Composite thick film based on diamond-like carbon thin film and coating method of composite thick film

A diamond thin film and diamond layer technology, applied in the field of composite thick film and its coating, can solve problems such as the influence of the service life and efficiency of the coating, the influence of the bonding force between the coating and the substrate, and the increase of the surface roughness of the coating, so as to achieve adhesion. Excellent performance, simple structure, and the effect of reducing surface defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Objects, advantages and features of the present invention will be illustrated and explained by the following non-limiting description of preferred embodiments. These embodiments are only typical examples of applying the technical solutions of the present invention, and all technical solutions formed by adopting equivalent replacements or equivalent transformations fall within the protection scope of the present invention.

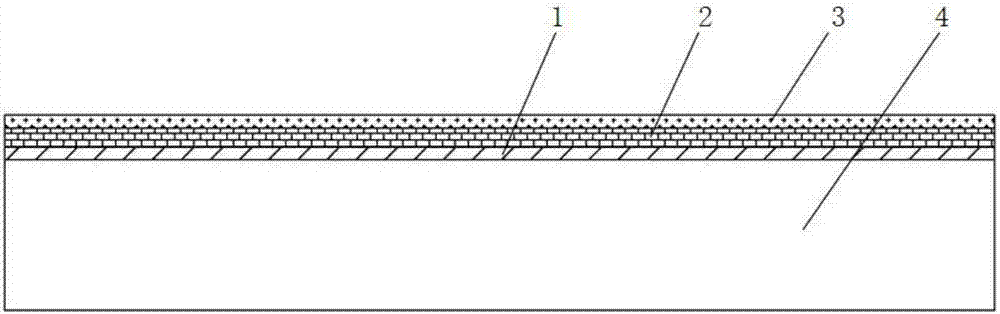

[0033] The present invention discloses a composite thick film based on a diamond-like carbon film, including a metal bottom layer 1, a transition layer 2, and a diamond-like layer 3 sequentially formed from the surface of a substrate 4, wherein the metal bottom layer 1 is a Cr layer and a Ti layer Or one of the Ni layers, which are generated by magnetron sputtering technology, with a thickness between 0.2 and 1 μm. Metal Cr, Ti or Ni are beneficial to enhance the bonding force between the entire composite thick film and the substrate.

[0034] The tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com