Thick film substrate having low void content and high reliability and manufacturing method thereof

A manufacturing method and reliable technology, applied in semiconductor/solid-state device manufacturing, printing devices, printing, etc., to achieve the effect of reducing void rate, ensuring effective welding area, and simple and effective implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

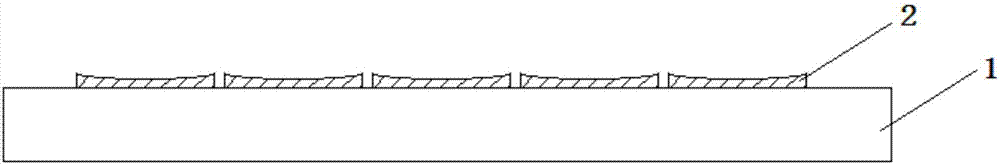

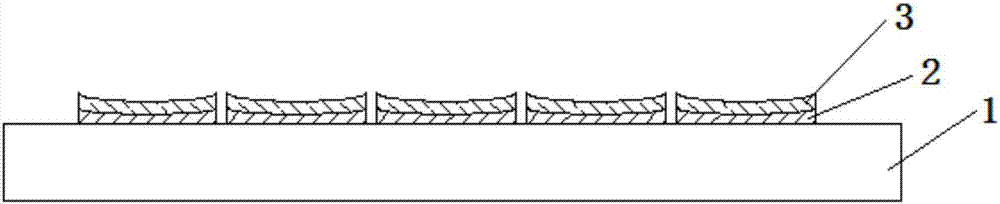

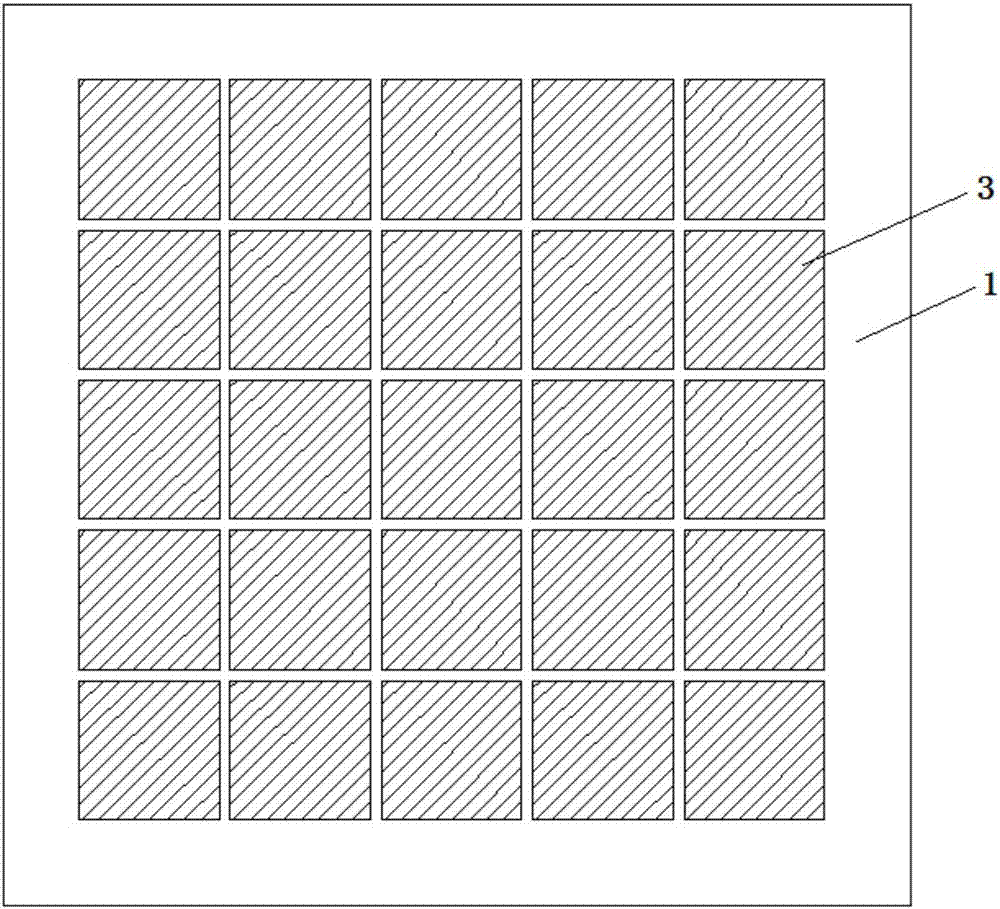

[0037] Fabrication of a Thick Film Substrate with Low Voiding Rate and High Reliability

[0038] (1) Use 250-mesh screen to stretch the printing screen frame with a tension of 20N. After cleaning the stretched printing screen frame, stick a 50μm film, dry it at 45°C for 15min, and then use the first grid layer The exposure of the mask plate needs to print graphics. The grid unit size of the printed graphics is 1.85mm×1.85mm, and the gap between the grids is 0.15mm. After the exposure is completed, take out the printing screen frame and remove the mask. After stencil printing, put the printing screen frame into the screen cleaning machine, soak it in warm water at 40°C for 20 minutes, and then rinse and develop it. After the graphic development is complete, seal the area of the screen frame that does not need to be printed with a sealant, and dry it at 45°C 15min, make the required printing screen frame of grid layer;

[0039](2) Use 250-mesh screen to stretch the printing s...

Embodiment 2

[0046] Fabrication of a Thick Film Substrate with Low Voiding Rate and High Reliability

[0047] (1) Stretch the printing screen frame with 250-mesh screen, the tension is 25N, clean the stretched printing screen frame, paste it with 50μm film, dry it at 35°C for 20min, and then use the first grid layer The exposure of the mask plate needs to print graphics. The grid unit size of the printed graphics is 1.85mm×1.85mm, and the gap between the grids is 0.15mm. After the exposure is completed, take out the printing screen frame and remove the mask. After stencil printing, put the printing screen frame into the screen cleaning machine, soak it in warm water at 35°C for 30 minutes, and then rinse and develop it. After the graphic development is complete, seal the area of the screen frame that does not need to be printed with a sealant, and dry it at 35°C 20min, make the required printing screen frame of grid layer;

[0048] (2) Use 250-mesh screen to stretch the printing screen ...

Embodiment 3

[0055] Fabrication of a Thick Film Substrate with Low Voiding Rate and High Reliability

[0056] (1) Use 250-mesh screen to stretch the printing screen frame with a tension of 35N. After cleaning the stretched printing screen frame, stick a 50μm film, dry it at 40°C for 18 minutes, and then use the first grid layer The exposure of the mask plate needs to print graphics. The grid unit size of the printed graphics is 1.85mm×1.85mm, and the gap between the grids is 0.15mm. After the exposure is completed, take out the printing screen frame and remove the mask. After stencil printing, put the printing screen frame into the screen cleaning machine, soak it in warm water at 45°C for 10 minutes, then rinse and develop it. After the graphic development is complete, seal the area of the screen frame that does not need to be printed with sealing glue, and dry it at 40°C 18min, make the required printing screen frame of grid layer;

[0057] (2) Use 250-mesh screen to stretch the print...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com