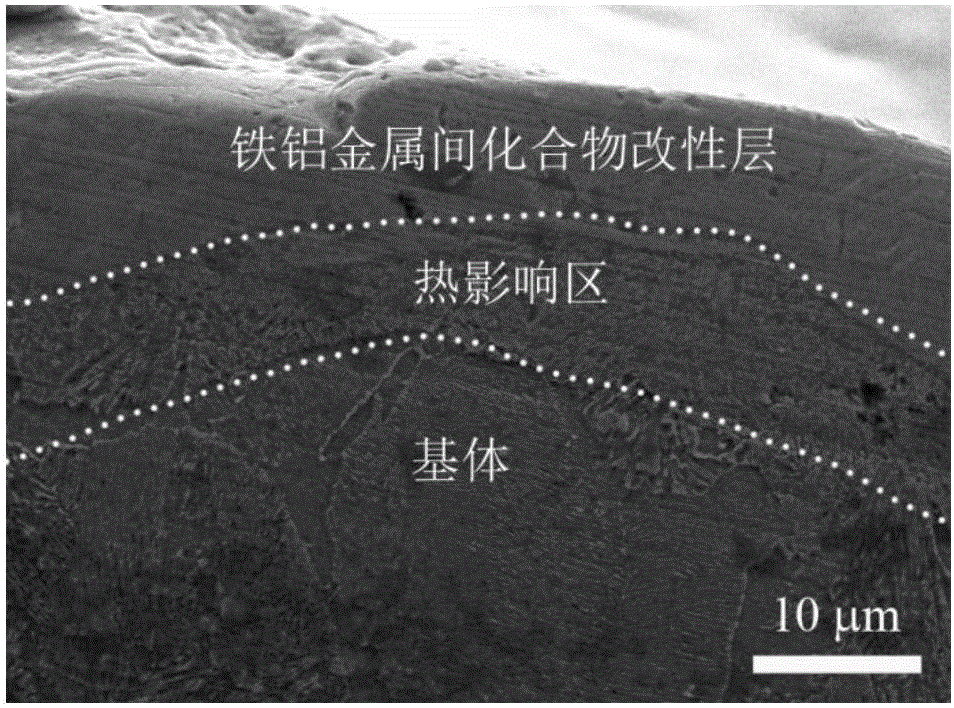

[0030] S3. Use the pulse discharge to break down the working fluid, form a high-energy plasma dis...

Embodiment 2

[0037] The difference from Example 1 is that the pulse discharge parameters in step S2 are set as follows: pulse width 50μs, peak current 15A, pulse-to-pulse 20μs, discharge time 30min; The gap between them is controlled to about 200 μm, at this time the modified layer is made of FeAl and Fe 4 Al 13 Main phase, the total content of the two is about 90wt.%, Fe 3 C and Fe are the second phase.

Embodiment 3

[0039] Unlike Example 1, the concentration of aluminum powder added in step S1 is 1gL -1 The forming pressure of the aluminum powder tool electrode in step S2 is 30MPa; the pulse discharge parameters in step S2 are set as follows: pulse width 10μs, peak current 3A, pulse-to-pulse 100μs, discharge time 15min, aluminum powder tool electrode 2 in step S2 The gap between the common low carbon steel workpiece 3 is controlled to about 50 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com