Preparation method of high-temperature-resistant high-persistent-adhesivity cover film or protective adhesive tape

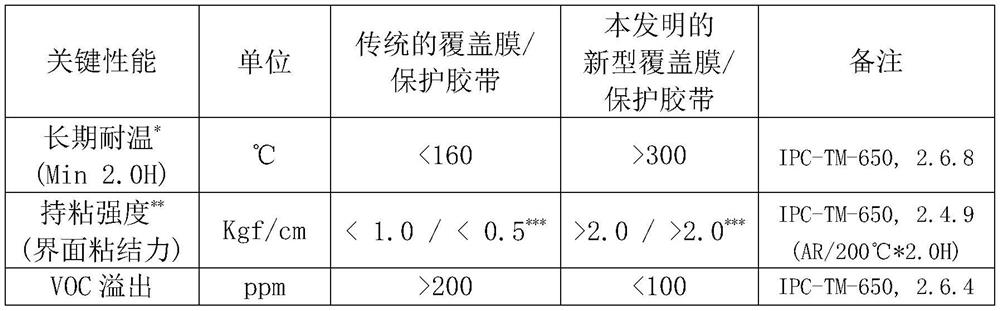

A technology for protecting tapes and covering films, which is applied in the direction of polymer adhesive additives, film/sheet without carrier, film/sheet-shaped adhesive, etc. It can solve the problem of stickiness that cannot be maintained, excessive VOC overflow, and easy aging To achieve the effect of ensuring cohesion and high stickiness, removing residual VOC, and improving output efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

