Lean cemented concrete prepared from aggregate chip iron tailings sand and polycarboxylate water reducer

A technology of iron tailings sand and water reducer, which is applied in the fields of construction raw materials and poor-adhesive concrete, which can solve problems such as environmental pollution and land occupation, and achieve the effects of reducing production costs, reducing water consumption, and ensuring water retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The low-adhesive concrete prepared by using stone chips, iron tailings and polycarboxylate superplasticizer in this embodiment includes the following components in parts by weight: 100 parts of cement, 75 parts of fly ash, and 120 parts of mineral powder; 260 parts of tailings sand, 850 parts of stone chips, 780 parts of gravel, 185 parts of water, 3.8 parts of polycarboxylate superplasticizer; the sand ratio is 0.59;

[0024] The particle size of stone chips is 0.1-2.5mm, the fineness modulus is 3.1, and the mud content is 5%; the particle size of tailings sand is 0.1-5mm, and the fineness modulus is 1.7; the particle size of stones is 5-31.5 mm continuous gradation, mud content 2.4%;

[0025] Polycarboxylate superplasticizer contains 0.5% thickener, thickener contains aggregate thickener, cellulose ether, air-entraining agent, inhibitor of aggregate stone powder adsorption superplasticizer, the superplasticizer mixed with The water reduction rate is 18% when the cont...

Embodiment 2

[0028] The low-adhesive concrete prepared by using stone chips, iron tailings and polycarboxylate superplasticizer in this embodiment includes the following components in parts by weight: 130 parts of cement, 50 parts of fly ash, and 115 parts of mineral powder; 250 parts of tailings sand, 830 parts of stone chips, 790 parts of gravel, 180 parts of water, 3.8 parts of polycarboxylate superplasticizer; sand ratio is 0.58; others are the same as in Example 1.

Embodiment 3

[0030] The low-adhesive concrete prepared by using stone chips, iron tailings and polycarboxylate superplasticizer in this embodiment includes the following components in parts by weight: 110 parts of cement, 65 parts of fly ash, and 120 parts of mineral powder; 280 parts of tailings sand, 840 parts of stone chips, 800 parts of gravel, 175 parts of water, 3.9 parts of polycarboxylate superplasticizer; sand ratio is 0.58; others are the same as in Example 1.

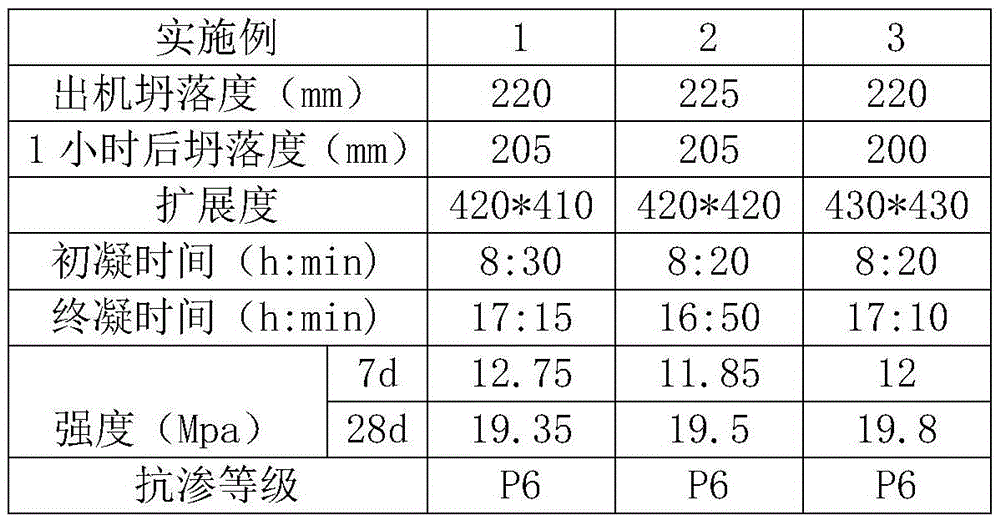

[0031] Table 1 is the performance table of the poor glue material concrete prepared by the embodiment of the present invention

[0032] Table 1

[0033]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com