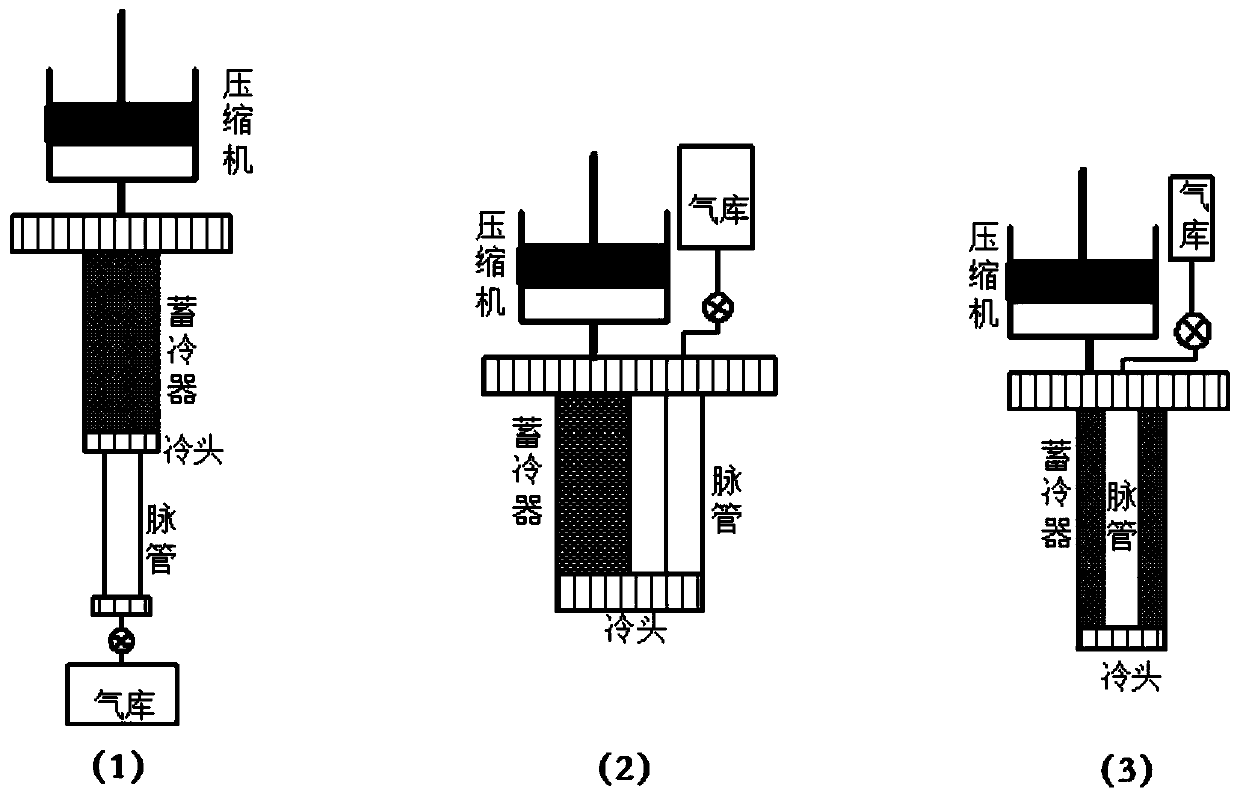

Stress-resistant linear pulse tube refrigerator and Dewar coupling structure

A technology of pulse tube refrigerator and coupling structure, which is applied in refrigerators, refrigeration and liquefaction, compressors, etc., can solve the problems of how to ensure mechanical reliability and not involve it, and achieve the effect of ensuring mechanical reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

