Rolling-free sealing lead-out bushing and assembling method thereof

An outlet bushing and rolling technology, applied in the field of power transmission and transformation, can solve the problems of reducing the strength of the bushing 2, uncontrolled deformation, small strength, etc., to ensure the mechanical strength and reliability, the assembly process is simple, and the guarantee The effect of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

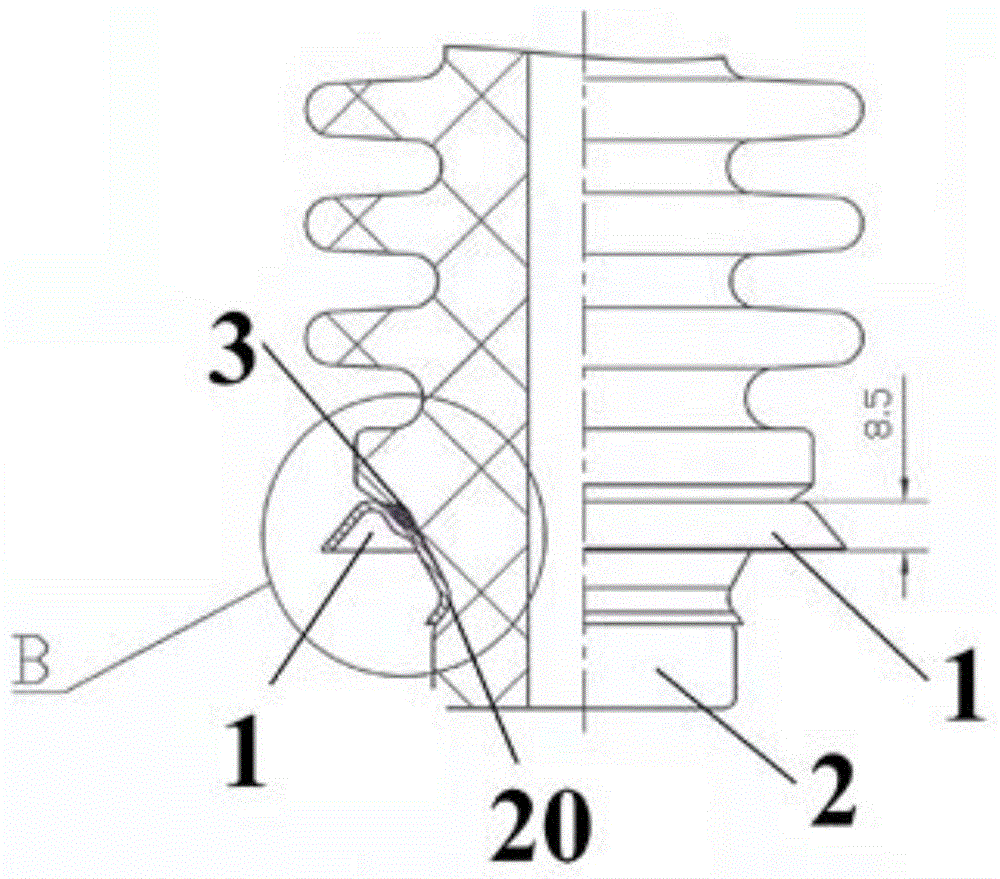

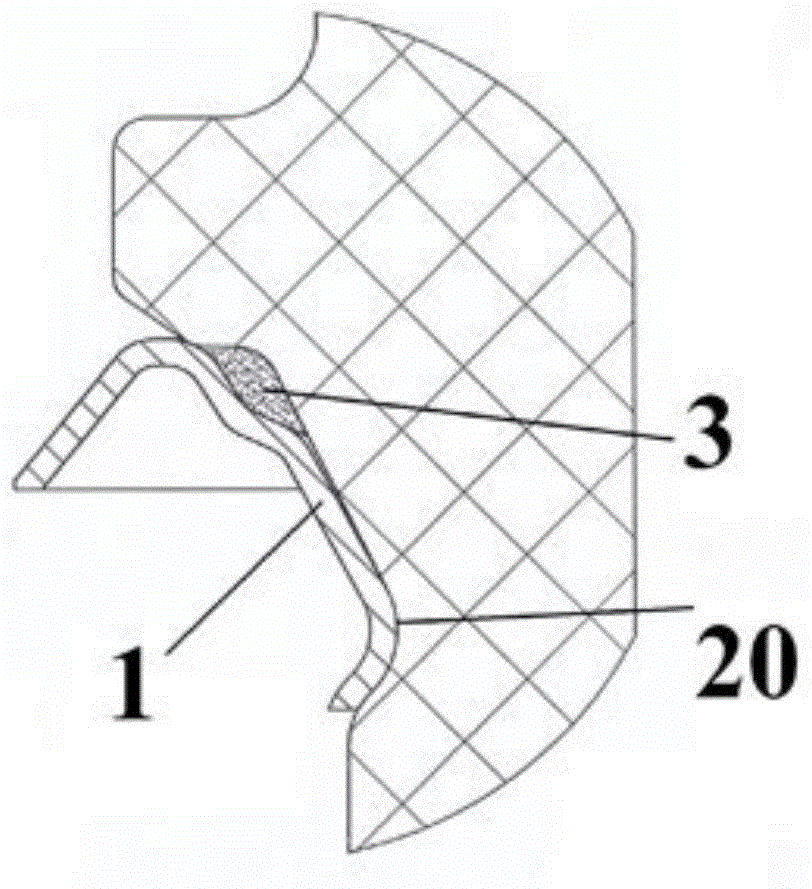

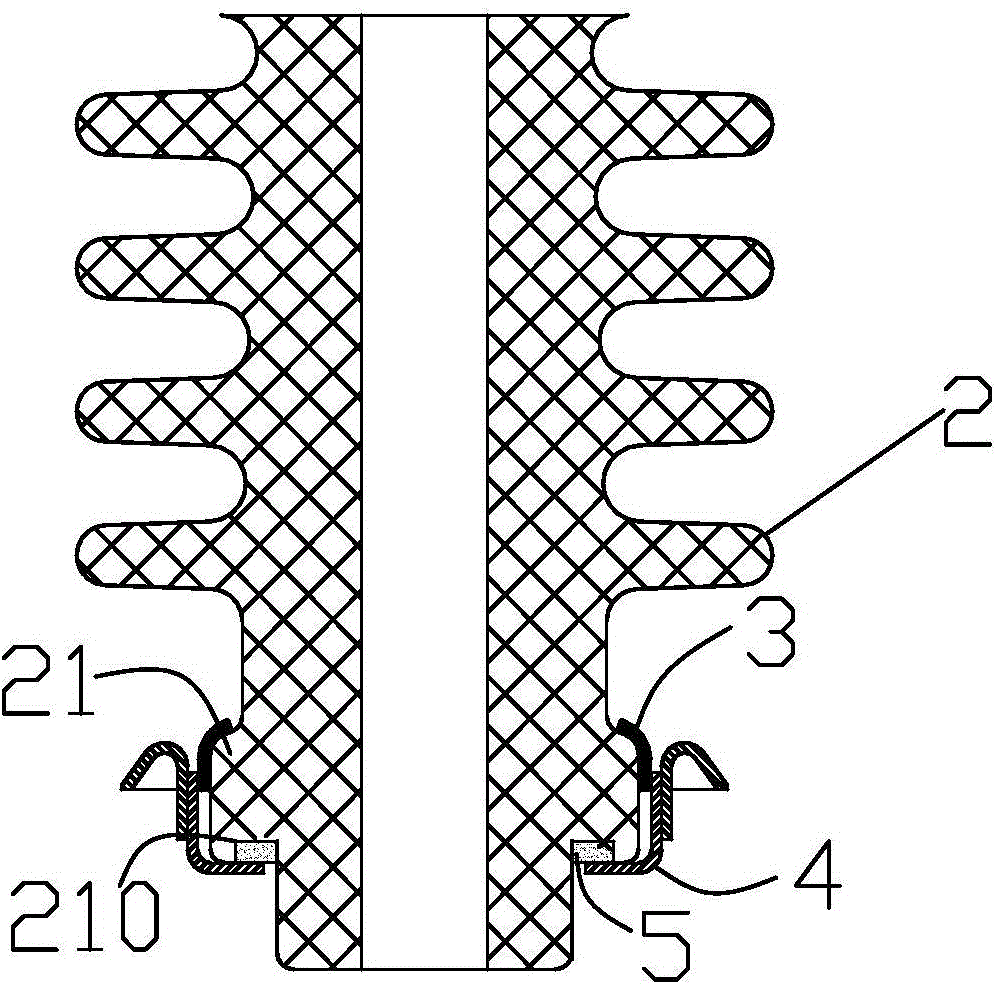

[0035] see image 3 As shown, a rolling-free sealed outlet bushing of the present invention includes a porcelain sleeve 2 , an annular pressing flange 3 and a sealing connecting flange 4 .

[0036] The porcelain sleeve 2 is provided with a porcelain flange 21 ; the lower part of the porcelain flange 21 is provided with a sealing ring accommodation groove 210 . A sealing ring 5 is installed in the sealing ring accommodating groove 210; in the natural state that the sealing ring 5 is not compressed, the sealing ring 5 protrudes only outside the sealing ring accommodating groove 210; the height of the sealing ring accommodating groove 210 is 5 50% to 70% of the height in the natural state.

[0037] see Figure 6 and Figure 7 As shown, the annular clamping flange 3 includes a cylindrical portion 31 and a cover 32 (or only the cover 32 ) disposed on the top of the cylindrical portion 31 , and the center of the cover 32 is provided with a first through hole 33 . The annular com...

Embodiment 2

[0041] The difference between Embodiment 2 and Embodiment 1 is that the upper part of the porcelain flange 21 has a plane, and the cover body 32 is provided with a platform matching the plane, which can increase the ring clamping flange 3 to be fixed on the porcelain flange 21. retention.

Embodiment 3

[0042] The difference between embodiment 3 and embodiment 2 is that in embodiment 2, the turned-out connecting flange 45 and the cylindrical part 41 are separate structures ( Figure 4 shown); in embodiment 3, the eversion-type connecting flange 45 and the cylindrical portion 41 can be of an integrated structure ( Figure 5 shown).

[0043] In the present invention, there is an anti-rotation matching structure between the porcelain flange 21 and the sealing connection flange 4 to prevent the sealing connection flange 4 from rotating around the axis of the porcelain flange 21:

[0044] A plurality of grooves are set on the porcelain flange 21, and a plurality of protrusions are correspondingly arranged on the sealing connection flange 4 to snap into the corresponding grooves, so that after the sealing connection flange 4 is fixed on the porcelain flange 21, the sealing connection flange 4. It cannot rotate around the axis of the porcelain flange 21;

[0045]Alternatively, a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com