Method for treating protein powder through extrusion and application thereof

A technology of extrusion puffing, protein powder, applied in the direction of texturization, application, protein food processing, etc., can solve problems such as texture hardening, and achieve the effect of slowing quality deterioration, ensuring texture, and ensuring cohesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

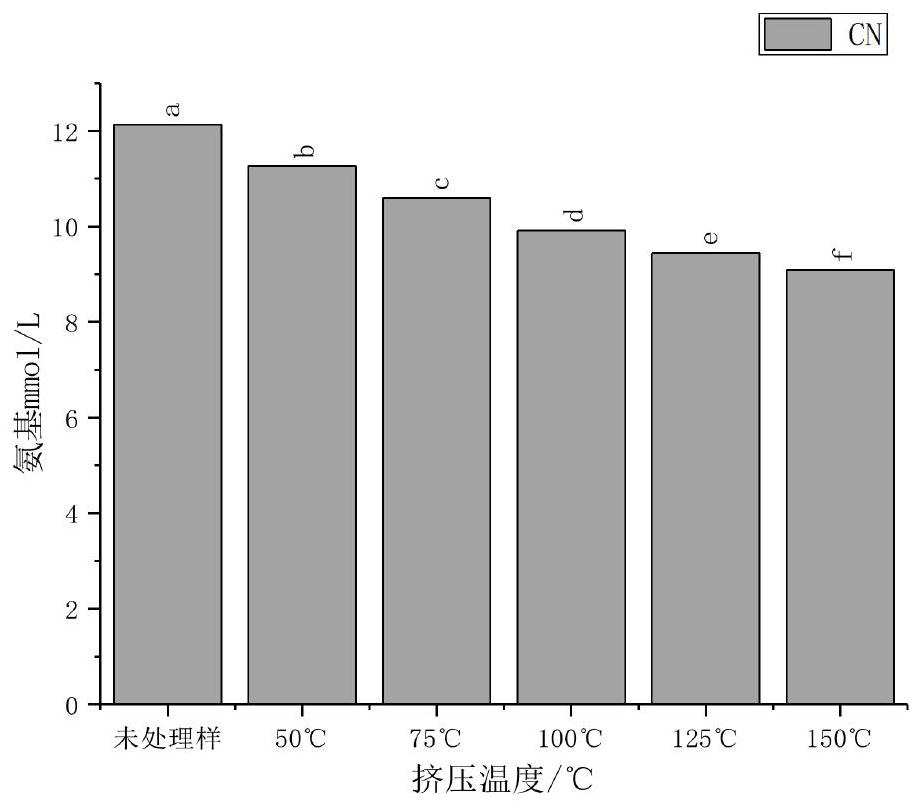

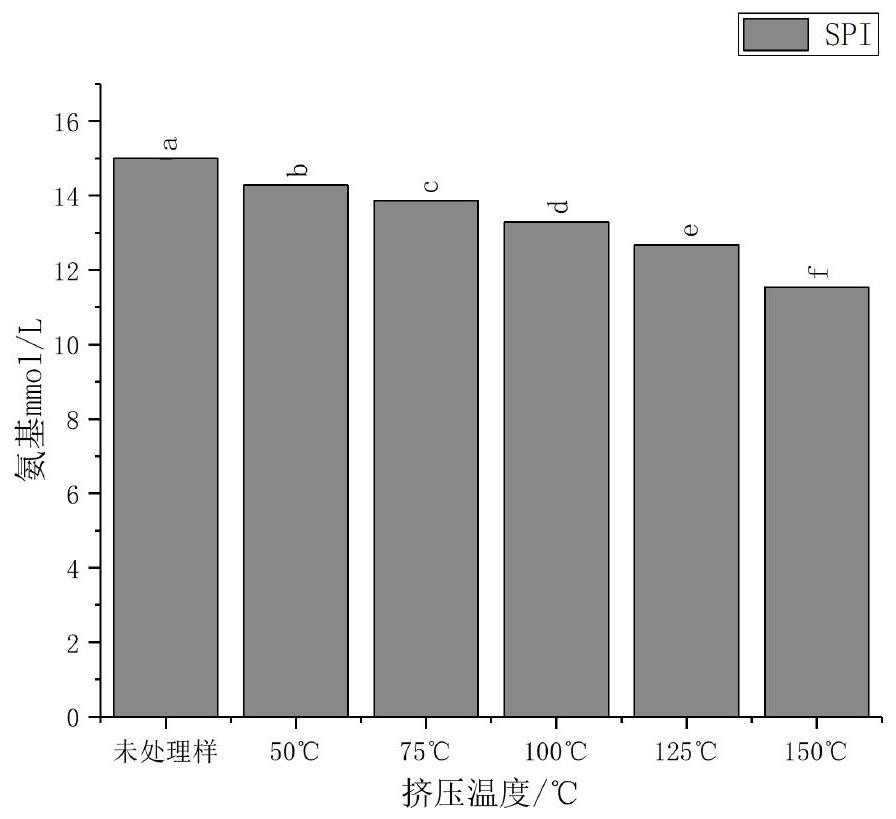

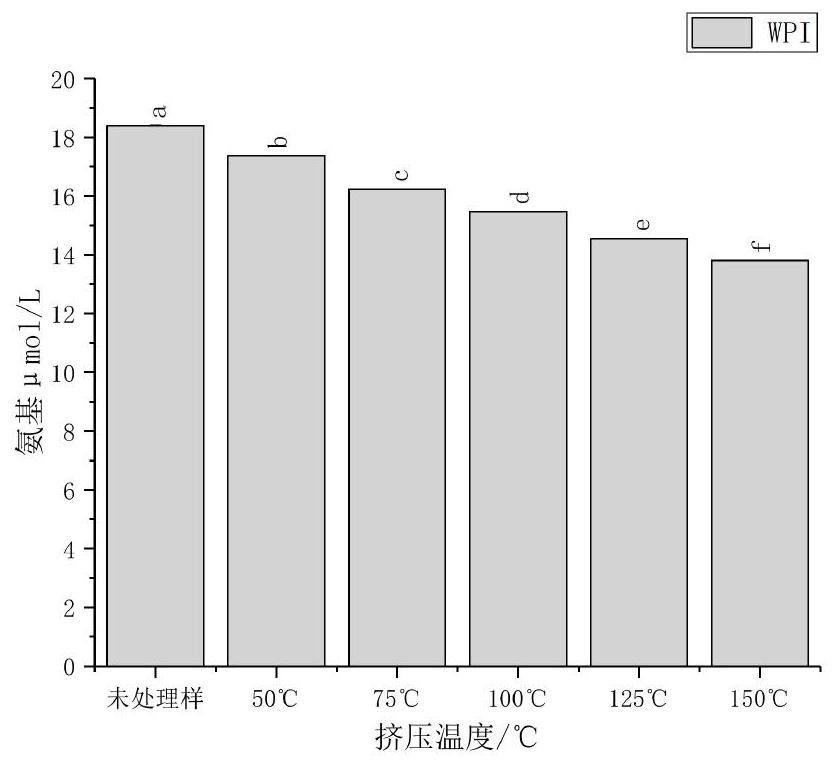

[0019] Embodiment 1: This embodiment describes a method for extruding and expanding protein powder. The method specifically includes: putting whey protein isolate, soybean protein isolate and sodium caseinate into co-rotating twin-screw extruders Extrude at a speed of 240 rpm in the machine, and the parameters of extrusion pretreatment are set as follows: the temperature is 75±2°C, the moisture content is adjusted to 38±1%, and the screw is designed to provide low shear to prepare whey The protein isolate extrudate, the soybean protein isolate extrudate and the sodium caseinate extrudate are cooled and granulated, ground into powder after vacuum freeze-drying, and sieved twice to obtain the modified protein powder, which is then sealed and stored for later use. The model of the co-rotating twin-screw extruder is: Process 11 twin-screw extruder. Manufacturer: Thermo Fisher Scientific Inc. Thermo Fisher Scientific Inc. Before extrusion, set the temperature to 75±2°C, wait until...

specific Embodiment approach 2

[0020] Embodiment 2: A method for extrusion processing protein powder described in Embodiment 1 is characterized in that: all modified protein powders should pass through a 200-mesh sieve, which can ensure that the particle size of the protein powder is uniform, and ensure the accuracy of the experiment. consistency.

specific Embodiment approach 3

[0021] Embodiment 3: In Embodiment 1, a method for processing protein powder by extrusion and puffing, the parameters of the vacuum freeze-drying are: temperature below -40°C, time 13 hours, and vacuum degree 0.001 Pa. Advantages: It is not easy to change the performance of the dried items, and the color, aroma and taste of the food can be preserved to the greatest extent, such as the loss of aromatic substances can be reduced to a minimum; the growth of microorganisms is inhibited when operating under vacuum and low temperature; Under low temperature operation, there is very little oxygen. Therefore, freeze-drying is better than ordinary freezing for storing protein-containing foods; freeze-drying can remove more than 95% to 99% of water, and the product can be stored for a long time without deterioration.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water activity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com