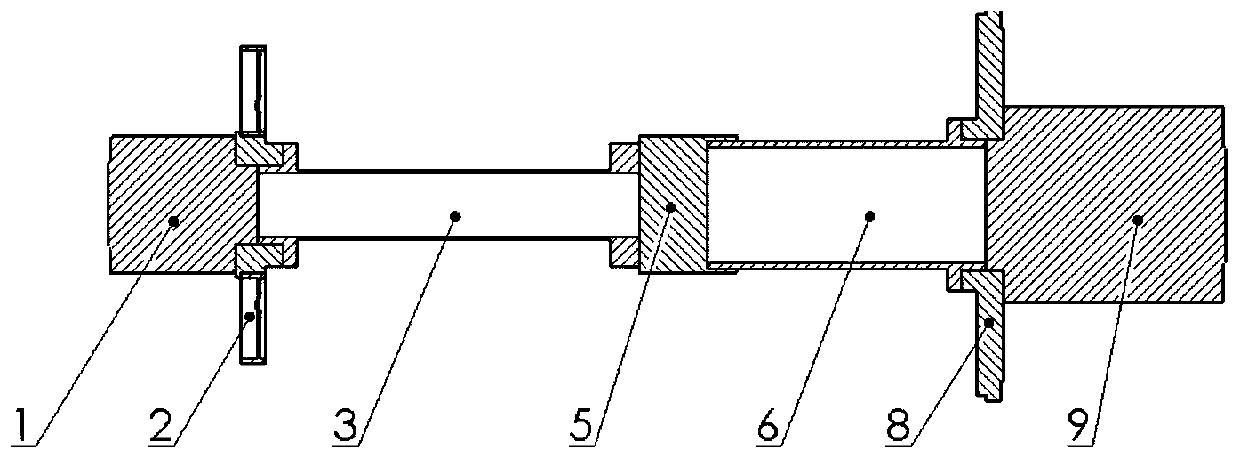

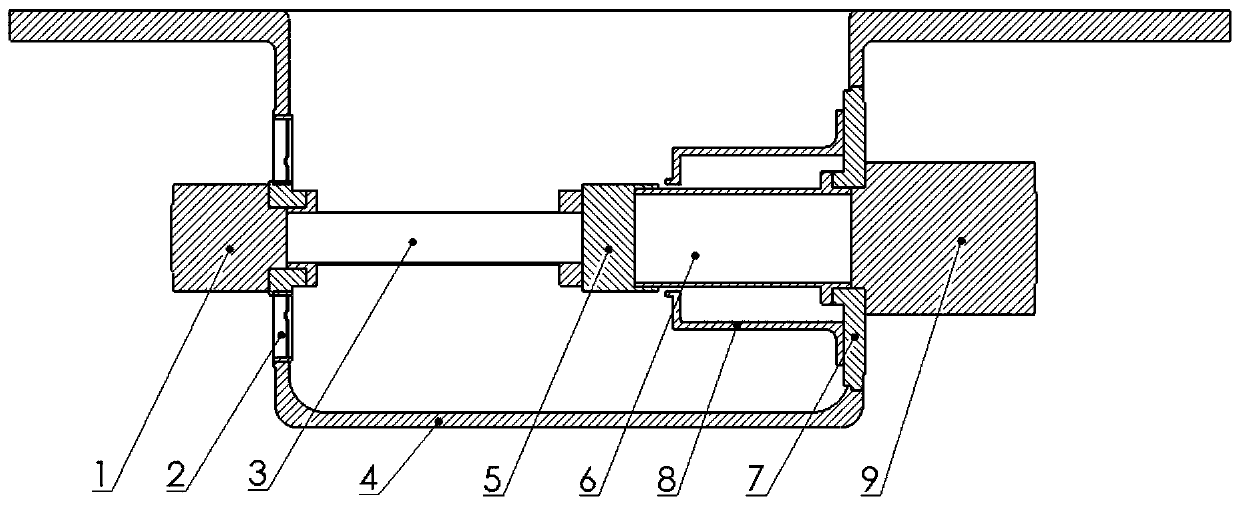

[0016] Below in conjunction with accompanying drawing and embodiment the specific embodiment of the present invention is described in further detail:

[0017] according to figure 2 The structure shown in the present invention is a linear cold finger and Dewar coupling structure, the coupling structure includes vessel end cooling 1, vessel end flexible part 2, pulse tube 3, Dewar shell 4, cold head 5, Cold accumulator 6, cold finger mechanical protection cover 7, cold accumulator end fixing flange 8, cold accumulator end heat dissipation 9. Among them, the heat dissipation 1 at the vessel end, the flexible part 2 at the vessel end, the pulse tube 3, the cold head 5, the regenerator 6, the fixing flange 8 at the regenerator end, and the heat dissipation 9 at the regenerator end form a linear vessel cold finger. The linear pulse tube cold finger and the Dewar shell 4 are welded and fixed through the fixing flange 8 at the regenerator end and the flexible piece 2 at the pulse tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com