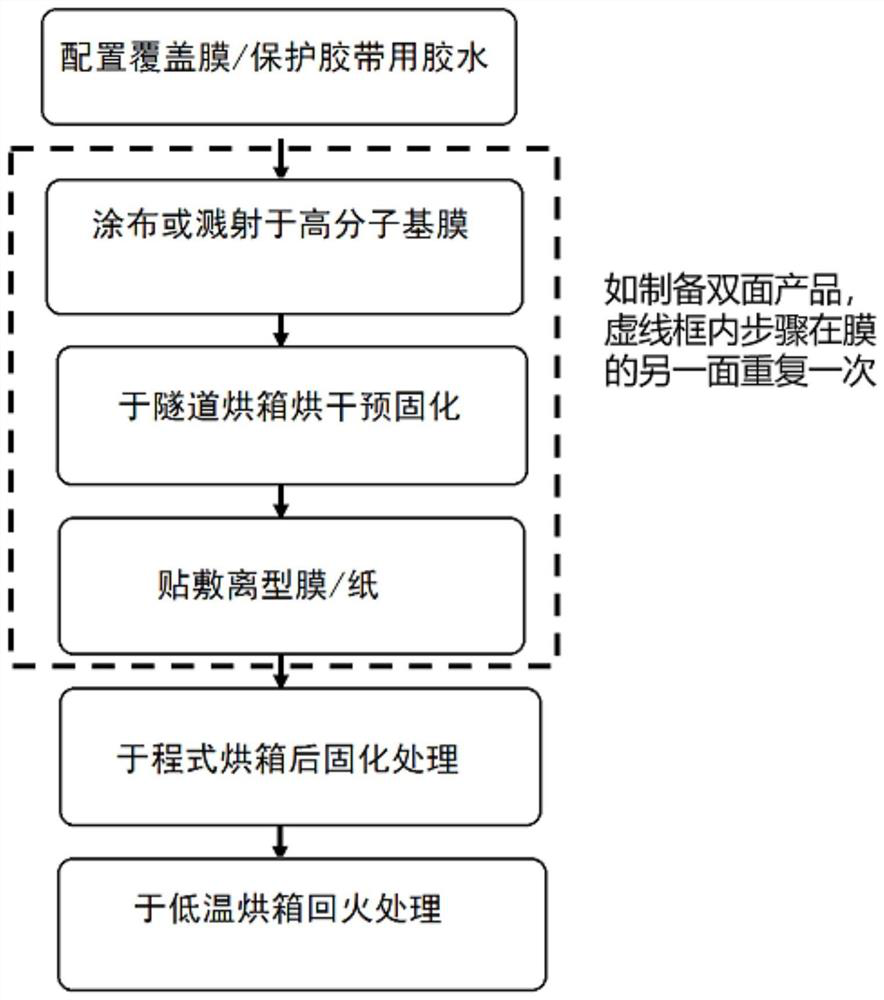

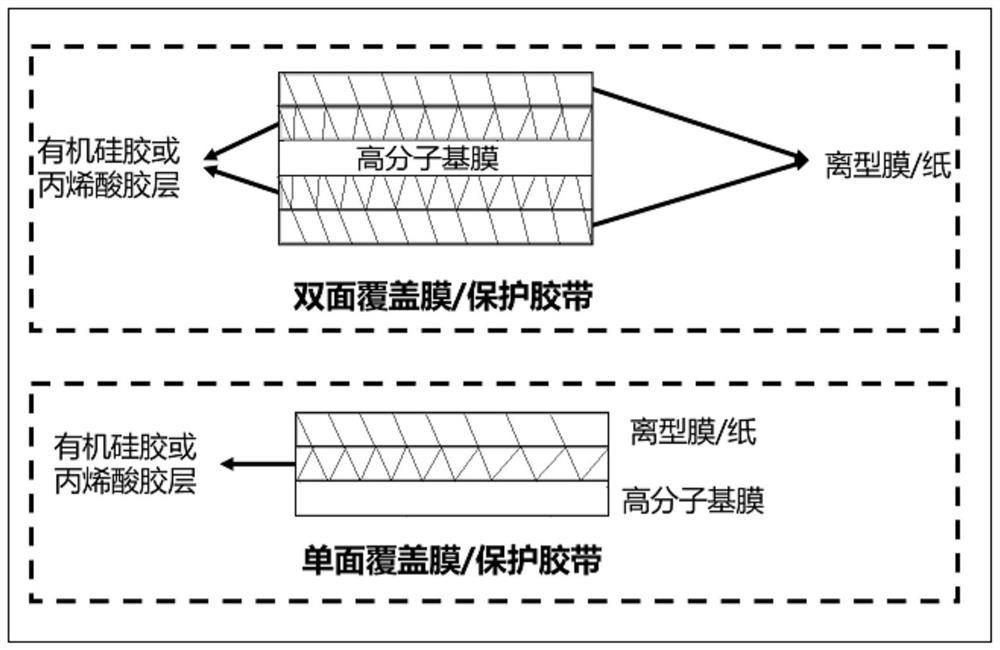

Method used

Image

Examples

Embodiment 1

[0037] Components and content (wy%) in the glue: 40% of acrylic glue, 4% of performance-enhancing components, and the balance of solvent ethyl acetate, the sum of the total mass percentage is 100%.

[0038] The performance enhancing component includes hydroxyethyl acrylate and azobisisobutyronitrile, in parts by weight, 40 parts of hydroxyethyl acrylate and 20 parts of azobisisobutyronitrile.

[0039] The performance enhancing component additionally contains Antioxidant 1010, UV Absorber UV-531 and Toughener ETBN. The addition amount of antioxidant 1010 is 5‰ of the total mass of the glue, the addition amount of ultraviolet light absorber UV-531 is 1%, and the addition amount of toughening agent ETBN is 1%.

[0040]Add the acrylic glue and the performance enhancing components to the ethyl acetate solvent in proportion, mix well and prepare the glue for covering film. The particle size of each substance in the glue is less than 0.5um. Then the prepared glue was coated on a 0.0...

Embodiment 2

[0042] Components and content (wy%) in the glue: 50% of acrylic glue, 5% of performance-enhancing components, and the balance of solvent ether, the sum of the total mass percentage is 100%.

[0043] The performance enhancing component includes hydroxyethyl acrylate and azobisisobutyronitrile, in parts by weight, the hydroxyethyl acrylate is 50 parts, and the azobisisobutyronitrile is 26 parts.

[0044] The performance enhancing component additionally contains antioxidant 1010 and toughening agent ETBN; the added amount of antioxidant 1010 is 3‰ of the total mass of the glue, and the added amount of toughening agent ETBN is 3%.

[0045] Add the acrylic glue and the performance enhancing component into the ether solvent, mix well and prepare the glue for protective tape. The particle size of each material in the glue is less than 0.5um. Then the prepared glue is coated on a layer of 0.100mm thick LCP base film with a coating thickness of 0.003mm, and then enters a tunnel oven at...

Embodiment 3

[0047] Components and content (wy%) in the glue: 40% of organic silica gel, 4% of performance-enhancing components, and the balance of solvent toluene, the sum of the total mass percentage is 100%.

[0048] The performance enhancing component includes hydroxyethyl acrylate and azobisisobutyronitrile, in parts by weight, the hydroxyethyl acrylate is 30 parts, and the azobisisobutyronitrile is 25 parts.

[0049] The performance enhancing component additionally includes a toughening agent ETBN and a plasticizer triphenyl phosphate; the addition amount of the toughening agent ETBN is 2% of the total mass of the glue, and the addition amount of the plasticizer triphenyl phosphate is 3‰.

[0050] Add acrylic glue and performance-enhancing components to the solvent toluene in proportion, and mix well to prepare a covering film glue. The particle size of each substance in the glue is less than 0.5um. Then the prepared glue is coated on a layer of 0.500mm thick PET base film with a coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com